A/A/O system for synchronously strengthening biochemical phosphorus removal based on powdery lanthanum-based adsorbent

A biochemical and adsorbent technology, applied in the field of A/A/O system, can solve the problems of chemical phosphorus removal with a large amount of excess sludge, total phosphorus in the effluent is not up to the standard, etc., achieve good chemical adsorption, stable water quality indicators, and promote growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

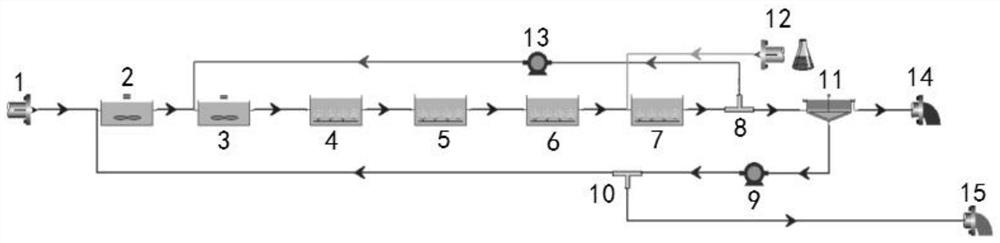

[0023] Specific Embodiment 1: In this embodiment, an A / A / O system based on a powdered lanthanum-based adsorbent for synchronously enhanced biochemical phosphorus removal includes sequentially connected anaerobic pools, anoxic pools, aerobic pool groups, and sedimentation pool, the aerobic pool group includes No. 1 aerobic pool, No. 2 aerobic pool, No. 3 aerobic pool and No. 4 aerobic pool; There are agitators in the pool, No. 2 aerobic pool, No. 3 aerobic pool and No. 4 aerobic pool; the No. 1 aerobic pool, No. 2 aerobic pool, No. 3 aerobic pool and No. The bottom of the tank is equipped with a disc-type microporous aeration head; the disc-type micro-porous aeration head is connected to an air compressor, and an electromagnetic flowmeter is used to control the aeration amount; a part of the mud-water mixture at the outlet of the No. 4 aerobic tank It flows into the sedimentation tank, and the other part is returned to the anoxic tank through the nitrification mixed return pipe...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment differs from Embodiment 1 in that: the total hydraulic retention time of the anaerobic pool, the anoxic pool and the aerobic pool group is 8-12 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the reflux ratio of the nitrification liquid in the nitrification mixing return pipe is 135%-200%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com