An integral scaffolding node

A kind of scaffolding and integral technology, applied in the field of scaffolding, can solve the problems of fasteners such as weak anti-sliding rigidity and bending rigidity, poor connection effect, complex connection structure, etc., to improve anti-sliding rigidity, increase ultimate bearing capacity, provide anti- The effect of bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described below with reference to the accompanying drawings and embodiments

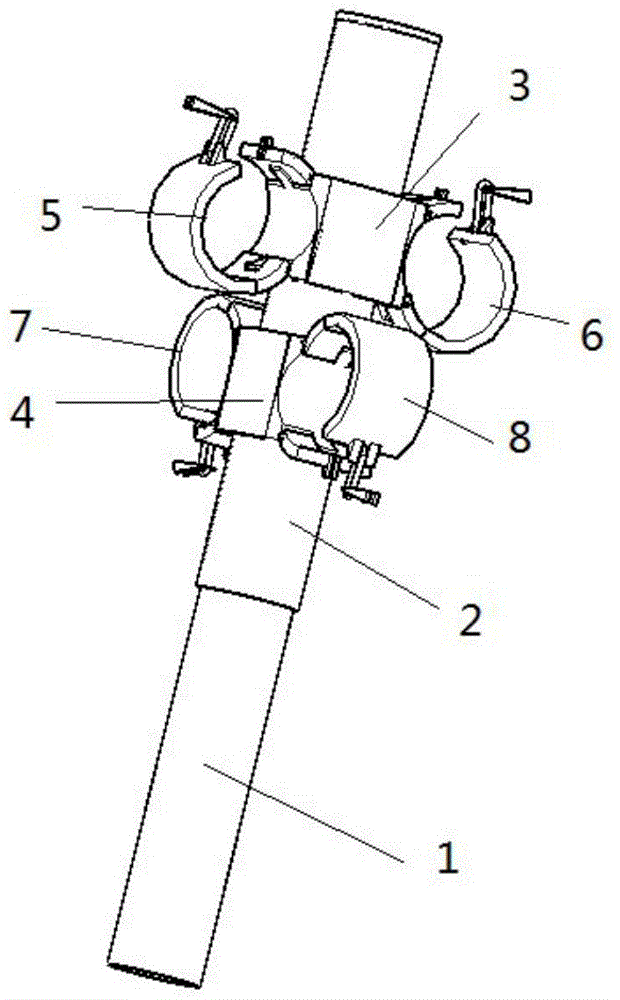

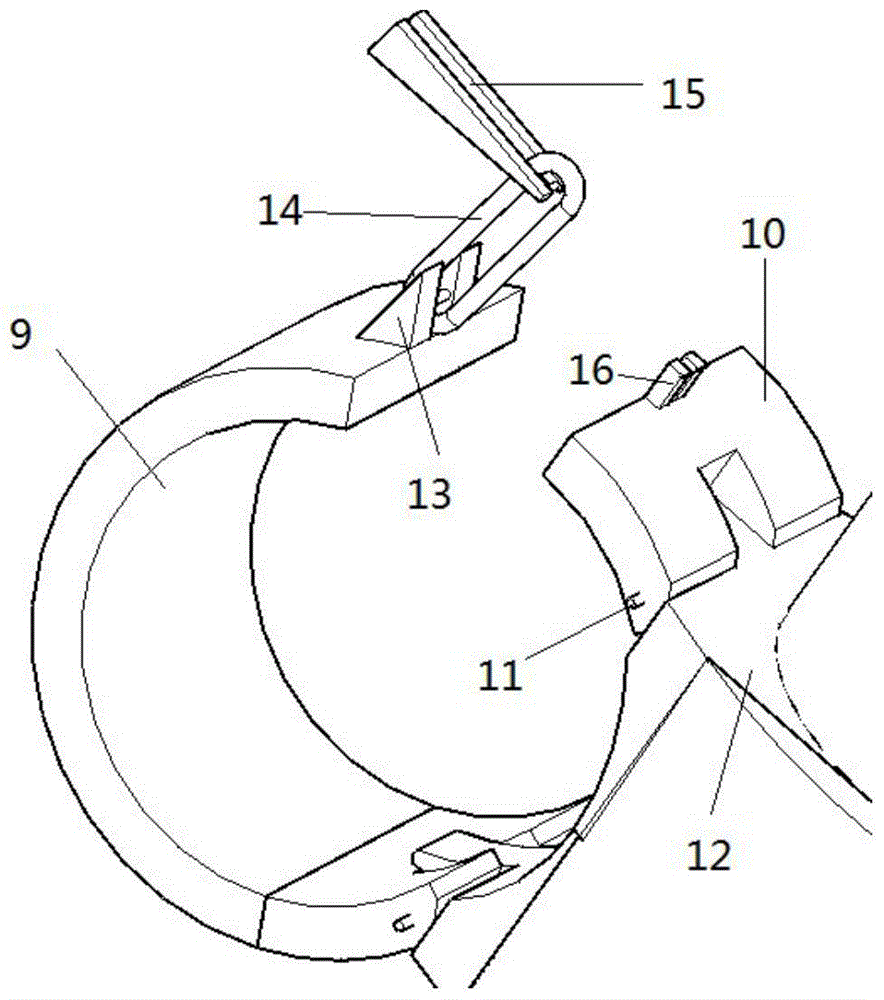

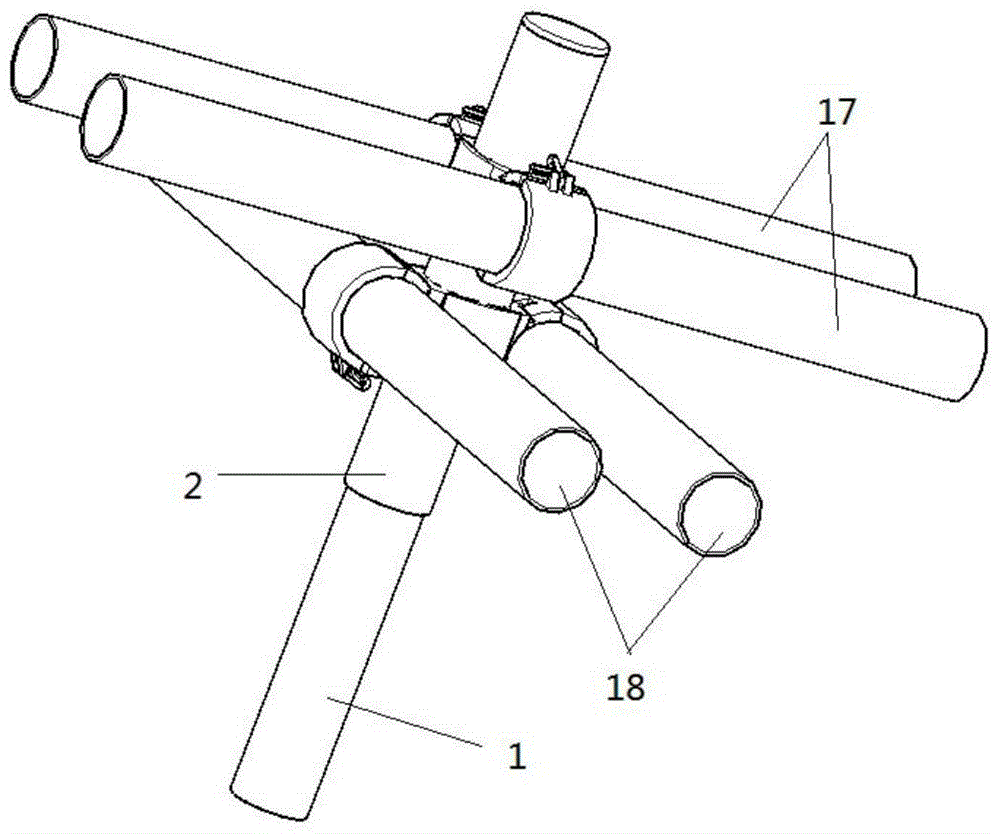

[0020] exist figure 1 , the integral scaffolding node includes a sleeve 2 , an upper node 3 , and a lower node 4 . Among them, the inner diameter of the sleeve 2 is slightly larger than the outer diameter of the scaffolding vertical rod 1 to ensure that the sleeve can be sleeved on the scaffolding vertical rod, and the top of the sleeve is closed, so that the sleeve and the vertical rod can be fixed. A fastener node is welded to the upper and lower parts of the sleeve 2: the upper node 3 and the lower node 4. The upper node 3 includes a casting 12 and two fasteners 5 and 6 for connecting a transverse horizontal rod 17 . The lower node 4 includes a casting 12 and two fasteners 7 and 8 for connecting the longitudinal horizontal rods 18 . The casting 12 is welded to the sleeve 2 . In order to facilitate the installation of the scaffold during construction, the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com