Sidesway separation movable bracket type tubular belt conveyor

A tubular belt conveyor technology, applied in conveyors, transportation and packaging, etc., can solve the problems of large belt tension, wear, and high operating power of the whole machine, achieving no power loss, reducing power loss, and improving service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

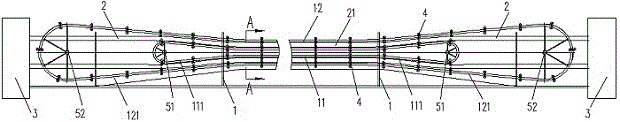

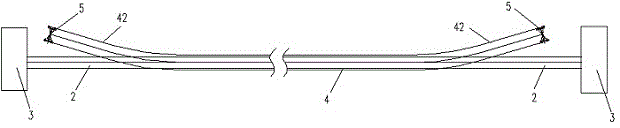

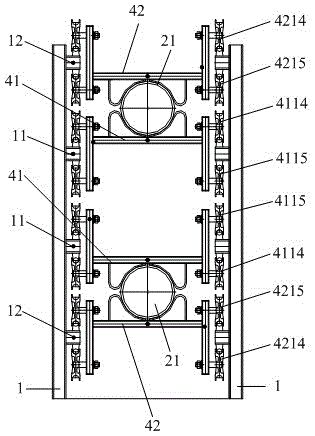

[0015] The technical solutions and implementation effects of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] see Figure 1 to Figure 5 , side shift separation mobile bracket tubular belt conveyor includes a frame 1, an annular belt 2 capable of carrying materials, a driving part 3 of the belt 2 arranged at the nose and tail of the machine, and a belt capable of supporting the snap-in belt The ring-shaped supporting and engaging part 4 of 2, the guide rail reversing wheel 5, the ring-shaped adhesive tape 2 sets are hung and wound on the driving part 3, and the supporting and engaging part 4 is movable and supported and engaged between the adhesive tape 2 and the frame 1 , the supporting and engaging parts 4 near the nose and tail are separated from the tape 2, and shifted to one side of the tape 2, so that the ring-shaped supporting and engaging parts 4 near the nose and tail avoid the tape The driving part 3 of 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com