Flow guide plate of fuel cell

A fuel cell and deflector technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve the problems of air waste, increased mechanical power consumption of transporting air or circulating hydrogen, and reducing the efficiency of fuel cell systems, etc., to achieve Improve delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

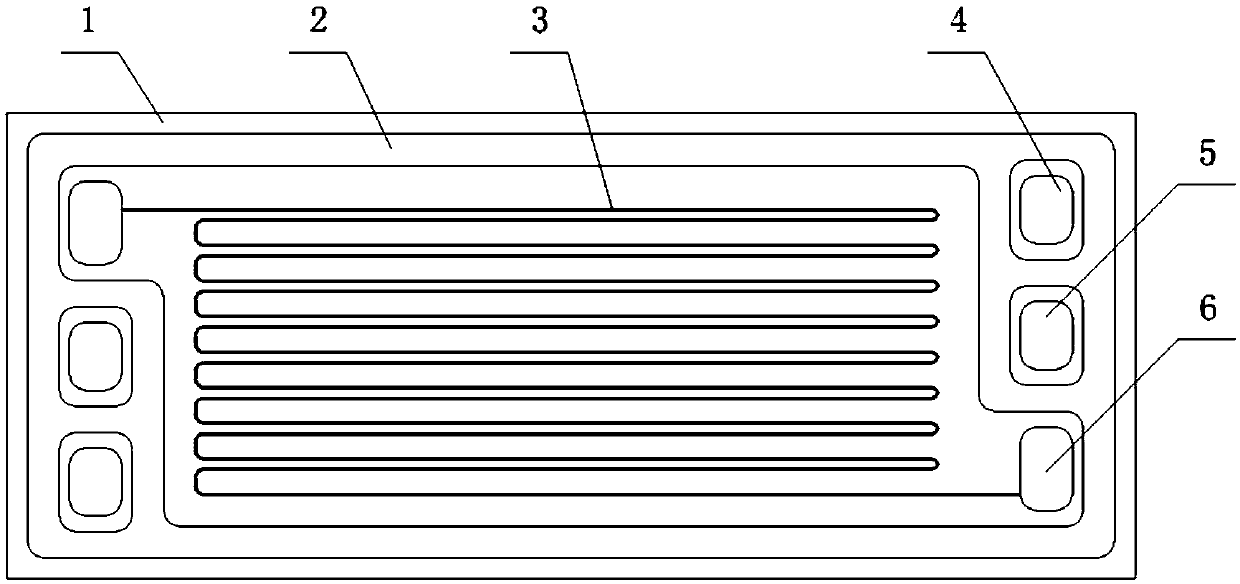

[0040] Such as figure 1 As shown, it is a structural schematic diagram of a conventional direct-flow deflector. The deflector 1 is provided with a linear fluid channel 3, and the two ends of the deflector 1 are provided with a fuel inlet and outlet 4, a cooling fluid inlet and outlet 5, and an oxidant inlet and outlet. 6. A sealing groove 2 is also provided.

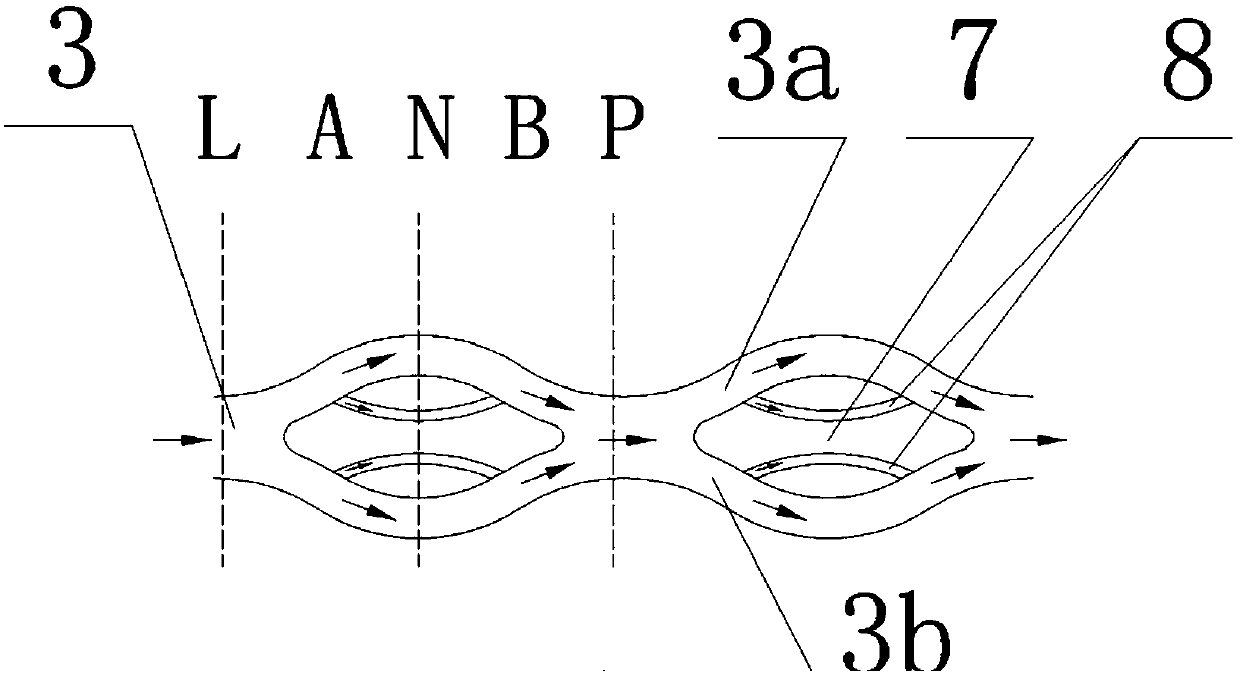

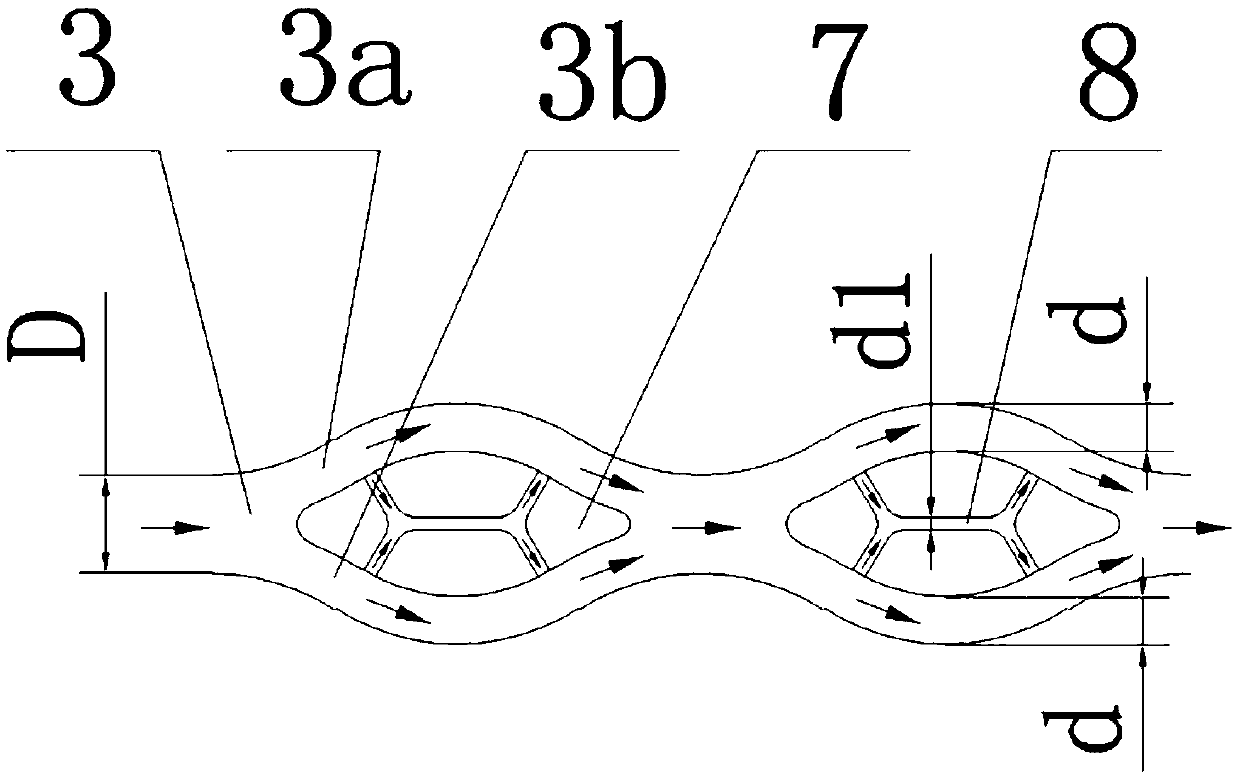

[0041] The present invention changes fluid channel 3 into such as figure 2 In the shown structure, a plurality of flow-distributing islands 7 are arranged in the middle of each fluid channel 3, so that the fluid channel is divided into two when passing through the flow-distributing islands 7 (such as Figure 2-5 As shown, when the fluid passage 3 is in the L cross section, it is divided into two paths: the shunt passage 3a and the shunt passage 3b), and after passing through the shunt island 7, they are merged into one at the P cross section to form a wave-like fluid passage that continuously expands and converges . ...

Embodiment 2

[0049] A plurality of diversion islands 7 are arranged in the middle of each fluid channel 3, so that the fluid channel is divided into three flow channels when passing through each diversion island 7, and after passing through the diversion island 7, there is a joint to form a wave-like expansion and convergence fluid channel. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com