Mixer element for fluid that is guided in pipe

A technology for mixing parts and pipes, applied in the field of pipes, can solve problems such as ineffective heat exchange, and achieve the effects of preventing heat-induced damage, uniform temperature distribution, and small axial space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

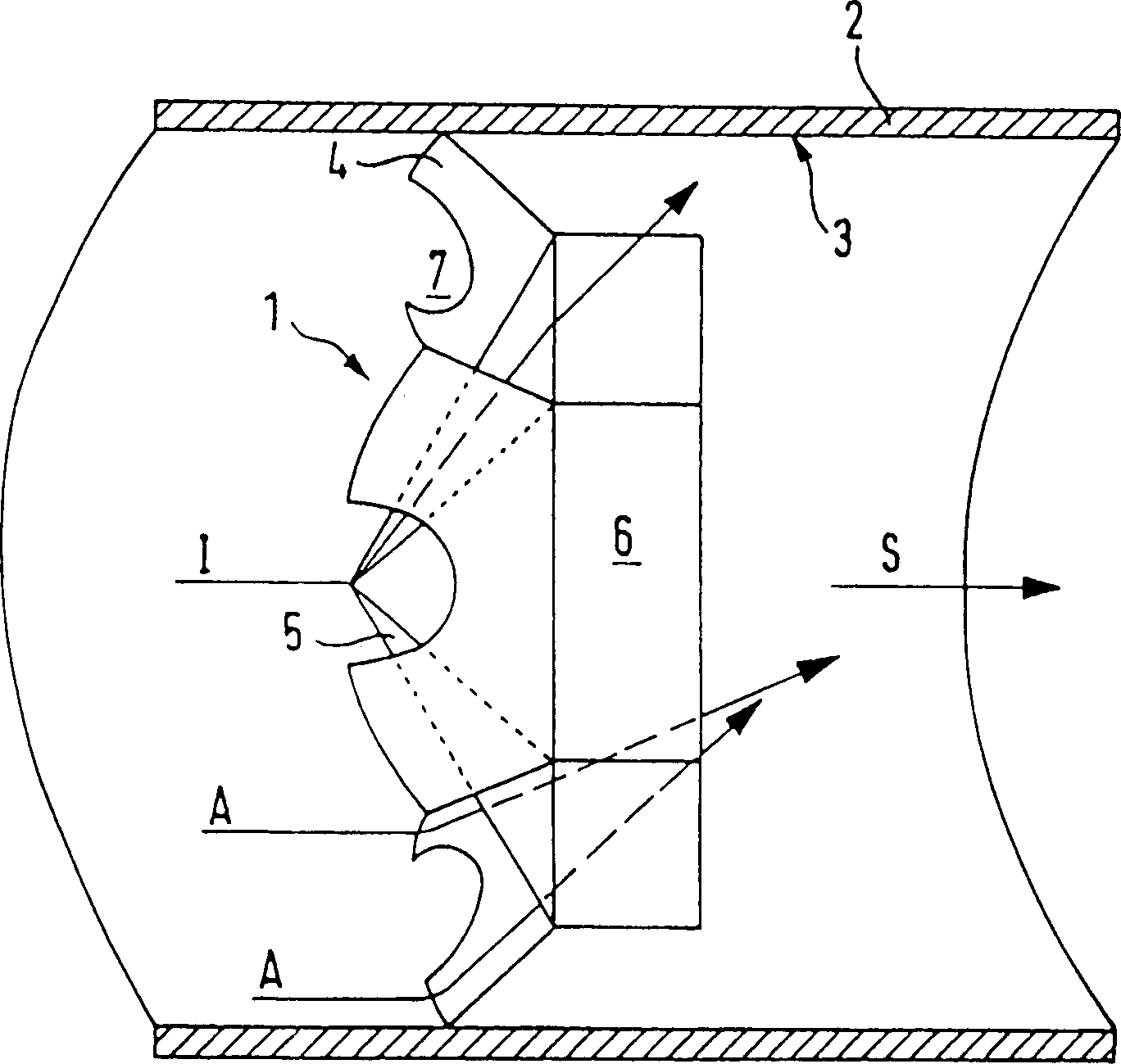

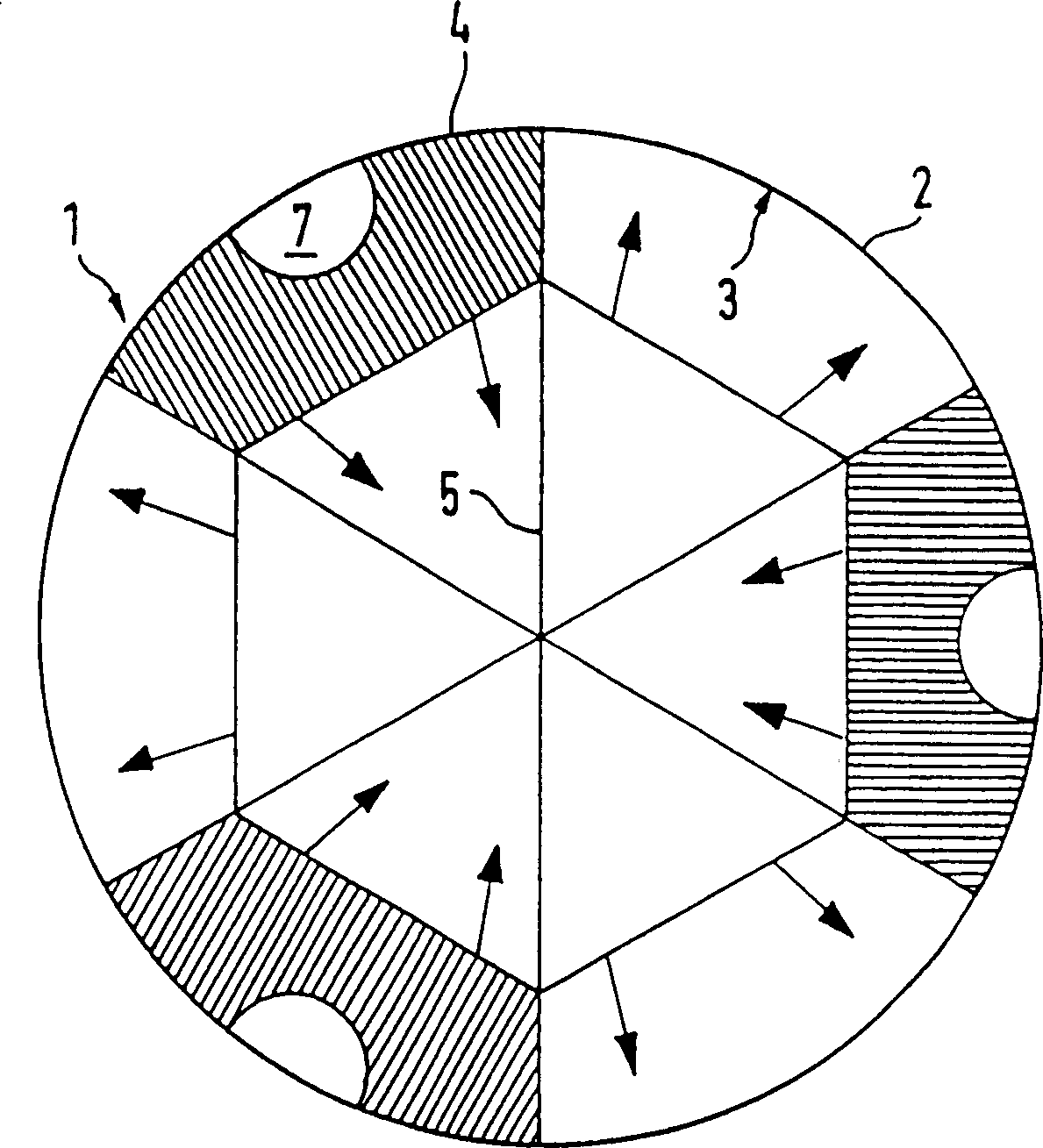

[0029] figure 1 A mixing element 1 according to the invention is shown schematically in side view, which is installed in a line 2, for example an exhaust pipe of an internal combustion engine (not shown). Exhaust gases from an internal combustion engine (not shown) are passed into an exhaust pipe 2 in which the mixing element 1 is arranged so as to lie approximately in one plane while deflecting part of the outer flow A adjacent the inner surface 3 of the duct 2 towards the inside , while part of the inner flow I is turned outward.

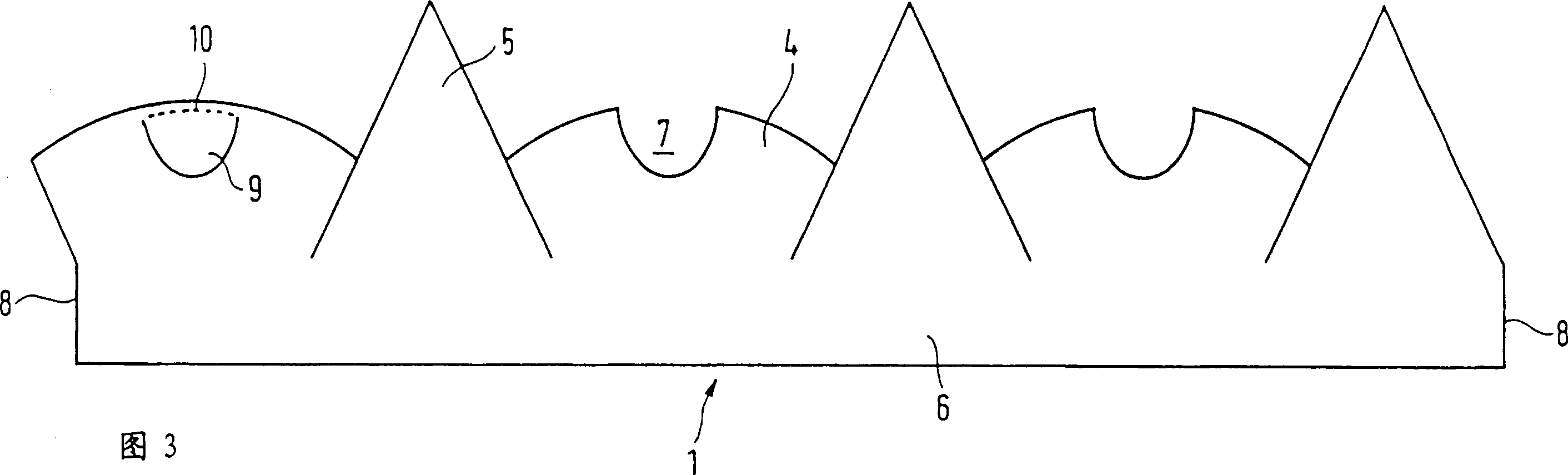

[0030] For this purpose, the mixing element 1 according to this exemplary embodiment has in each case 3 outer guide surfaces 4 and 3 inner guide surfaces 5, as from figure 2 and 3, the outer guide surface 4 resembles a trapezoid, while the inner guide surface 5 is triangular. The outer guide surface 4 serves to divert the outer flow A towards the inside; the inner guide surface 5 serves to divert the inner flow I towards the outside. In partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com