Device for treating pile head for vertical static load test and construction method thereof

A technology of processing device and construction method, which is applied in the direction of measuring device, infrastructure test, infrastructure engineering, etc. to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

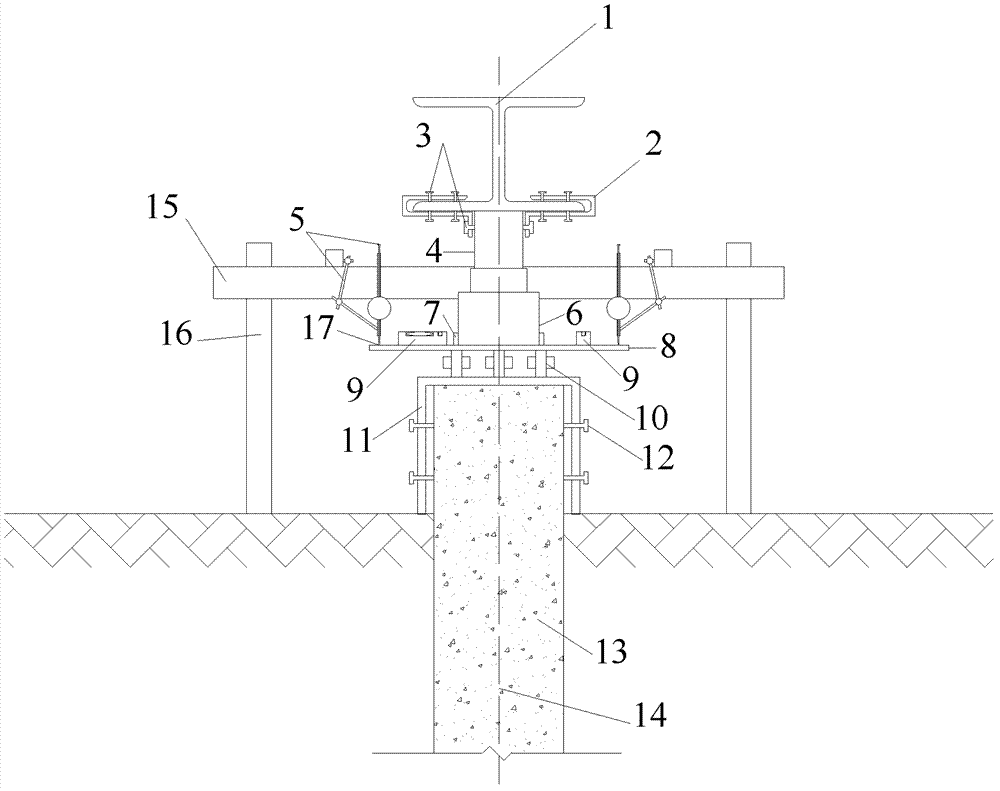

[0025] refer to figure 1 As shown, the pile head processing device for vertical static load test includes pile head pressure-bearing casing 11, pressure-bearing leveling screw 10, pressure-bearing plate 8, strip level 9, jack fixing ring 7, jack 6, load sensor 4. Load sensor fixing device 2, reference beam 15, reference pile 16.

[0026] Among them, the center line of the pile head pressure casing 11, the pressure plate 8, the jack fixing ring 7, the load sensor fixing device 2 coincides with the axis 14 of the pile 13, which can ensure that the force center line of the jack and the load sensor 4 is in line with the pile. The body axis coincides.

[0027] The pile head pressure-bearing casing 11 is open downward and has a height of 0.5m. It is made of steel pipe, and its inner diameter is slightly larger than the outer diameter of the pile body 13 to be tested. Two layers of corner bolt holes are arranged on the side wall, and each layer has three corner bolt holes. , it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com