Thin-layer fluid type low-stress polishing device

A polishing device and low-stress technology, applied in the field of ultra-precision optical processing, can solve the problems of medium and high frequency error, small material removal rate, low processing efficiency, etc., and achieve the effect of high polishing precision, low stress processing, and improvement of medium and high frequency error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

[0028] The device of the present invention will be further described below in conjunction with the accompanying drawings.

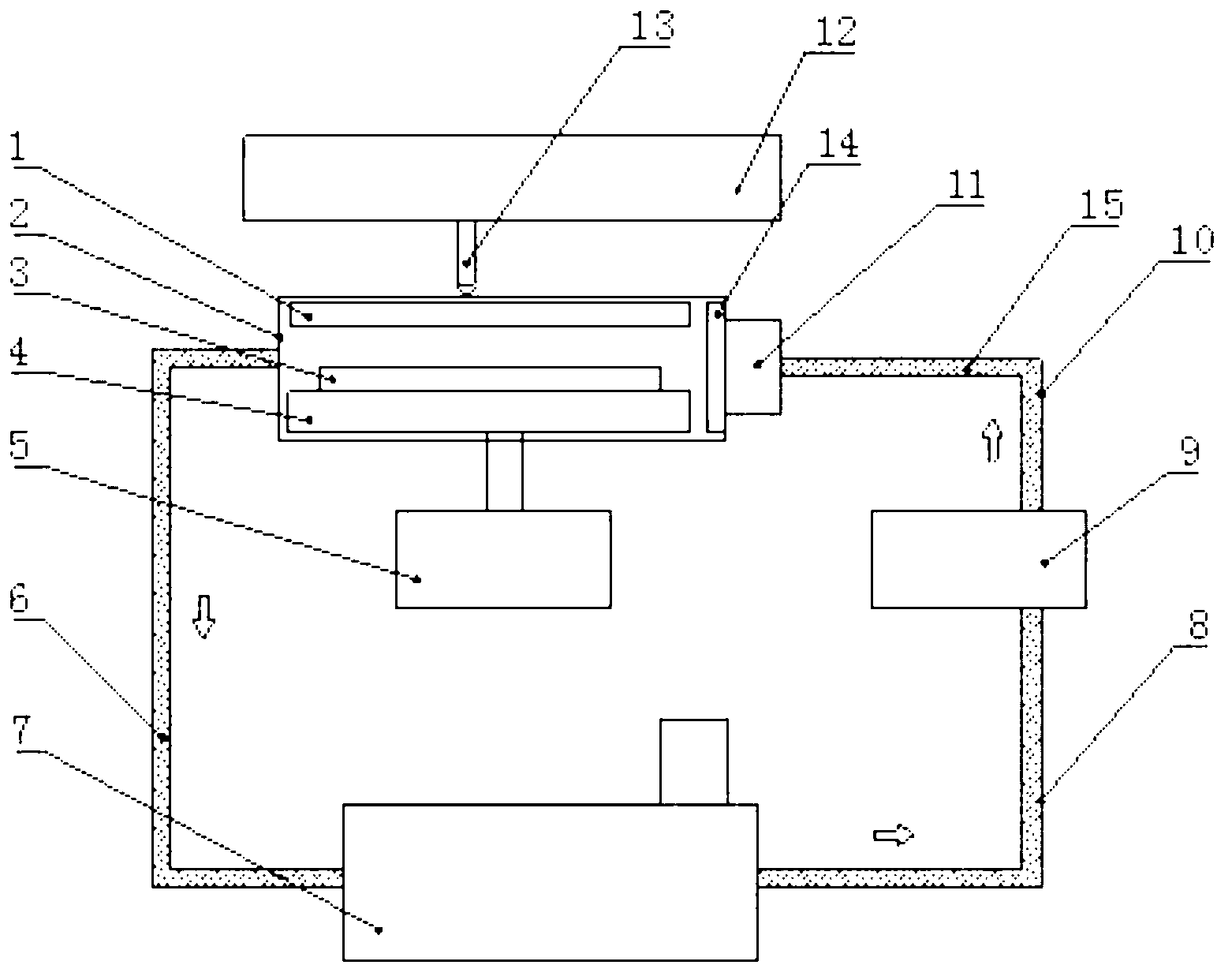

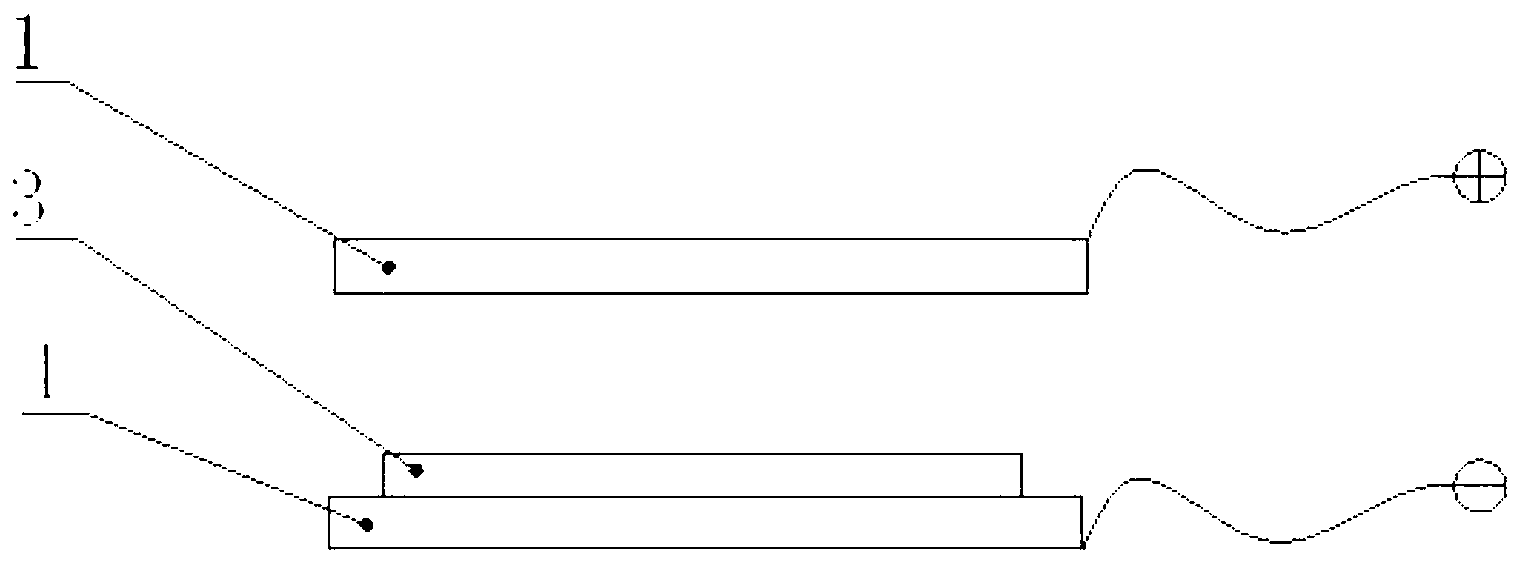

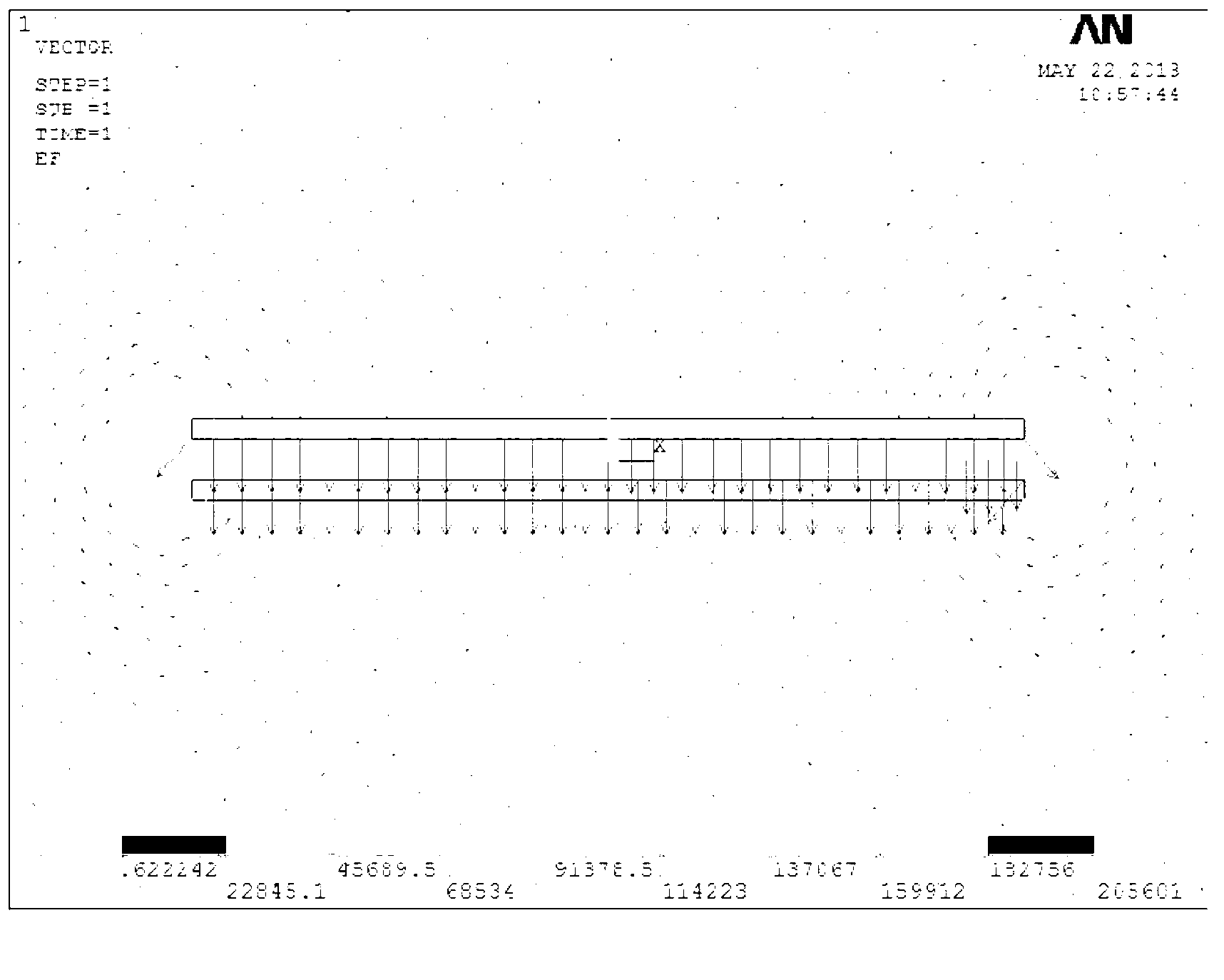

[0029] figure 1It is a structural schematic diagram of the device of the present invention, including an anode plate 1, a sealed working cabin 2, a workpiece 3, a cathode platform 4, a lifting platform 5, a polishing waste liquid 6, a waste liquid separation and stirring device 7, a first conduit 8, and a booster pump 9 , a second conduit 10, a polishing liquid collecting device 11, a two-dimensional motion platform 12, an anode probe 13, a shaping nozzle 14, and an electrorheological polishing liquid 15. The cathode platform 4 is insulated and fixed on the platform of the lifting platform 5 and connected to the cathode of the high-voltage power supply; the anode plate 1 is opposite to the cathode platform 4, and is insulated and fixed on the top of the sealed working cabin 2; the sealed working cabin 2 connects the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com