An a/a/o system for simultaneous enhanced biochemical phosphorus removal based on powdered lanthanum-based adsorbent

A biochemical and adsorbent technology, applied in the field of A/A/O system, can solve the problems of chemical phosphorus removal of a large amount of excess sludge, and the total phosphorus in effluent is not up to standard, etc., to achieve good chemical adsorption, stable water quality indicators, and enhanced biological Phosphorus removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

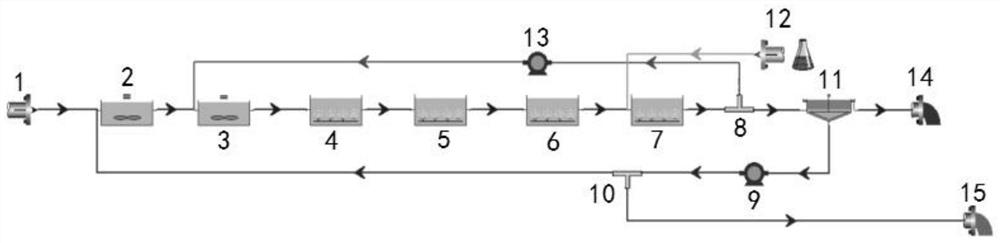

[0023] Specific Embodiment 1: In this embodiment, an A / A / O system based on a powdered lanthanum-based adsorbent for synchronously enhanced biochemical phosphorus removal includes sequentially connected anaerobic pools, anoxic pools, aerobic pool groups, and sedimentation pool, the aerobic pool group includes No. 1 aerobic pool, No. 2 aerobic pool, No. 3 aerobic pool and No. 4 aerobic pool; There are agitators in the pool, No. 2 aerobic pool, No. 3 aerobic pool and No. 4 aerobic pool; the No. 1 aerobic pool, No. 2 aerobic pool, No. 3 aerobic pool and No. The bottom of the tank is equipped with a disc-type microporous aeration head; the disc-type micro-porous aeration head is connected to an air compressor, and an electromagnetic flowmeter is used to control the aeration amount; a part of the mud-water mixture at the outlet of the No. 4 aerobic tank It flows into the sedimentation tank, and the other part is returned to the anoxic tank through the nitrification mixed return pipe...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment differs from Embodiment 1 in that: the total hydraulic retention time of the anaerobic pool, the anoxic pool and the aerobic pool group is 8-12 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the reflux ratio of the nitrification liquid in the nitrification mixing return pipe is 135%-200%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com