Full-granularity steel slag pavement base material for heavy-duty pavement

A technology for pavement base material and steel slag aggregate, which is applied in the field of building materials, can solve the problems of low utilization rate of steel slag, rising cost, complex composition, etc., and achieves the effects of small cement consumption, improved gradation and natural resource conservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

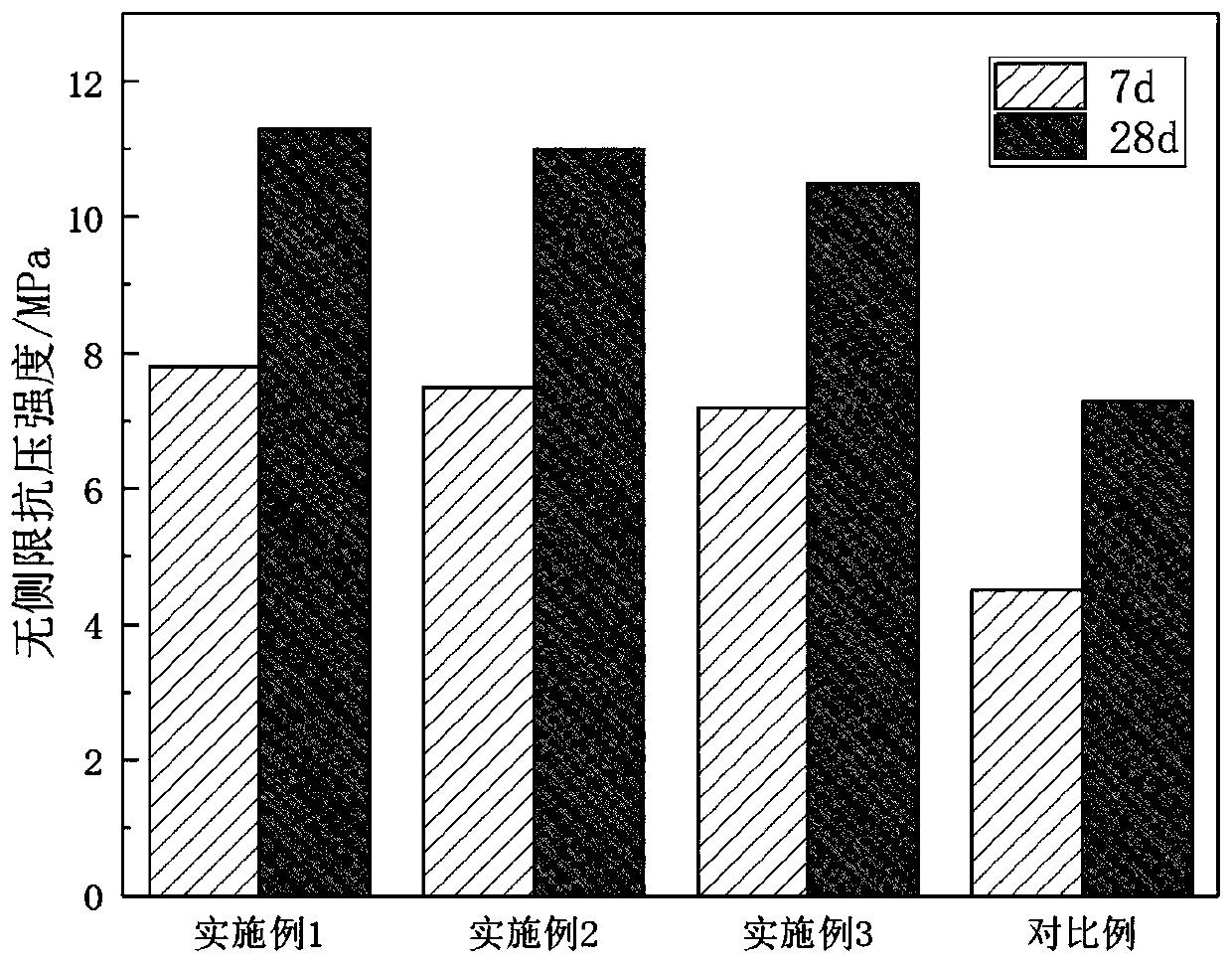

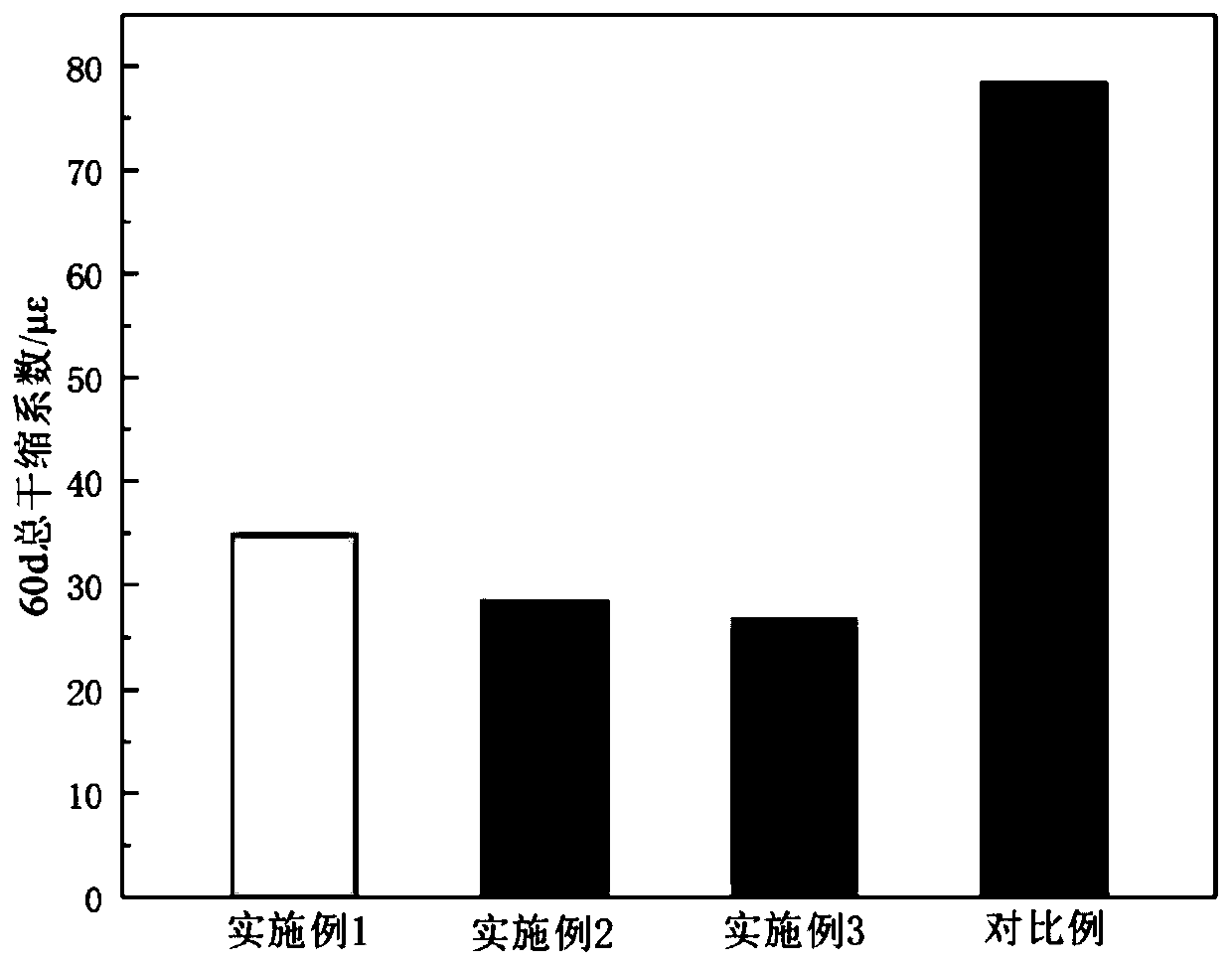

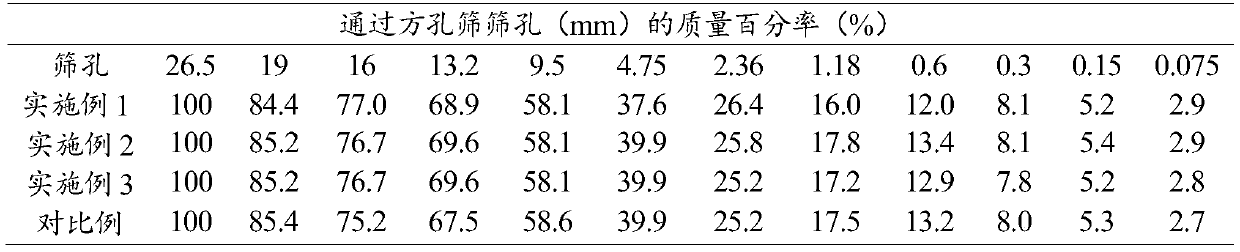

Embodiment 1

[0037] A full-grained steel slag pavement base material for heavy-duty road surfaces. The percentages of the total mass of cement and steel slag aggregates in the dry material are: cement 4.8%, steel slag coarse aggregate 95.2%, and the cement and steel slag fine powder Prepared by mixing, the mass ratio of cement and steel slag powder is 9:1. The gradation of steel slag is: 19mm-26.5mm: 17wt%; 9.5mm-19mm: 23wt%; 4.75mm-9.5mm: 20wt%; 2.36mm-4.75mm: 15wt%; 0-2.36mm: 25wt%.

[0038] Above-mentioned a kind of preparation method for the full-grain steel slag pavement base material that is used for heavy-duty pavement, it comprises the following steps:

[0039] 1) Weigh the steel slag aggregate and cementing material according to the above mixing ratio, and see Table 1 for the synthetic gradation of the steel slag aggregate.

[0040] 2) Put the steel slag aggregate in an environment of 105°C±5°C and dry it to constant weight (generally not less than 4~6h);

[0041] 3) Take 5 part...

Embodiment 2

[0046] A full-grained steel slag pavement base material for heavy-duty pavement. The percentages of the total mass of cement, natural aggregate, and steel slag aggregate in the dry material are: cement 4.3%, steel slag coarse aggregate 95.7%, and the cement is It is prepared by mixing cement and steel slag powder, and the mass ratio of cement and steel slag powder is 7:3. The gradation of steel slag is: 19mm-26.5mm: 16wt%; 9.5mm-19mm: 24wt%; 4.75mm-9.5mm: 20wt%; 2.36mm-4.75mm: 14wt%; 0-2.36mm: 26wt%.

[0047] The preparation method of the above-mentioned full-grain steel slag pavement base material for heavy-duty pavement is the same as that described in Example 1.

Embodiment 3

[0049] A full-grained steel slag pavement base material for heavy-duty pavement. The percentages of the total mass of cement, natural aggregate, and steel slag aggregate in the dry material are: cement 3.4%, steel slag aggregate 96.6%, and the cement is cement Prepared by mixing with steel slag powder, the mass ratio of cement to steel slag powder is 9:1. The gradation of steel slag is: 19mm-26.5mm: 16wt%; 9.5mm-19mm: 24wt%; 4.75mm-9.5mm: 20wt%; 2.36mm-4.75mm: 15wt%; 0-2.36mm: 25wt%.

[0050] The preparation method of the above-mentioned full-grain steel slag pavement base material for heavy-duty pavement is the same as that described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com