Guar gum fracturing fluid for ultrahigh-temperature reservoirs and method for preparing guar gum fracturing fluid

A guar gum fracturing fluid and ultra-high temperature technology are applied in the directions of chemical instruments and methods, drilling compositions, etc., which can solve the problem that the guar gum fracturing fluid cannot be used for fracturing and stimulation construction, so as to improve the effect of fracturing and reconstruction. , The effect of low surface interfacial tension and small residue content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

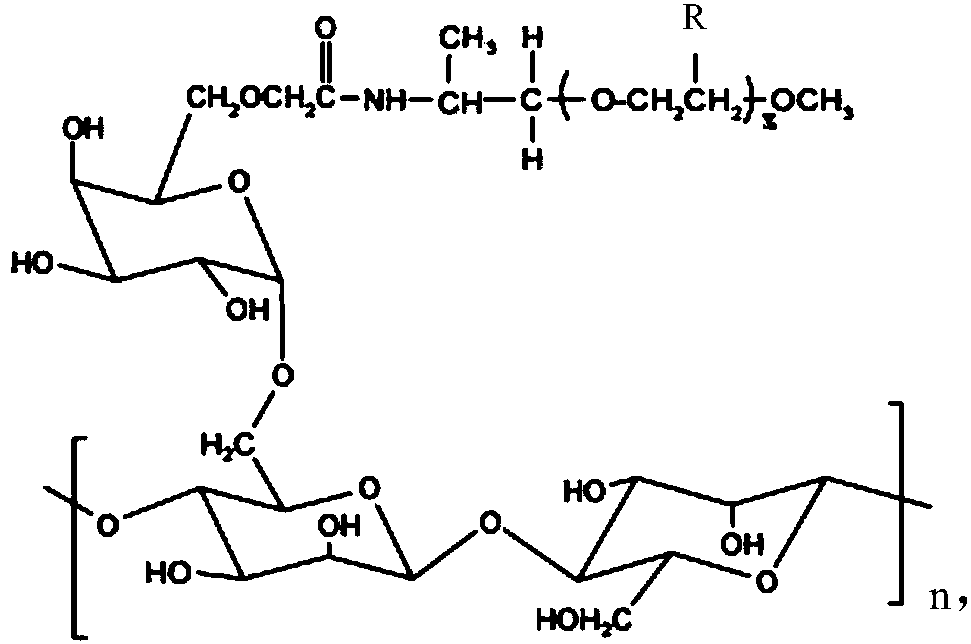

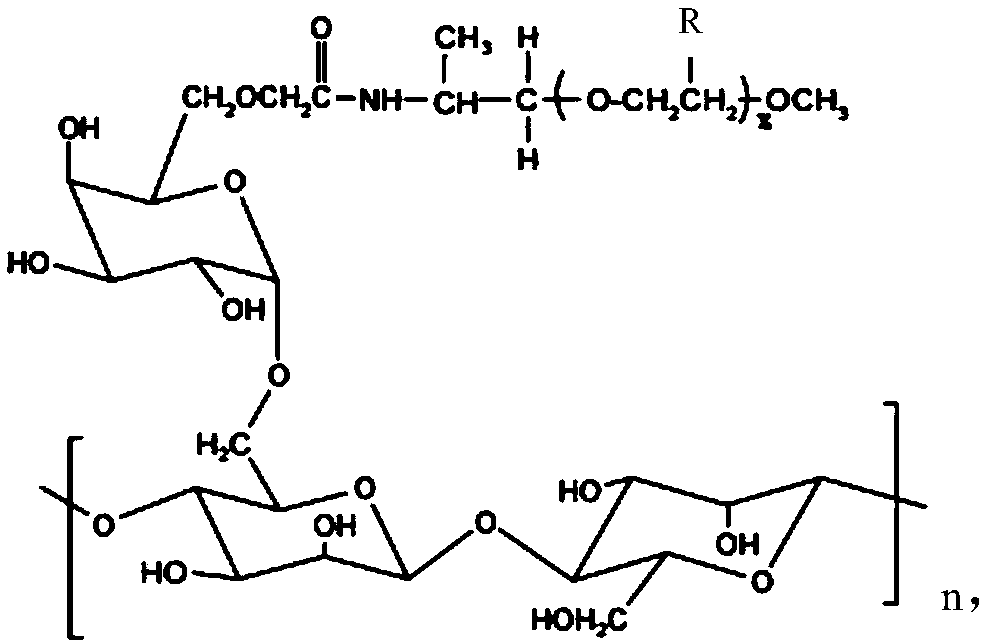

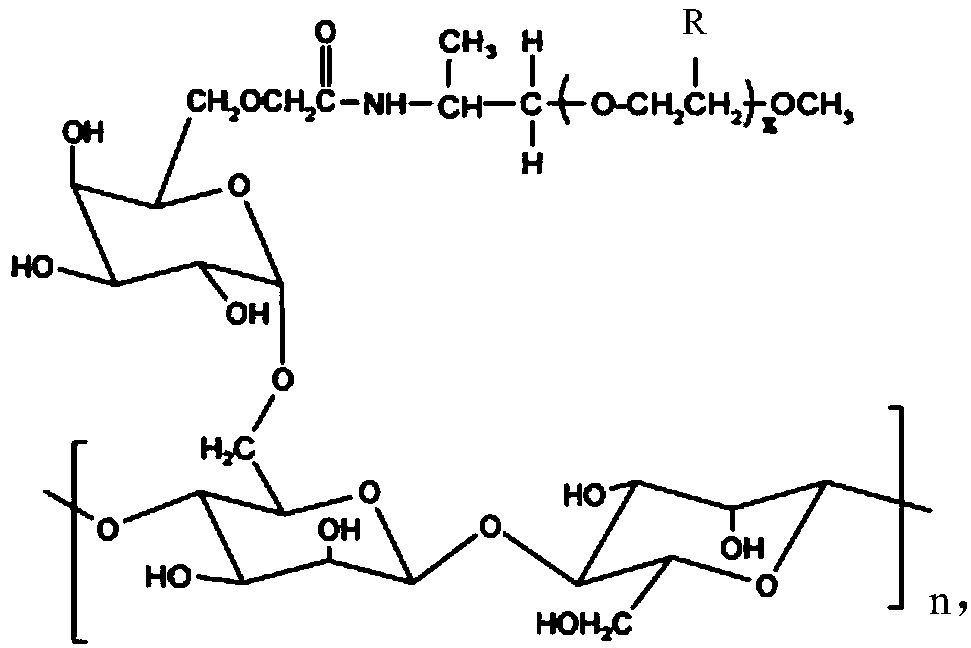

Method used

Image

Examples

Embodiment 1

[0041] Every 100ml of guar gum fracturing fluid used for ultra-high temperature reservoirs contains the following components: 0.55g of modified guar gum thickener, 2g of potassium chloride, 0.2ml of fungicide, 0.5ml of clay stabilizer, 0.3ml of foaming agent, 0.5ml of drainage aid, 0.1ml of sodium hydroxide solution (concentration 0.1g / ml), 0.35ml of crosslinking agent and 0.3g of gel breaker, and the balance is water. Wherein, the volume ratio of trioctyl borate and tetraisopropylacetonate zirconate in the crosslinking agent is 100:4.

[0042] Project case:

[0043] Well Travi-08 in the Punda de mada block, Venezuela, is a directional well, a development well, the construction well section is 6040.4m~6055.3m, the reservoir temperature is 175.2℃, and the above-mentioned modified guar gum thickener is used as an additive at a concentration of 0.55%. Construction fluid 670.4m 3 , construction displacement 5.0-6.2m 3 / min, the construction pressure is 70.5MPa~75.6MPa, and the ...

Embodiment 2

[0045] Every 100ml of guar gum fracturing fluid used for ultra-high temperature reservoirs contains the following components: 0.4g of modified guar gum thickener, 1g of potassium chloride, 0.1ml of fungicide, 0.3ml of clay stabilizer, 0.1ml of foaming agent, 0.3ml of drainage aid, 0.05ml of sodium hydroxide solution (concentration 0.25g / ml), 0.15ml of crosslinking agent and 0.1g of gel breaker, and the balance is water. Wherein, the volume ratio of trioctyl borate and tetraisopropylacetonate zirconate in the crosslinking agent is 100:2.

[0046] Project case:

[0047] RPN-59 in Anago Block, Venezuela, vertical well, development gas well, construction well section 4056.7-4068.7m, reservoir temperature 153.3℃, using the additive of the above-mentioned modified guar gum thickener, using concentration 0.4%, construction fluid 508.7m 3 , construction displacement 4.7-5.5m 3 / min, construction pressure 68.5MPa~77.6MPa, daily gas production after pressure 217031m 3 / d, the produ...

Embodiment 3

[0049] Every 100ml of guar gum fracturing fluid used for ultra-high temperature reservoirs contains the following components: 0.8g of modified guar gum thickener, 4g of potassium chloride, 0.4ml of fungicide, 0.8ml of clay stabilizer, 0.5ml of foaming agent, 0.8ml of drainage aid, 0.2ml of sodium hydroxide solution (concentration 0.05g / ml), 0.5ml of crosslinking agent and 0.5g of gel breaker, and the balance is water. Wherein, the volume ratio of trioctyl borate and tetraisopropylacetonate zirconate in the crosslinking agent is 100:5.

[0050] Project case:

[0051] RPN-59 in the Anago block of Venezuela, vertical well, development gas well, construction well section 4125.1-4376.7m, reservoir temperature 157.5℃, using the additive of the above-mentioned modified guar gum thickener, the use concentration is 0.7%, and the construction fluid is 556.7m 3 , construction displacement 4.8-5.4m 3 / min, construction pressure 71.2MPa~80.4MPa, daily gas production after pressure 203211...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com