Heat dissipater and manufacturing method thereof

A manufacturing method and radiator technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of inability to provide good heat dissipation performance, limited number of heat dissipation fins, and inability to shorten the distance between heat dissipation fins, etc., to improve heat dissipation efficiency and simplify process, the effect of increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

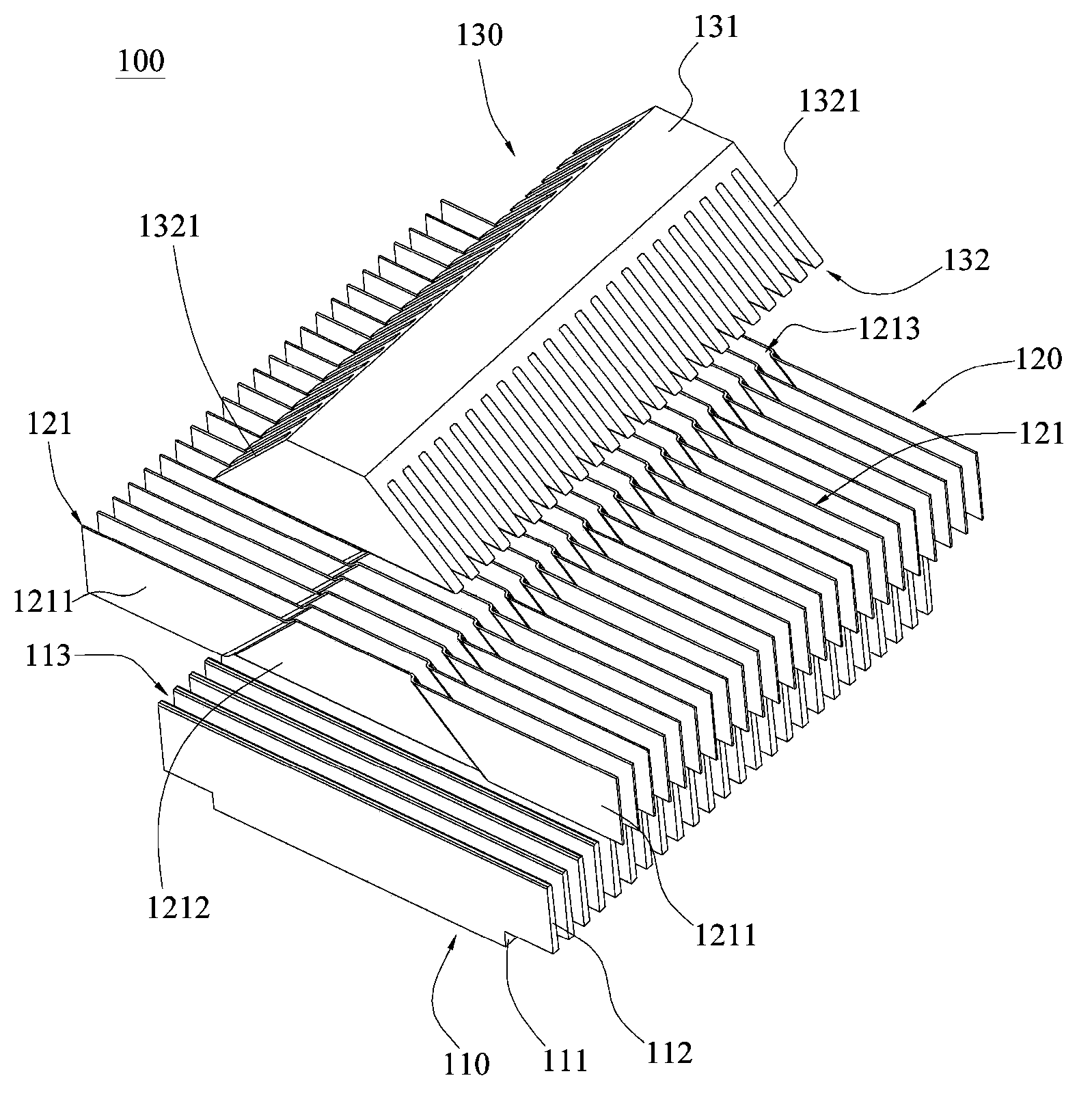

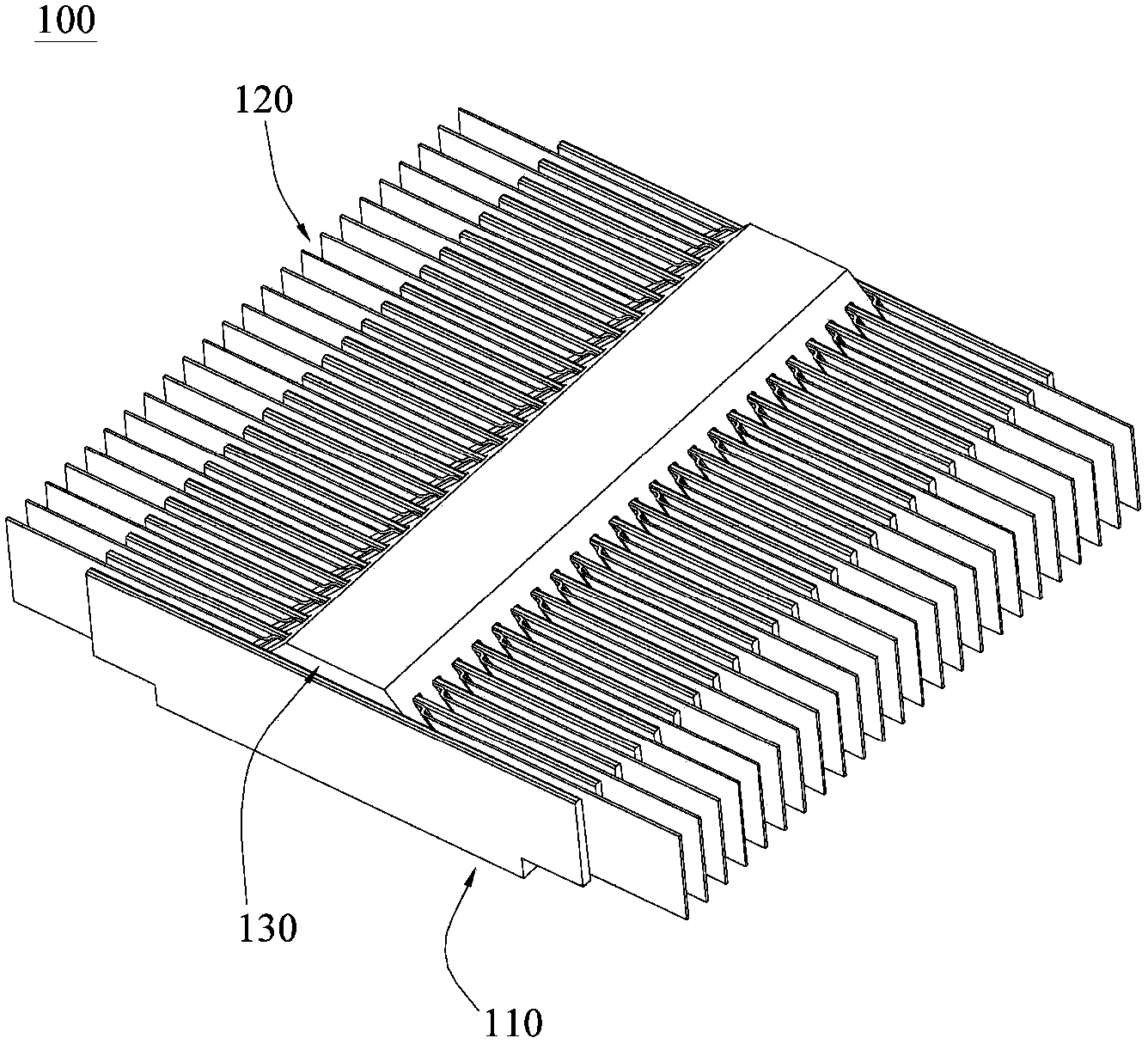

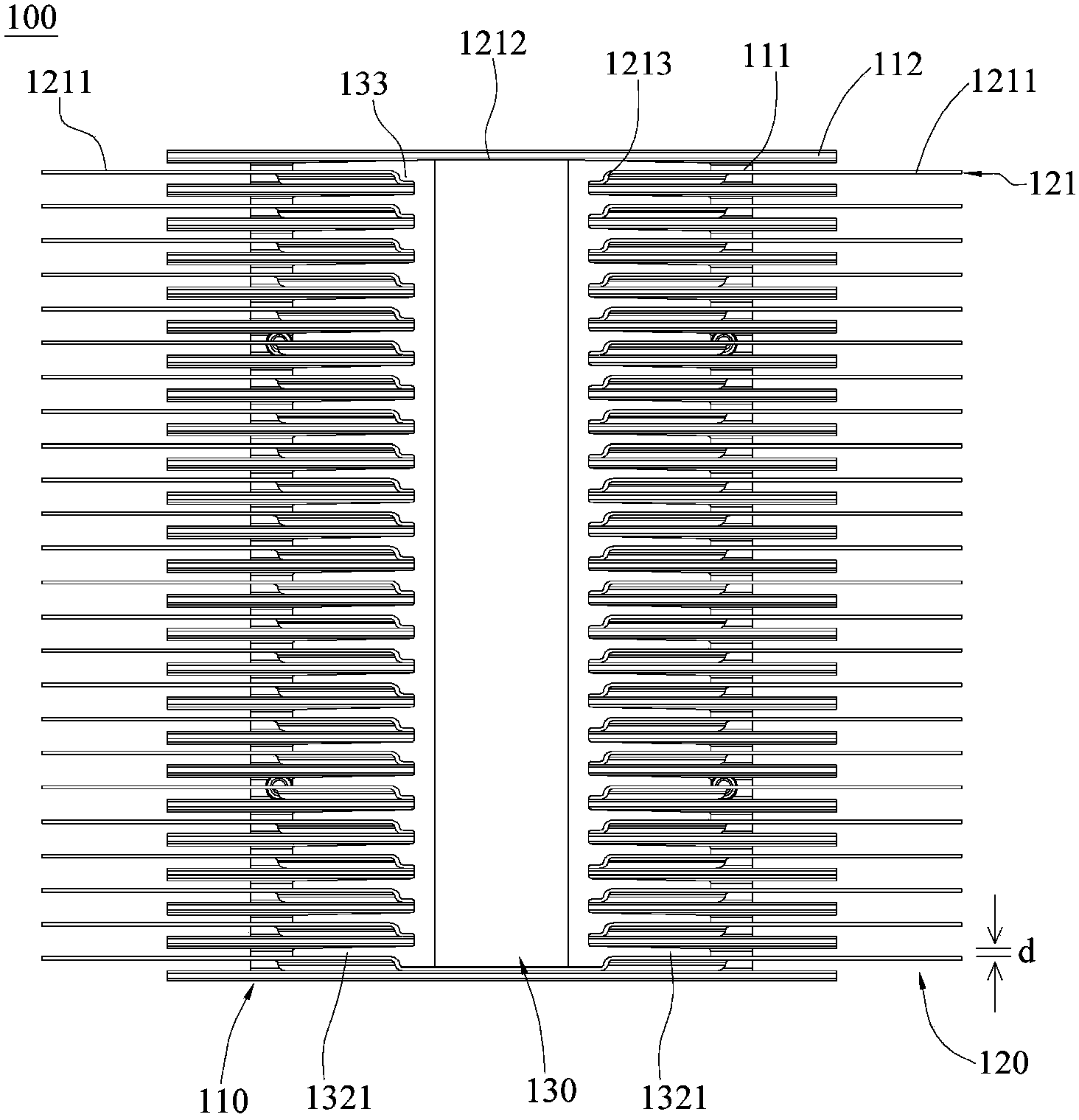

[0039] Such as Figure 1 to Figure 3 As shown, the heat sink 100 disclosed in the first embodiment of the present invention includes a base 110, a fin set 120 and a buckle 130, the base includes a bottom plate 111 and a plurality of first heat dissipation fins 112, a plurality of first fins 112 A heat dissipation fin 112 is disposed on the bottom plate 111 at intervals, and a slot 113 is formed between adjacent first heat dissipation fins 112, wherein a plurality of first heat dissipation fins 112 are along a first direction (such as the direction of the bottom plate 111 Long side direction) are arranged at intervals, and the opposite ends of each first cooling fin 112 extend along a second direction perpendicular to the first direction (for example, the short side direction of the bottom plate 111), and protrude from the bottom of the bottom plate 111. opposite sides.

[0040] The fin group 120 includes a plurality of second heat dissipation fins 121, the length of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com