Pre-built-in template frame of composite block and method for moulding composite block

A composite block and pouring molding technology, which is applied in the direction of ceramic molding machines, molds, manufacturing tools, etc., can solve the problems of undiscovered technical solutions, high production costs, complicated processes, etc., and achieve dry shrinkage, short construction period, thermal good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

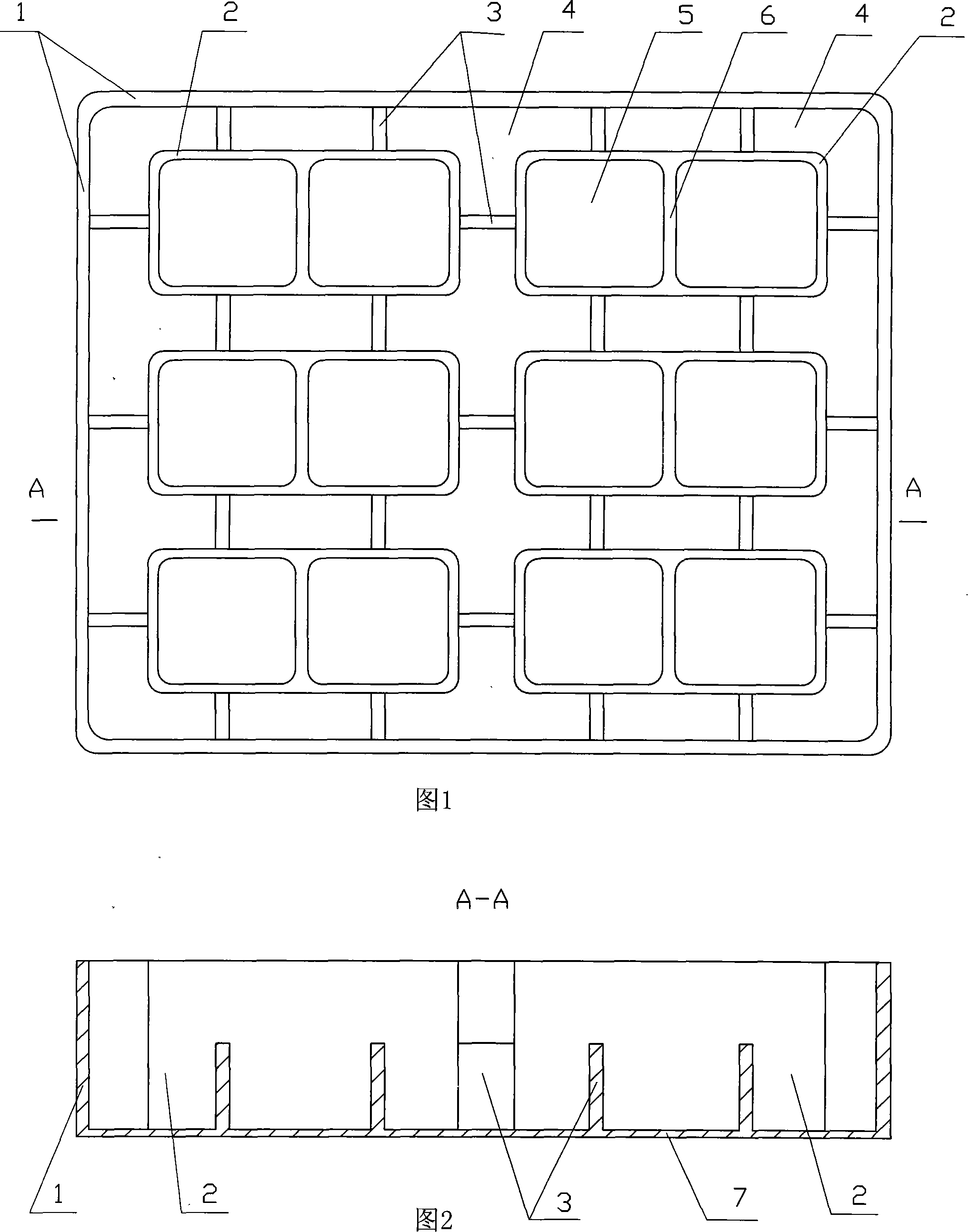

[0014] The composite block pre-embedded formwork frame provided by the present invention is shown in Figure 1 and Figure 2, and its basic composition is that it first includes a rectangular peripheral frame 1, and then a group of 6 rectangular inner partition frames 2 are arranged in the peripheral frame 1 (The optional quantity of each group of inner bulkheads is 2-12). On the basis of the above basic structure, in order to increase the connection strength, connecting ribs 3 can be provided between the inner frame and between the inner frame and the outer frame respectively, and set on one side of the outer frame 1 and the inner frame 2 The common bottom surface 7 and the inner partition frame 2 are provided with partition ribs 6 to form two inner mold cavities 5 and increase the bearing capacity of the inner partition frame 2 . The pre-embedded formwork of the composite block is made of foamed concrete and pressed by a brick making machine.

[0015] The above composite bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com