Bearing bush friction wear testing machine and testing method thereof

A friction and wear, testing method technology, applied in the field of tribology, to achieve the effect of optimizing working conditions, high measurement accuracy, and stable structural force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

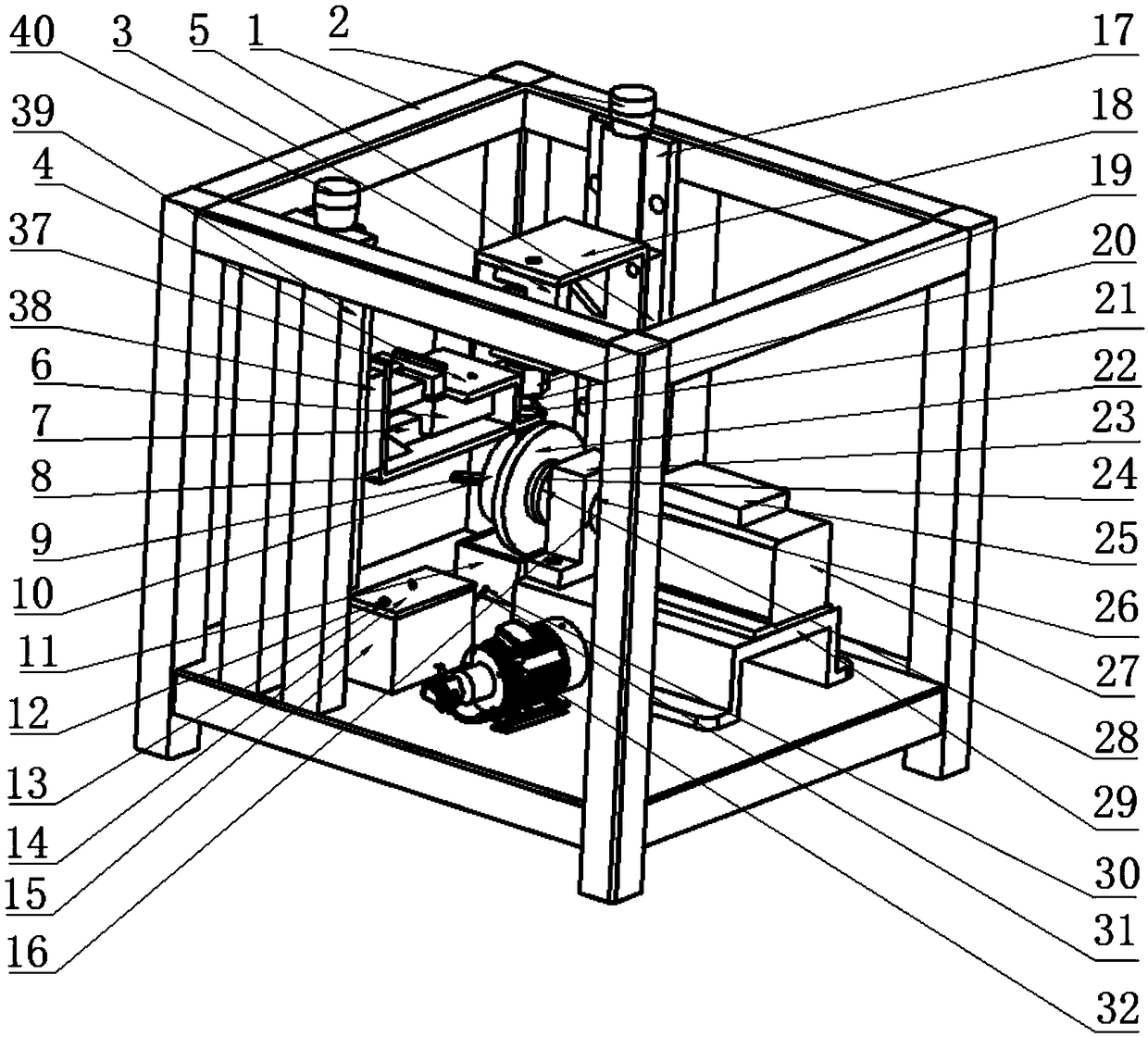

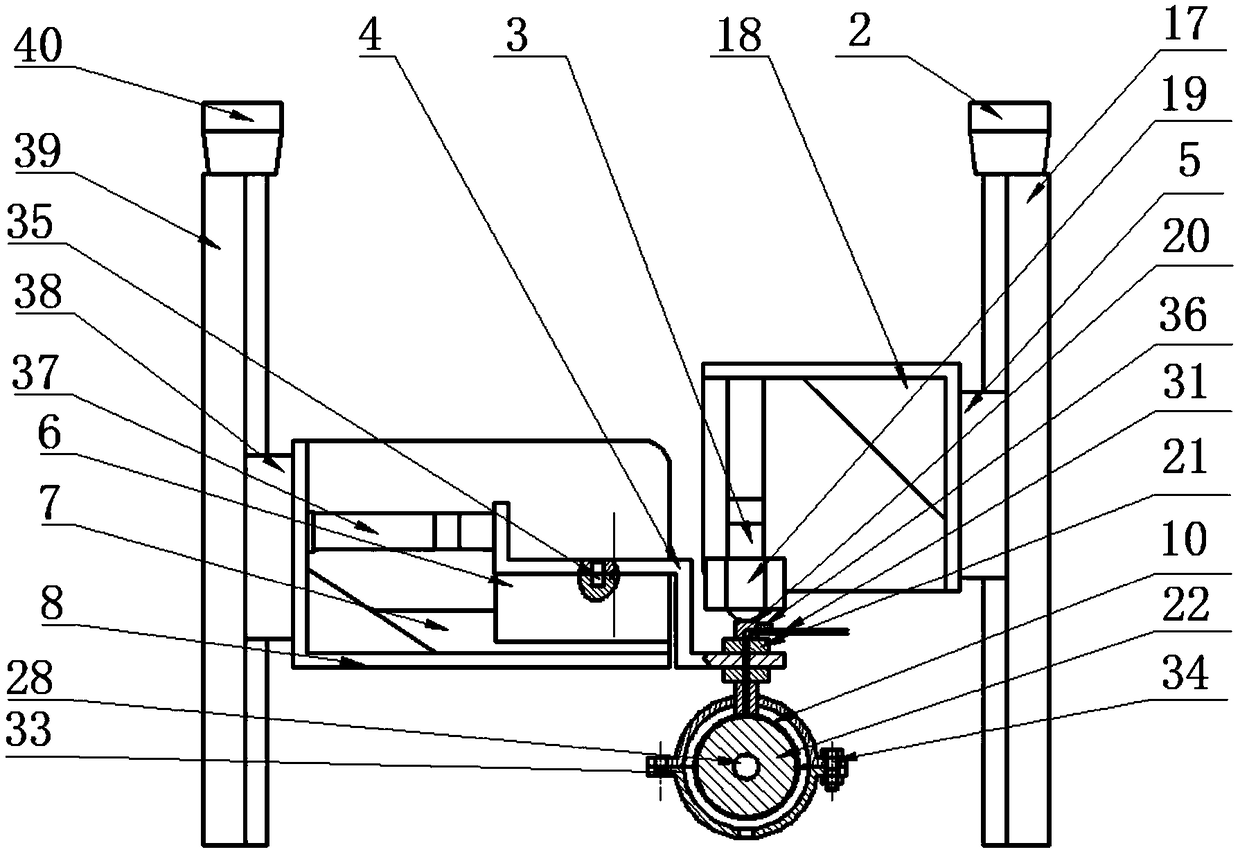

[0036] Such as figure 1 As shown, a bearing pad friction and wear testing machine includes a support 1 and a driving device installed in the support 1, a test device, a loading device, a measuring device and a lubricating oil circulation supply device;

[0037] Such as figure 1 As shown, the drive unit includes a speed-regulating motor 27, a frequency converter 25, a shaft coupling 16, a main shaft 28, a bearing seat 23, a bearing 26 and a motor support 29, and the speed-regulating motor 27 is installed on the On the support 1, the speed-regulating motor 27 is connected to the main shaft 28 through the coupling 16, the main shaft 28 is supported by the bearing 26, and the bearing 26 is installed in the bearing seat 23, The speed regulating motor 27 is connected with the frequency converter 25;

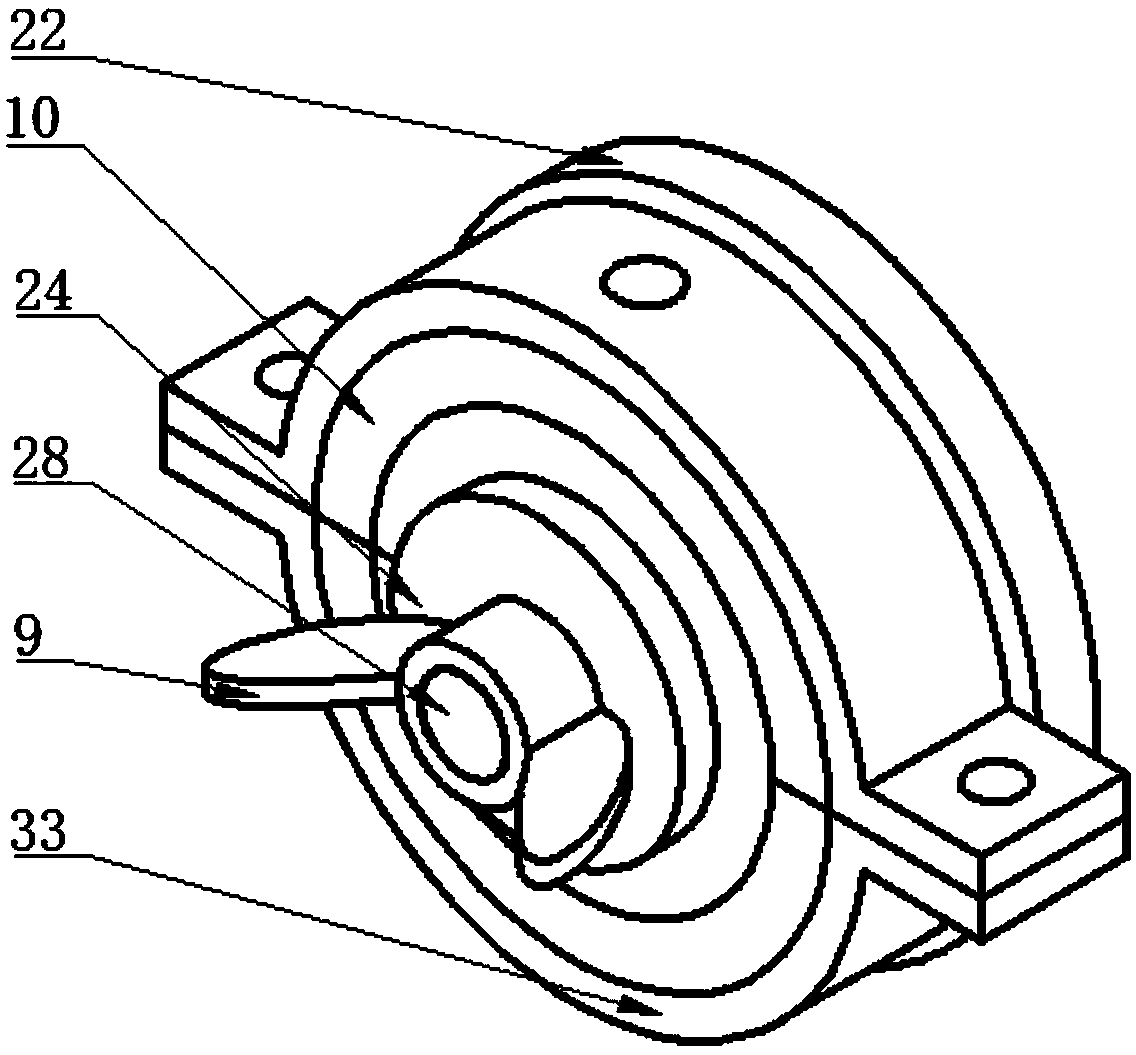

[0038] Such as image 3 As shown, the test device includes a rubber sheet 24, a ring sample friction member 22, a bearing pad fixture 33, a bearing pad 10, a bolt 34 and a wing nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com