Decelerating clutch casing of washing machine and washing machine

A deceleration clutch and washing machine technology, applied in the field of washing machines, can solve the problems of increasing the axial length of the deceleration clutch, and achieve the effects of increasing the washing capacity, reducing the overall height, and reducing the axial length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

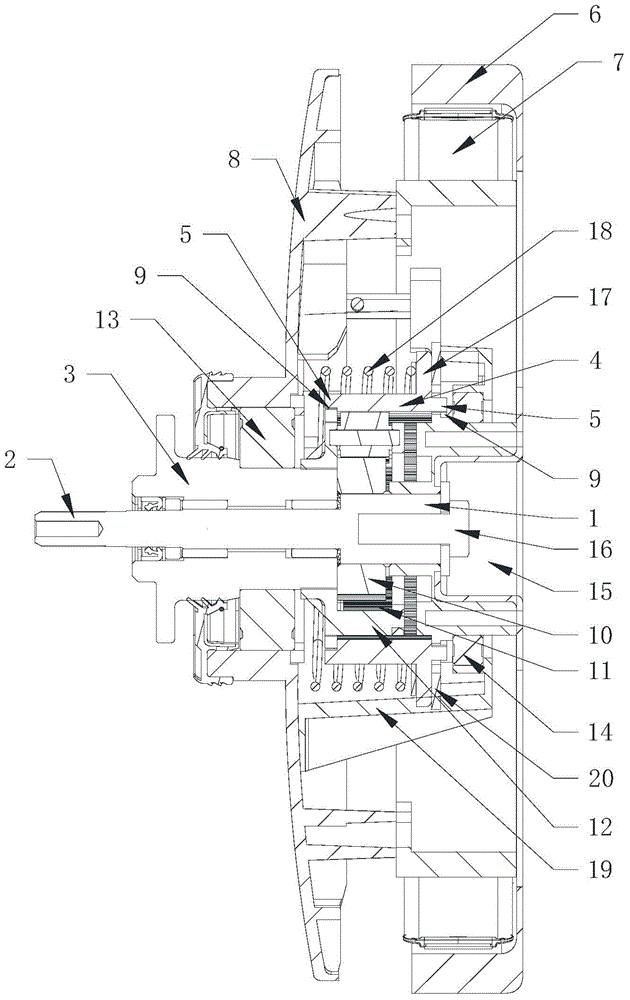

[0041] As a preferred embodiment of the present invention, it also includes a mounting plate 8, which is fixedly connected to the outer cylinder of the washing machine; the second end 193 is fixedly mounted on the mounting plate 8; the mounting plate 8 is provided with a tooth groove 9 for fixed engagement with the clutch sleeve 4 on one side facing the inner chamber.

[0042] The deceleration clutch housing of the present invention is made of metal material integrally formed, on the one hand, it can meet the stress requirements of the deceleration clutch housing, especially to meet the supporting effect of the bearing seat 195 of the first end 191 on the second bearing 14; on the other hand On the one hand, the processing is simple, and the installation and disassembly are convenient.

[0043] As a preferred embodiment of the present invention, the clutch device further includes an input shaft, a speed reduction device, an output shaft and an output bushing, the input end of ...

Embodiment 1

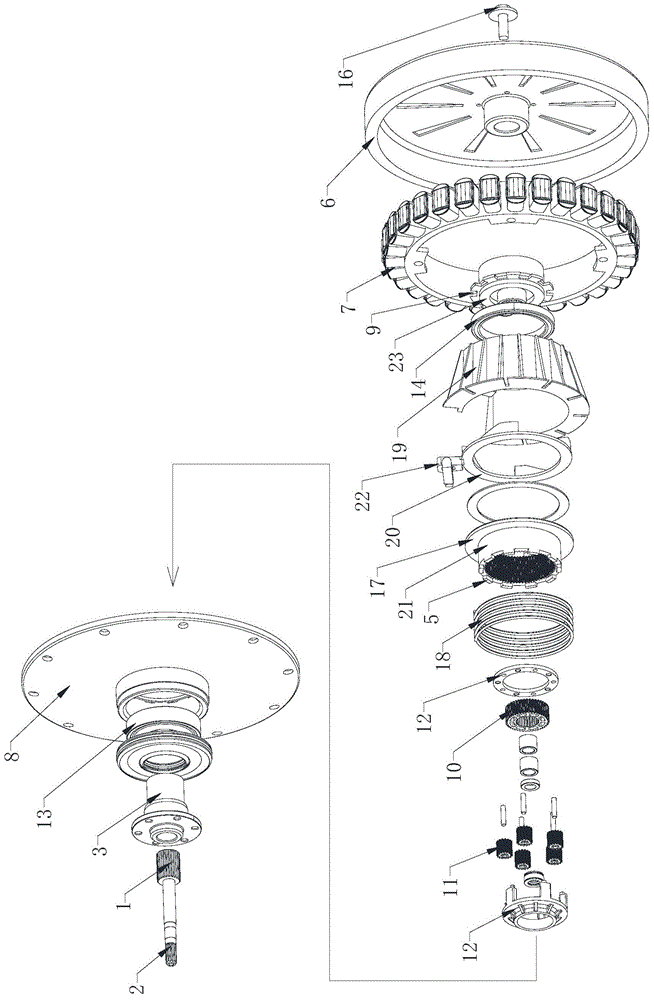

[0045] Such as figure 1 , figure 2 As shown, a washing machine deceleration clutch according to the present invention includes: an input shaft 1, a deceleration device, a clutch device, an output shaft 2 and an output sleeve 3, and the clutch device is arranged on the outer periphery of the deceleration device, on the line where the input shaft is located. The projections on are at least partially overlapped. The clutch device at least includes an axially movable clutch bushing, which is the inner ring gear of the reduction gear. The axial movement of the clutch bushing 21 is connected with structures in different states, and the control Different output states of the output shaft 2 and the output sleeve 3, the clutch sleeve 21 meshes with at least part of the gears in the reduction gear.

[0046] If the above-mentioned washing machine is a vertical bucket pulsator washing machine, the output shaft 2 is connected to the pulsator, and the output bushing 3 is connected to the ...

Embodiment 2

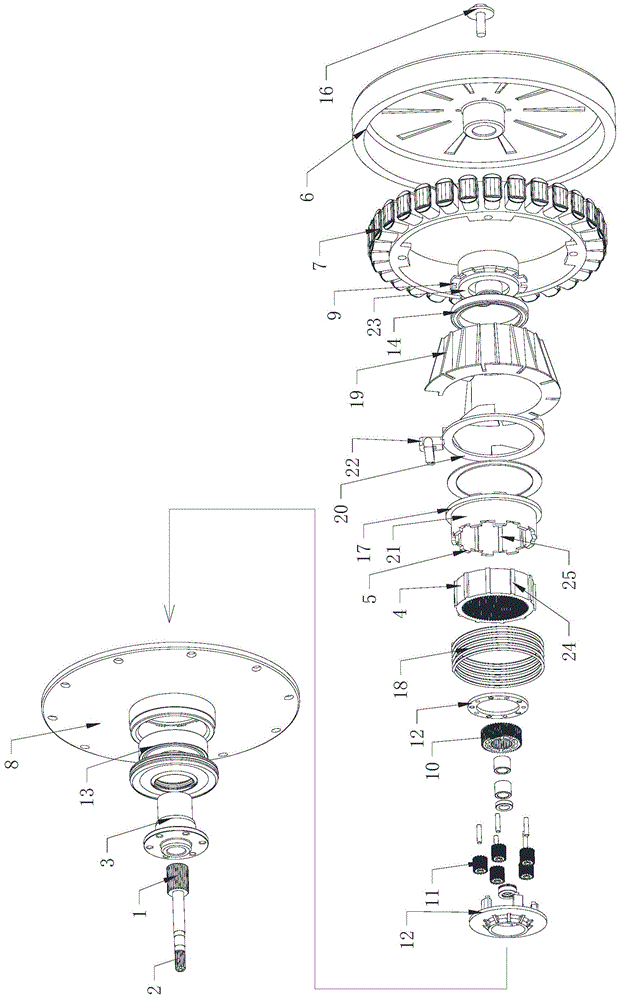

[0077] Such as image 3 , Figure 4 As shown, a washing machine deceleration clutch according to the present invention includes: an input shaft 1, a deceleration device, a clutch device, an output shaft 2 and an output shaft sleeve 3, the clutch device is arranged on the outer periphery of the deceleration device, and the clutch device is at least It includes a clutch sleeve 21 that can move axially. The clutch sleeve 21 is arranged outside the ring gear 4 of the deceleration device, and is connected with the ring gear 4 in an axially relatively sliding and circumferentially non-rotatable manner. 21 Axial movement connects the ring gear 4 to structures in different states through the clutch sleeve 21 to control the different output states of the output shaft 2 and the output sleeve 3, and the ring gear 4 meshes with at least part of the gears in the reduction gear .

[0078] If the above-mentioned washing machine is a vertical bucket pulsator washing machine, the output shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com