Induction heating cooking equipment

A technology for induction heating and cooking appliances, applied in induction heating, induction heating devices, electric/magnetic/electromagnetic heating, etc., can solve the problems of undisclosed component installation or structure, and achieve reduced ventilation resistance, high cooling performance, expansion The effect of the exhaust port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

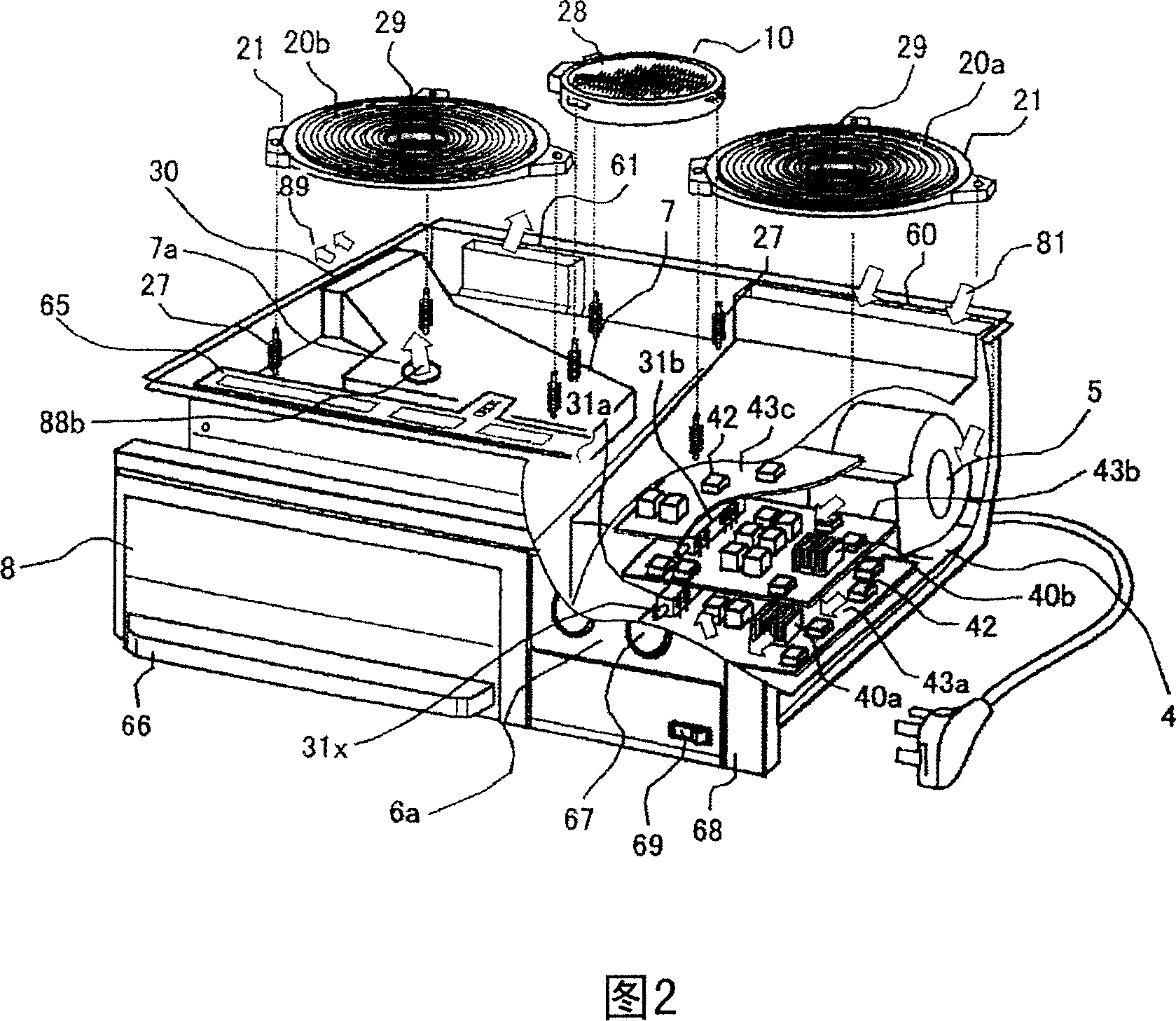

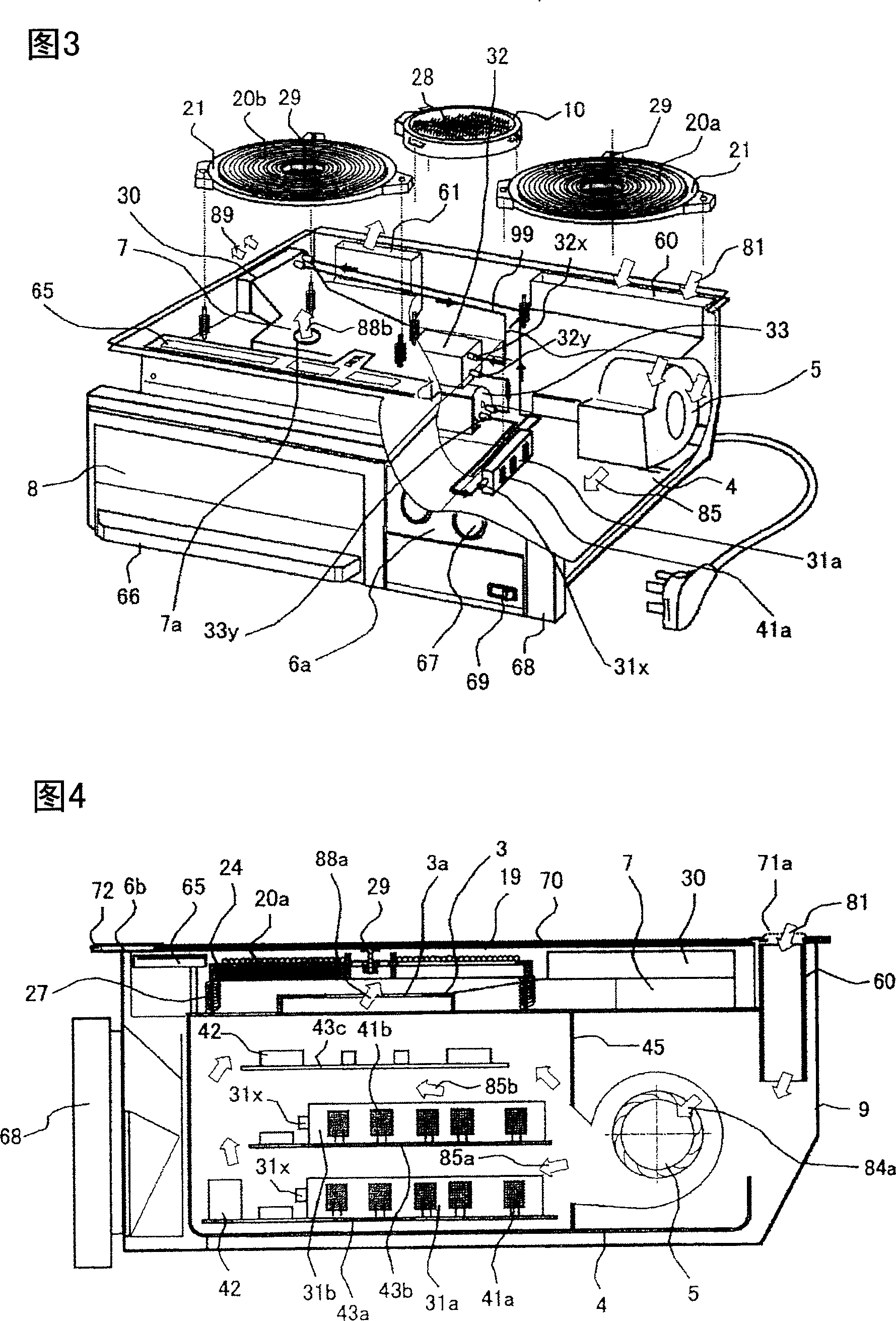

[0048] Embodiments of the present invention will be described below with reference to the drawings.

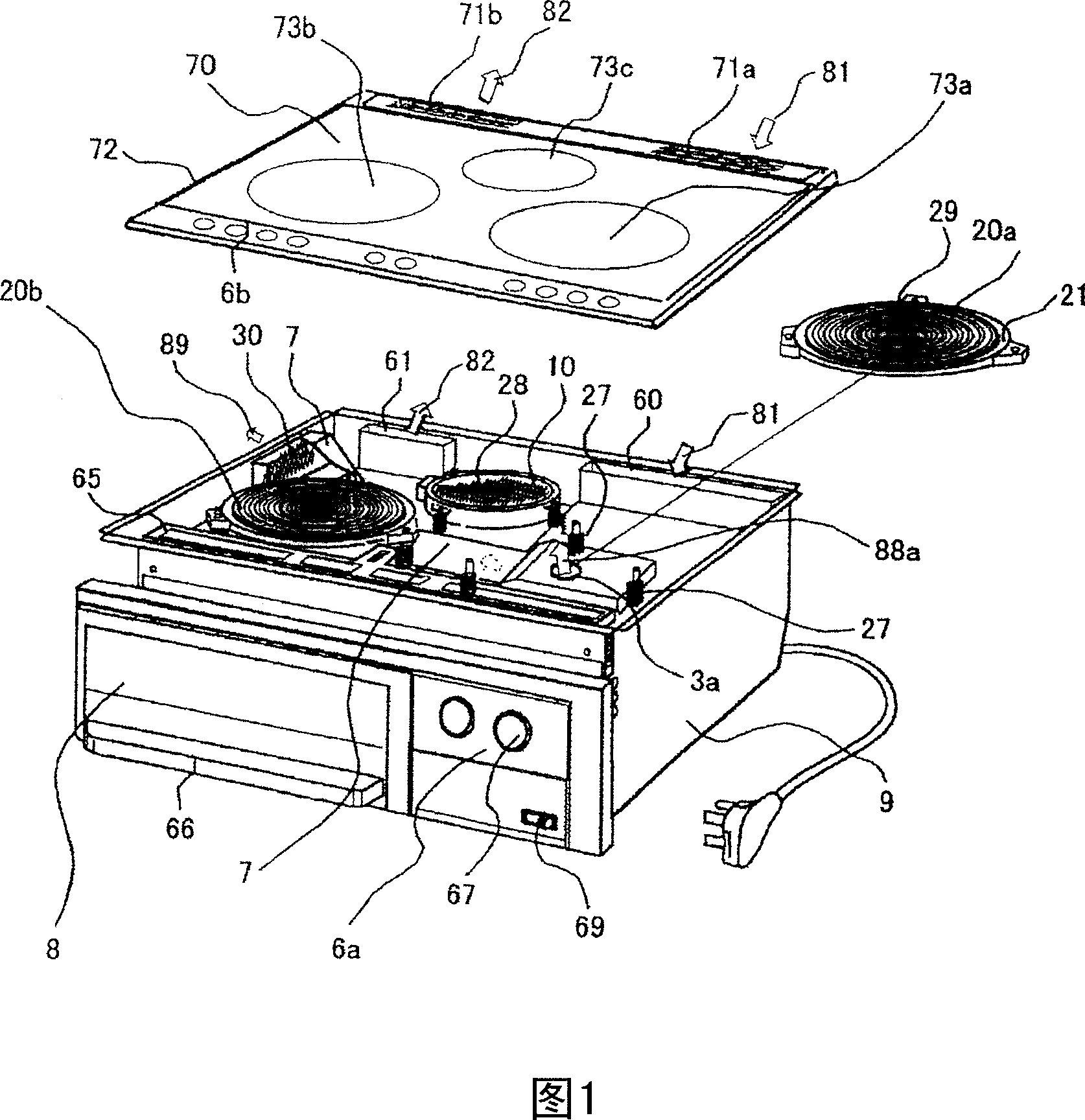

[0049] 1 to 7 show an embodiment of the present invention, showing a built-in type induction heating cooker in which three pot placement parts 73a, 73b, and 73c are provided on a top plate 70. As shown in FIG.

[0050] In addition, this invention is not limited to this structure, The induction heating cooker which provided the pan placement part of at least one induction heating may be sufficient. In addition, it is not a built-in type installed in the kitchen, but a shelf type induction heating cooker placed in the kitchen is fine.

[0051]FIG. 1 shows a state in which the top plate 70 is detached from the induction heating cooker main body 9 of the present embodiment. The induction heating cooker of this embodiment is provided with: the pot placement parts 73a, 73b that supply the heating coil 20 with high-frequency current to inductively heat the cooking pot (not shown) ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com