A unidirectional moisture-wicking asymmetric polyester fabric and its preparation and application

A polyester fabric, unidirectional moisture conductivity technology, applied in textiles and papermaking, liquid repellent fibers, fiber processing, etc., can solve the problems of complex technical process, insufficient durability, general unidirectional moisture conductivity, etc., and achieve simple operation. , good durability, excellent unidirectional moisture conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Using 3-mercaptopropyltrimethoxysilane to modify polyester fabric with mercapto group, and react with hydrophilic 3-sulfopropyl acrylate to obtain an asymmetric polyester fabric with good unidirectional moisture transfer performance and durability. The specific steps are:

[0042] (1) Preparation stage:

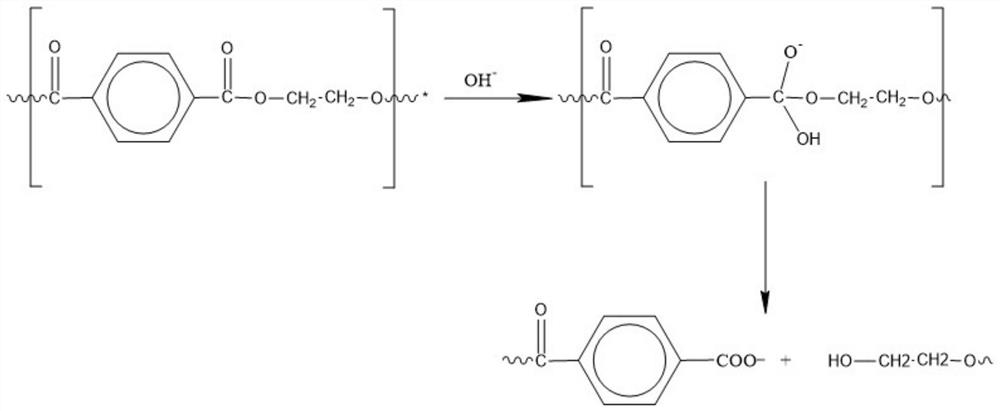

[0043] ① Immerse the polyester fabric in 200g / L sodium hydroxide solution, react at 80°C for 30 minutes, stir at the same time to make the fabric fully contact with the solution, then take out the polyester fabric and wash it with hot water and then cold water to fully wash off the residual lye on the fabric To neutral, dry at 80°C;

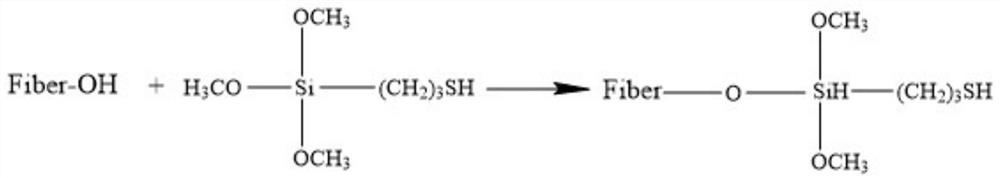

[0044] ②Add 2wt% 3-mercaptopropyltrimethoxysilane to the hydroalcoholic solution of 80mL ethanol and 20mL water, add acetic acid at the same time to adjust the pH value to 5, and fully hydrolyze at room temperature for 30min;

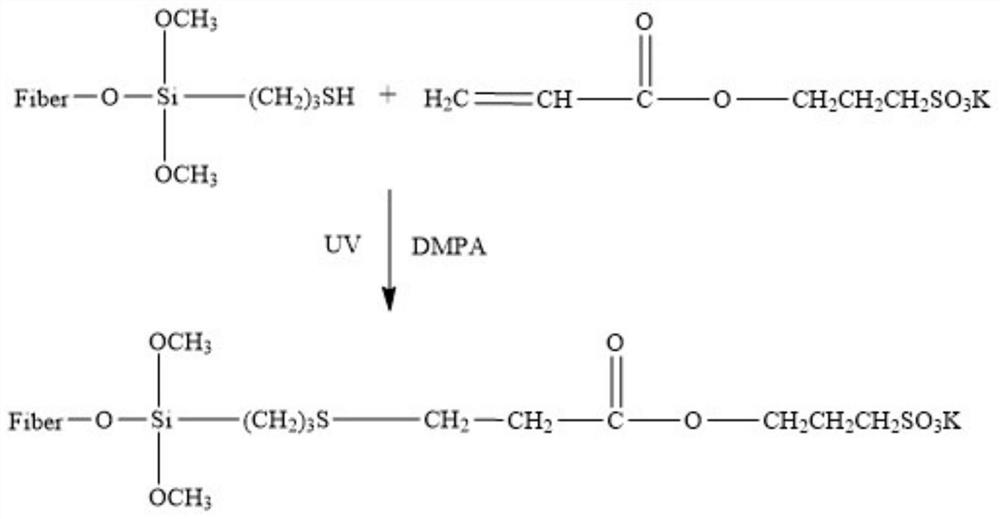

[0045] ③Sonicate the finishing solution prepared by 10wt% 3-sulfopropyl acrylate, 1wt% photoinitiator DMPA, an...

Embodiment 2

[0052] Using 3-mercaptopropyltrimethoxysilane to modify polyester fabric with mercapto group, and react with hydrophilic 3-sulfopropyl acrylate to obtain an asymmetric polyester fabric with good unidirectional moisture transfer performance and durability. The specific steps are:

[0053] (1) Preparation stage:

[0054] ① Immerse the polyester fabric in 200g / L sodium hydroxide solution, react at 80°C for 30 minutes, stir at the same time to make the fabric fully contact with the solution, then take out the polyester fabric and wash it with hot water and then cold water to fully wash off the residual lye on the fabric To neutral, dry at 80°C;

[0055] ②Add 2wt% 3-mercaptopropyltrimethoxysilane to the hydroalcoholic solution of 80mL ethanol and 20mL water, add acetic acid at the same time to adjust the pH value to 5, and fully hydrolyze at room temperature for 30min;

[0056] ③Sonicate the finishing solution prepared by 15wt% 3-sulfopropyl acrylate, 1wt% photoinitiator DMPA, an...

Embodiment 3

[0063] Using 3-mercaptopropyltrimethoxysilane to modify polyester fabric with mercapto group, and react with hydrophilic 3-sulfopropyl acrylate to obtain an asymmetric polyester fabric with good unidirectional moisture transfer performance and durability. The specific steps are:

[0064] (2) Preparation stage:

[0065] ① Immerse the polyester fabric in 200g / L sodium hydroxide solution, react at 80°C for 30 minutes, stir at the same time to make the fabric fully contact with the solution, then take out the polyester fabric and wash it with hot water and then cold water to fully wash off the residual lye on the fabric To neutral, dry at 80°C;

[0066] ②Add 2wt% 3-mercaptopropyltrimethoxysilane to the hydroalcoholic solution of 80mL ethanol and 20mL water, add acetic acid at the same time to adjust the pH value to 5, and fully hydrolyze at room temperature for 30min;

[0067] ③Sonicate the finishing solution prepared by 20wt% 3-sulfopropyl acrylate, 1wt% photoinitiator DMPA, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com