Preparation method of clean thickening agent for fracturing

A thickening agent and cleaning technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of weak ability to form micelles, weak sand-carrying ability, high production cost, etc., to reduce repulsion, Good for oil displacement and good for environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

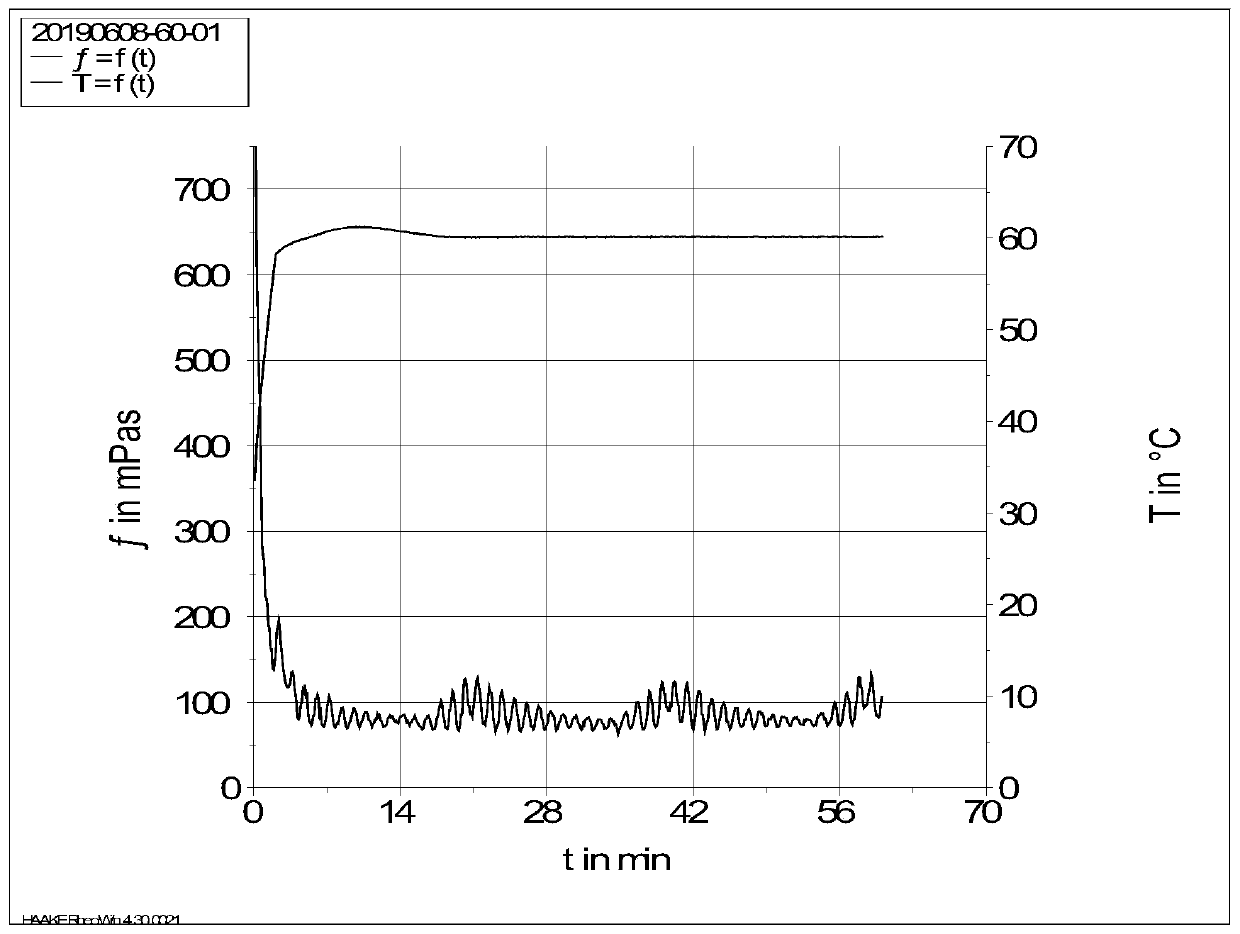

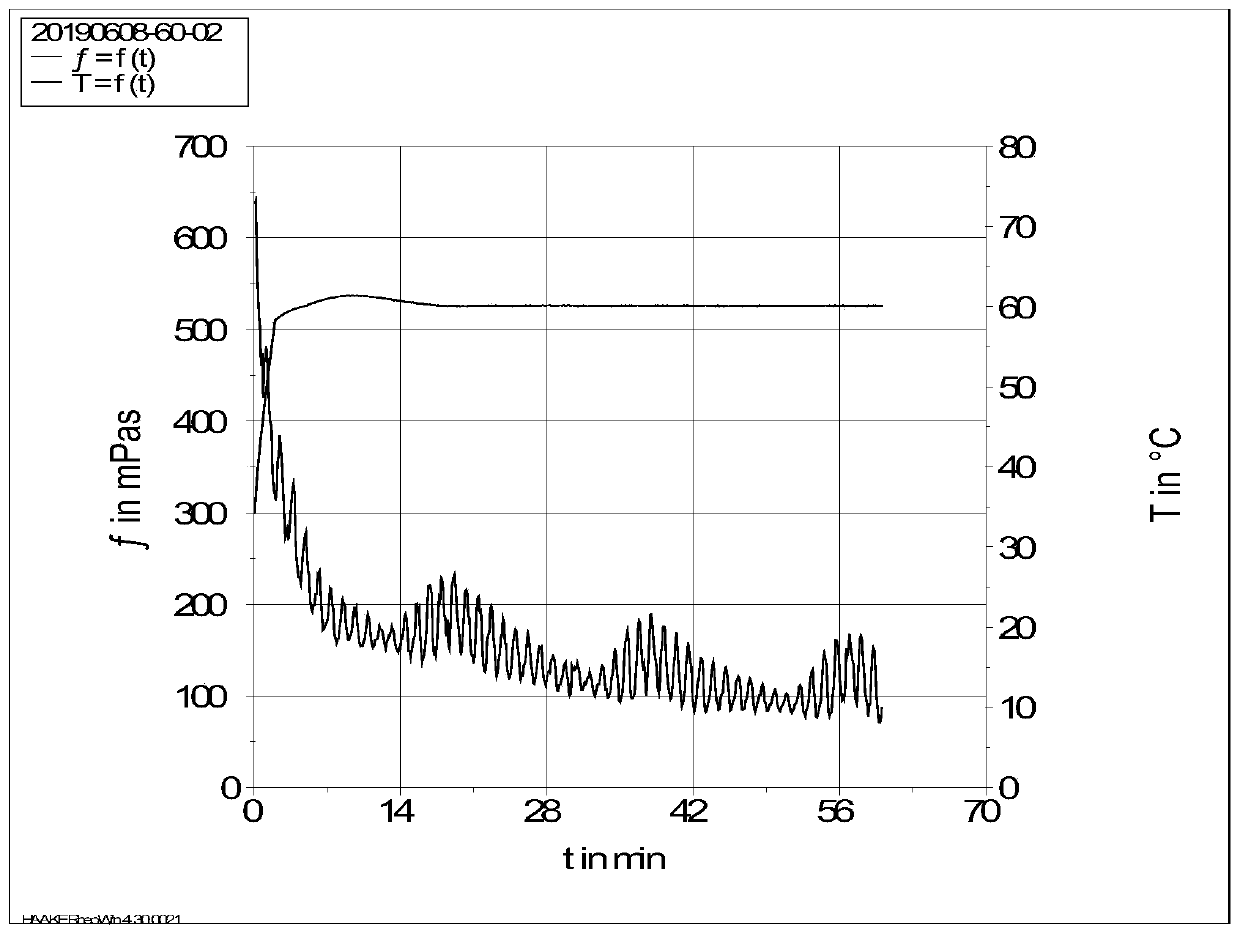

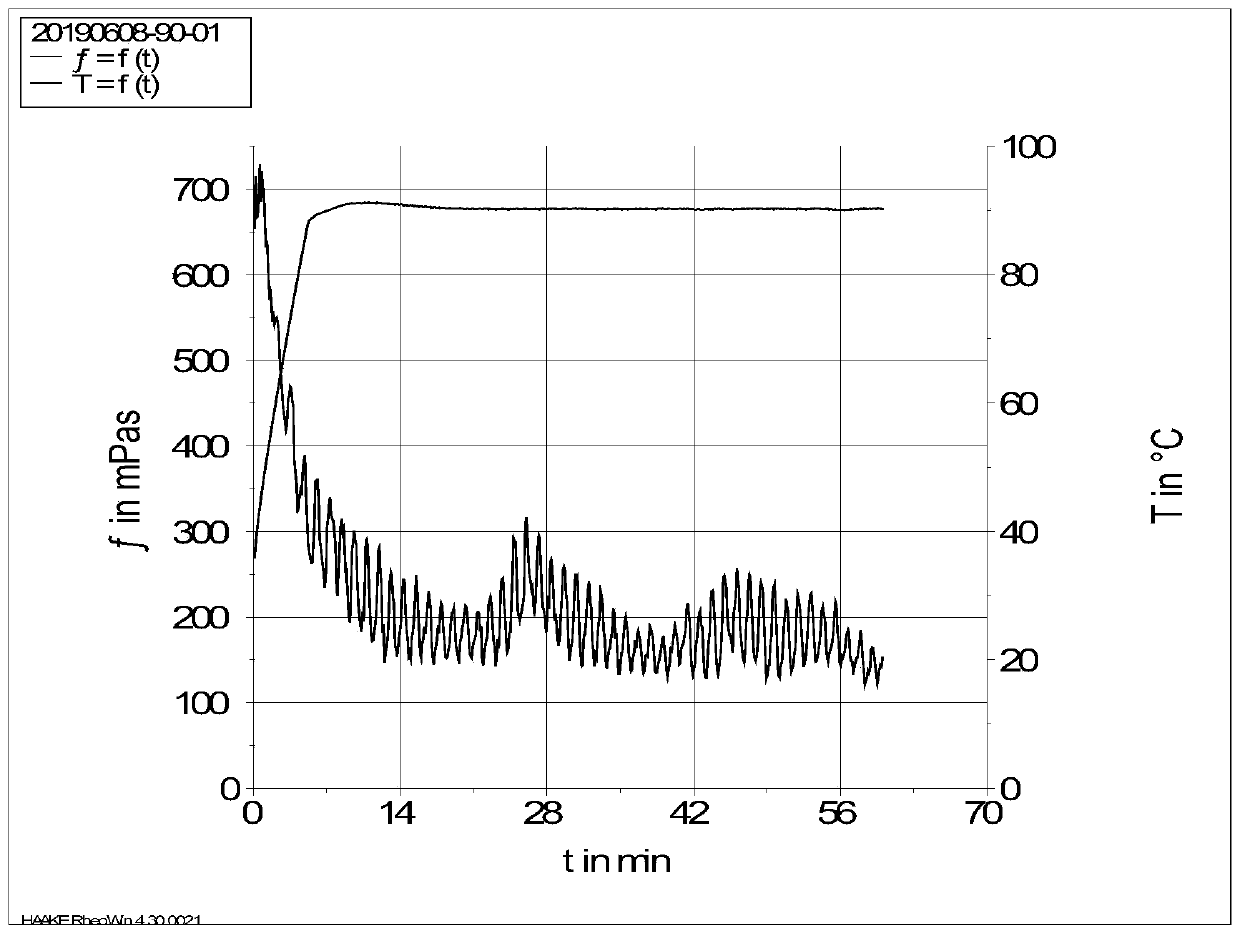

Image

Examples

Embodiment 1

[0021] (1) Add α-aminopropanamide into a reaction kettle with a certain amount of water added, heat to 40-60°C, and after α-aminopropanamide is completely melted, add palmitamide, isoamyl alcohol and sorbitol in sequence, Keep the temperature at 60°C for 2 hours;

[0022] (2) Add N,N'-ethylene bisstearamide, stir for 10-30 minutes, and keep the temperature at 60°C;

[0023] (3) Heat up to 70-80°C, add dichloropropanol and o-toluic acid several times, this process is an exothermic reaction, strictly control the feeding speed, cool with water when the temperature is at 70°C, then add some dichloropropanol Propanol and part o-toluic acid, this process is circulated, until dichloropropanol and o-toluic acid are all added in the reactor;

[0024] (4) Keep the heating rate at 30°C / h, raise the temperature to 120°C-130°C, react for 10-12 hours, and start cooling to 50-60°C after the reaction is over;

[0025] (5) Finally, add the remaining isoamyl alcohol, sorbitol and water, stir ...

Embodiment 2

[0027] (1) Add α-aminopropanamide into a reaction kettle with a certain amount of water added, heat to 40-60°C, and after α-aminopropanamide is completely melted, add palmitamide, isoamyl alcohol and sorbitol in sequence, Keep the temperature at 60°C for 2 hours;

[0028] (2) Add N,N'-ethylene bisstearamide, stir for 10-30 minutes, and keep the temperature at 60°C;

[0029] (3) Heat up to 70-80°C, add dichloropropanol and o-toluic acid several times, this process is an exothermic reaction, strictly control the feeding speed, cool with water when the temperature is at 70°C, then add some dichloropropanol Propanol and part o-toluic acid, this process is circulated, until dichloropropanol and o-toluic acid are all added in the reactor;

[0030] (4) Keep the heating rate at 30°C / h, raise the temperature to 120°C-130°C, react for 10-12 hours, and start cooling to 50-60°C after the reaction is over;

[0031] (5) Finally, add the remaining isoamyl alcohol, sorbitol and water, stir ...

Embodiment 3

[0033] (1) Add α-aminopropanamide into a reaction kettle with a certain amount of water added, heat to 40-60°C, and after α-aminopropanamide is completely melted, add palmitamide, isoamyl alcohol and sorbitol in sequence, Keep the temperature at 60°C for 2 hours;

[0034] (2) Add N,N'-ethylene bisstearamide, stir for 10-30 minutes, and keep the temperature at 60°C;

[0035] (3) Heat up to 70-80°C, add dichloropropanol and o-toluic acid several times, this process is an exothermic reaction, strictly control the feeding speed, cool with water when the temperature is at 70°C, then add some dichloropropanol Propanol and part o-toluic acid, this process is circulated, until dichloropropanol and o-toluic acid are all added in the reactor;

[0036] (4) Keep the heating rate at 30°C / h, raise the temperature to 120°C-130°C, react for 10-12 hours, and start cooling to 50-60°C after the reaction is over;

[0037] (5) Finally, add the remaining isoamyl alcohol, sorbitol and water, stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com