Array substrate and manufacturing method thereof, and liquid crystal display device

A liquid crystal display device and array substrate technology, which is applied in the manufacture of array substrates, array substrates and liquid crystal display devices, can solve problems such as disconnection, influence yield rate, defects, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

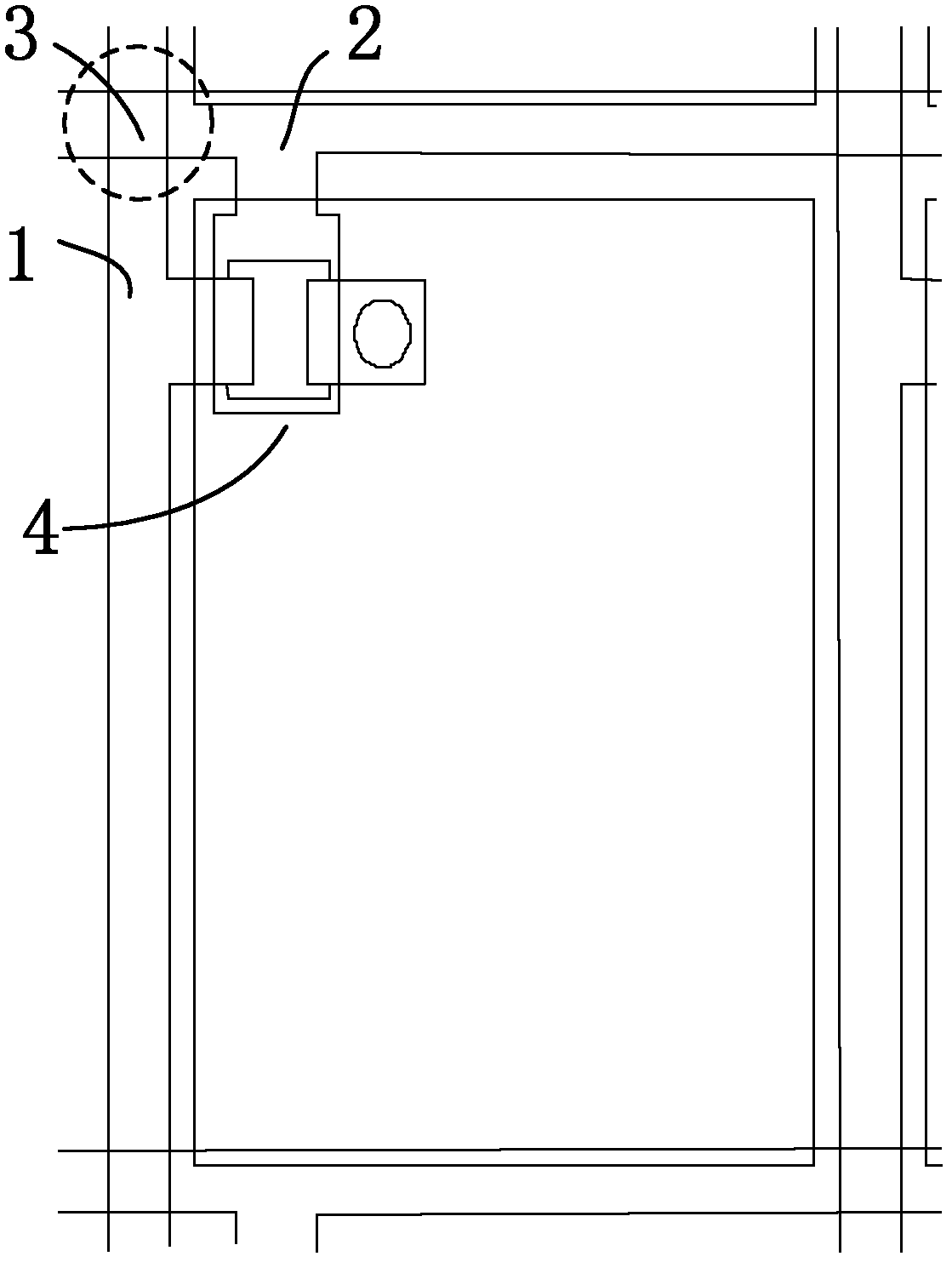

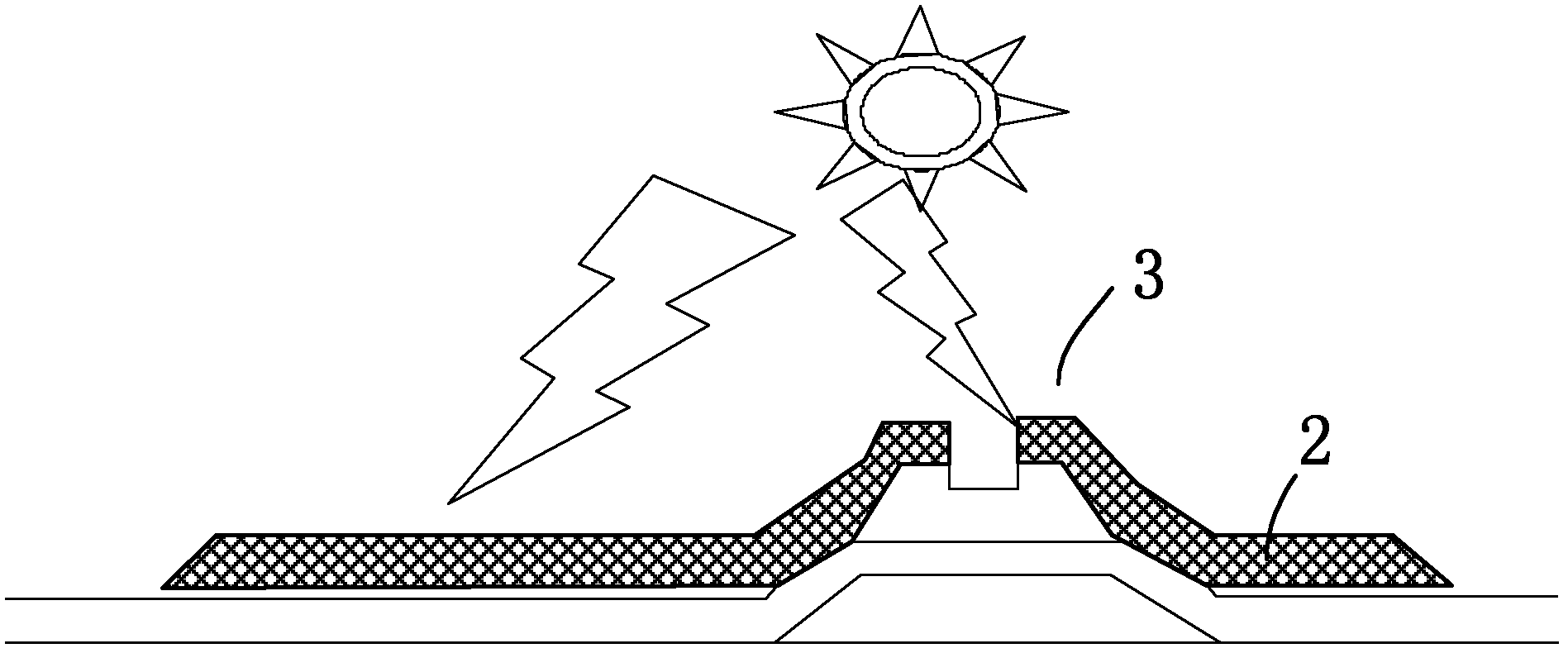

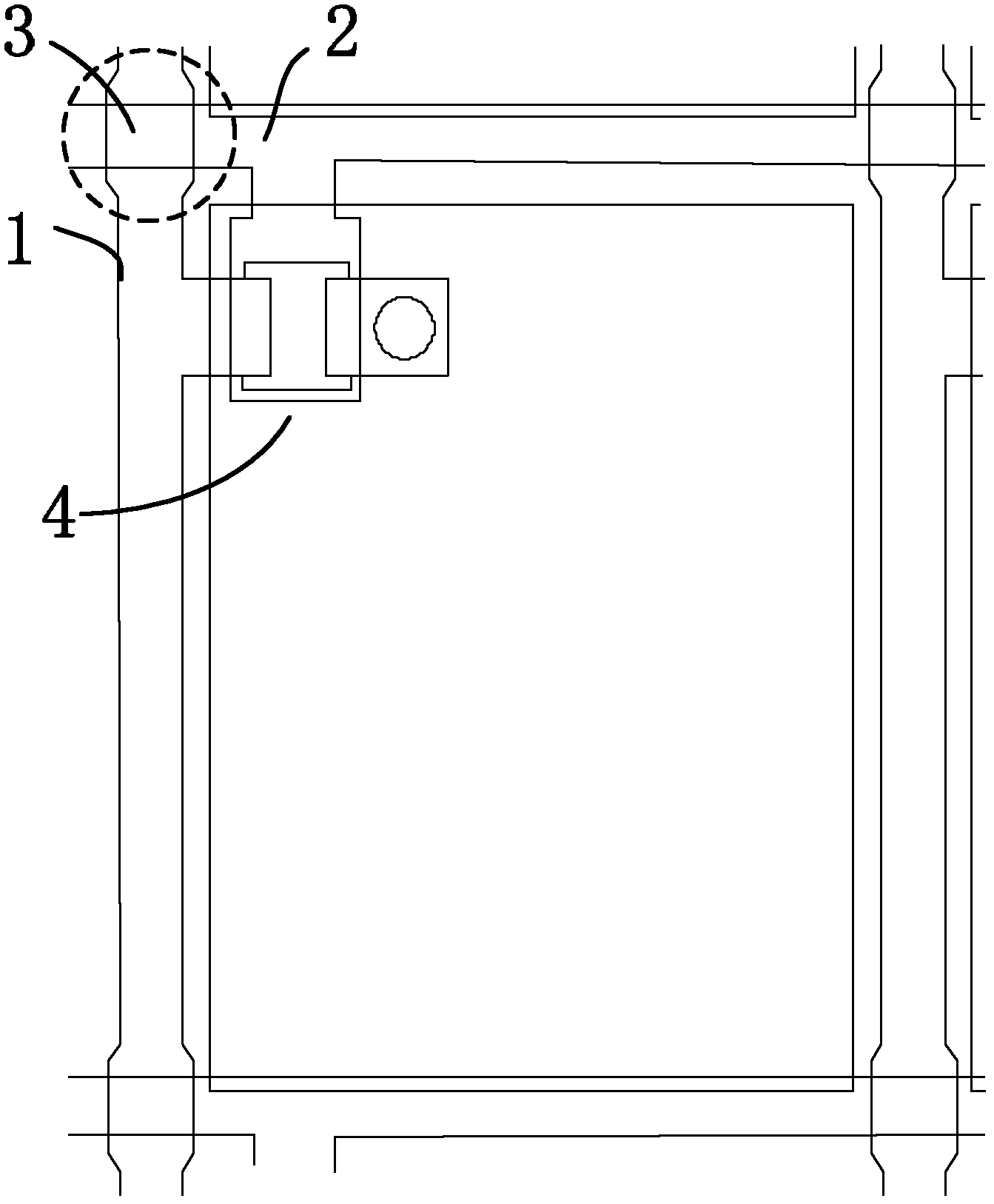

[0020] Such as image 3 As shown, a liquid crystal display device includes an array substrate, and the array substrate includes a plurality of thin film transistors 4, a scanning line 1 connected to the gates of the thin film transistors 4, a data line 2 connected to the sources of the thin film transistors 4, and the data lines 2 The width of the junction 3 of the data line 2 and the scan line 1 is greater than the width of the rest of the data line 2. Further, the widening width of the data line 2 on both sides of the junction 3 is equal. During the exposure and etching process, the intensity received by both sides of the data line 2 is equal, so the width of the widening is kept equal. After the exposure and etching process, the width of the data line 2 is uniform, and there will be no local narrowing or even disconnection.

[0021] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com