Assembly process of magnetron anode assembly

An anode assembly and assembly process technology, applied in the field of magnetrons, can solve the problems of low yield of anode assemblies and inaccurate antenna positioning, and achieve the effect of improving product qualification rate, ensuring assembly accuracy, and ensuring assembly accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

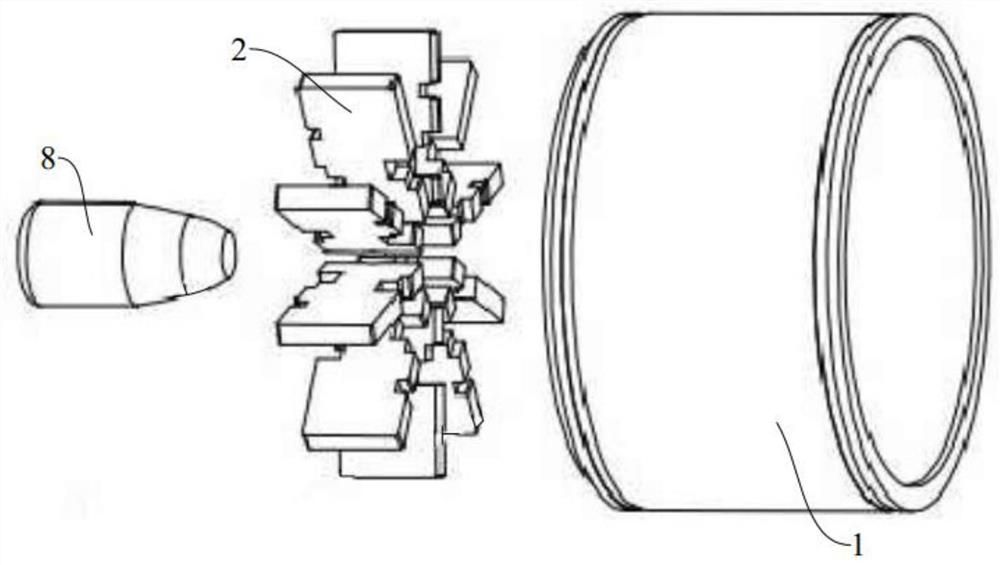

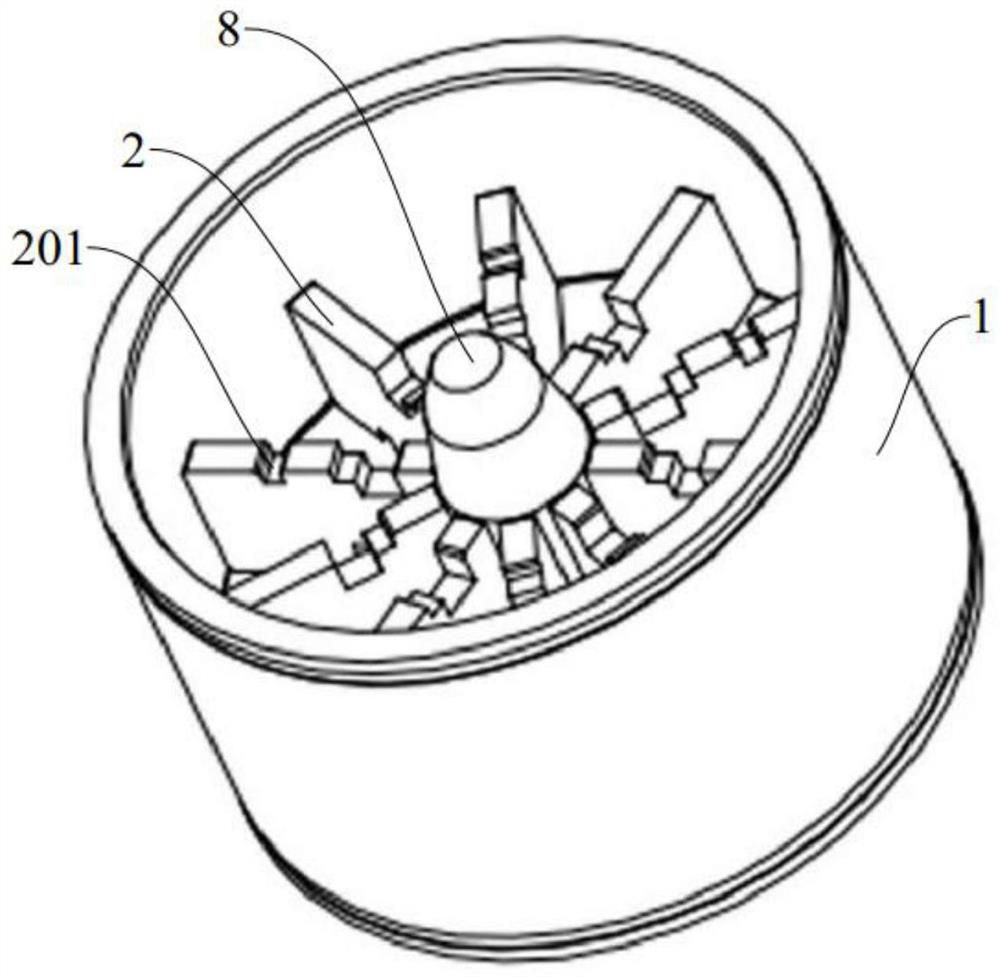

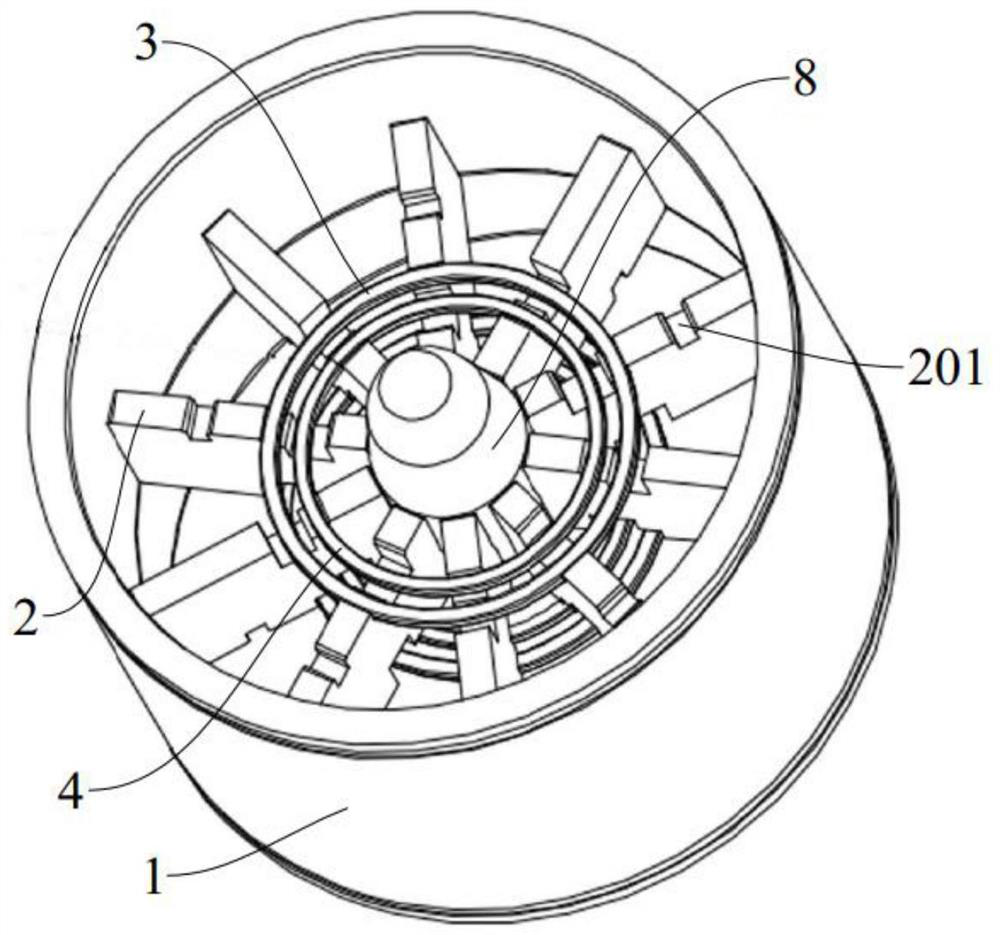

[0087] This embodiment provides an assembly process of a magnetron anode assembly, such as figure 1 , 2 , 13, 14, and 15, in order to facilitate the introduction of the assembly relationship, the anode assembly is first introduced. The anode assembly includes an anode cylinder 1, and a plurality of anode plates 2 are arranged in the anode cylinder 1. The anode plates 2 are equidistant and coaxially arranged radially in the anode cylinder 1. Specifically, the anode plates 2 are provided with antenna slots 201, and the antenna slots 201 on two adjacent anode plates 2 have different orientations. A plurality of anode plates 2 are fixedly connected to the inner peripheral surface of the anode cylinder 1, a large pressure equalizing ring 3 and a small pressure equalizing ring 4 are arranged on the plurality of anode plates 2, and the large pressure equalizing ring 3 and the small grading ring 4 are respectively electrically connected to half of the anode plates 2, specifically, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com