Biological enzyme composite blocking remover and preparation method thereof

A technology of compound plug removing agent and biological enzyme, applied in chemical instruments and methods, drilling composition, etc., can solve the problems of limited pH value application range, reduced permeability, low-efficiency and high-efficiency development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

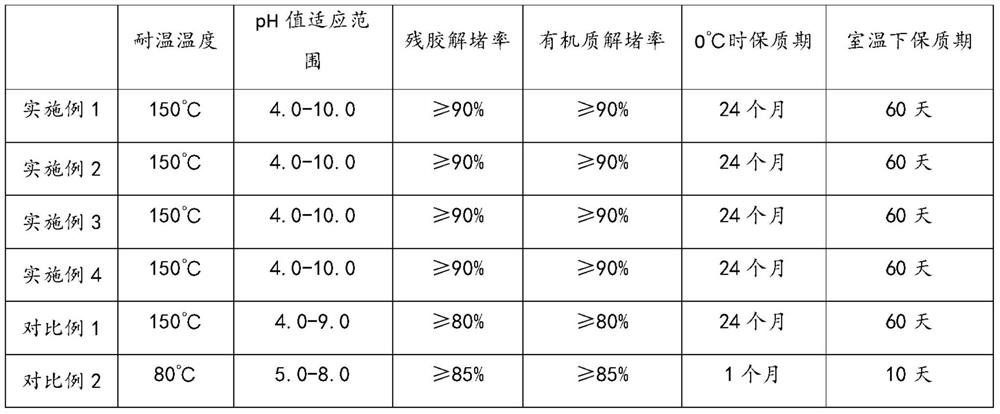

Examples

Embodiment 1

[0082] The preparation method of the bio-enzyme composite plug-removing agent provided in this embodiment:

[0083] S1. Preparation of biological surfactant. In a beaker, add rhamnolipid, sophorolipid and N-acetylgalactosamine in a mass ratio of 2:1:1, and stir evenly.

[0084] S2, preparing a biological enzyme stabilizer. In a beaker, add disodium edetate, citric acid, and triethanolamine in a mass ratio of 2:0.5:0.3, and stir evenly.

[0085] S3, preparing biological enzyme. In a beaker, add xylanase, cellulase, mannanase, amylase and xanthan gum lyase in a mass ratio of 4:2:3:1:1, and stir evenly.

[0086] S4. Add 90.8 parts of water into the beaker, then sequentially add 3 parts of biological surfactant, 6 parts of biological enzyme stabilizer, and 0.2 part of biological enzyme, and stir evenly to obtain a biological enzyme composite plugging remover.

Embodiment 2

[0088] The preparation method of the bio-enzyme composite plug-removing agent provided in this embodiment:

[0089] S1. Preparation of biological surfactant. In a beaker, add rhamnolipid, sophorolipid and N-acetylgalactosamine in a mass ratio of 2:1:1, and stir evenly.

[0090] S2, preparing a biological enzyme stabilizer. In a beaker, add disodium edetate, citric acid, and triethanolamine in a mass ratio of 1.5:1:0.3, and stir evenly.

[0091] S3, preparing biological enzyme. In a beaker, add xylanase, lipase, mannanase, protein compound enzyme and amylase in a mass ratio of 3:2:2:1:1, and stir evenly.

[0092] S4. Add 88.7 parts of water into the beaker, then sequentially add 3 parts of biological surfactant, 8 parts of biological enzyme stabilizer, and 0.3 part of biological enzyme, and stir evenly to obtain a biological enzyme composite plugging remover.

Embodiment 3

[0094] The preparation method of the bio-enzyme composite plug-removing agent provided in this embodiment:

[0095] S1. Preparation of biological surfactant. In a beaker, add rhamnolipid and N-acetylgalactosamine in a mass ratio of 1:1, and stir evenly.

[0096] S2, preparing a biological enzyme stabilizer. In a beaker, add disodium edetate, citric acid, and triethanolamine in a mass ratio of 1:1:0.2, and stir evenly.

[0097] S3, preparing biological enzyme. In a beaker, add xylanase, mannanase, protein complex enzyme and xanthan gum lyase in a mass ratio of 1:2:0.2:0.5, and stir evenly.

[0098] S4. Add 86.7 parts of water into the beaker, then sequentially add 5 parts of biological surfactant, 8 parts of biological enzyme stabilizer, and 0.3 part of biological enzyme, and stir evenly to obtain a biological enzyme composite plugging remover.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com