Waterborne priming coating compound, polarizing plate containing compound, and preparation method of optical film containing priming coating

A primer and composition technology, applied in nonlinear optics, chemical instruments and methods, coatings, etc., can solve problems such as corrosion, damage to the working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

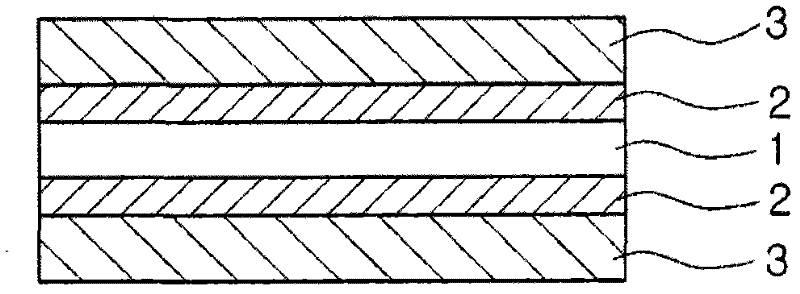

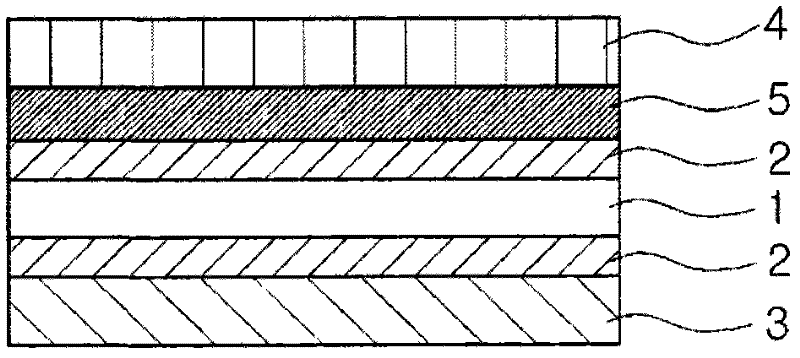

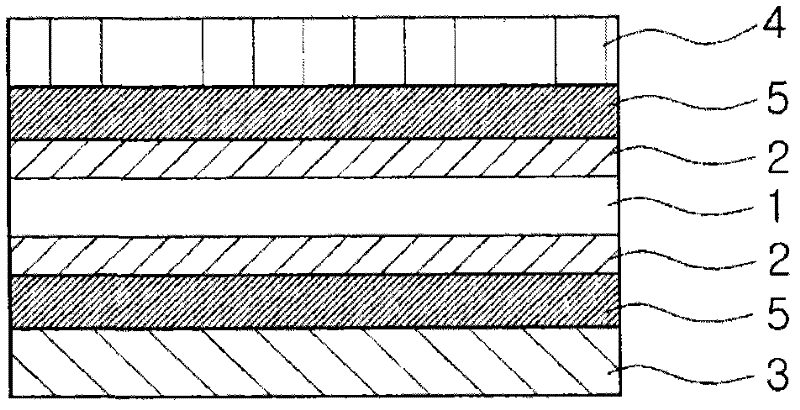

[0092] A primer-treated acrylic film was prepared as follows: A 10 wt % primer composition was prepared by mixing 33.3 g of CK-PUD-F (Chokwang-polyurethane dispersion: aqueous solution with 30% solids), 1.4 g Colloidal silica (with 20% solids in water) and 65.3 g of pure water; use a #3 rod to coat the primer composition onto a corona-treated acrylic film to a thickness of about 300 nm; and at 100° C. Leave the acrylic film under dry for five minutes.

[0093] As the acrylic film, an AX film product (manufactured by Nippon Shokubai) having a thickness of 50 μm was used, and the acrylic film was heated at 50 W / m 2 / min under the conditions of corona treatment to prepare corona-treated acrylic film. A polarizing plate was prepared according to the following procedure. Apply PVA adhesive to both sides of the polarizer. A primer-treated acrylic film was on one side of the polarizer, and an alkali-treated TAC film was on the other side of the polarizer. Then, the primer-treated...

Embodiment 2

[0095] The primer composition except 10wt% is obtained by mixing 33.3g of CK-PUD-F (Chokwang-polyurethane dispersion: an aqueous solution with a 30% solid content), 1.4 g of colloidal silica (aqueous solution with a 20% solid content) ) and 65.3 g of pure water; and using a #5 rod to coat the primer composition onto a corona-treated acrylic film to a thickness of about 500 nm, a polarizing plate was prepared in the same manner as in Example 1.

Embodiment 3

[0097]The primer composition except 10wt% is obtained by mixing 33.3g of SUPERFLEX210 (Nippon Shokubai-polyurethane dispersion: an aqueous solution with a 30% solid content), 1.4 g of colloidal silicon dioxide (aqueous solution with a 20% solid content) and 65.3 g of pure water; and use a #5 rod to coat the primer composition onto a corona-treated acrylic film to a thickness of about 500 nm, and prepare a polarizing plate in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com