Microdiaphragm pump

A micro-diaphragm pump and diaphragm technology, used in pumps, pump components, variable-capacity pump components, etc., can solve problems such as difficulty in increasing fluid attraction and discharge force, small change in pressure chamber volume, and incorrect discharge management. problems, to achieve the effect of improving production efficiency, increasing volume change, and good productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

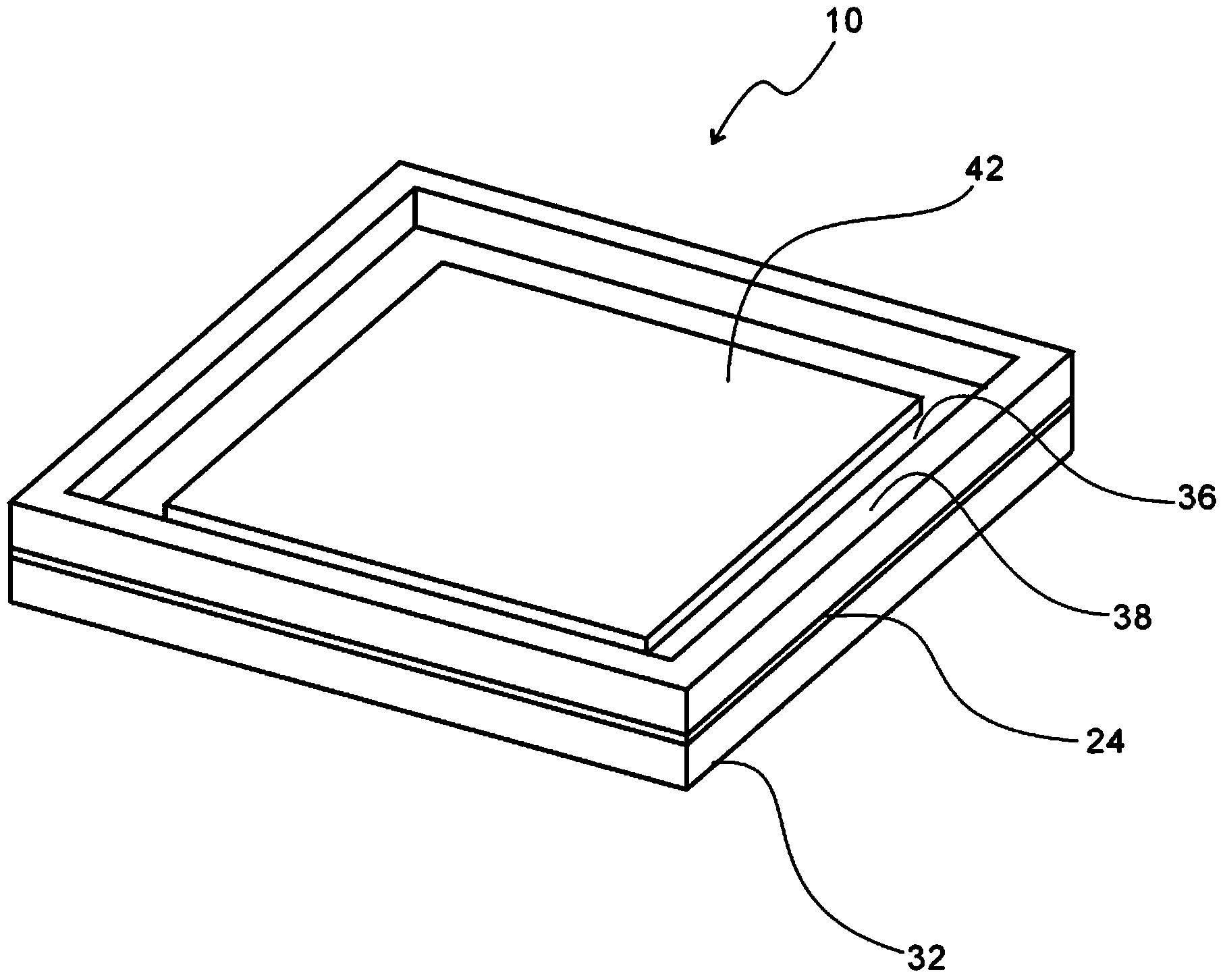

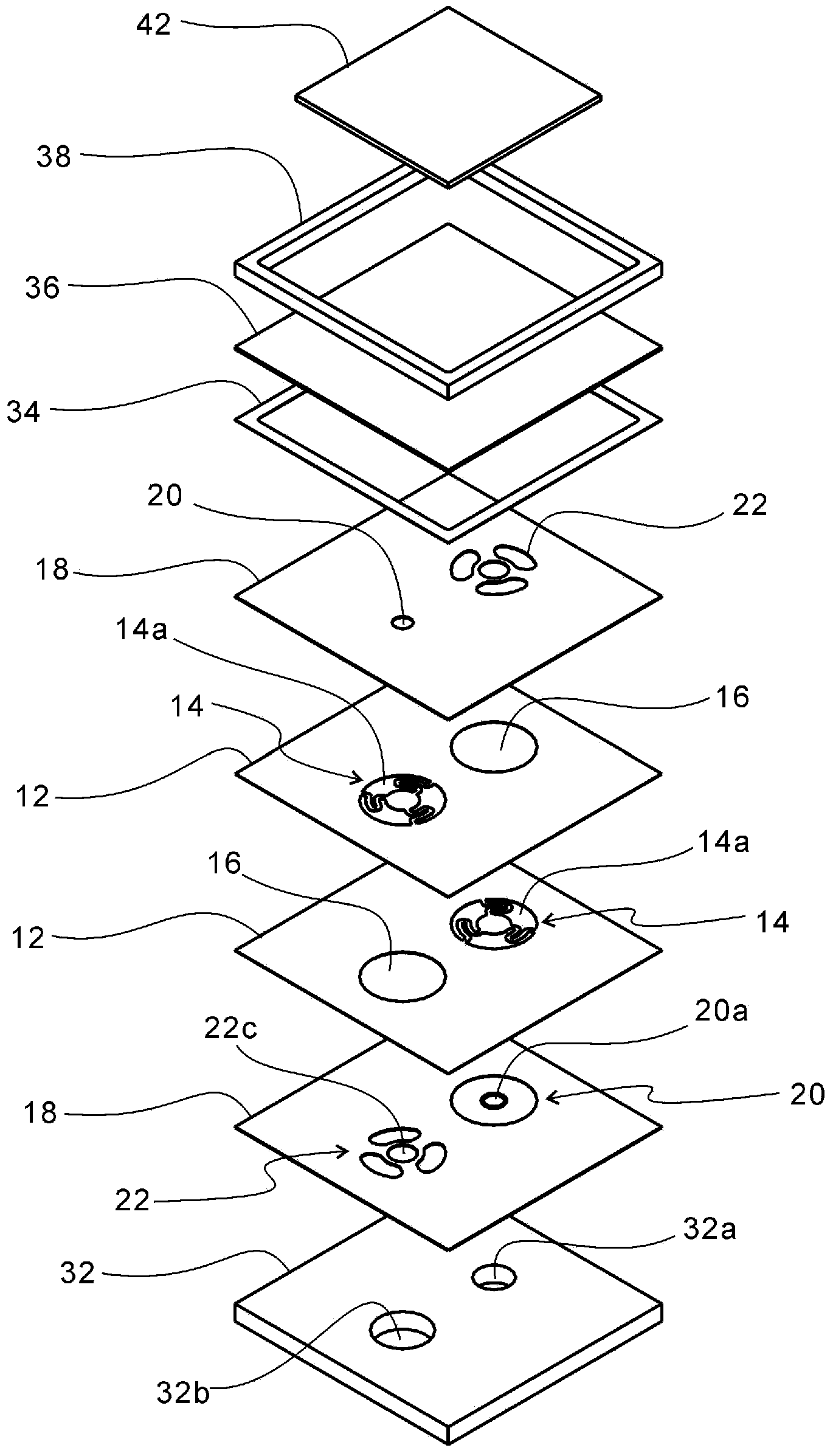

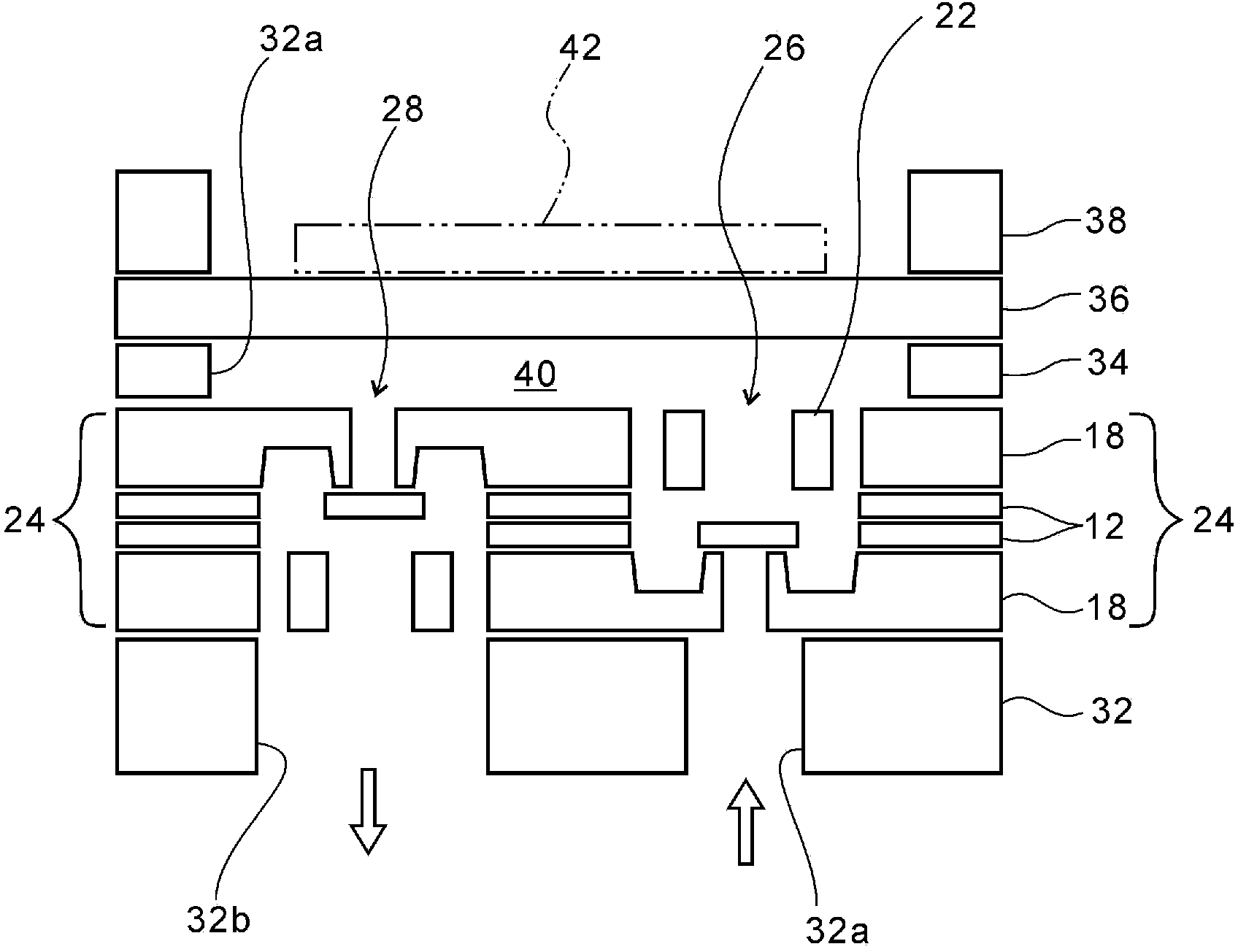

[0036] Figure 1~4 Among them, symbol 10 is the micro-diaphragm pump related to the present invention. The pump 10 is a pump in which a plurality of stainless thin metal plates and a frame are laminated and bonded, that is, the metal thin plates are aligned, stacked and bonded, and has a square shape of about 7 to 10 mm on one side. 12 is the valve plate sheet, such as Figure 5 Shown is a valve plate sheet in which a valve plate 14 and flow path openings 16 are formed on a stainless thin plate with a thickness of 0.01 mm (10 microns) by etching and press-cutting. Here, the valve plate 14 is held by a support arm 14 b that extends while being bent toward the inner diameter side from a valve plate opening 14 a having substantially the same diameter as the flow path opening 16 .

[0037] 18 is a valve seat sheet, such as Image 6 Shown is a valve seat sheet in which a valve seat 20 and a valve stopper 22 are formed on a stainless thin plate with a thickness of 0.05 mm by etch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com