A kind of grouting simulation test device and its test method

A simulation test and grouting technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of difficult control of working conditions, difficulty in simulating the water content of the formation, and the consumption of manpower and material resources, etc., to achieve Effect of preventing eccentric compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

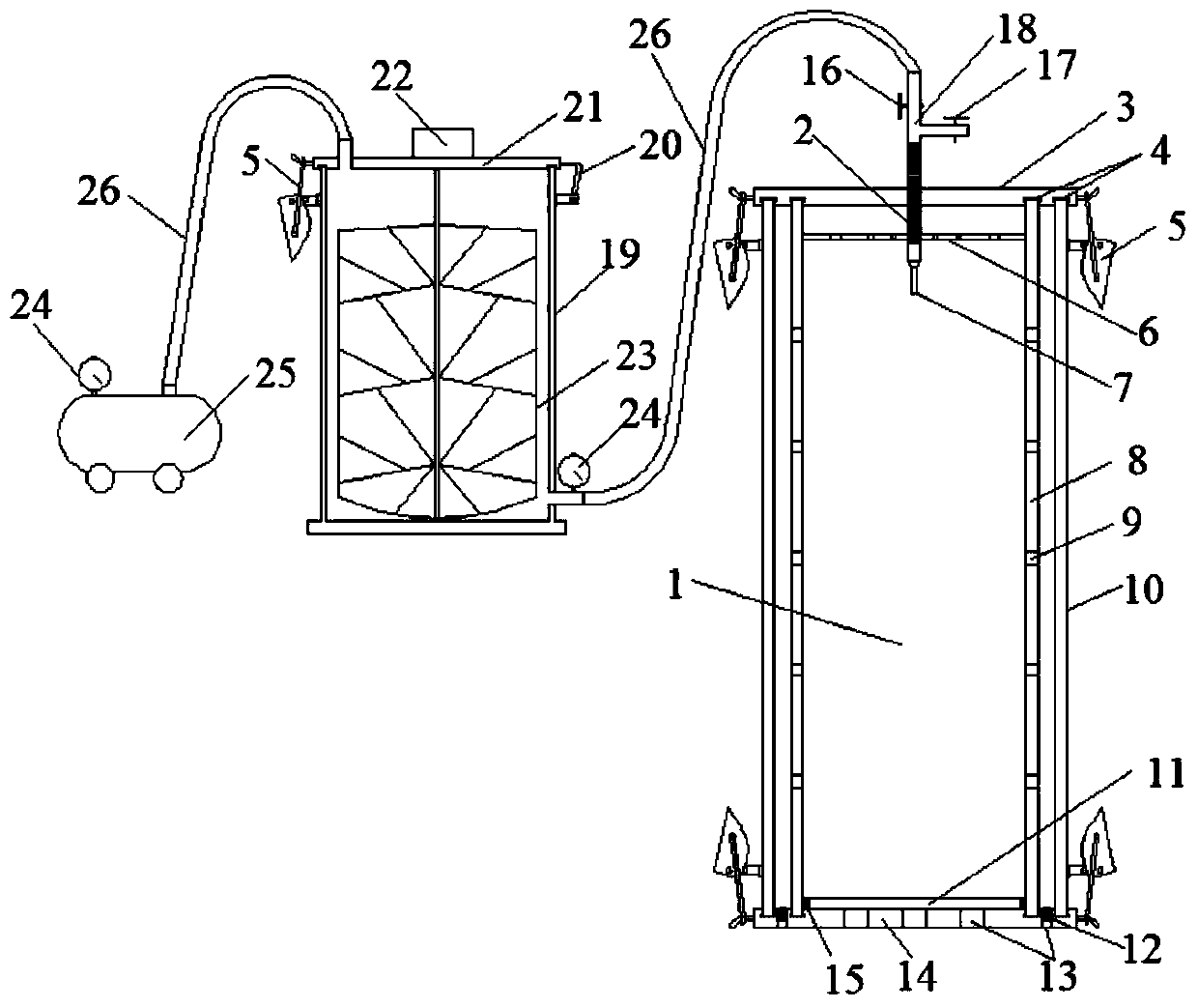

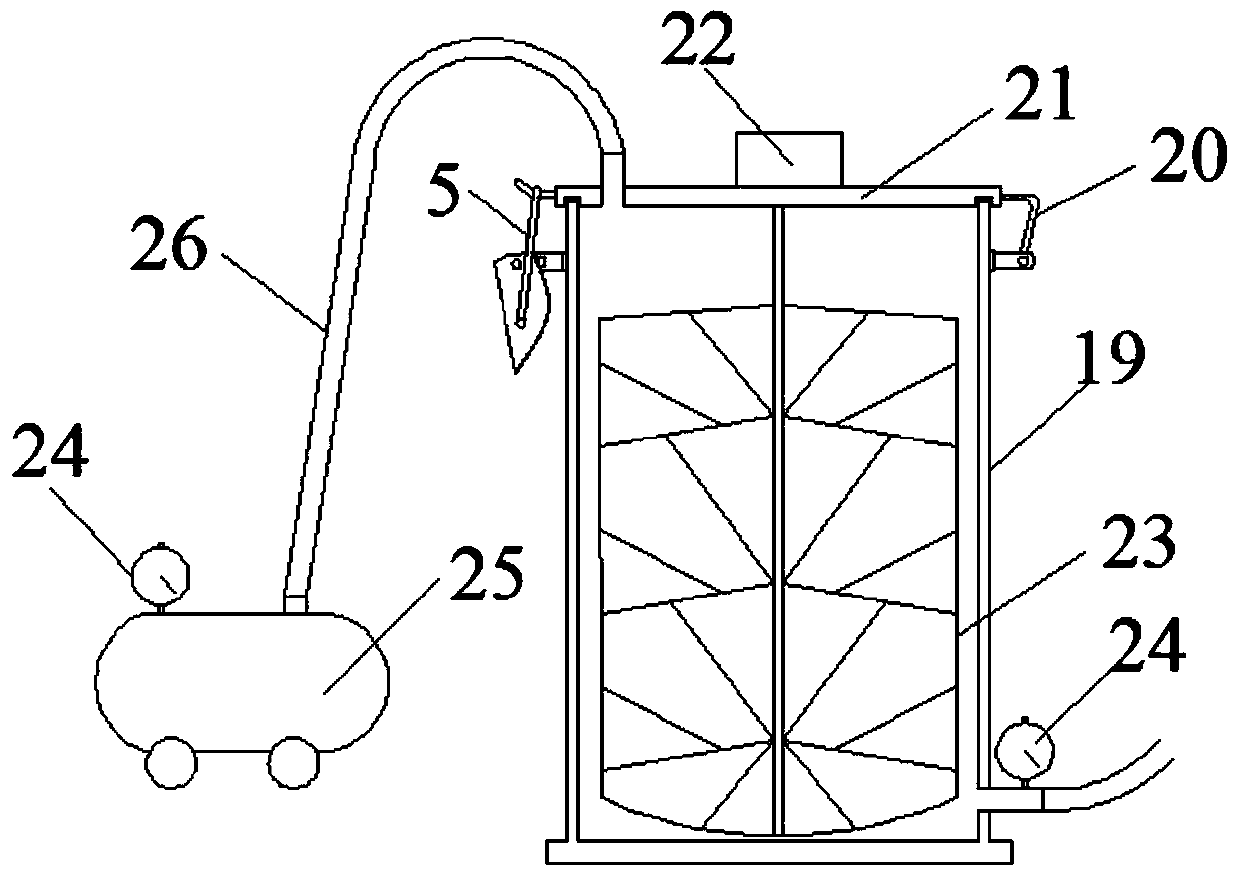

[0038] Examples of the present invention provide a kind of grouting simulation test device, such as figure 1 As shown, the device includes a pressurization system and a grouting penetration device.

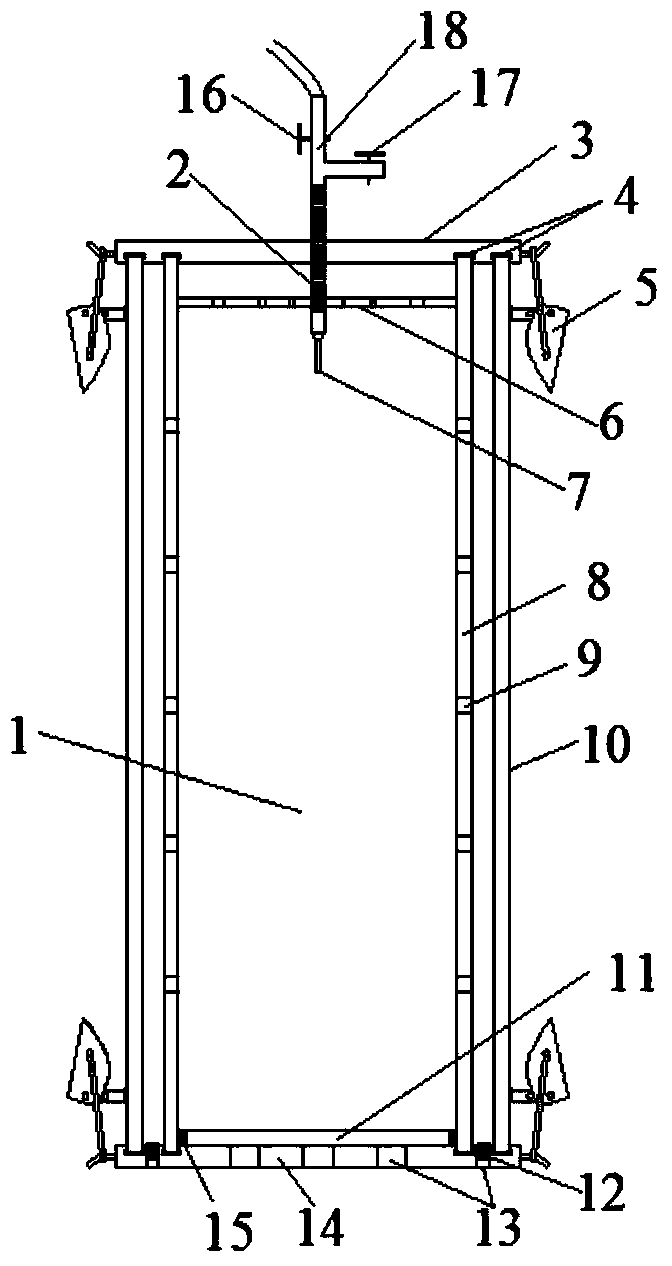

[0039] Such as figure 2 As shown, the grouting penetration device includes: a grouting chamber 1, a top cover 3, a sealing buckle 5, a porous isolation plate 6, a grouting nozzle 7, an inner cylinder 8, an outer cylinder 10, a base 14, a slurry control valve 16, a Water valve 17. The top cover 3 and the base 14 are respectively connected to the outer cylinder 10 through four symmetrically distributed sealing buckles, grooves are provided on the connection contact surfaces, and the sealing rubber pad 4 is built in, and the external threaded grouting pipe 2 is isolated from the porous The contact surfaces of the plate 6 and the top cover 3 have threads that match ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com