Preparing method for unidirectional wet-conduction pure cotton fabric based on nano-zinc oxide

A nano-zinc oxide and unidirectional moisture-conducting technology, which is applied in plant fibers, textiles, papermaking, fiber treatment, etc., can solve the problem that unidirectional moisture-conducting fabrics do not have a cooling effect, achieve excellent unidirectional moisture-conducting performance, and improve cooling performance , the effect of meeting the requirements of heat and humidity comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Mix the nano-ZnO powder with a mass concentration of 1% and a phthalate coupling agent with a mass concentration of 1.25%, and stir magnetically for 10 minutes. At this time, add a dispersant Tween-80 with a mass concentration of 1% to continue magnetic Stir for 30 minutes, disperse evenly, and ultrasonically disperse it for 1 hour to obtain a modified nano-ZnO finishing solution.

[0042] (2) Dip 24 single-strand all-cotton plain yarn single-yarn cotton wool cloths in the modified nano-ZnO finishing solution obtained in step (1), and treat them in a constant temperature oscillating water bath at 25°C for 20 minutes, using two dipping and two rolling, The liquid squeeze rate is 90%, and then the finishing process of pre-baking (80°C, 3min) and baking (150°C, 2min) is carried out, so that the cotton fabric and zinc oxide form a firm combination, and the cotton fabric finished with nano-ZnO is obtained.

[0043] (3) Prepare printing slurry, which includes sodium algin...

Embodiment 2

[0045] (1) Mix the nano-ZnO powder with a mass concentration of 1.5% and a phthalate coupling agent with a mass concentration of 1.25%, and stir magnetically for 10 minutes. At this time, add a dispersant Tween-80 with a mass concentration of 1% and magnetically Stir for 30 minutes, disperse evenly, and ultrasonically disperse it for 1 hour to obtain a modified nano-ZnO finishing solution.

[0046] (2) Immerse 32 single-strand all-cotton plain yarn single-yarn cotton wool cloths in the modified nano-ZnO finishing solution obtained in step (1), and treat them in a constant temperature oscillating water bath at 25°C for 20 minutes. Rolling, the liquid rolling rate is 90%, and then the finishing process of pre-baking (80°C, 3min) and baking (150°C, 2min) is carried out, so that the cotton fabric and zinc oxide form a firm combination, and the cotton fabric finished with nano-ZnO is obtained. .

[0047] (3) Prepare printing slurry, which includes sodium alginate with a mass conce...

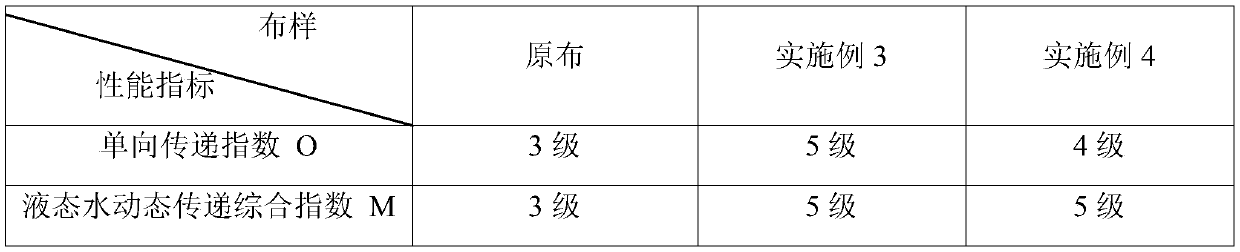

Embodiment 3

[0049] (1) Mix the nano-ZnO powder with a mass concentration of 2% and a phthalate coupling agent with a mass concentration of 1.25%, and stir magnetically for 10 minutes. At this time, add a dispersant Tween-80 with a mass concentration of 1% and magnetically Stir for 30 minutes, disperse evenly, and ultrasonically disperse it for 1 hour to obtain a modified nano-ZnO finishing solution.

[0050] (2) Soak 24 single-ply cotton plain yarn single-yarn cotton wool cloths in the modified nano-ZnO finishing solution obtained in step (1), and treat them in a constant temperature oscillating water bath at 25°C for 20 minutes. , the liquid squeeze rate is 90%, and then the finishing process of pre-baking (80°C, 3min) and baking (150°C, 2min) is carried out to make the cotton fabric and zinc oxide form a firm combination, and obtain the cotton fabric finished by nano-ZnO.

[0051] (3) Prepare printing slurry, which includes sodium alginate with a mass concentration of 5%, a hydrophobic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com