AC plasma display panel

A display panel and plasma technology, applied in alternating current plasma display panels, tube structural parts, sustain/scan electrodes, etc., can solve the problems of display unit interference, reduced operating voltage range, low discharge efficiency of linear discharge electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

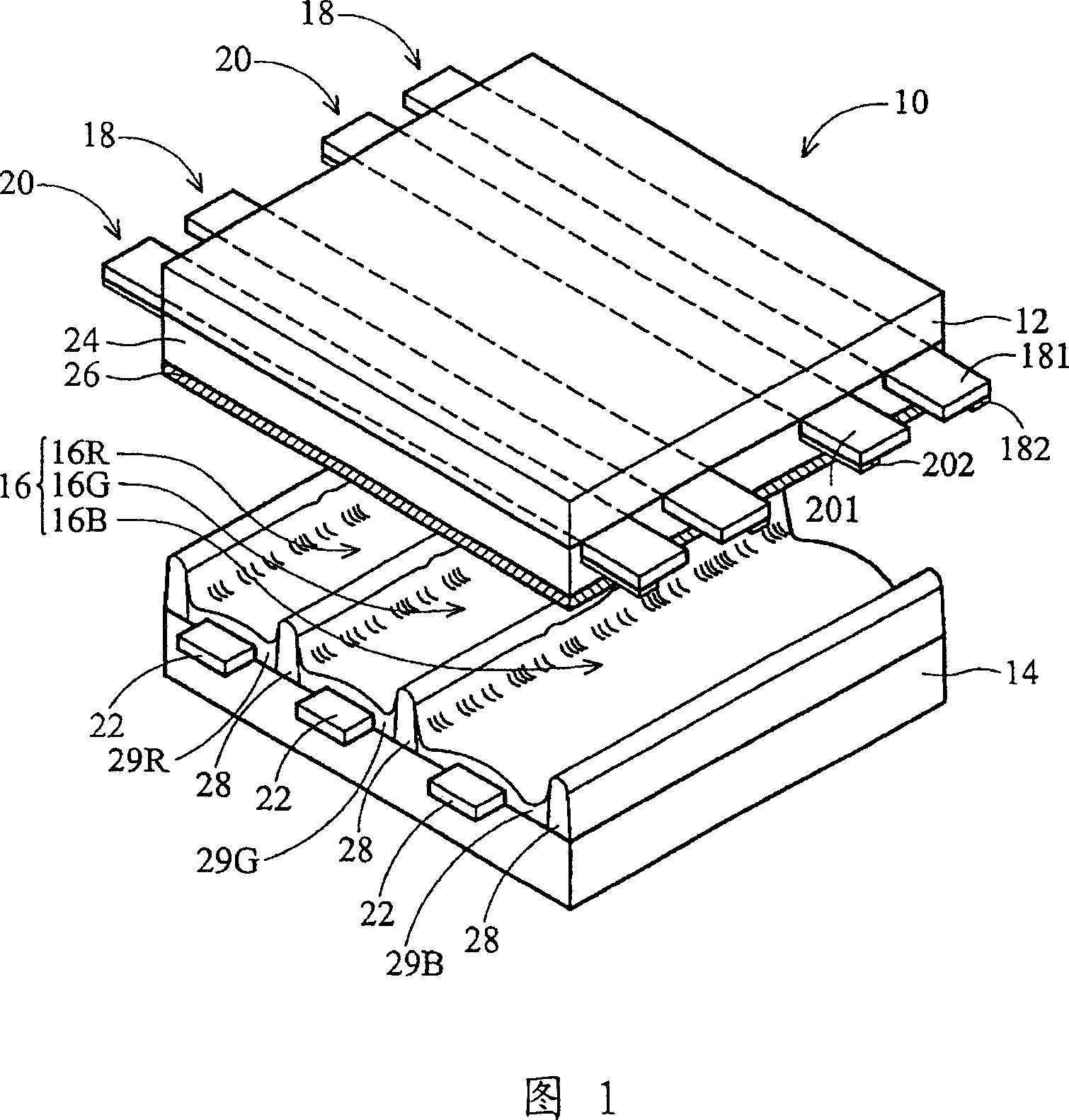

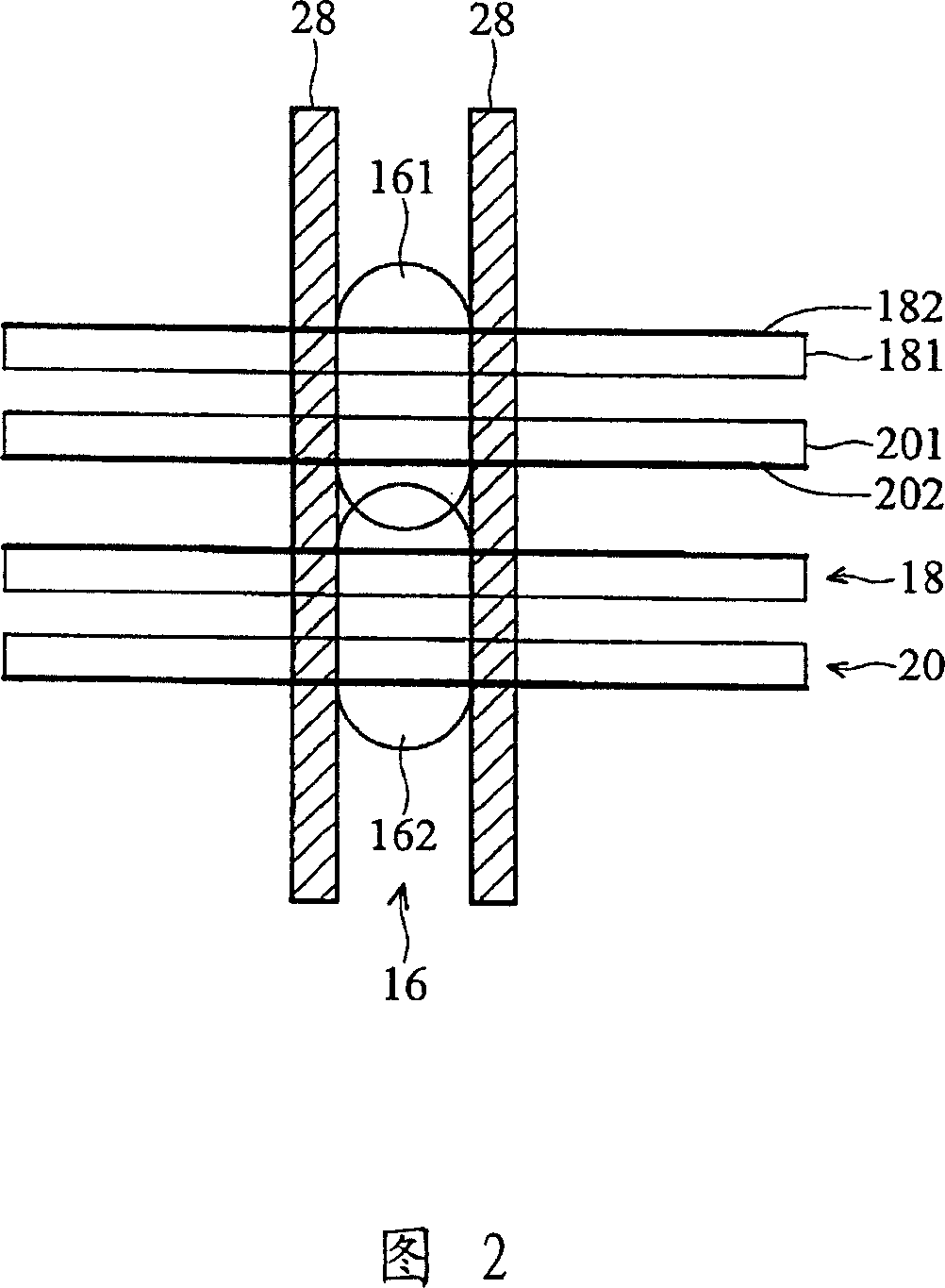

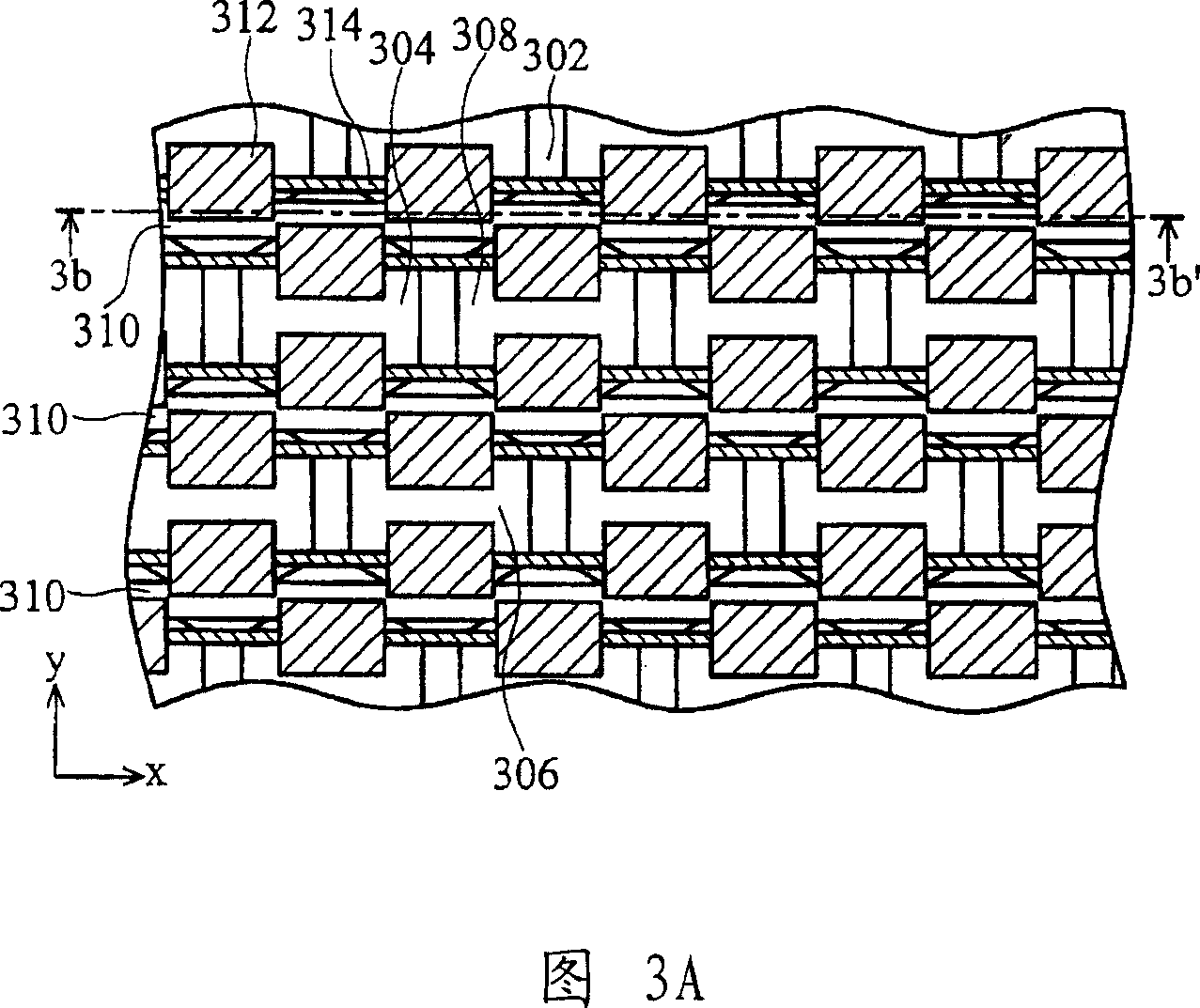

[0070] Please refer to FIG. 3A and FIG. 3B at the same time. FIG. 3A shows a plan view of the barrier rib and electrode structure of the first embodiment of the present invention, and FIG. 3B shows a cross-sectional view along 3b-3b' in FIG. 3A.

[0071] A plurality of barrier ribs 302 are arranged on the back plate 382 in a triangular pixel arrangement, and are divided into a plurality of sub-pixel regions. The sub-pixel regions can be polygonal or circular, and in this preferred embodiment, they are hexagonal shape. The rear plate 382 is preferably a glass substrate. In a preferred embodiment of the present invention, the triangular pixels are arranged in accordance with the three primary colors , and the hexagonal barrier ribs are arranged in a triangular form to form R discharge space 304, G discharge space 306, and B discharge Space 308, and its barrier wall 384 is preferably divided into two colors, upper and lower layers. The upper layer is black to increase the contra...

no. 2 example

[0077] Please refer to FIG. 9 and FIG. 8 at the same time. FIG. 9 shows a plan view of the barrier rib and electrode structure of the second embodiment of the present invention, and FIG. 8 shows a cross-sectional view along 8-8' in FIG. 9 of the present invention.

[0078] A plurality of hexagonal barrier ribs 902 are arranged in a triangular pixel arrangement on the rear panel 800, and the rear panel 800 is preferably a glass substrate. In a preferred embodiment of the present invention, the triangular pixels are arranged in accordance with the three primary colors , and the hexagonal barrier ribs are arranged in a triangle to form R discharge space 904, G discharge space 906, and B discharge. Space 908, and its barrier wall 902 is preferably divided into two colors, upper and lower layers. The upper layer is black to increase the contrast of the picture, while the lower layer is white to reflect visible light to increase the brightness of the picture. The preferred height of ...

no. 3 example

[0082] As shown in FIG. 11 , a plurality of hexagonal barrier ribs 452 are arranged in a triangular pixel arrangement on the rear panel, and the rear panel is preferably a glass substrate. In a preferred embodiment of the present invention, the triangular pixels are arranged in accordance with the three primary colors , and the hexagonal barrier ribs are arranged in a triangle to form R discharge space 454, G discharge space 456, and B discharge. Space 458, and its barrier wall 452 is preferably divided into two colors, upper and lower layers. The upper layer is black to increase the contrast of the picture, while the lower layer is white to reflect visible light to increase the brightness of the picture. The preferred height of the barrier wall 452 is 100 μm to 180 μm.

[0083]In addition, a plurality of auxiliary electrodes 460 are disposed on the upper glass substrate to form a zigzag shape that changes with the shape of the barrier ribs. In this preferred embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com