Single-surface adhesive tape for lithium battery and preparation method for single-surface adhesive tape

A lithium battery, single-sided technology, applied in the direction of adhesive, adhesive type, film/sheet adhesive, etc., can solve the problem that the electrode group and the outer packaging material are prone to relative displacement and do not meet the requirements of the lithium battery production process , Affect the appearance and performance of lithium batteries and other issues, to achieve the effect of good viscosity, long service life, and stable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A single-sided adhesive tape for lithium batteries of the present invention comprises a sealing hot-melt pressure-sensitive adhesive layer and a base film layer, and the sealing hot-melt pressure-sensitive adhesive layer and the base film layer are connected to each other.

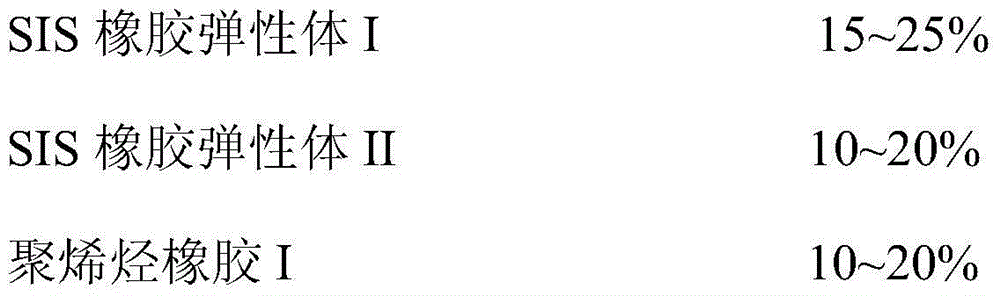

[0039] The sealing hot-melt pressure-sensitive adhesive layer of the present embodiment comprises the following raw materials in mass percentage:

[0040]

[0041] The base film layer in this embodiment is a PET film layer.

[0042] The base film layer in this embodiment has a thickness of 10 microns, and the sealing hot-melt pressure-sensitive adhesive layer has a thickness of 40 microns.

[0043] The average molecular weight of the SIS rubber elastic body I in this embodiment is 320,000, and the average molecular weight of the SIS rubber elastic body II is 160,000.

[0044] A preparation method of single-sided adhesive tape for lithium batteries, comprising the following processing steps:

[00...

Embodiment 2

[0052] A single-sided adhesive tape for lithium batteries of the present invention comprises a sealing hot-melt pressure-sensitive adhesive layer and a base film layer, and the sealing hot-melt pressure-sensitive adhesive layer and the base film layer are connected to each other.

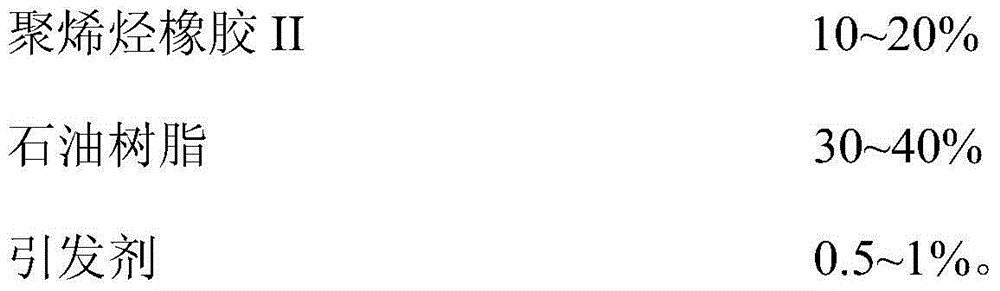

[0053] Wherein, the sealing hot-melt pressure-sensitive adhesive layer includes the following raw materials in mass percentage:

[0054]

[0055]

[0056] The base film layer in this embodiment is a BOPP film layer.

[0057] The thickness of the base film layer in this embodiment is 20 microns, and the thickness of the sealing hot-melt pressure-sensitive adhesive layer is 60 microns.

[0058] The average molecular weight of the SIS rubber elastic body I in this embodiment is 370,000, and the average molecular weight of the SIS rubber elastic body II is 280,000.

[0059] A preparation method of single-sided adhesive tape for lithium batteries, comprising the following processing steps:

[006...

Embodiment 3

[0067] A single-sided adhesive tape for lithium batteries of the present invention comprises a sealing hot-melt pressure-sensitive adhesive layer and a base film layer, and the sealing hot-melt pressure-sensitive adhesive layer and the base film layer are connected to each other.

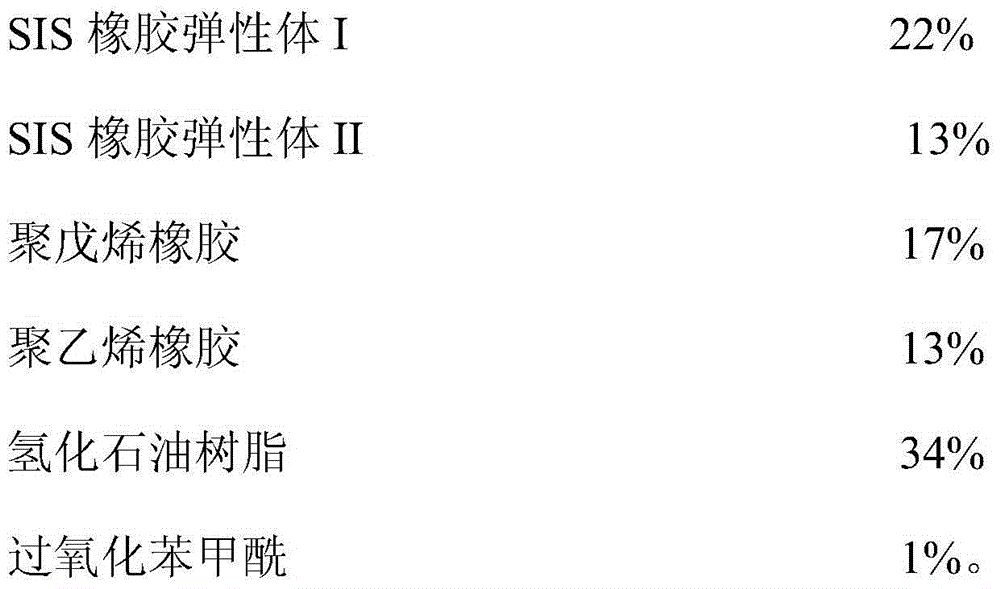

[0068] The sealing hot-melt pressure-sensitive adhesive layer of the present embodiment comprises the following raw materials in mass percentage:

[0069]

[0070] The base film layer in this embodiment is a PET film layer.

[0071] The thickness of the base film layer in this embodiment is 30 microns, and the thickness of the sealing hot-melt pressure-sensitive adhesive layer is 90 microns.

[0072] The average molecular weight of the SIS rubber elastic body I in this embodiment is 350,000, and the average molecular weight of the SIS rubber elastic body II is 250,000.

[0073] A preparation method of single-sided adhesive tape for lithium batteries, comprising the following processing steps:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com