Large workpiece clamping device and clamping system

A workpiece clamping and large-scale technology, applied in the field of tooling and fixtures, can solve the problems of relative displacement between the clamping surface and the workpiece surface, lack of safety, poor flexibility, etc., to achieve convenient and flexible adaptive adjustment, increase the effective contact area, and avoid local damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

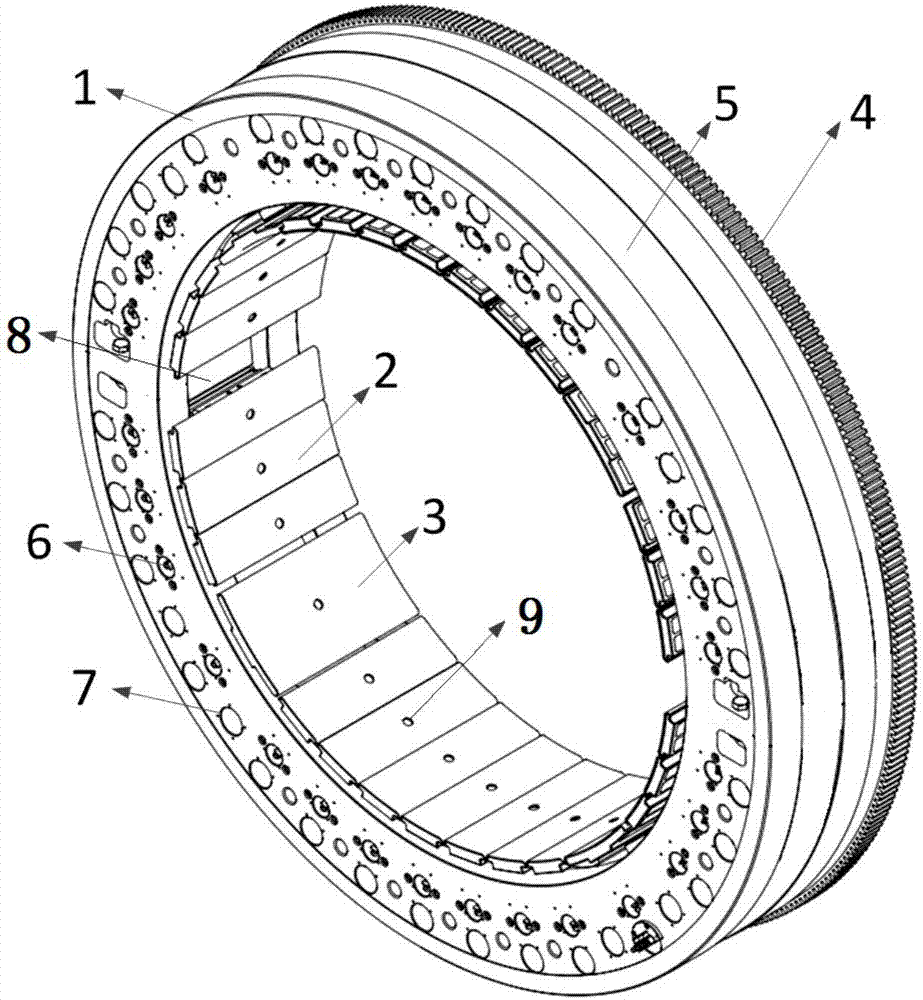

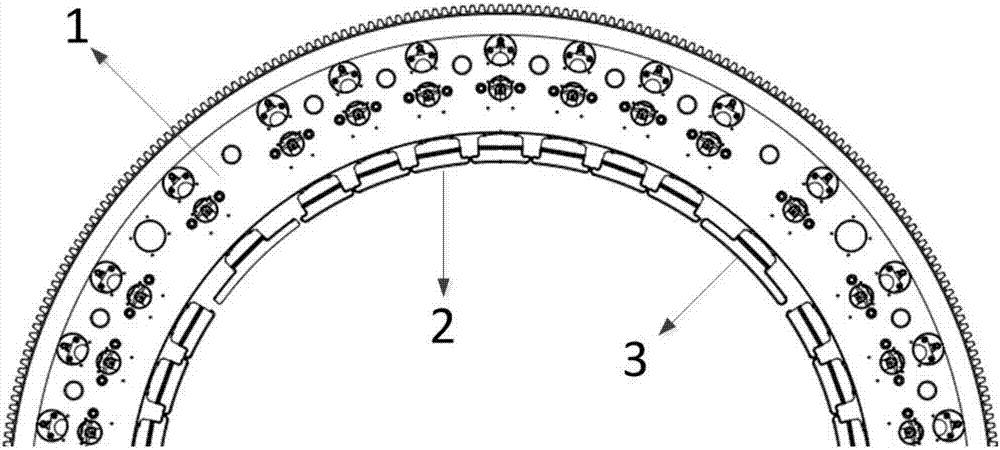

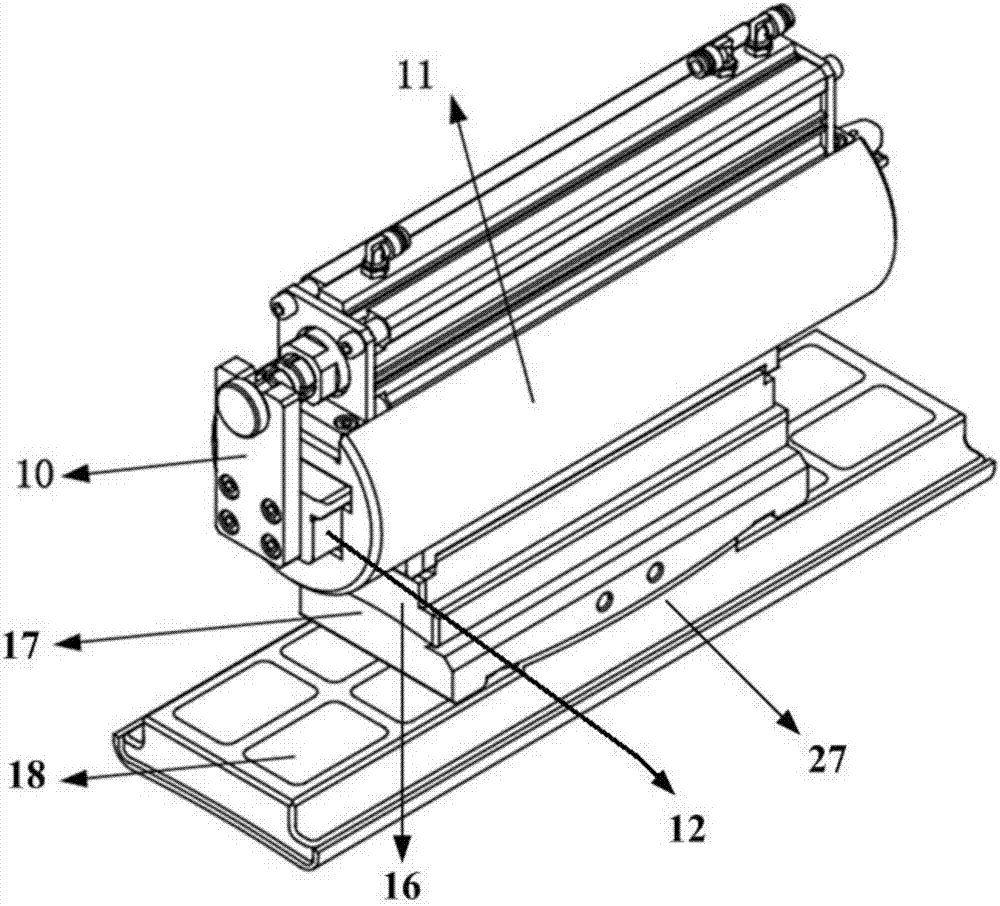

[0028] A workholding device such as figure 1 , figure 2 As shown, it includes a circular clamp body 1, and an installation groove 8 is provided on the inner ring of the clamp body 1 to install a detachable clamping unit. The number of clamping units that can be installed at the same time is 30 to 48; the clamp The main body 1 is provided with a transmission tooth 4 on the outer ring side of its ring for meshing with the external gear; a groove 5 is provided in the middle of the outer arc surface of the fixture body 1 along its ring to be suitable for clamping of external devices , hoisting, positioning, or guidance when the fixture body rotates; a number of mounting holes 6 and guide holes 7 are provided on one side of the fixture body 1; the mounting holes 6 are used for mounting and fixing the clamping unit; the guide hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com