Spinous process and vertebral plate stabilizer

A technology of stabilizer and spine plate, applied in the direction of spinal implants, etc., can solve the problems of low complication long-term effect, weak resistance to elastic attenuation, impossibility of prosthetic placement, etc., to reduce the difficulty and risk of surgery, and resist The effect of strong elastic attenuation ability and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

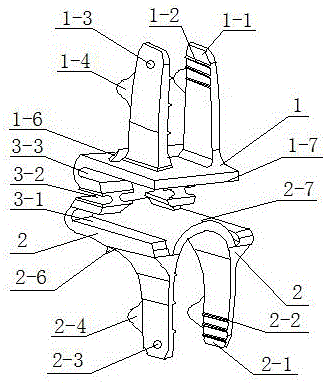

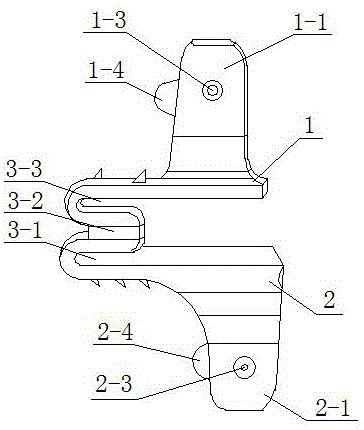

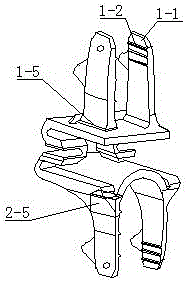

[0036] In order to make the purpose of the present invention, technical solutions and advantages clearer, the following will be combined with the appended Figure 1-10, clearly and completely describe the technical solutions of the embodiments of the present invention.

[0037] The inter-ratchet stabilizer includes a first fixing part 1 , a second fixing part 2 and an elastic device 3 , wherein the first fixing part 1 is connected to the second fixing part 2 through the elastic device 3 . Since the size and shape of the adjacent spinous processes are inconsistent, the first fixing part 1 and the second fixing part 2 can have an asymmetric structure, which is also conducive to better matching with the spinous process bone. But optionally, according to different application situations, the first fixing part 1 and the second fixing part 2 may also adopt a symmetrical structure.

[0038] The first fixing part 1 is composed of two side wings a1-1 and a bottom plate 1-7 to form a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com