Feeding structure for feeding assembly line

An assembly line and material feeding technology, which is applied in the direction of conveyor control devices, conveyor objects, conveyors, etc., can solve the problem of inaccurate material retrieving in the assembly line, and achieve the effect of accurate retrieving and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

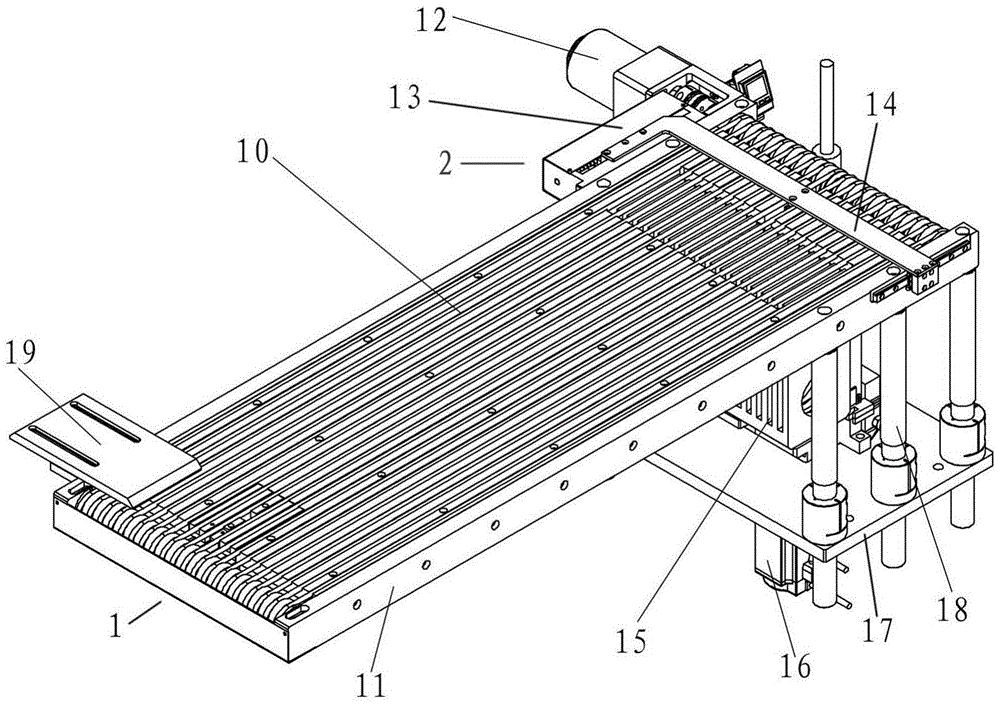

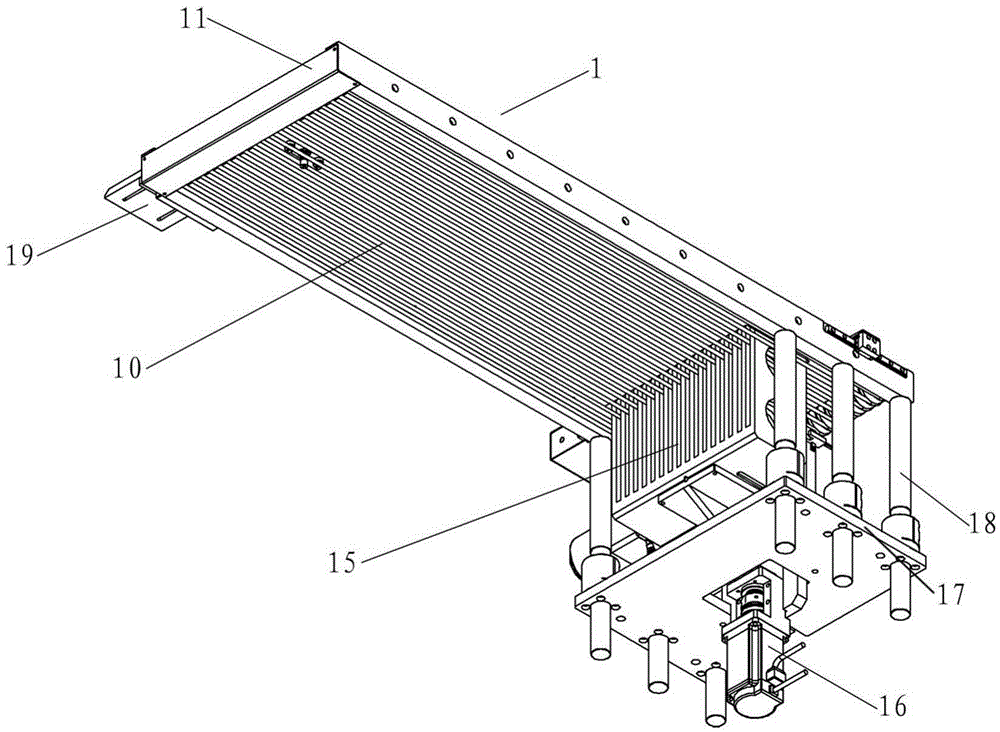

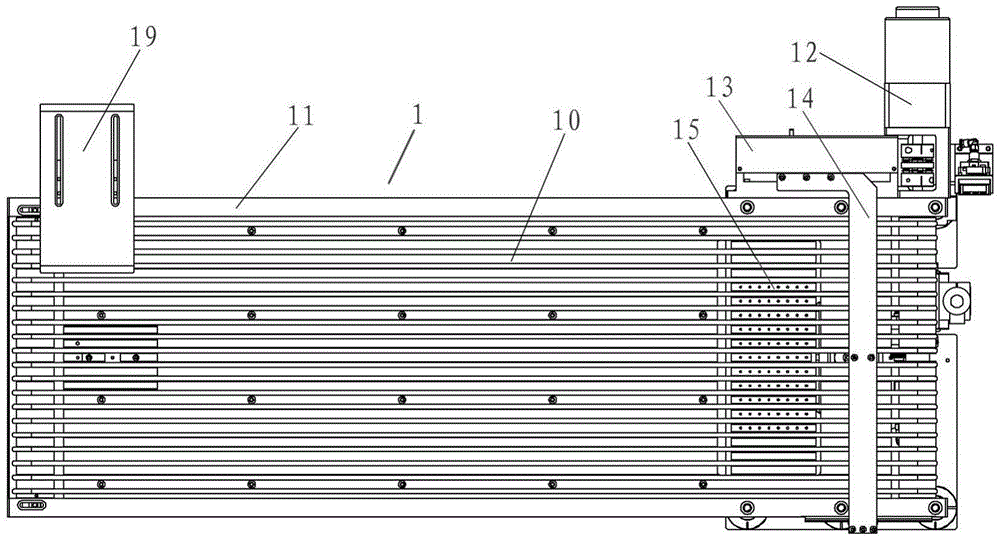

[0026] combined reference figure 1 and figure 2 , is a three-dimensional structural schematic diagram of the feeding line material structure in this embodiment, wherein each component is the assembly line 1, the detection and correction device 2, the transmission motor 12, the lifting platform 15, the lifting motor 16, the supporting plate 17, the column 18, the discharging Baffle 19; the assembly line 1 includes a belt 10, an assembly line baffle 11, and a rotating shaft (not shown), and the detection and correction device 2 includes a correction baffle cylinder 13, a correction baffle 14, and a detection fiber (not shown).

[0027] In this embodiment, the feeding line material structure includes a line 1, a detection and correction device 2, a conveying motor 12, a lifting platform 15, a lifting motor 16 and a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com