Method for rapid, high-efficiency and selective degradation of trace benzopyrene in water

A benzopyrene and selective technology, applied in chemical instruments and methods, water pollutants, oxidized water/sewage treatment, etc., can solve problems such as selective removal of difficult targets, destruction of ozone tail gas, ozone escape, etc., to achieve The effect of increasing the effective contact area, speeding up the process of dissolving gas, and improving the update rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

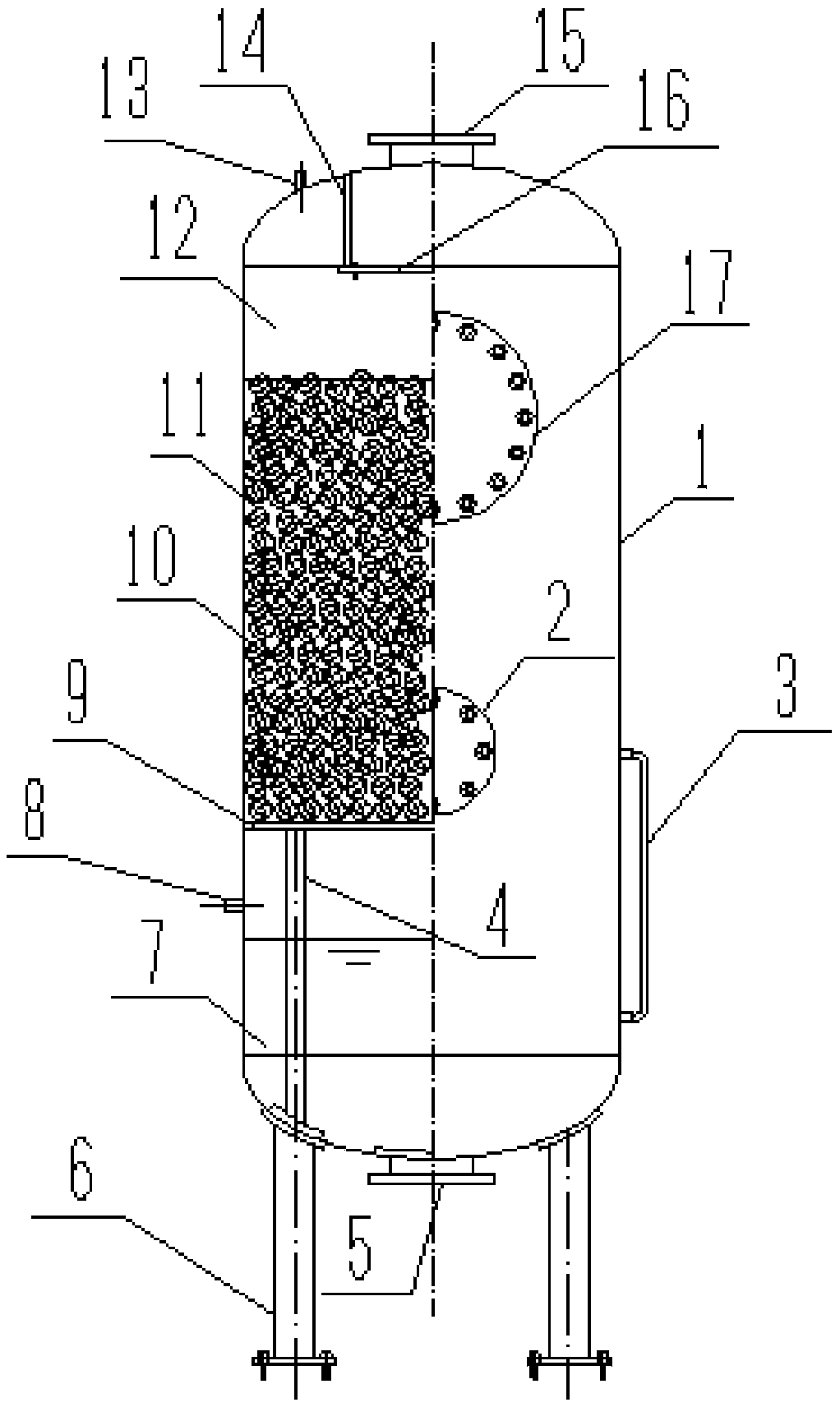

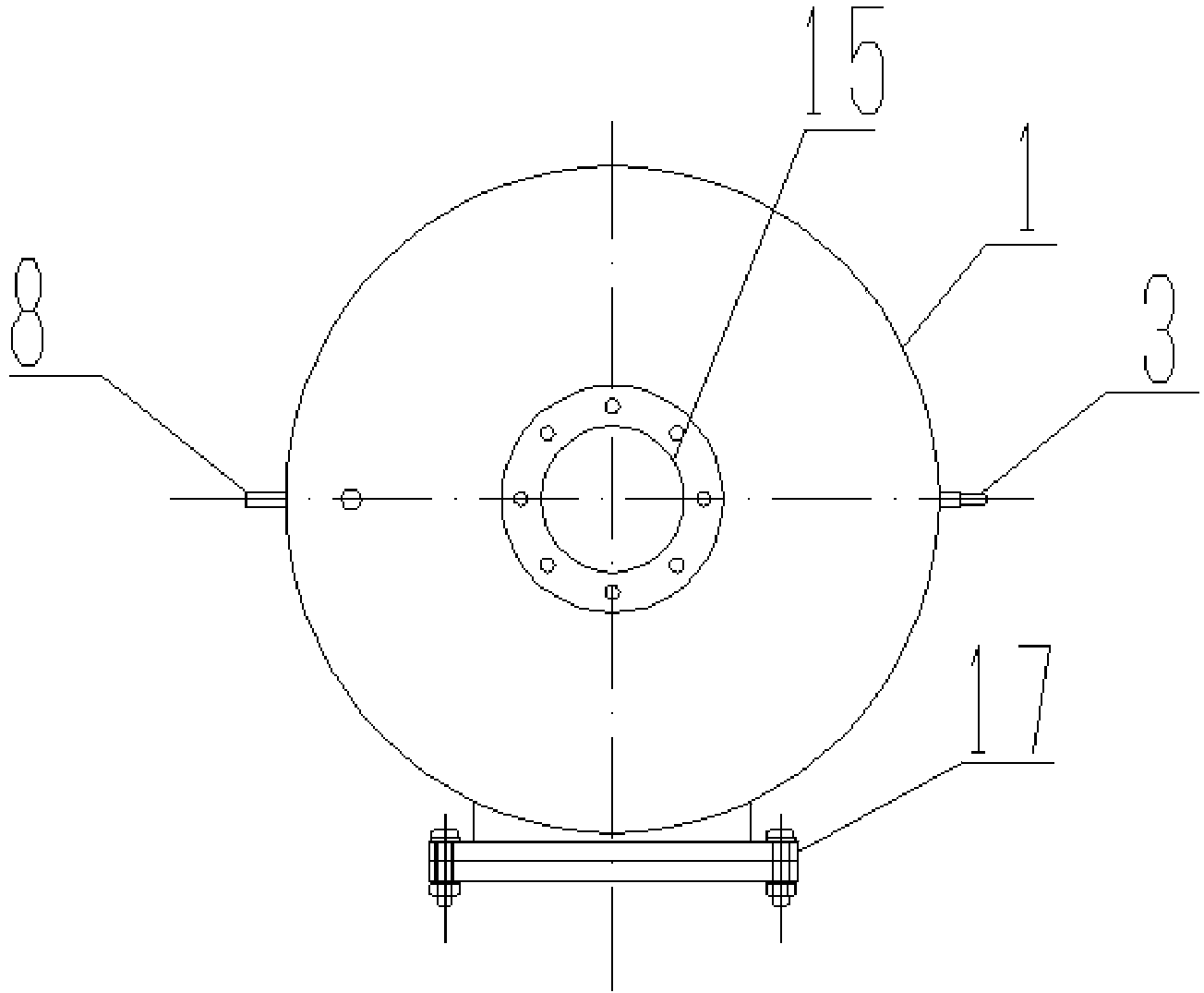

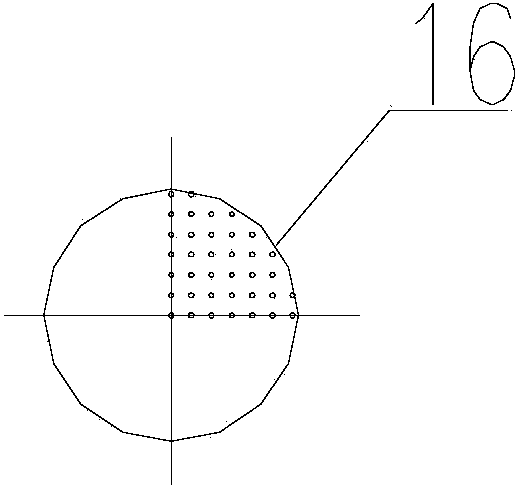

[0031] see Figure 1-4 .

[0032] The ozone catalytic oxidation reactor 1 is constructed first. The bottom of the ozone catalytic oxidation reactor 1 is supported by support legs 6 . The housing of the ozone catalytic oxidation reactor 1 can be made of stainless steel, glass fiber reinforced plastics, polyvinyl chloride plates and other ozone-resistant materials, or concrete structures and other materials whose inner surfaces are protected from ozone corrosion. A manhole 17 and a filler discharge port 2 are provided on the front of the housing, and a liquid level gauge 3 and an air inlet 8 for ozonized gas are provided at the lower end of one side of the housing (the water storage layer 7 ). A water inlet 15 is provided at the center of the top of the housing, an exhaust gas outlet 13 is provided at one side of the top, and a water outlet 5 is provided at the center of the bottom of the housing.

[0033] In the ozone catalytic oxidation reactor 1 of the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com