Rapid hardening early strength type composite repair mortar

A repair mortar and early-strength technology, which is applied in the field of building materials, can solve the problems of repair mortar strength shrinkage, large dry shrinkage rate, and low bond strength, and achieve improved water retention, dry shrinkage, and strong adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

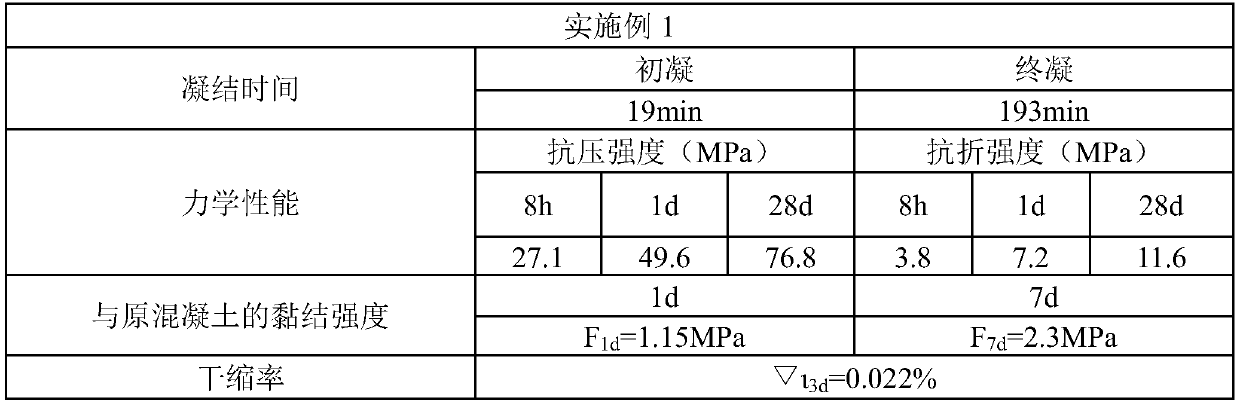

Embodiment 1

[0033] A rapid-hardening and early-strength composite repair mortar, consisting of the following components in weight percentage:

[0034] Water 5%, cement 20%, silica fume 1%, fly ash 2%, quartz sand 70% (coarse sand 25%, medium sand 25%, fine sand 20%), composite early strength agent 0.4% (A component : Nano calcium carbonate whisker 0.21%, B component: triisopropanolamine: 0.01% and aluminum sulfate: 0.22%), water reducing agent 0.06%, rubber powder 1.48%, hybrid fiber 0.06% (basalt fiber 0.05%, polypropylene fiber 0.01%), the particle diameter of coarse sand is 2.36-4.75mm, the particle diameter of medium sand is 1.18-2.36mm, and the particle diameter of fine sand is 0.6-1.18mm.

[0035] Its preparation method comprises the following steps:

[0036] S1. According to the above formula of a fast-hardening and early-strength composite repair mortar, weigh each component for later use;

[0037] S20: mechanically milling and activating the fly ash to a particle size of 200 me...

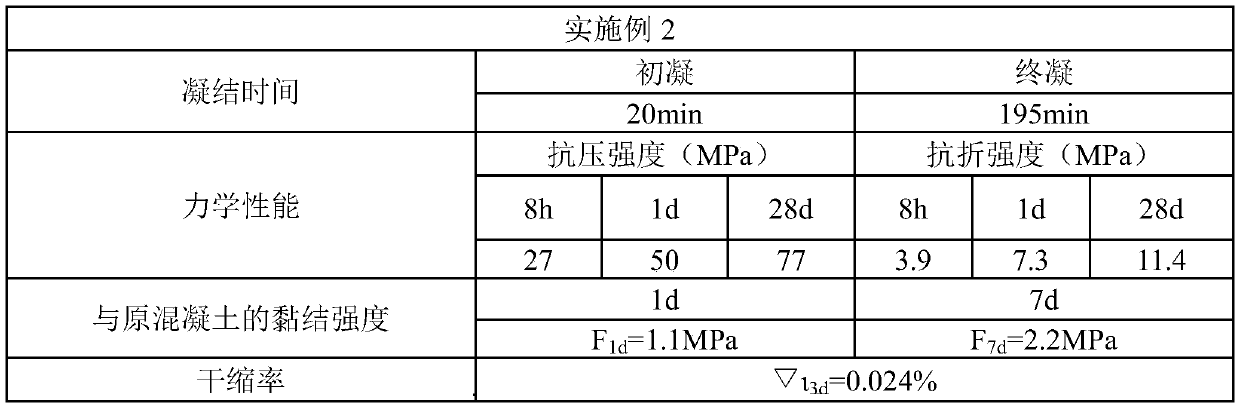

Embodiment 2

[0047] A rapid-hardening and early-strength composite repair mortar, consisting of the following components in weight percentage:

[0048] Water 7.29%, cement 22.25%, silica fume 2.47%, fly ash 1.3%, quartz sand 65.05% (coarse sand: 25.13%; medium sand: 21.16%; fine sand 18.76%), composite early strength agent 0.44% (A Components: nano calcium carbonate whiskers 0.21%, B component: triisopropanolamine 0.01%, aluminum sulfate 0.22%), water reducing agent 0.08%, rubber powder 1.05%, hybrid fiber 0.07% (basalt fiber 0.06%, Polypropylene fiber 0.01), the particle size of coarse sand is 2.36-4.75mm, the particle size of medium sand is 1.18-2.36mm, and the particle size of fine sand is 0.6-1.18mm.

[0049] Its preparation method comprises the following steps:

[0050] S1. According to the above formula of a fast-hardening and early-strength composite repair mortar, weigh each component for later use;

[0051] S20: mechanically milling and activating the fly ash to a particle size ...

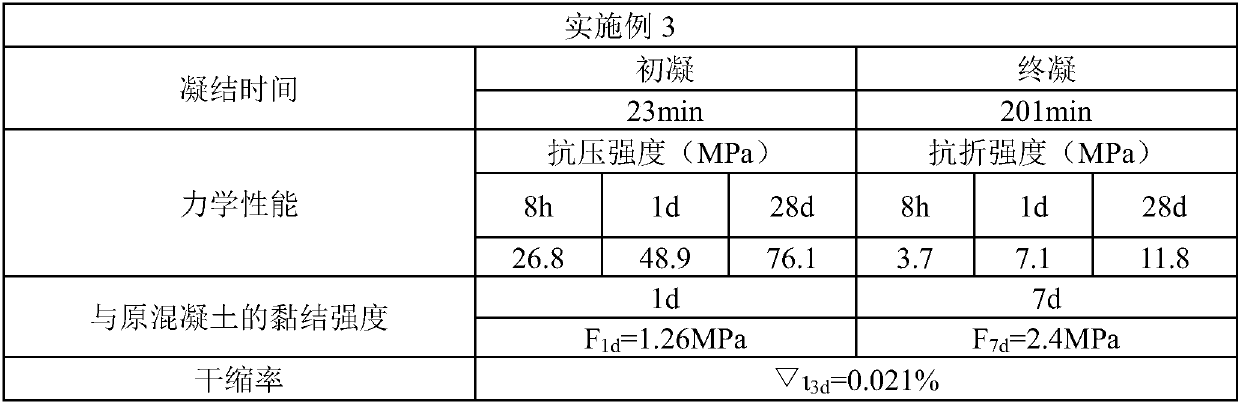

Embodiment 3

[0061] A rapid-hardening and early-strength composite repair mortar, consisting of the following components in weight percentage:

[0062] Water 6.79%, cement 20.75%, silica fume 2.31%, fly ash 1.21%, quartz sand 67.41% (coarse sand: 26.04%; medium sand: 21.92%; fine sand 19.44%), composite early strength agent 0.42% (A Components: nano calcium carbonate whiskers 0.20%, B component: triisopropanolamine: 0.01% and aluminum sulfate: 0.21%), water reducer 0.07%, rubber powder 0.97%, hybrid fiber 0.07% (basalt fiber 0.06 %, polypropylene fiber 0.01), the particle size of coarse sand is 2.36-4.75mm, the particle size of medium sand is 1.18-2.36mm, and the particle size of fine sand is 0.6-1.18mm.

[0063] Its preparation method comprises the following steps:

[0064] S1. According to the above formula of a fast-hardening and early-strength composite repair mortar, weigh each component for later use;

[0065] S20: mechanically milling and activating the fly ash to a particle size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com