Rubbing cloth and production method thereof

A rubbing cloth and bottom layer technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problem that car wiping cloths cannot meet the actual needs of users, and achieve high strength, easy fibrillation, good absorption and moisture conduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

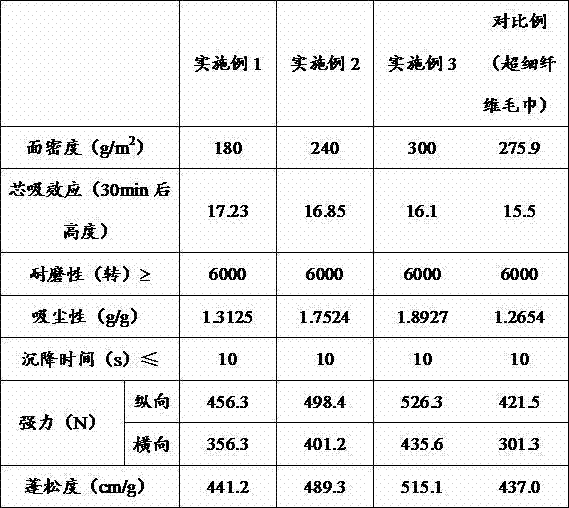

Embodiment 1

[0027] 1. Fiber material and pre-fibrillation treatment

[0028] The tencel fiber linear density is 2.2 D, and the length is 51 mm. The tencel fiber is sprayed with the Turkish red oil aqueous solution. The consumption of the Turkish red oil is 2% of the quality of the tencel fiber, and the consumption ratio of the Turkish red oil and water is 1: 8. Make the tencel fiber diameter swelling rate reach 15%, and the moisture regain rate reach 20%; select three-dimensional crimped polyester fiber with a linear density of 6 D and a length of 51 mm.

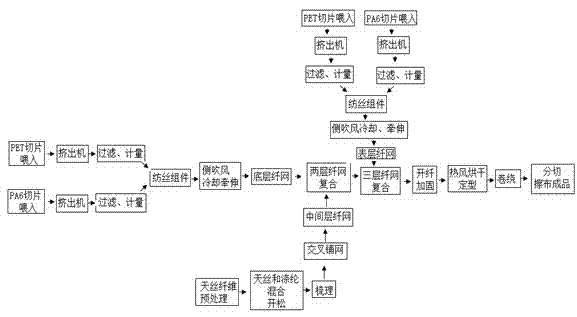

[0029] 2. Preparation method

[0030] 1) Preparation of the bottom fiber web: After PET slices and PA6 slices pass through their respective feeding, extruder, filtration and melt distribution systems, the two melts are compounded and extruded at the exit of the spinneret to form a composite PET / PA6 filament, in which PET is distributed into a gear-shaped skeleton part in the cross-section of the composite PET / PA6 filament, and PA6 is d...

Embodiment 2

[0036] 1. Fiber material and pre-fibrillation treatment

[0037] The tencel fiber linear density is 3 D, and the length is 51 mm. The tencel fiber is sprayed with the Turkish red oil aqueous solution. The consumption of the Turkish red oil is 3% of the quality of the tencel fiber, and the consumption ratio of the Turkish red oil and water is 1: 9. Make the tencel fiber diameter swelling rate reach 18%, and the moisture regain rate reach 23%; select three-dimensional crimped polyester fiber with a linear density of 8 D and a length of 65 mm.

[0038] 2. Preparation method

[0039] 1) Preparation of the bottom fiber web: After PET slices and PA6 slices pass through their respective feeding, extruder, filtration and melt distribution systems, the two melts are compounded and extruded at the exit of the spinneret to form a composite PET / PA6 filament, in which PET is distributed into a gear-shaped skeleton part in the cross-section of the composite PET / PA6 filament, and PA6 is dis...

Embodiment 3

[0045] 1. Fiber material and pre-fibrillation treatment

[0046] The tencel fiber linear density is 3 D, and the length is 65 mm. The tencel fiber is sprayed with the Turkish red oil aqueous solution. The consumption of the Turkish red oil is 5% of the quality of the tencel fiber, and the consumption ratio of the Turkish red oil and water is 1: 10. Make the diameter swelling rate of Tencel fiber reach 20%, and the moisture regain rate reach 25%; select three-dimensional crimped polyester fiber with a linear density of 11 D and a length of 65 mm.

[0047] 2. Preparation method

[0048] 1) Preparation of the bottom fiber web: After PET slices and PA6 slices pass through their respective feeding, extruder, filtration and melt distribution systems, the two melts are compounded and extruded at the exit of the spinneret to form a composite PET / PA6 filament, in which PET is distributed into a gear-shaped skeleton part in the cross-section of the composite PET / PA6 filament, and PA6 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fiber linear density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com