Soil sample eccentric compression prevention strain control type direct shearing tester

An eccentric compression and strain control technology, applied in the direction of applying stable shear force to test material strength, instruments, scientific instruments, etc., can solve the problems of eccentric compression of soil samples and affecting the accuracy of direct shear test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are merely examples of implementation of the present invention, and should not limit the scope of the present invention. That is, all insubstantial changes and modifications made according to the patent scope of the present invention should still fall within the scope covered by the patent of the present invention.

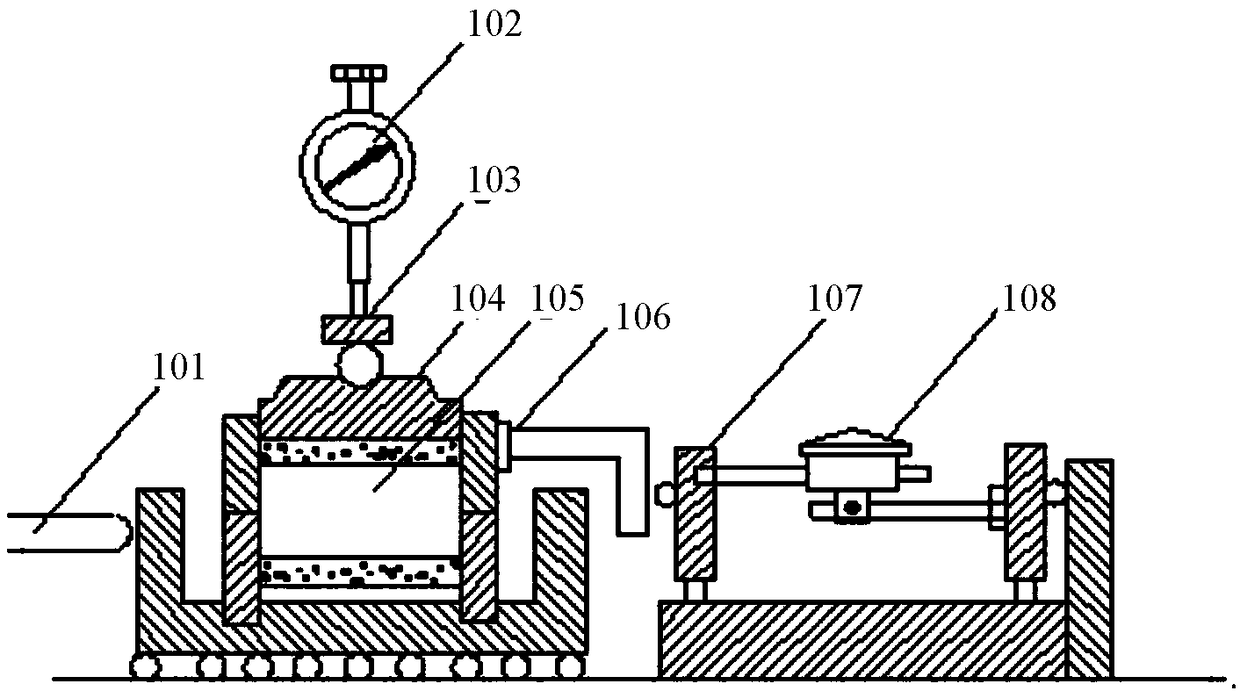

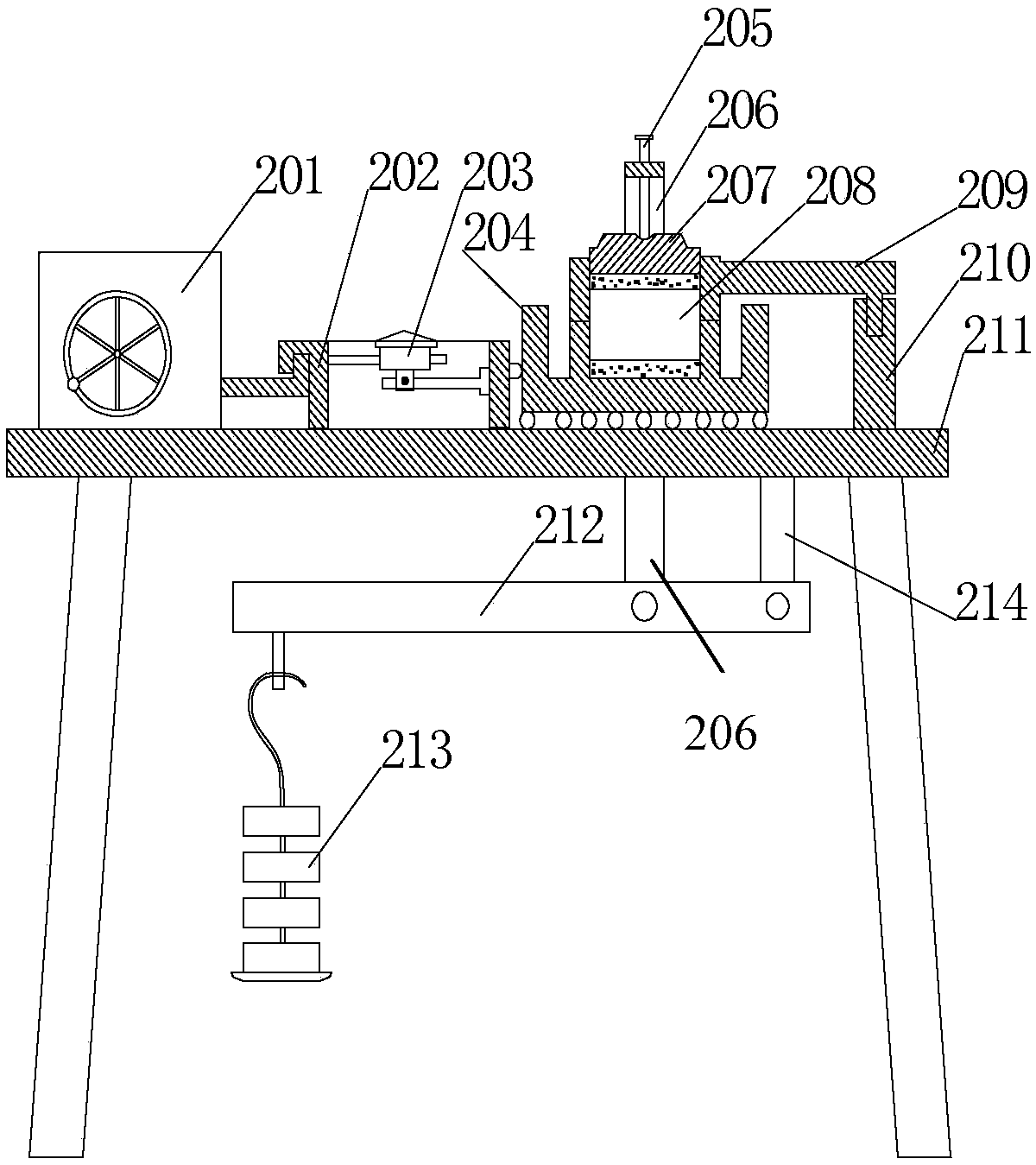

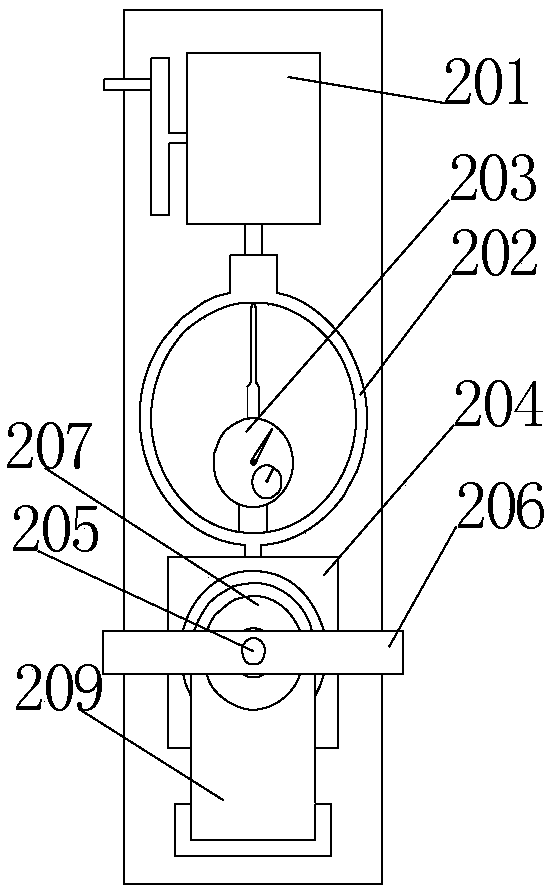

[0038] The anti-soil sample eccentric compression strain control type direct shear tester of the present invention has an overall structure as follows: Figure 2 ~ Figure 3 As shown, the main components are as Figure 4-11 shown.

[0039] Such as figure 2 As shown, the eccentric compressive strain control type direct shear instrument for preventing soil samples of the present invention has a basic structure including a shear box, a vertical pressure applying device, a horizontal pressure applying device, an instrument table and an instrument pedestal.

[0040] The shear box is composed of an upper shear box 209 and a lower shear box 204. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com