Discharging hopper capable of achieving flat heaping of fallen materials

An unloading hopper and leveling technology, which is applied in the field of unloading and unloading hoppers for bulk materials, can solve the problems of wasting manpower and material resources, and achieve the effect of improving operating efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

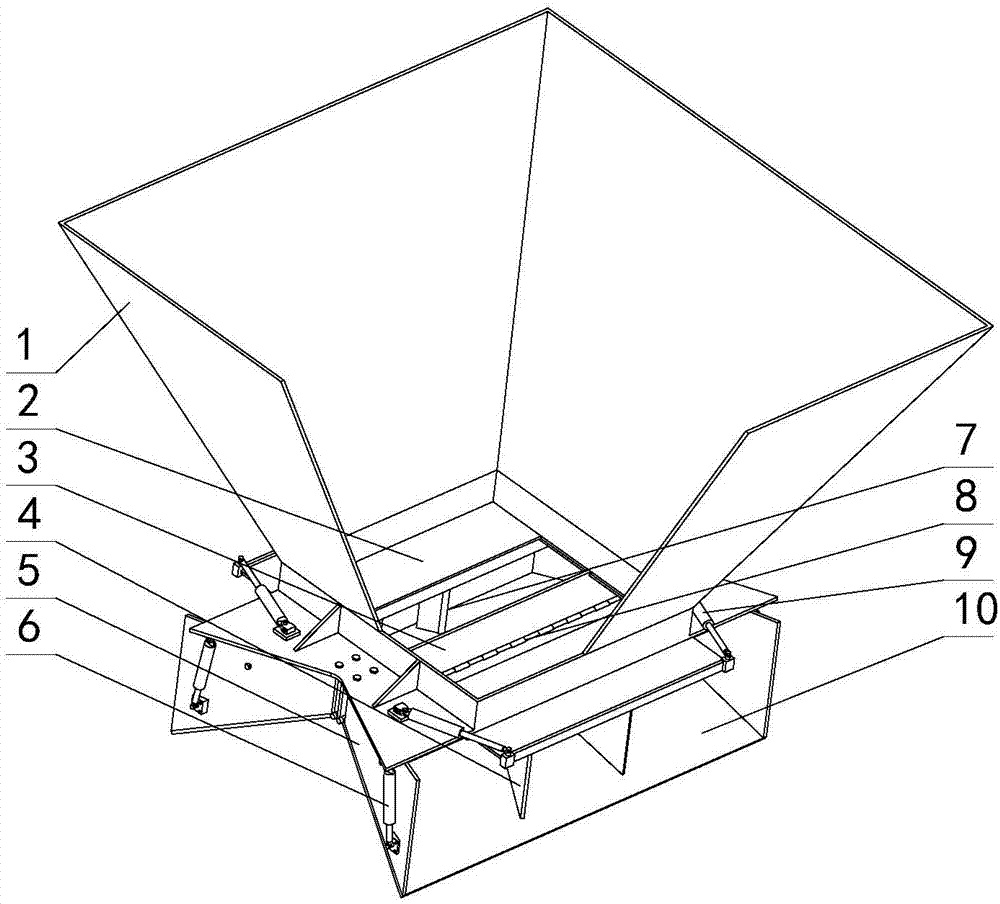

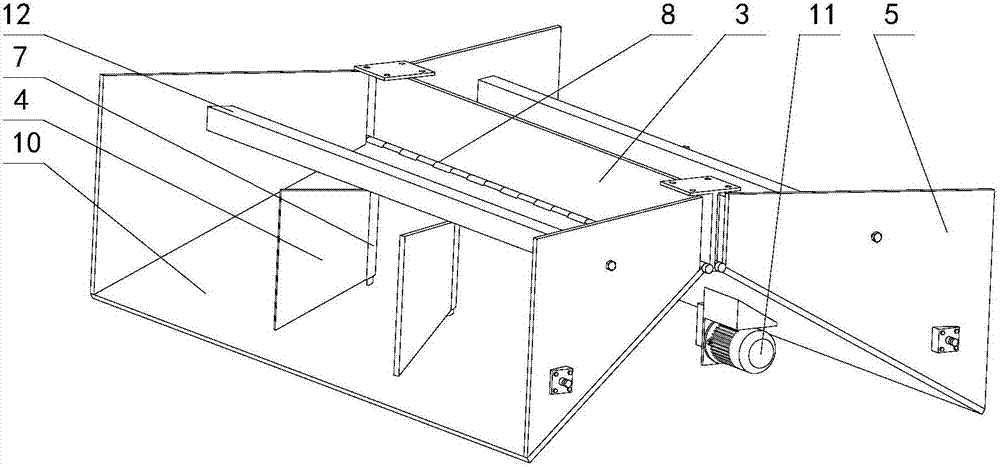

[0018] Such as figure 1 , 2 As shown, this embodiment provides a discharge hopper for realizing the flat accumulation of blanking, including a hopper 1, a partition 3 is provided in the middle of the discharge opening at the bottom of the hopper 1, and it is vertically arranged. The partition 3 and the discharge port Through fixed connection with screws, material guide grooves are arranged symmetrically on both sides of the partition plate, and the material guide grooves are movably connected with the partition plate 3 through the first rotating shaft 8, so as to realize the adjustment of its inclination angle with the horizontal direction. The guide trough is provided with a guide port to communicate with the discharge port, and a second hydraulic cylinder 6 is arranged on the discharge hopper platform, and the piston rod of the second hydraulic cylinder 6 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com