Ultrasonic energy control system and method in ultrasonic emulsification operation

A phacoemulsification and ultrasonic energy technology, applied in the field of medical devices, can solve the problems of ultrasonic energy waste, energy waste, efficiency reduction, etc., and achieve the effects of improving utilization rate, improving safety, and reducing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

[0038] The words expressing position and direction described in the present invention refer to the operator of the instrument, the end close to the operator is the proximal end, and the end far away from the operator is the distal end.

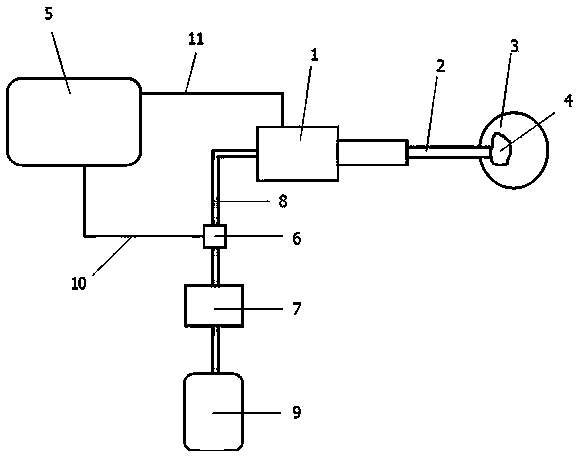

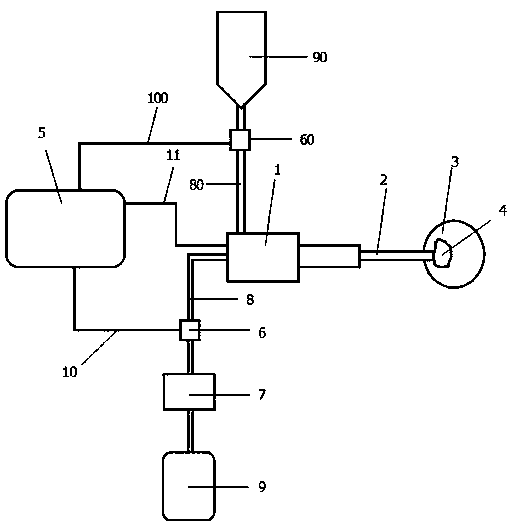

[0039] Refer to attached figure 1 As shown, the energy control system in a phacoemulsification operation disclosed by the present invention includes: a phacoemulsification handle 1 and a phacoemulsification needle 2 coupled to its distal end; the phacoemulsification handle 1 is connected to the ultrasonic An electric generator 5, the electro-acoustic conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com