Method for removing toxicity of tail water of fine chemical biochemical treatment

A biochemical treatment and fine chemical technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of consuming large chemical agents, increasing ozone oxidation activity, and not mentioning the toxicity of sewage, etc. Achieve the effect of improving the comprehensive index of water quality, realizing the removal of COD, and reducing the emission of toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

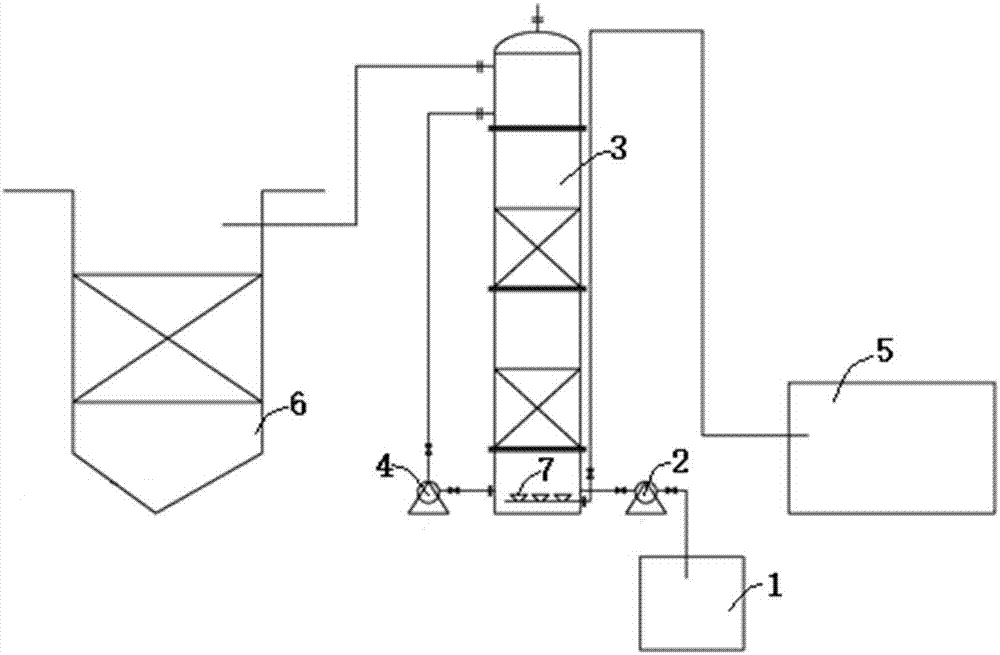

[0040] figure 1 In order to remove the toxicity of fine chemical biochemical tail water, the device includes a sewage collection tank 1, an inlet pump 2, a catalytic ozonation tower 3, an internal return pump 4, an ozone generator 5, and an adsorption filter 6. The inlet pump 2 respectively communicate with the sewage collection tank 1 and the catalytic ozone oxidation tower 3; the catalytic ozone oxidation tower 3 communicates with the adsorption filter 6, the ozone generator 5 is filled in the bottom of the catalytic ozone oxidation tower 3, and the internal reflux pump 4 Connect with the bottom and the top of the catalytic ozonation tower 3 respectively.

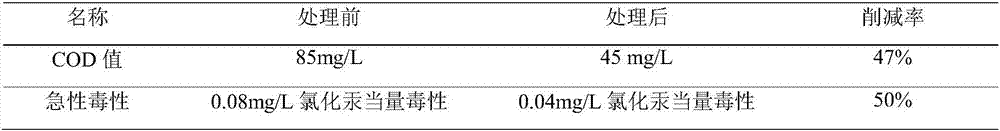

[0041] The above-mentioned device is used to carry out advanced treatment of the tail water after biochemical treatment of the sewage discharged from a large sewage chemical plant in Yancheng, Jiangsu. The biochemical treatment process of the sewage station of the enterprise is: collection pool → anaerobic hydrolysis acid...

Embodiment 2

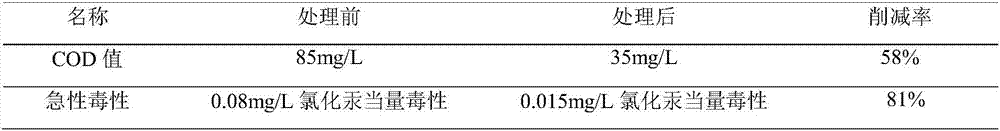

[0086] The treatment object of this embodiment comes from the tail water after biochemical treatment of sewage discharged from a large sewage chemical plant in Funing, Yancheng, Jiangsu. The existing process of the sewage station of this enterprise is as follows: collection pool → Fenton oxidation → anaerobic hydrolysis acidification pool → deficiency Oxygen / aerobic tank → secondary sedimentation tank → coagulation sedimentation tank → direct discharge, use the method of this embodiment to treat the tail water in depth, the treatment steps are basically the same as in Example 1, the difference is:

[0087] In step (1), the tail water pH measured value is 8, the COD measured value is 90mg / L, and the influent toxicity is equivalent to 0.10mg / L mercuric chloride equivalent toxicity;

[0088] In step (2), the loading volume of the catalyst in the catalytic ozonation tower 3 is 40%, and the mass percentage of beta-oxyhydroxide and aluminum oxide is 20:80; the treatment time of tail ...

Embodiment 3

[0096] The treatment object of this embodiment comes from the tail water after biochemical treatment of sewage discharged from a large sewage chemical plant in Lianyungang, Jiangsu. The existing process of the sewage station of this enterprise is as follows: collection pool → anaerobic hydrolysis acidification pool → anoxic / aerobic pool → Secondary sedimentation tank → coagulation sedimentation tank → direct discharge.

[0097] Using the method of this embodiment to treat the tail water in depth, the processing steps are basically the same as in Embodiment 1, the difference is that:

[0098] In step (1), tail water pH measured value is 9, and COD measured value is 102mg / L, and influent toxicity is 0.06mg / L mercuric chloride equivalent toxicity;

[0099] In step (2), the loading rate of the catalyst in the catalytic ozonation tower 3 is 50%, and the mass percentage of β-iron oxyhydroxide and aluminum oxide is 18:82; the treatment time of tail water in the catalytic ozonation to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com