Production process of cool coffee fiber knitted fabric

A coffee fiber and knitted fabric technology, applied in the field of textile fabrics, can solve the problems of lack, singleness, and uneven overall performance and quality, and achieve the effects of optimizing prescription, excellent cooling and heat dissipation, and fastness quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An iced coffee fiber knitted fabric, a double-sided fabric woven from differentiated polyester yarn and iced coffee fiber yarn, the inner layer of the fabric is made of iced coffee fiber yarn, and the outer layer is made of differentiated polyester yarn, specifically, differentiated polyester Silk uses T75D / 72F differentiated polyester yarn, the iced coffee fiber yarn uses T75D / 72F iced coffee fiber yarn, the line length of the differentiated polyester yarn is 28cm / 100G, and the line length of the iced coffee fiber yarn is 24cm / 100G, further, the iced coffee fiber knitted fabric includes 44% differentiated polyester yarn and 56% iced coffee fiber yarn by weight percentage;

[0039] A kind of production technology of iced coffee fiber knitted fabric, comprises the steps:

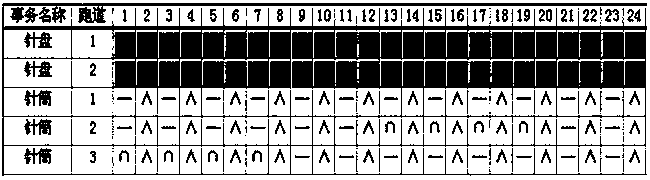

[0040] (1) Weaving: Gray fabric is woven from differentiated polyester yarn and iced coffee fiber yarn;

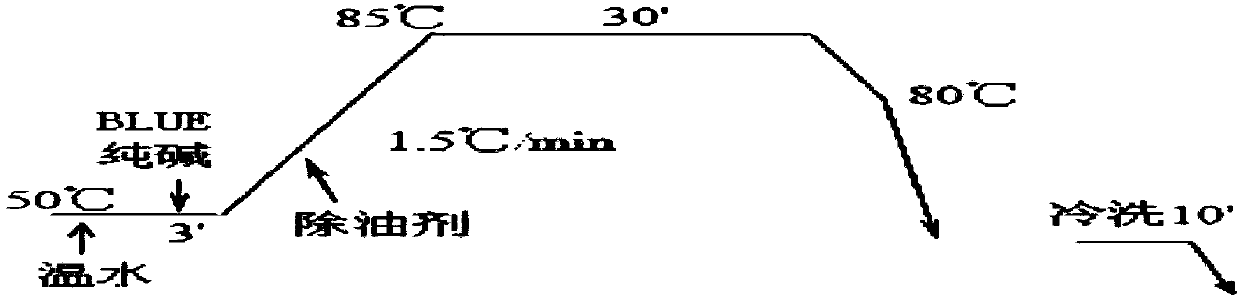

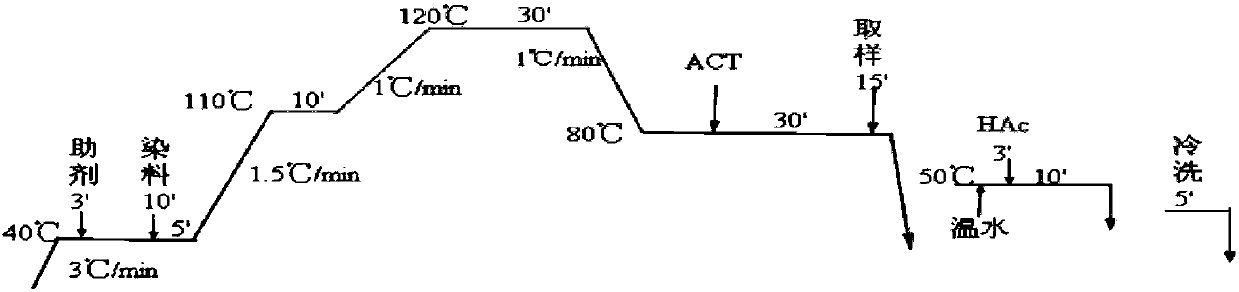

[0041] (2), pretreatment: carry out degreasing treatment to greige before dyeing, specificall...

Embodiment 2

[0046] An iced coffee fiber knitted fabric, a double-sided fabric woven from differentiated polyester yarn and iced coffee fiber yarn, the inner layer of the fabric is made of iced coffee fiber yarn, and the outer layer is made of differentiated polyester yarn, specifically, differentiated polyester Silk uses T75D / 72F differentiated polyester yarn, the iced coffee fiber yarn uses T75D / 72F iced coffee fiber yarn, the line length of the differentiated polyester yarn is 28cm / 100G, and the line length of the iced coffee fiber yarn is 24cm / 100G, further, the iced coffee fiber knitted fabric includes 48% differentiated polyester yarn and 52% iced coffee fiber yarn by weight percentage;

[0047] A kind of production technology of iced coffee fiber knitted fabric, comprises the steps:

[0048] (1) Weaving: Gray fabric is woven from differentiated polyester yarn and iced coffee fiber yarn;

[0049] (2), pre-treatment: before dyeing, the gray cloth is degreased. Specifically, the gray...

Embodiment 3

[0054] An iced coffee fiber knitted fabric, a double-sided fabric woven from differentiated polyester yarn and iced coffee fiber yarn, the inner layer of the fabric is made of iced coffee fiber yarn, and the outer layer is made of differentiated polyester yarn, specifically, differentiated polyester Silk uses T75D / 72F differentiated polyester yarn, the iced coffee fiber yarn uses T75D / 72F iced coffee fiber yarn, the line length of the differentiated polyester yarn is 28cm / 100G, and the line length of the iced coffee fiber yarn is 24cm / 100G, further, the iced coffee fiber knitted fabric includes 46.2% differentiated polyester yarn and 53.8% iced coffee fiber yarn by weight percentage;

[0055] A kind of production technology of iced coffee fiber knitted fabric, comprises the steps:

[0056] (1) Weaving: Gray fabric is woven from differentiated polyester yarn and iced coffee fiber yarn;

[0057] (2), pre-treatment: before dyeing, the gray cloth is degreased. Specifically, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com