Polymerization device for butyronitrile latex production

A technology of polymerization device and nitrile rubber, which is applied in chemical/physical process, chemical/physical/physical chemical process, chemical instrument and method, etc. It can solve the problem of slow material flow, reduced device practicability, long discharge time, etc. problem, achieve the effect of reducing heating or cooling time, speeding up moving speed and speeding up flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

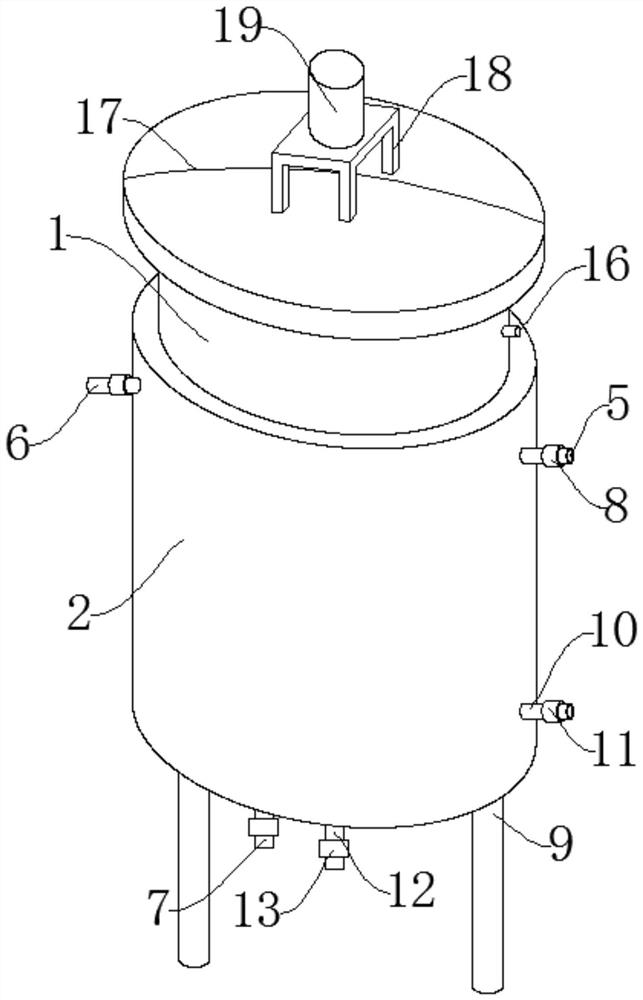

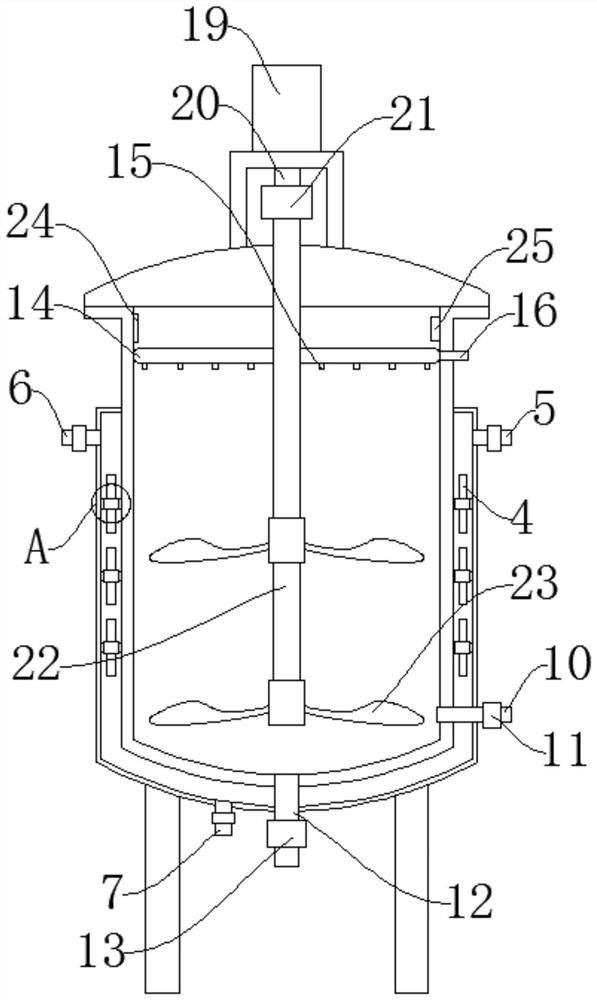

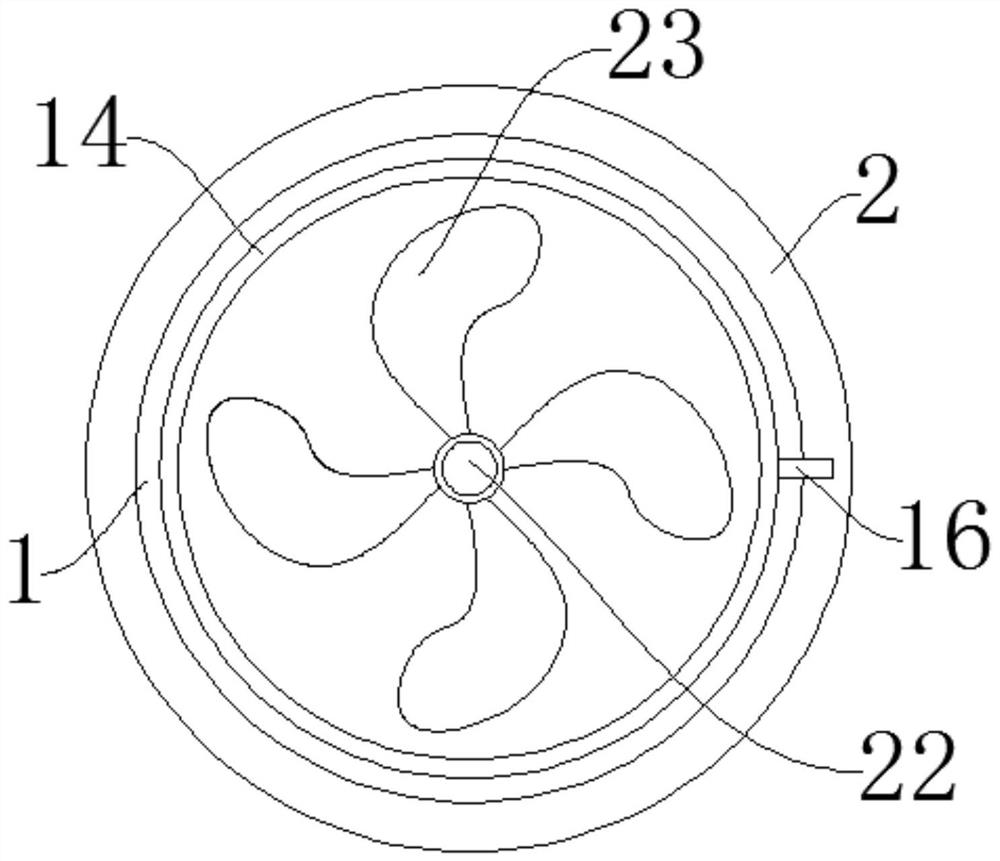

[0036] The present invention will be further described below in conjunction with accompanying drawing:

[0037] Such as Figure 1-Figure 4Shown, a kind of polymerization device for the production of nitrile latex comprises kettle body 1, pipe frame 14 and support frame 18, and jacket 2 is installed on the outside of described kettle body 1, by sending steam or cold water to described jacket 2 The kettle body 1 is heated and cooled. A support shaft 3 is installed between the kettle body 1 and the jacket 2. The support shaft 3 can support the impeller 4. The support shaft 3 is connected to There is an impeller 4, the impeller 4 can speed up the moving speed of steam or cold water, an inlet pipe 5 is installed on one side of the jacket 2, and steam can enter the jacket 2 through the inlet pipe 5, and the jacket 2 A water inlet pipe 6 is installed on the other side of the sleeve 2, and cold water can enter the jacket 2 through the water inlet pipe 6, and a drain pipe 7 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com