Novel electrophoresis waste gas treatment process and multi-stage efficient degreasing spraying tower thereof

A technology for waste gas treatment and oil spraying, which is used in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of air pollution, poor effect, complex process, etc. The full effect of the spray action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

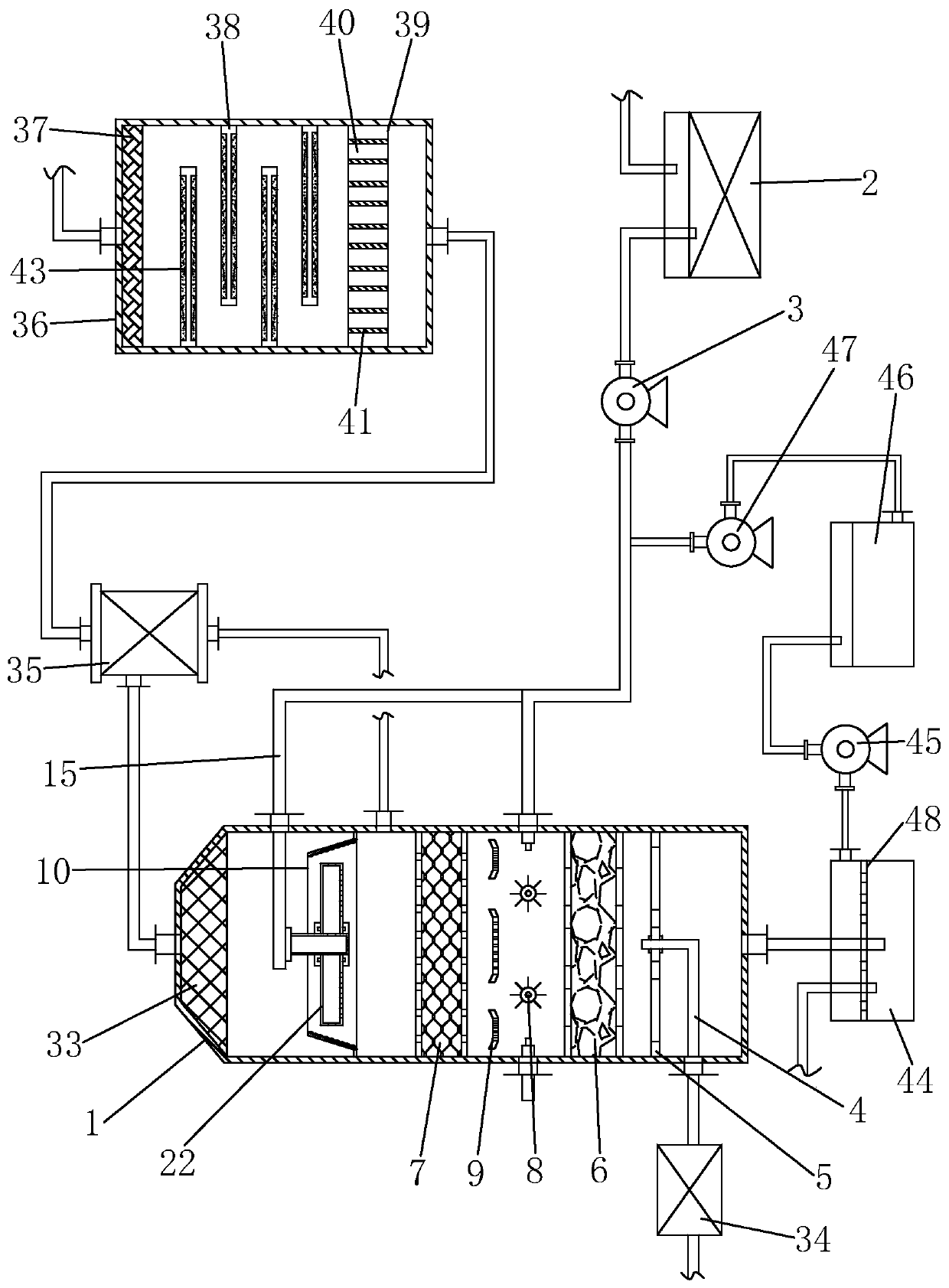

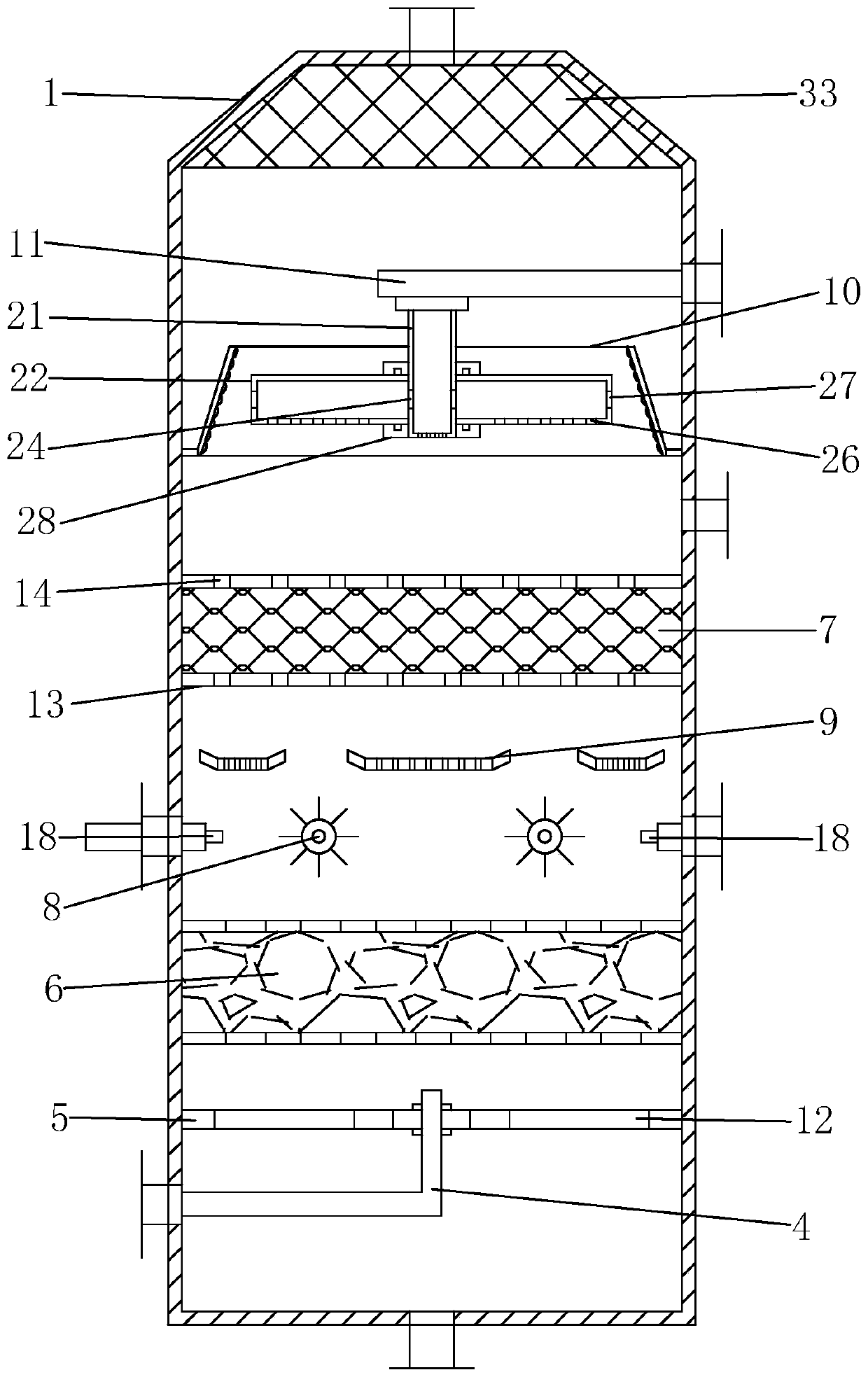

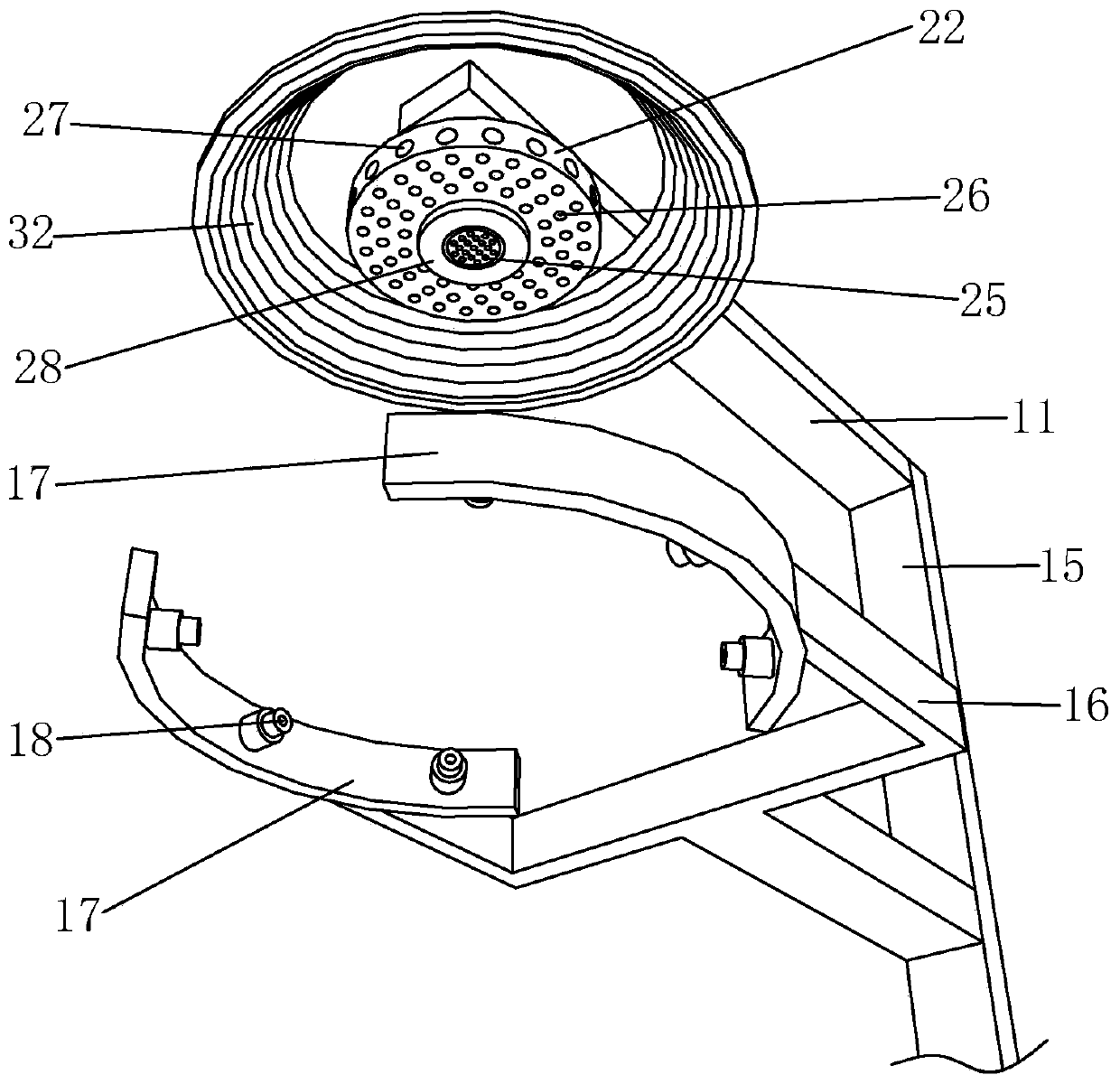

[0038] Such as Figure 1 to Figure 8 As shown, it is a multi-stage high-efficiency oil removal spray tower of the present invention, including a tower body 1 and a liquid storage tank 2, an infusion pump 3 is arranged between the liquid storage tank 2 and the tower body 1, and the liquid storage tank 2 is filled with absorption liquid , the absorption liquid adopts 5% NaOH aqueous solution, and the tower body 1 is respectively equipped with L-shaped air guide pipe 4, fixed plate 5, activated carbon packing layer 6, chemical packing layer 7, brush roller 8, baffle plate 9, liquid collecting cover 10 , the distribution pipe 11 and the liquid distributor, the L-shaped air duct 4 passes through the fixed plate 5, and the fixed plate 5 supports and fixes the L-shaped air duct 4, so as to avoid the large pressure of the exhaust gas in the L-shaped air duct 4 and cause the L-shaped air duct The vibration of the trachea 4 affects the smoothness of the air conduction. The fixed plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com