A combined multifunctional mixing and batching device for civil engineering

A civil engineering and multi-functional technology, which is applied in the direction of mixing operation control device, unloading device, clay preparation device, etc., can solve the inability to realize the function of mixing and stirring of various materials, lack of function of lifting material combination, and high labor intensity of discharging operation and other problems, to achieve the effect of reducing labor operation intensity, strong combination performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

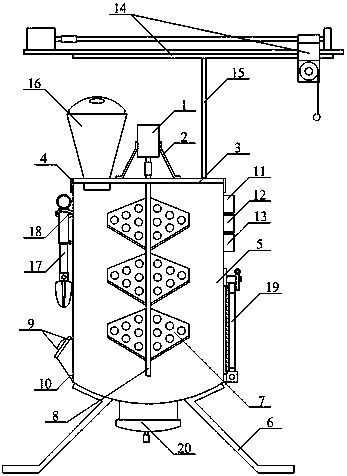

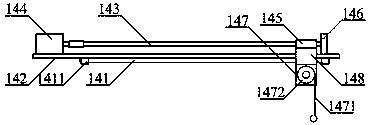

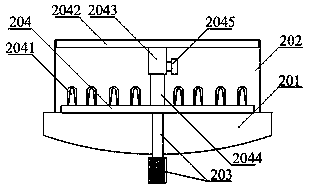

[0047] as attached figure 1 To attach Figure 6 shown

[0048] The invention provides a combined multifunctional civil engineering mixing and batching device, which includes a stirring motor 1, a support plate 2, a stainless steel cover 3, a locking device 4, a stirring steel shell 5, a bottom frame 6, a hollow stirring blade 7, a stirring Shaft 8, sampling steel cover with handle 9, sampling pipe 10, mobile switch 11, lifting switch 12, stirring switch 13, mobile lifting batching machine 14, machine base 15, mixing dust-proof bucket 16, sampling shovel 17, opening card Ring 18, discharge door 19 and cleaning nozzle structure 20 after mixing and stirring, the stirring motor 1 is installed on the upper middle position of the stainless steel cover 3 through the support plate 2 through bolts; the left and right ends of the stainless steel cover 3 are respectively Connected to the top of the stirring steel shell 5 through the locker 4; the bottom frame 6 and the bottom frame 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com