Polyimide porous film and preparation method thereof

A technology of porous film and polyimide, applied in the field of polyimide porous film and its preparation, can solve the problem of increasing surface densification and planarization of steps, increasing the preparation process and cost, preparation of polyimide porous film Complex process and other issues, to achieve the effect of easy mass production, low cost and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

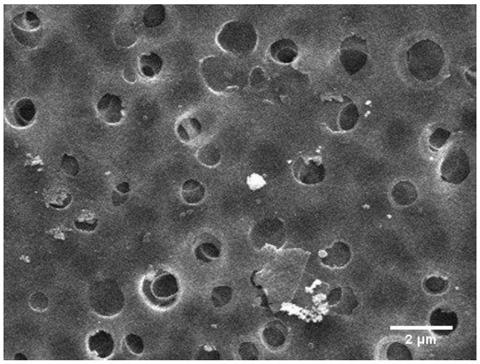

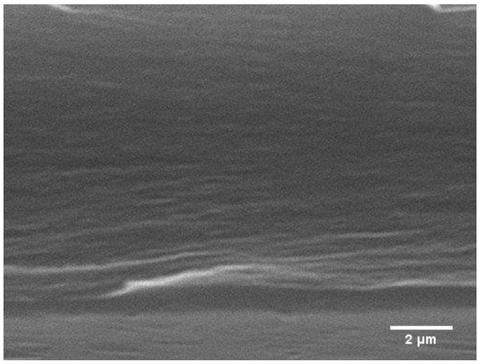

[0045] Based on this, the present invention provides a kind of preparation method of polyimide porous film, described method comprises the steps: the mixture that contains polyamic acid, porogen and solvent is coated on substrate and forms polyamic acid liquid film;

[0046] Drying the polyamic acid liquid film, during which the temperature on the base side of the polyamic acid liquid film is controlled to be lower than the temperature on the surface side of the polyamic acid liquid film; and

[0047] The dried polyamic acid film is imidized.

[0048] In the preparation method of the present invention, by improving the drying and curing process, the temperature on the substrate side of the polyamic acid liquid film is controlled to be lower than the temperature on the surface side of the polyamic acid liquid film, so that the internal solvent and pore-forming agent can diffuse into the liquid film The diffusion rate of the surface layer is lower than the rate at which the solv...

Embodiment 1

[0066] (1) Add 4,4'-diphenyl ether dianhydride and 4,4'-diaminodiphenyl ether to 90 grams of N,N-dimethylacetamide at a molar ratio of 1.01:1, so that The content is 10% by weight (the solid content is the percentage of the weight of the polyamic acid generated in the system to the total weight of the mixed solution). After stirring at 25°C for 6 hours, add 15 grams of pore-forming agent dioctyl phthalate, continue stirring for 1 hour, and vacuum degassing for 1 hour to obtain a viscous mixture. The intrinsic viscosity of the mixture is measured as η int =168 milliliters / gram (measurement condition: Ubbelohde viscometer, constant temperature 25 ℃, sample dilution to solid content is 0.002 grams / ml);

[0067] (2) Under the conditions of a temperature of 25°C and a relative humidity of 60%, scrape-coat the above mixture onto a glass plate, place it on a temperature-controllable platform, and set the temperature of the platform to 50°C. Dry for 12 hours to obtain a polyamic acid...

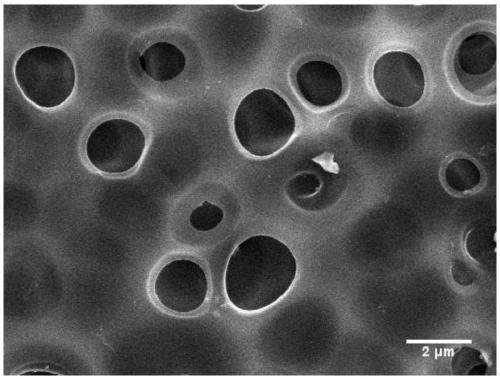

Embodiment 2

[0071](1) 4,4'-diphenyl ether dianhydride and 4,4'-diaminodiphenyl ether are added to 88 grams of N-methylpyrrolidone at a molar ratio of 1.01:1, so that the solid content is 12 wt. % (solid content is the percentage of the weight of polyamic acid generated in the system to the total weight of the mixed solution). Stir at 25°C for 24 hours, add 13 grams of pore-forming agent dioctyl phthalate, continue stirring for 1 hour, and vacuum degas for 1 hour to obtain a viscous mixture. The intrinsic viscosity of the mixture is measured as ηint=155 ml / g (measurement conditions: Ubbelohde viscometer, constant temperature 25°C, sample diluted to a solid content of 0.002 g / ml);

[0072] (2) Under the conditions of a temperature of 25°C and a relative humidity of 60%, scrape-coat the above mixture on a glass plate and place it on a temperature-controllable platform. Dry for 12 hours to obtain a polyamic acid film;

[0073] (3) Heat the above polyamic acid film in nitrogen to carry out i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com