Multistage parallel hydrocyclone capable of regulating flow velocity

A hydrocyclone and cyclone technology are applied in cyclone devices, devices whose axial directions of cyclones can be reversed, etc., and can solve the problems of low operating cost, low separation efficiency, and inability to adapt to working conditions, etc. Achieve the effect of small footprint, high work efficiency and best separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

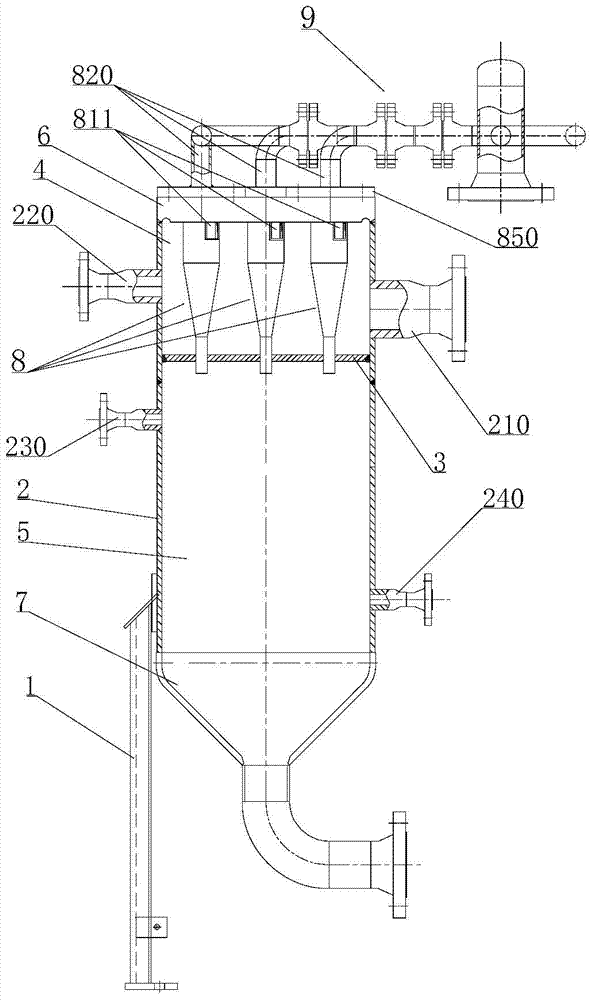

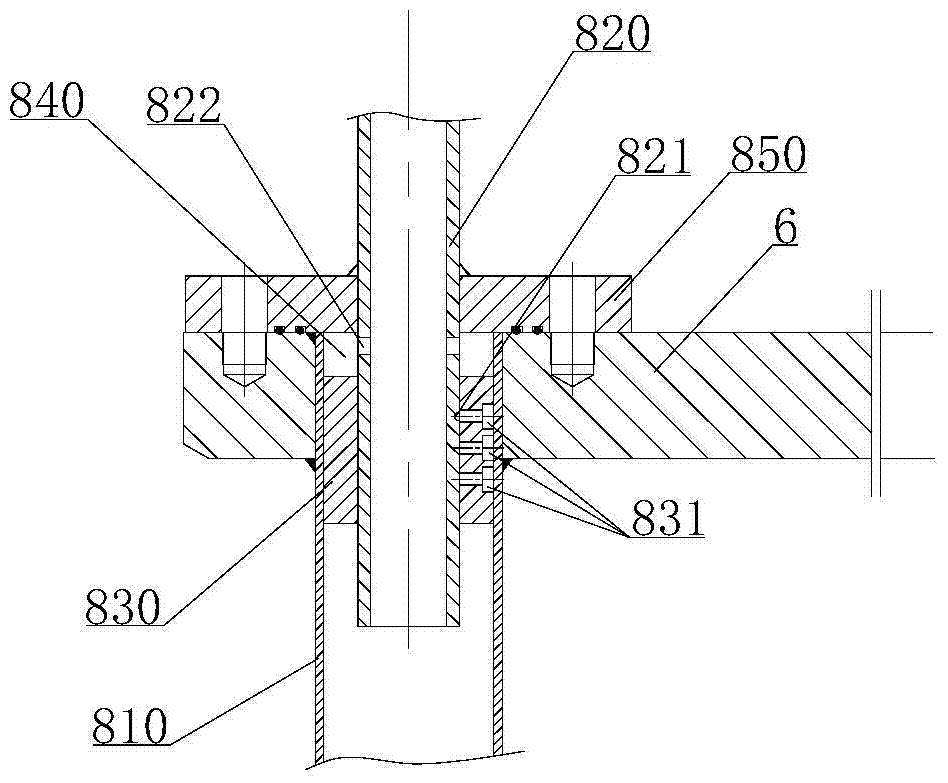

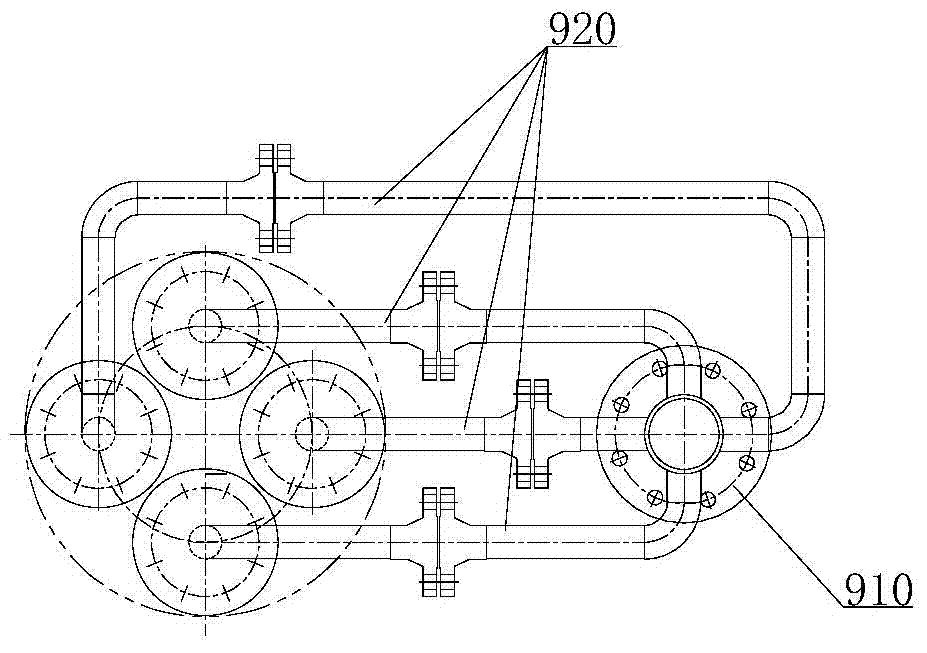

[0028] see Figure 1-3 , a multi-stage parallel hydrocyclone with adjustable flow rate, consists of the following parts:

[0029] The frame body 1 is included, and the frame body is fixed on the ground or the work platform.

[0030] The cyclone cylinder body 2 is included, and the cyclone cylinder body is fixedly supported on the frame body. A horizontal partition 3 is provided in the cyclone cylinder, and the horizontal partition divides the inner cavity of the cyclone cylinder into upper and lower chambers, wherein the upper chamber is a solid-liquid separation chamber 4, and the lower chamber is a discharge chamber. Solid cavity 5. A liquid inlet 210 is provided on the cylinder wall corresponding to the solid-liquid separation chamber. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com