Water topping unit for dairy filling equipment

A technology of filling equipment and water topping material, which is applied in packaging, liquid materials, transportation and packaging, etc., can solve the problems of increasing raw material consumption, increasing processing costs, affecting taste, etc., to reduce the risk of off-flavor and improve quality , the effect of improving the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

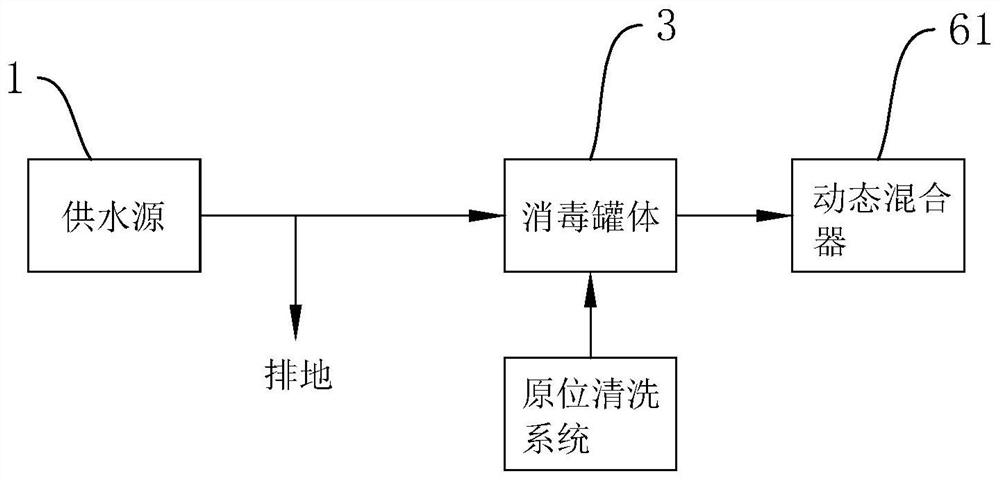

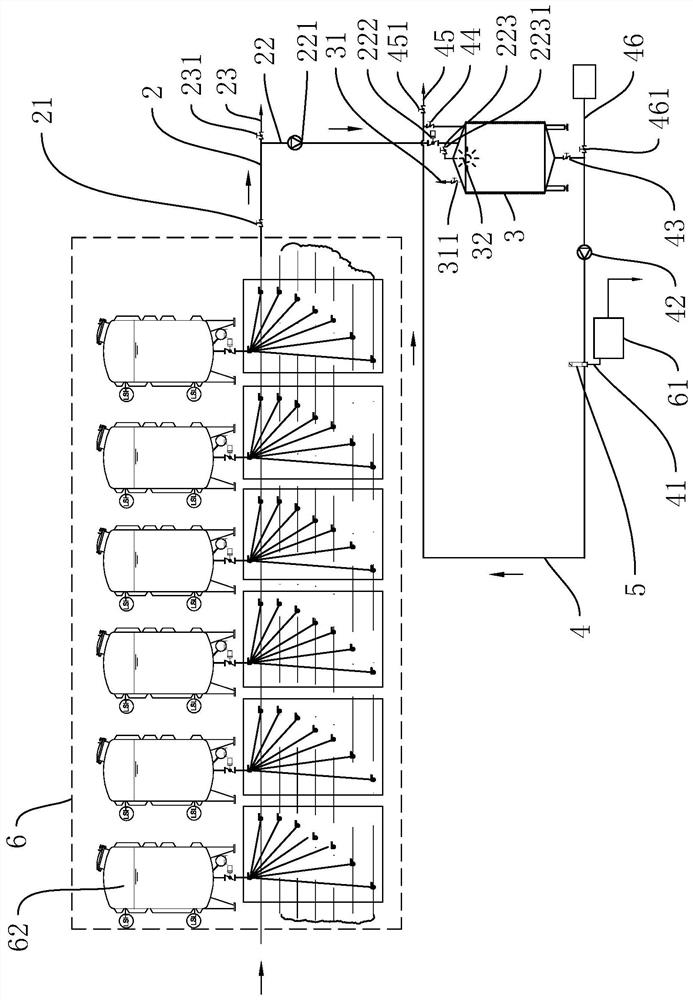

[0033] Attached to the following Figure 1-2 This application will be described in further detail.

[0034] The embodiment of the present application discloses a water topping device for dairy product filling equipment. refer to figure 1 and figure 2 The water top material device includes a water supply source 1 and a disinfection tank 3, wherein the disinfection tank 3 is located outside the filling equipment 6, and the water supply source 1 communicates with the disinfection tank 3 through a water supply pipeline 2. In this embodiment, the water supply source 1 is pasteurized water prepared by a pasteurizer, which can better react with the disinfection water in the disinfection tank body 3; the filling equipment 6 is provided with a plurality of fermentation tanks 62, such as 6 ~8 pieces, making it possible to process raw materials of various flavors, without frequently replacing the fermentation tank 62, and improving the convenience of use.

[0035] refer to figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com