Decelerating clutch of full-automatic washing machine

A technology for fully automatic washing machines and deceleration clutches, which is applied to other washing machines, washing machines with containers, washing devices, etc., and can solve the problems of reducing the rated capacity of washing and dehydration of washing machines, the difficulty of reducing the overall size of deceleration clutches, and reducing the volume of the outer tub of washing machines, etc. , to achieve the effect of simple and reliable structure, compact structure and increased height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

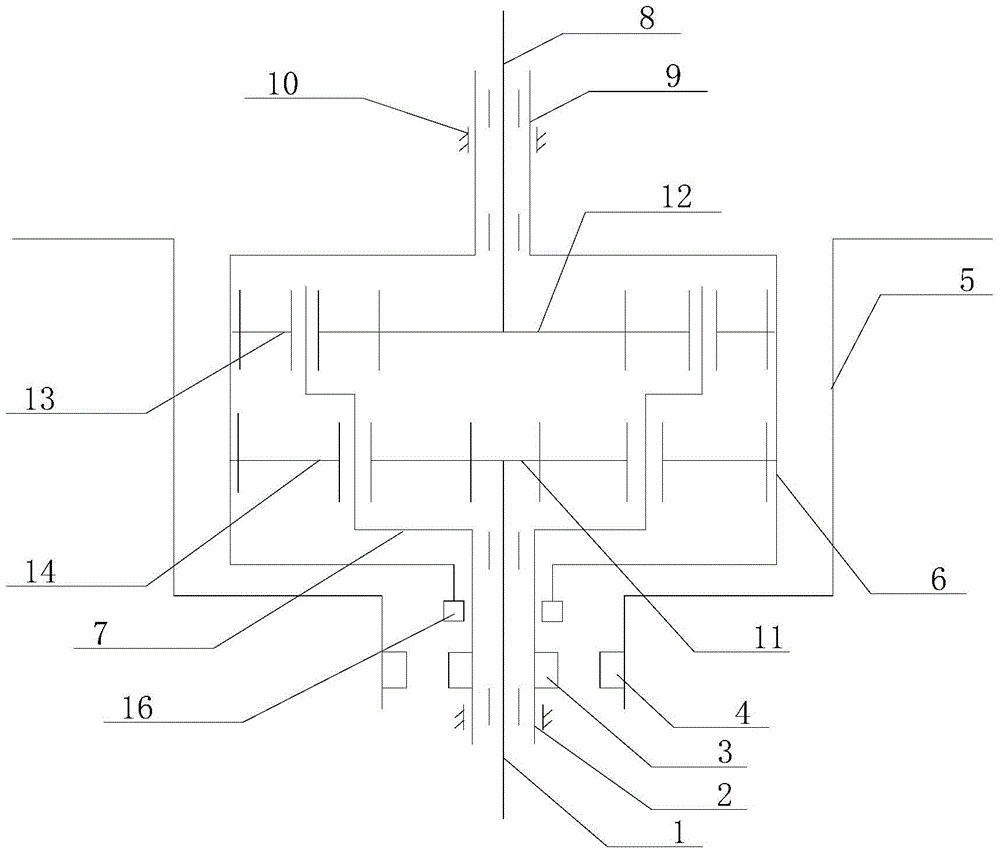

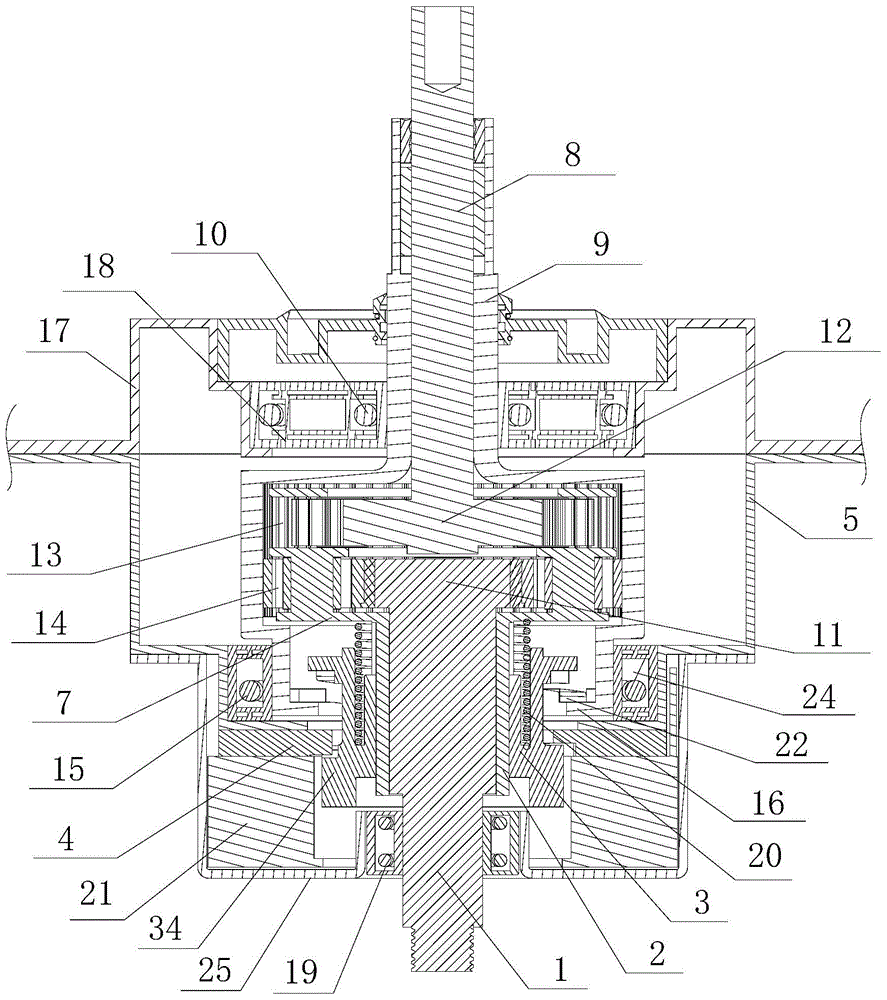

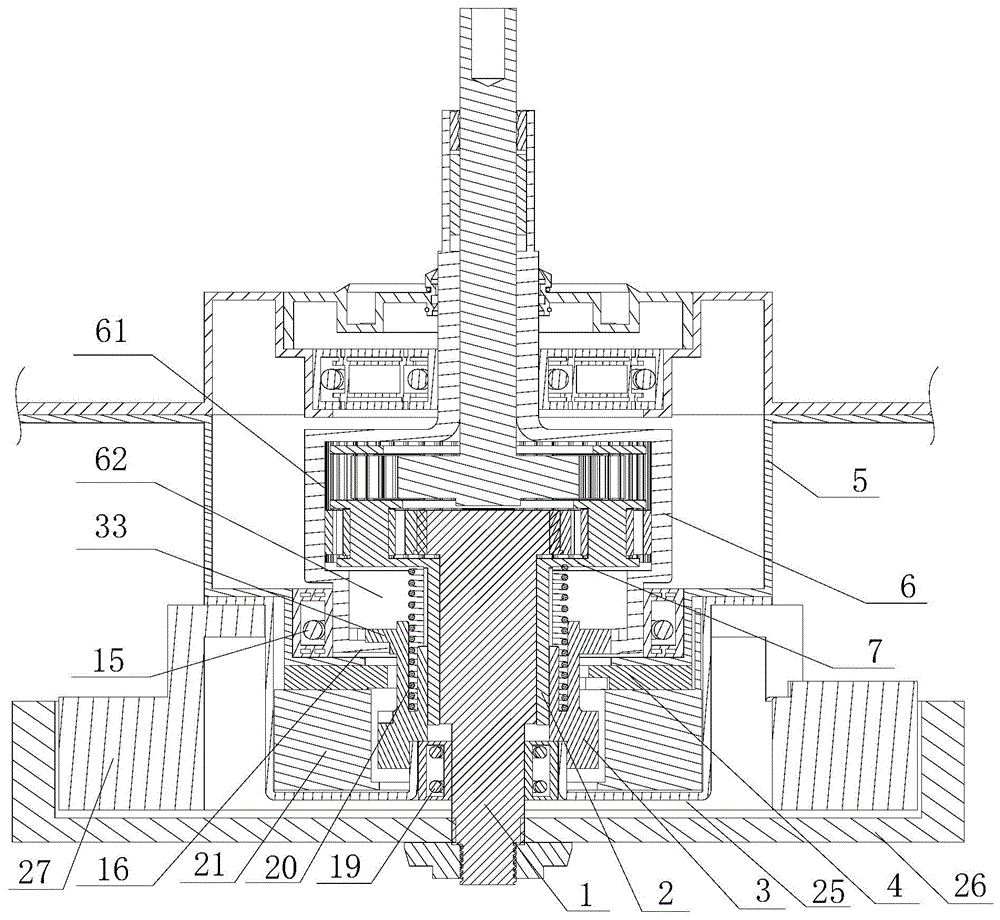

[0041] Such as Figure 1 to Figure 5 As shown, the deceleration clutch of the washing machine according to the present invention is mainly composed of an input shaft 1, an input shaft sleeve 2, an output shaft 8, an output shaft sleeve 9, a clutch mechanism, a housing 5 and a planetary gear train installed inside the gear train housing 5 . Planetary gear train is made up of mechanism such as input shaft gear 11, output shaft gear 12, a plurality of upper planetary gears 13, a plurality of lower planetary gears 14, planetary gear carrier 7, internal gear 6. The planetary gear train of the present invention is not only a deceleration transmission chain between the input shaft 1 and the output shaft sleeve 9, but also a transmission chain between the output shaft sleeve 9 and the output shaft 8 with deceleration and opposite directions.

[0042] The input shaft 1, the input shaft sleeve 2, the output shaft 8 and the output shaft sleeve 9 are all arranged coaxially, the input sha...

Embodiment 2

[0047] Such as Figure 2 to Figure 5 As shown, the clutch mechanism of the present invention includes a dehydration disc 16 mounted on the lower end of the internal gear 6, a clutch sleeve 3 mounted on the input shaft sleeve 2 and rotating integrally with the input shaft sleeve, and a brake disc 4 mounted on the casing 5. And driving the clutch cover 3 to slide up and down with the dehydration disc 16, the brake disc 4, the drive unit 21 and the clutch return spring 20, wherein the clutch return spring 20 is an extension spring, which is arranged between the planetary wheel carrier 7 and the clutch cover 3 The two ends are respectively fixedly connected with the planetary wheel carrier 7 and the clutch sleeve 3, and the clutch sleeve 3 is controlled to slide upward along the input shaft sleeve 2 to reset, so that the clutch sleeve 3 is disconnected from the dehydration disc 16, connected with the brake disc 4, and enters the washing process. operating conditions (see figure ...

Embodiment 3

[0054] Such as figure 2 As shown, the internal gear 6 of the present invention is in an inverted convex shape as a whole, and the internal teeth meshing with the upper planetary gear 13 and the lower planetary gear 14 are arranged in the upper gear chamber 61, and the space of the upper gear chamber 61 is larger than that of the lower clutch chamber 62 spaces.

[0055] Further, a bearing 15 is provided between the internal gear 6 and the housing 5. Preferably, the bearing 15 is located at a position corresponding to the outside of the lower clutch chamber 62. More preferably, the housing 5 is in an inverted convex shape as a whole. The space surrounded by the lower peripheral wall, the bottom wall of the housing, the upper bottom wall of the inner gear and the lower peripheral wall constitutes the mounting portion 24 of the bearing 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com