Self-restoring micro-fluid inertia power switch device

An electrical switch and microfluidic technology, applied in electrical switches, circuits, electrical components, etc., can solve problems such as affecting the normal operation of mechanical inertia switches, easy wear and degradation of metal solid surfaces, affecting the stability of inertia switches, etc. Effective contact area, light weight and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

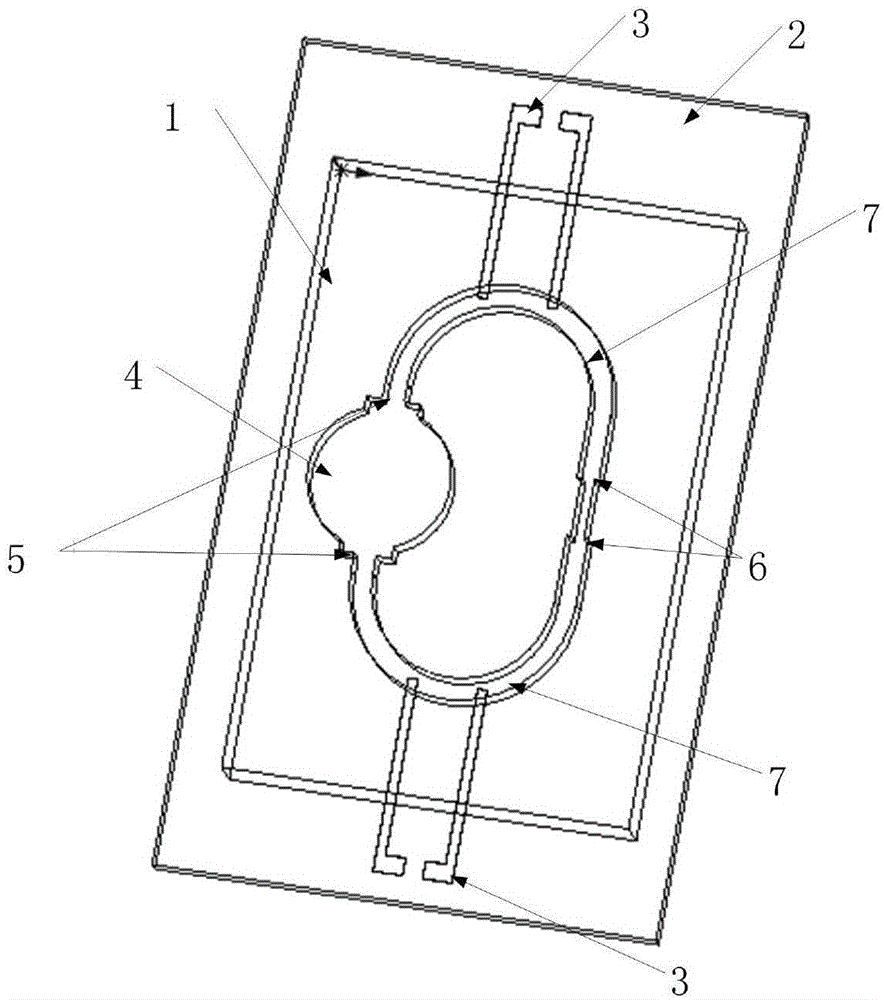

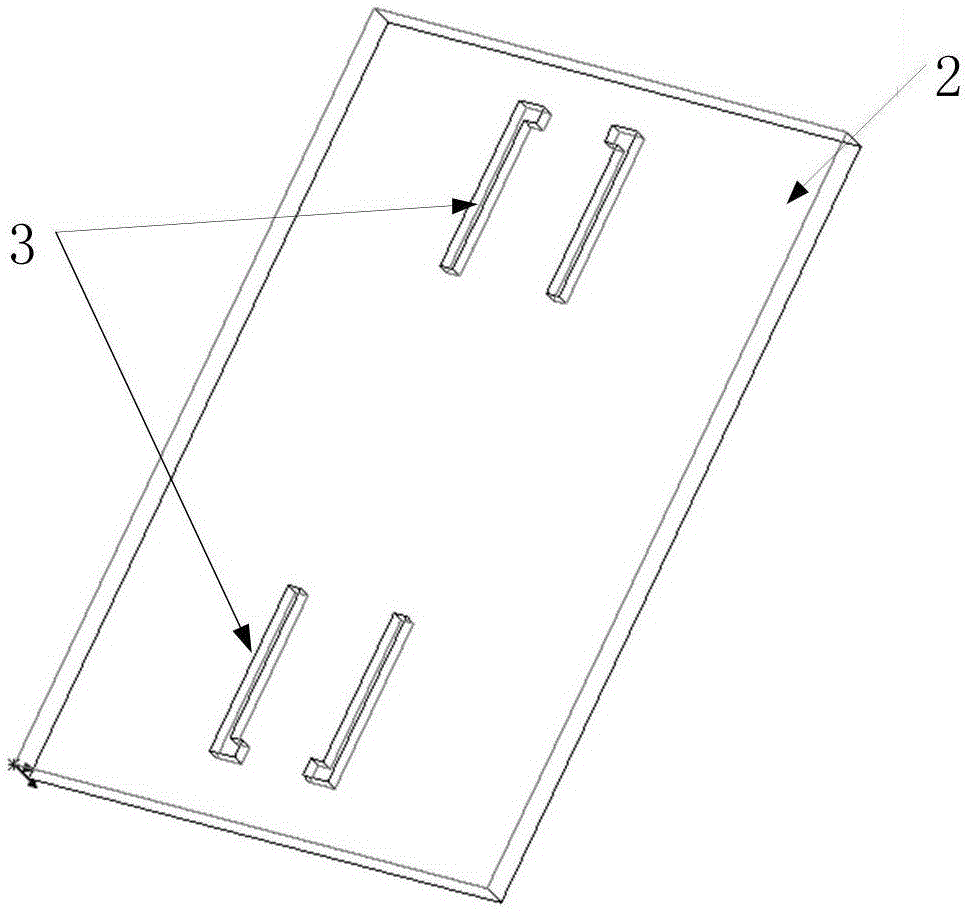

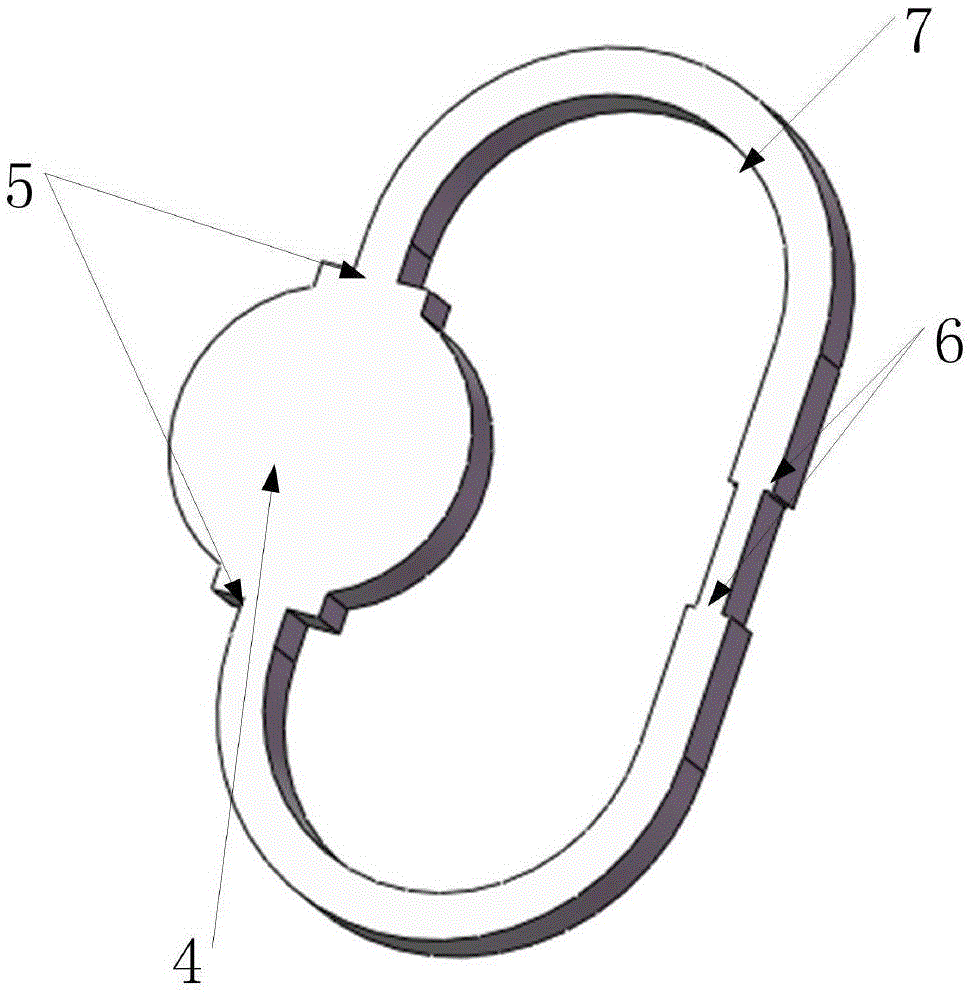

[0020] A self-recovery microfluidic inertial power switch device of the present invention comprises a PMMA substrate 1, a glass cover plate 2, a metal electrode 3, a droplet storage pool 4, and a U-shaped microchannel 7,

[0021] Described glass cover plate 2 is positioned at the top of PMMA substrate 1, and both are rectangular structure, and the quantity of metal electrode is two, and these two metal electrodes are respectively bonded on two short sides of glass cover plate 2 and with short side Vertically, a circular droplet storage tank 4 is set on the PMMA substrate 1, and two rectangular grooves with the same shape are arranged on the droplet storage tank 4, and the long sides of the two rectangular grooves are all parallel to the short sides of the glass cover plate 2 , the two rectangular grooves are symmetrical about the diameter of the droplet storage pool 4 at the same time, two U-shaped microchannels 7 are set on the PMMA substrate 1, and one end of each U-shaped mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com