A moisture-absorbing and sweat-wicking invisible graphic fabric and its production method

A moisture absorption and perspiration production method technology, applied in the field of textile fabrics, can solve the problems of poor contact between finishing agent and fiber surface, poor durability of unidirectional moisture guide function, poor affinity and hydrophobicity, etc., to achieve improved unidirectional moisture guide performance, excellent single The effect of moisture guiding performance and good moisture absorption and ventilation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0045] The following production methods are used to produce moisture-absorbing and perspiration-displayable graphic fabrics:

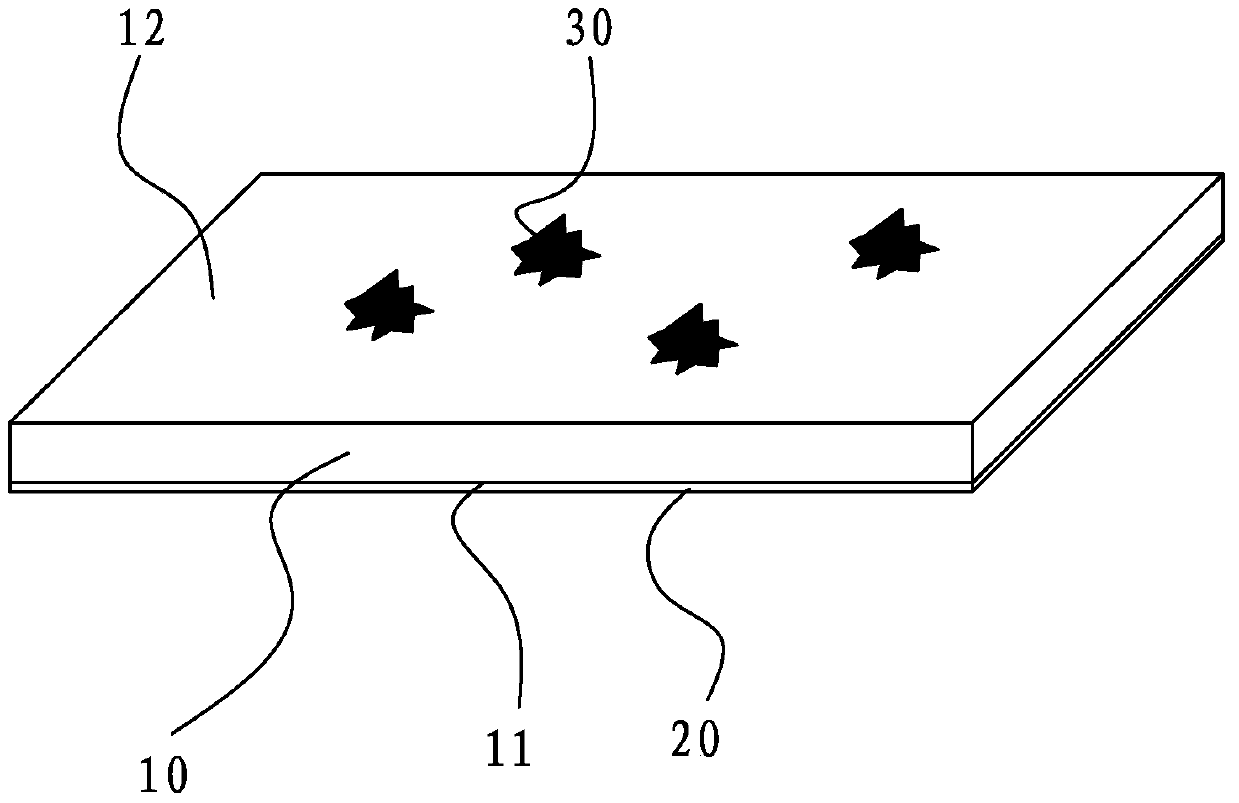

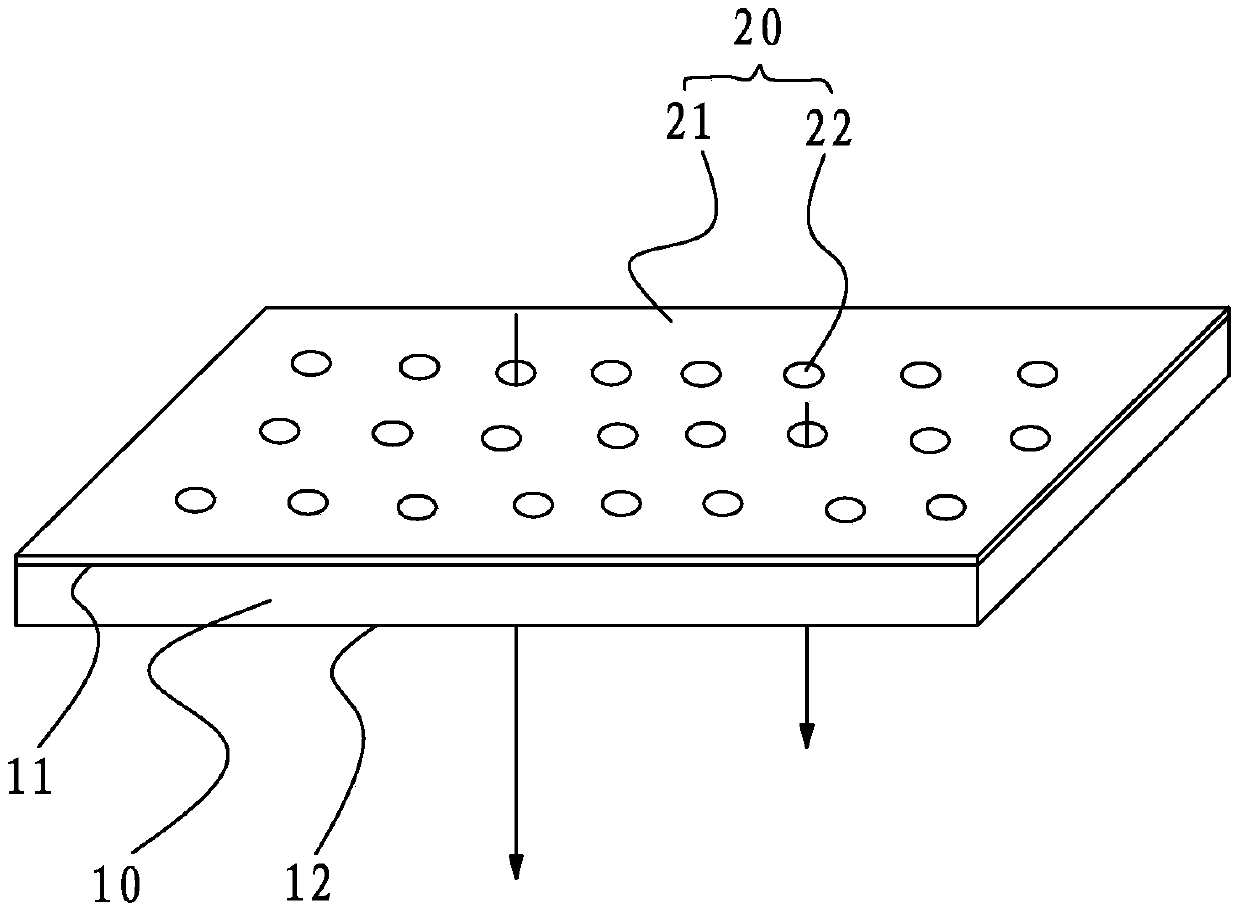

[0046] (1) Use a rotary screen printing machine or a flat screen printing machine to apply the first hydrophobic unidirectional moisture-wicking paste to the inner surface 11 of the fabric 10 to form a slurry coated with the first hydrophobic The hydrophobic area 21 of the unidirectional moisture-wicking slurry and the hydrophilic area 22 not coated with the first hydrophobic unidirectional moisture-wicking slurry, the second is printed by a rotary screen printing machine or a flat screen printing machine. Hydrophobic unidirectional moisture-wicking paste is pressed on the outer surface 12 of the fabric 10 to form the first invisible printing graphic 30; wherein, the first hydrophobic unidirectional moisture-wicking paste and the second hydrophobic The composition of the one-way moisture-wicking slurry is: waterproof agent EEE content: 4.2%, thickener ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com