A Diffusion-Contraction Dual-cavity Parallel Wall Jet Valveless Piezoelectric Micropump

A wall-attached jet and contraction technology, which is applied in the field of microfluidics, can solve the problems of little improvement in the back pressure performance of micropumps, and achieve the effects of miniaturization and integration, back pressure performance improvement, and volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

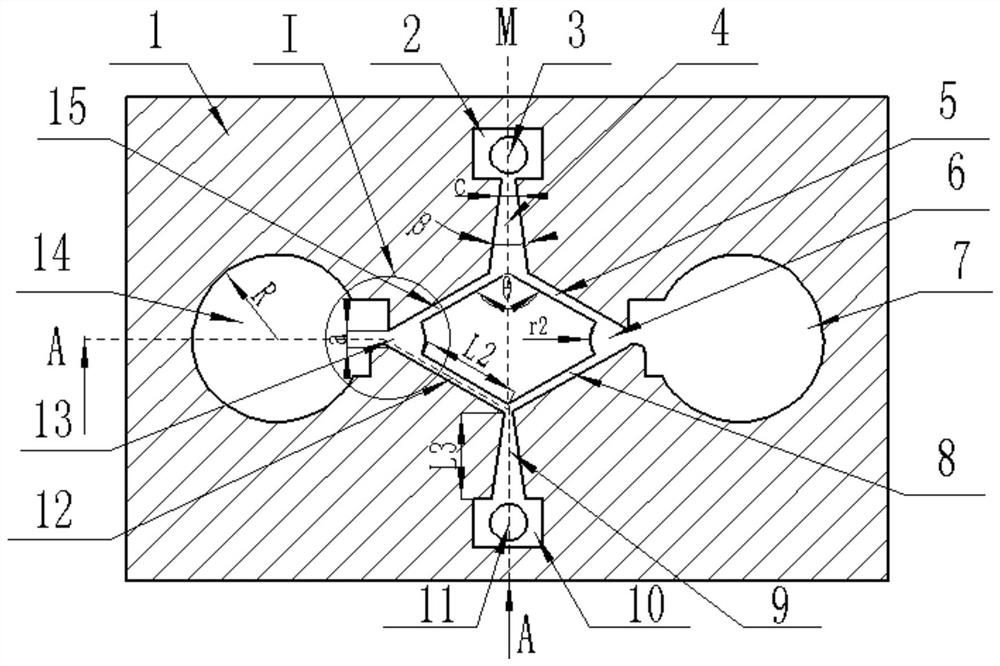

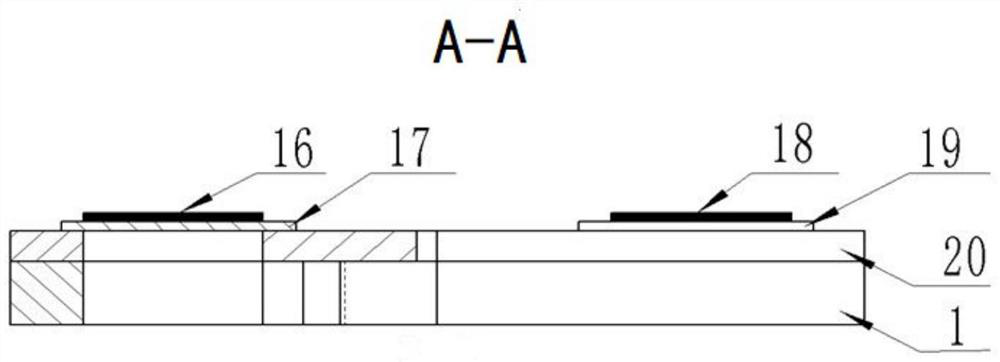

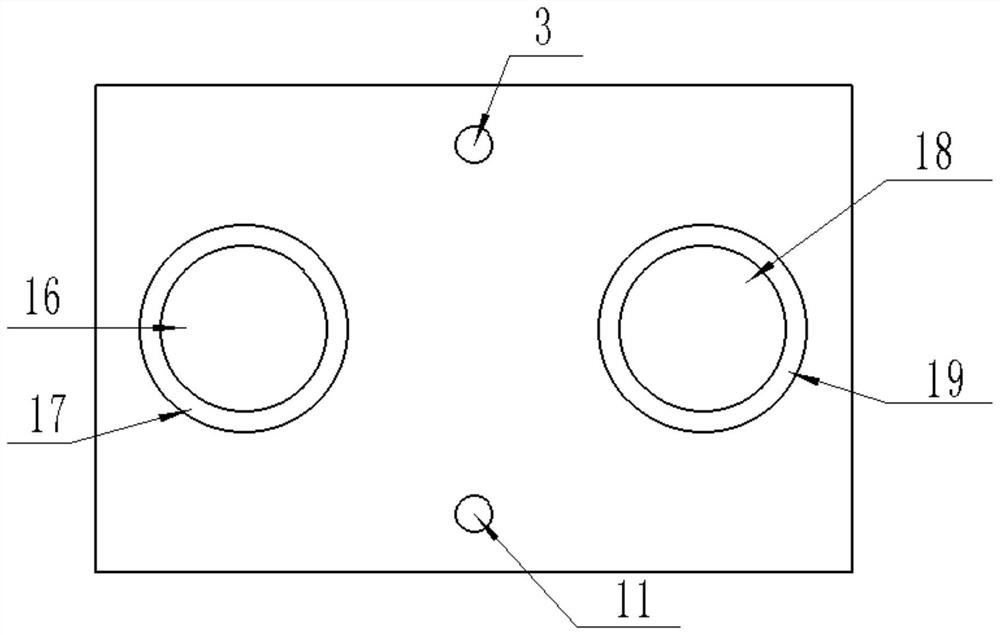

[0020] like figure 1 , figure 2 with image 3 As shown, the present invention includes a pump body 1, a pump cover 20, two piezoelectric vibrators 16, 18, and two vibrating diaphragms 17, 19. The material of the pump body 1 is silicon, and the pump cover 20 is above the pump body 1, the material of the pump cover 20 is glass. The pump body 1 and the pump cover 20 are closely bonded together by a vacuum oxygen plasma bonding process or an adhesive. The upper surface of the pump cover 20 is connected to the first vibrating diaphragm 19 and the second vibrating diaphragm 17, respectively, and each of the vibrating diaphragms is a piezoelectric vibrator, that is, the first piezoelectric resonator 18 and the first. The piezoelectric vibrator 16, two piezoelectric vibrators are drive elements, and the two piezoelectric vibrators 16, 18 are bonded directly above the two vibrating diaphragms 17, 19 by the epoxy resin.

[0021] The upper half of the inlet 3, the upper half of the first pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com