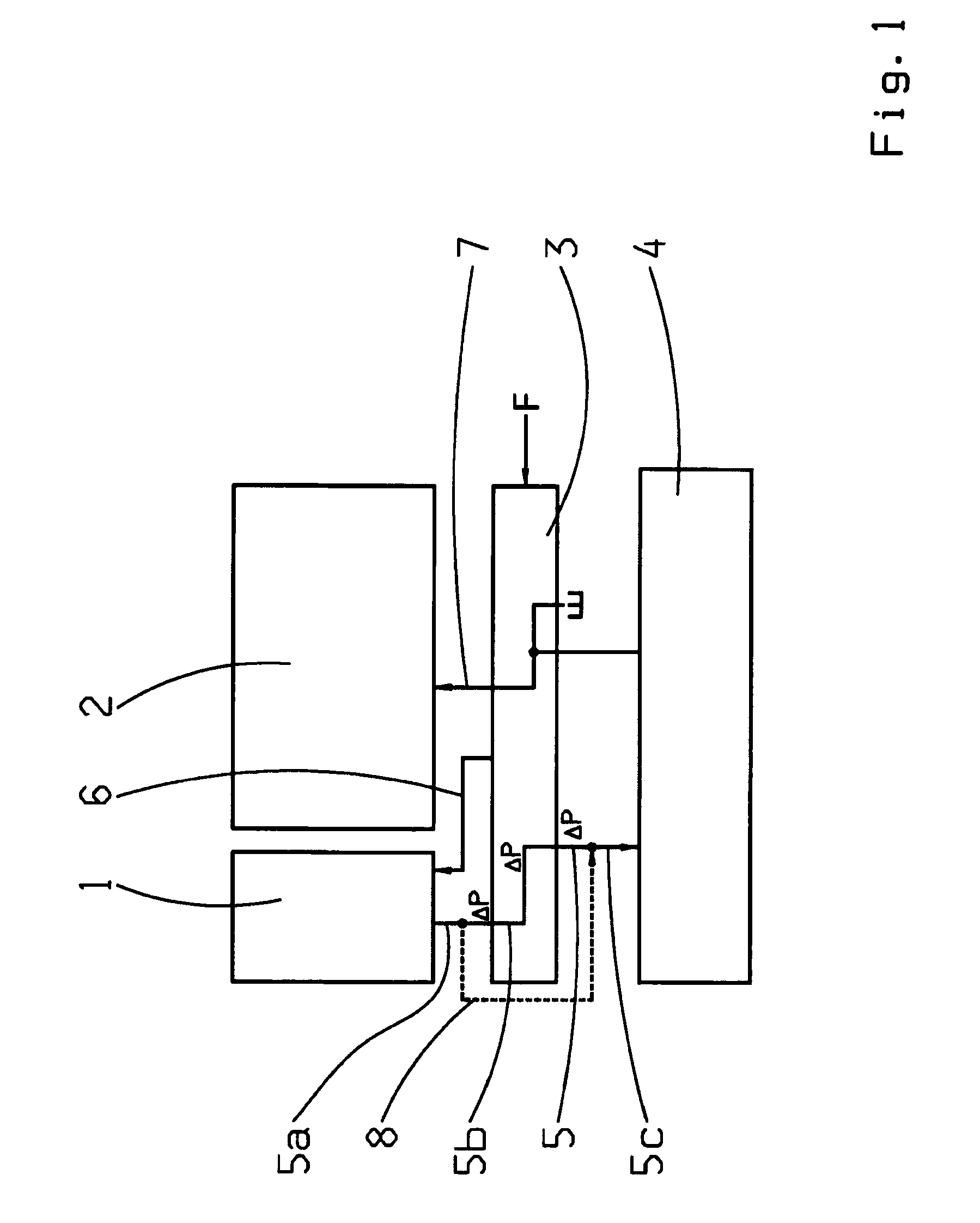

Patents

Literature

72results about How to "Runner short" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

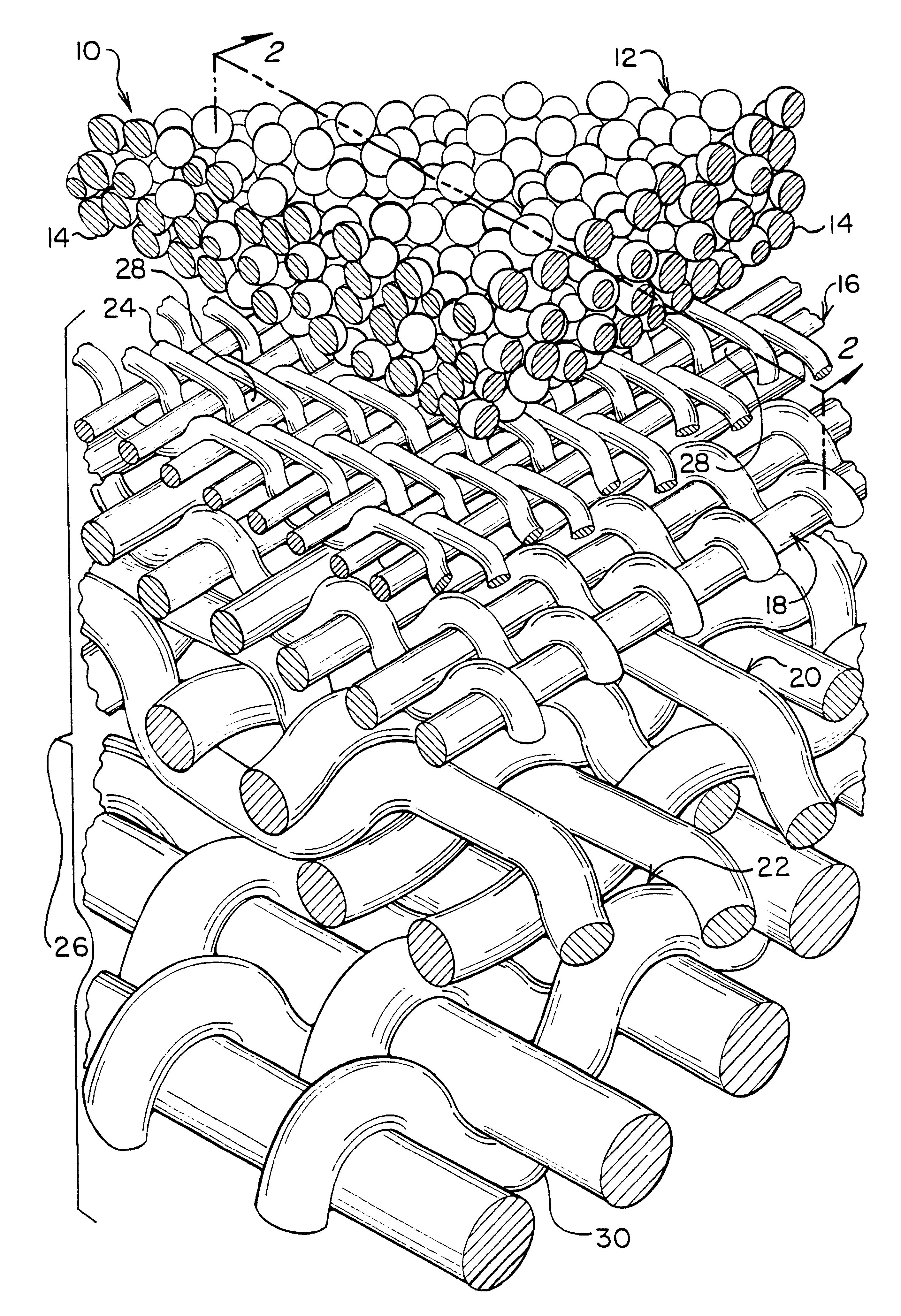

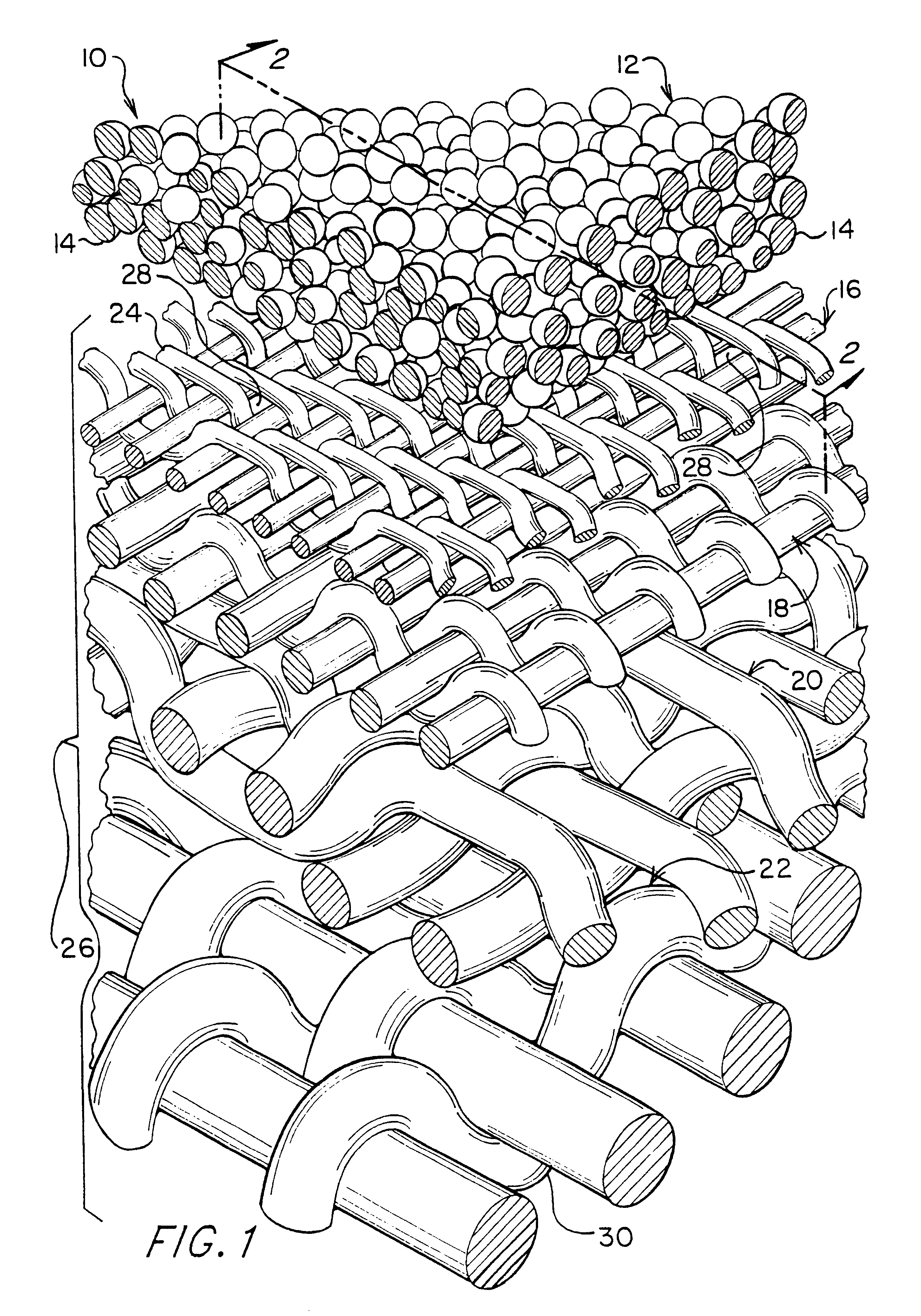

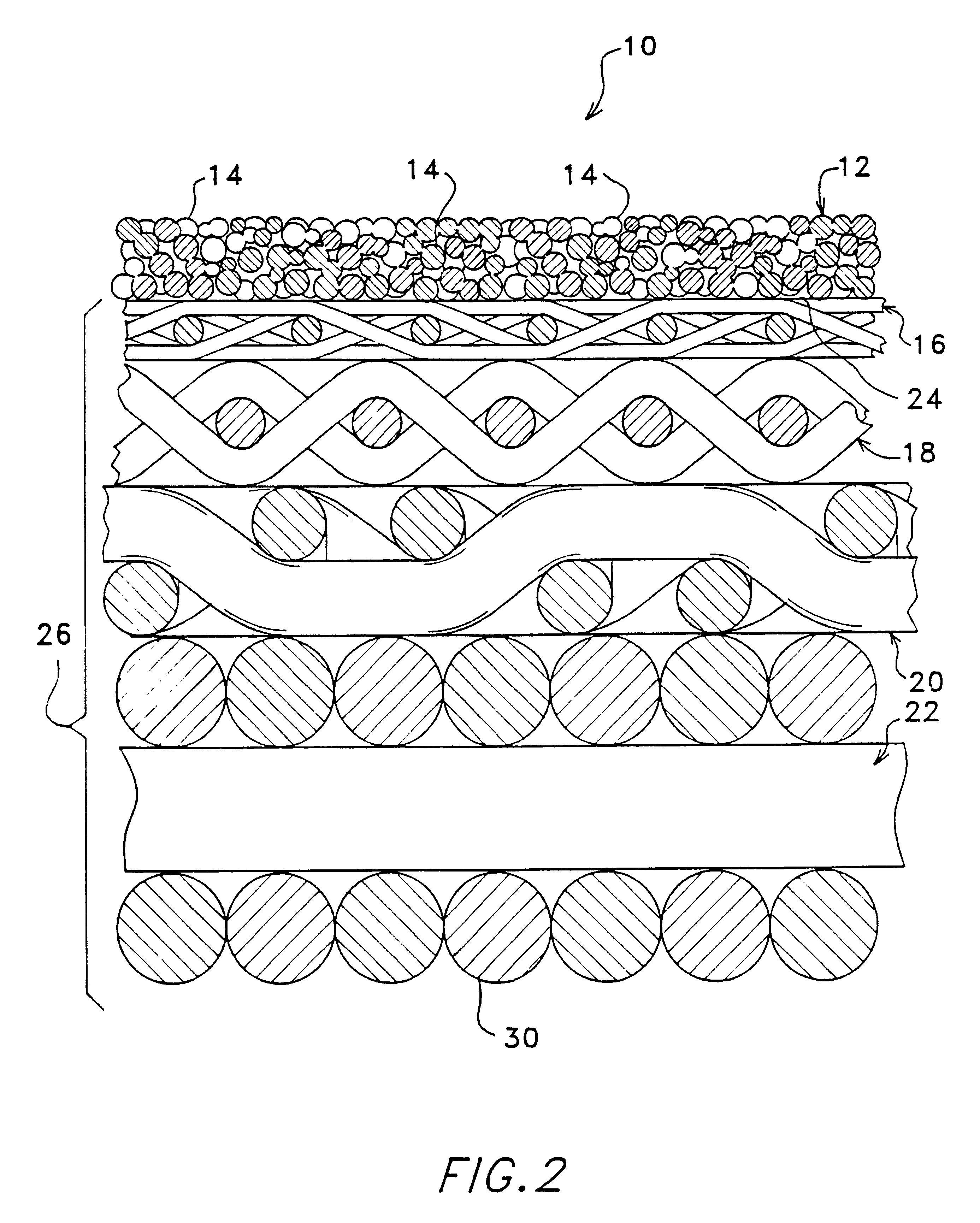

Micro and ultrafilters with controlled pore sizes and pore size distribution and methods for making

InactiveUS6309546B1High permeabilityMinimal pressure dropSemi-permeable membranesMembranesMicrometerPore diameter

A micro / ultrafiltering element (10) and method for making a filter element are provided. The filtering element comprises a multi-level support (26) having a filtering membrane layer (12) formed thereon comprising sintered particles (14) of uniform diameter. The filtering membrane preferably has an average pore size of from about 0.005-10 micrometers. The filter element is capable of being formed in a variety of geometrical shapes based on the shape of the porous support,

Owner:ELLIPSIS CORP

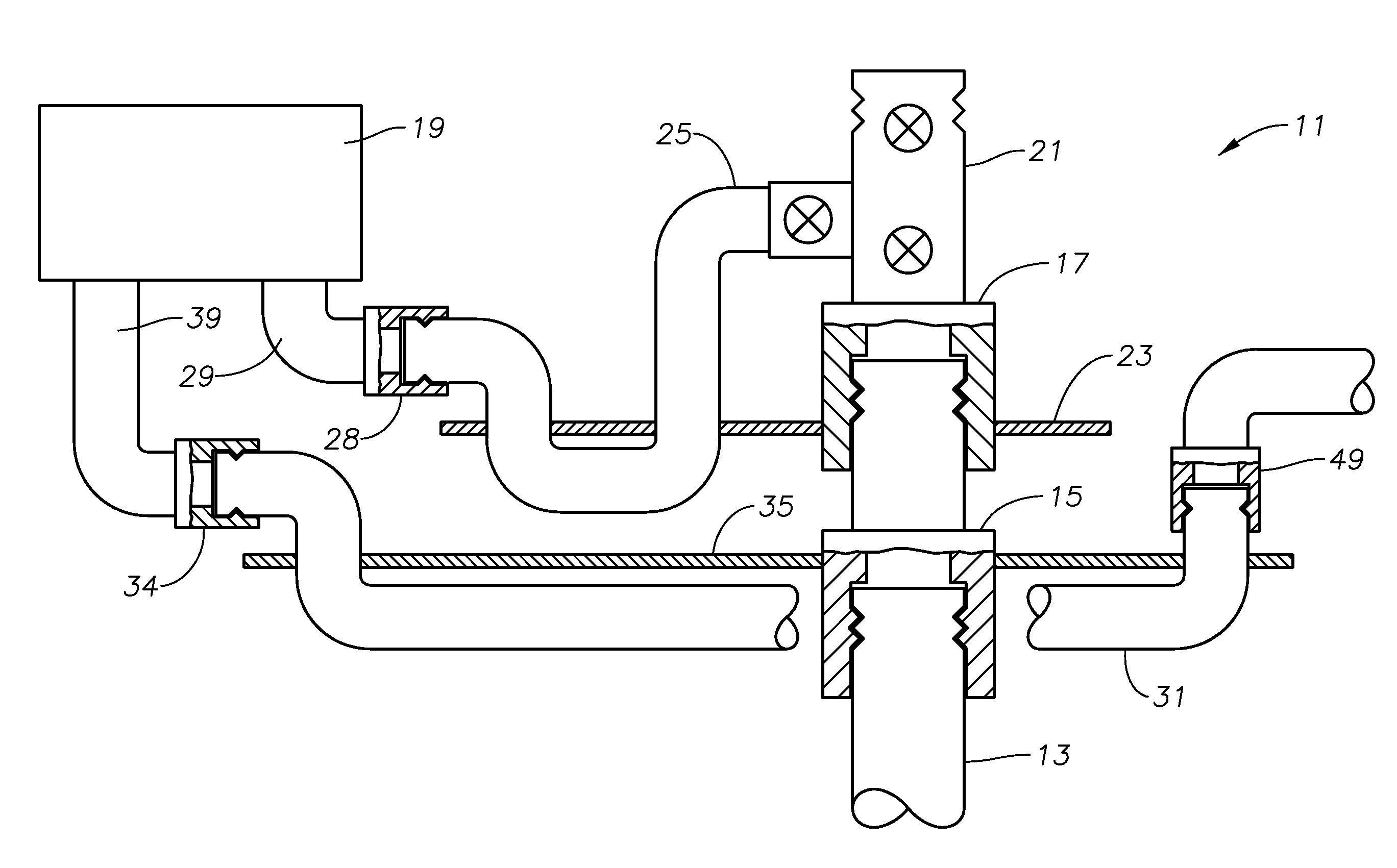

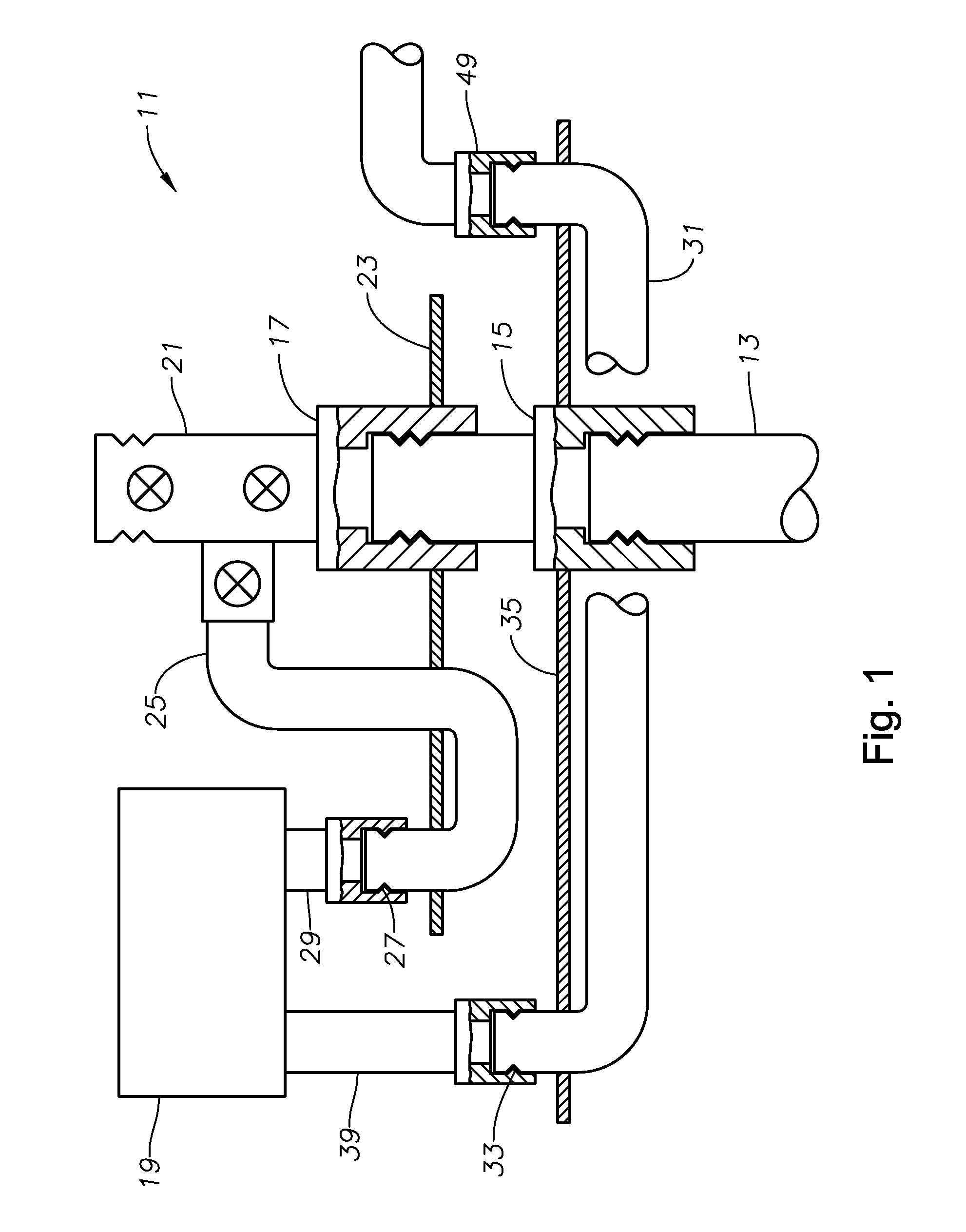

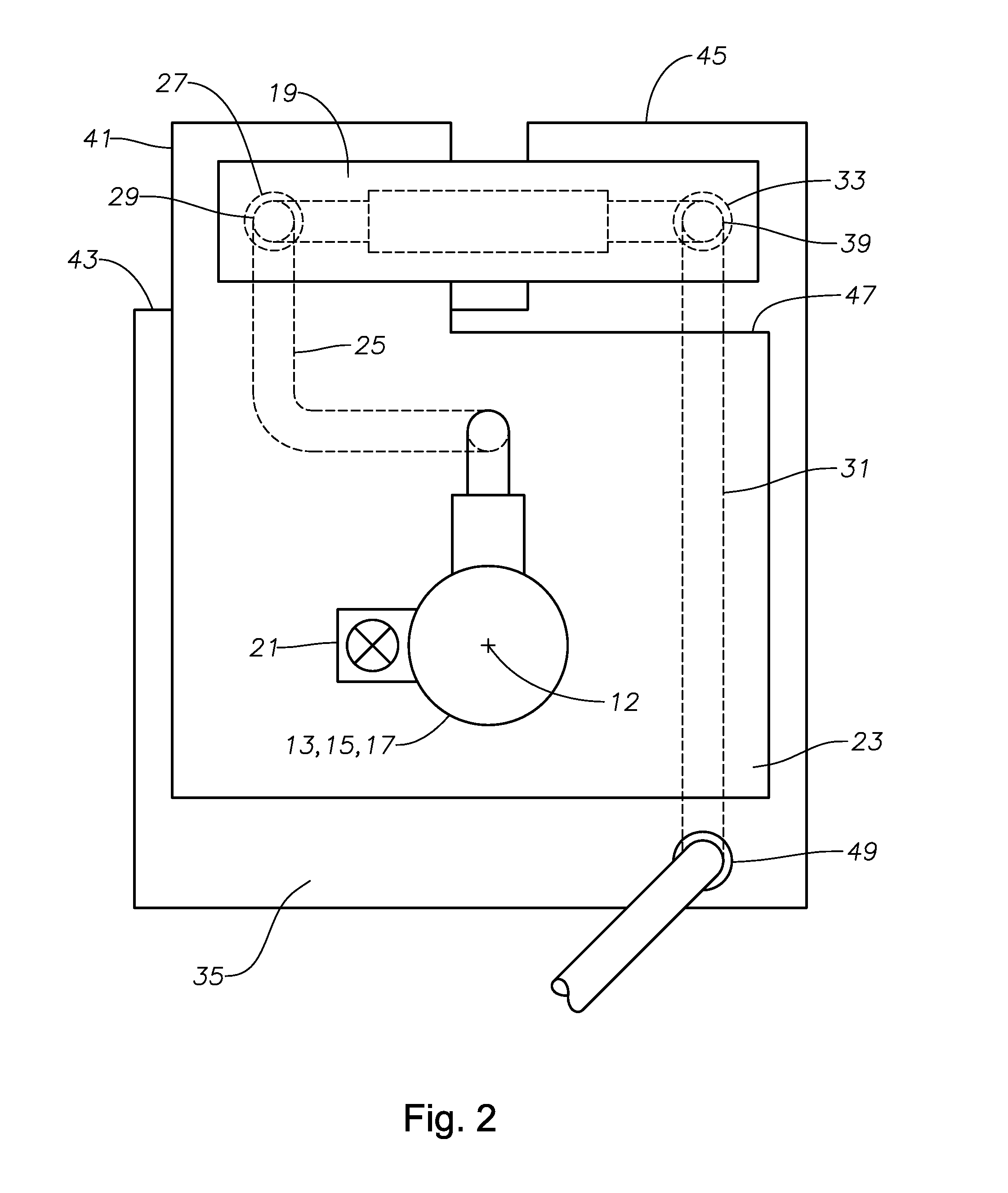

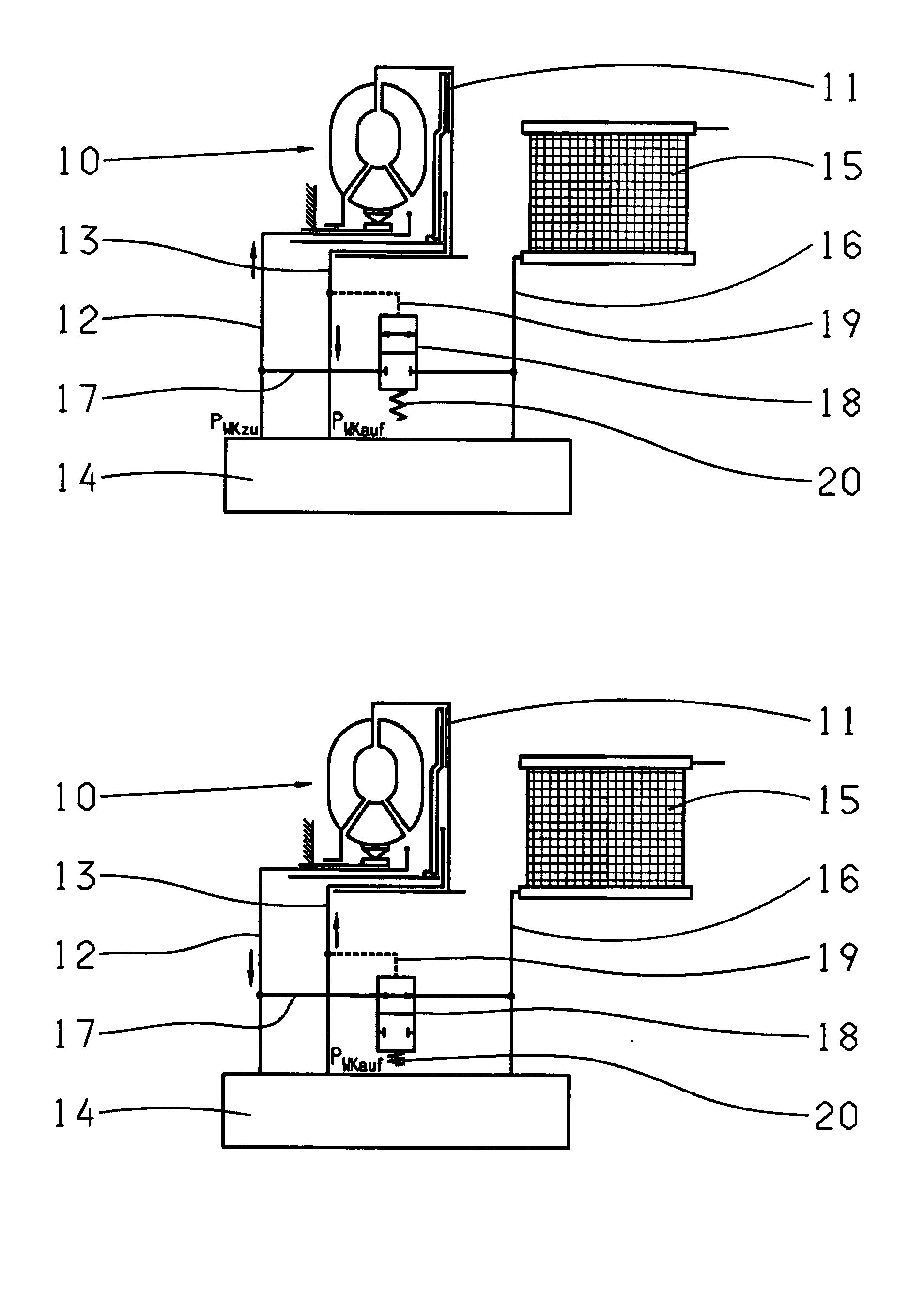

Flow module placement between a subsea tree and a tubing hanger spool

InactiveUS20130000918A1Runner shortLess opportunityFluid removalUnderwater drillingLine tubingTubing hanger

A subsea wellhead assembly positions a flow module between an outboard flowline of a subsea tree and a tubing hanger spool flowline. The subsea production assembly includes a wellhead, a tubing hanger spool disposed on the wellhead, and a subsea tree disposed on the tubing hanger spool. Production fluid may flow from the wellhead through the tubing hanger spool, and then through the tree. A tubing hanger spool frame mounts to and extends laterally from the tubing hanger spool and supports a downstream flowline having an upward facing hub. A tree frame mounts to and extends laterally from the subsea tree and supports an upstream flowline having an upward facing hub. A flow module having downward facing flowlines that couple to the hubs so that the weight of the flow module is distributed between the frames of the tubing hanger spool and the subsea tree.

Owner:VETCO GRAY

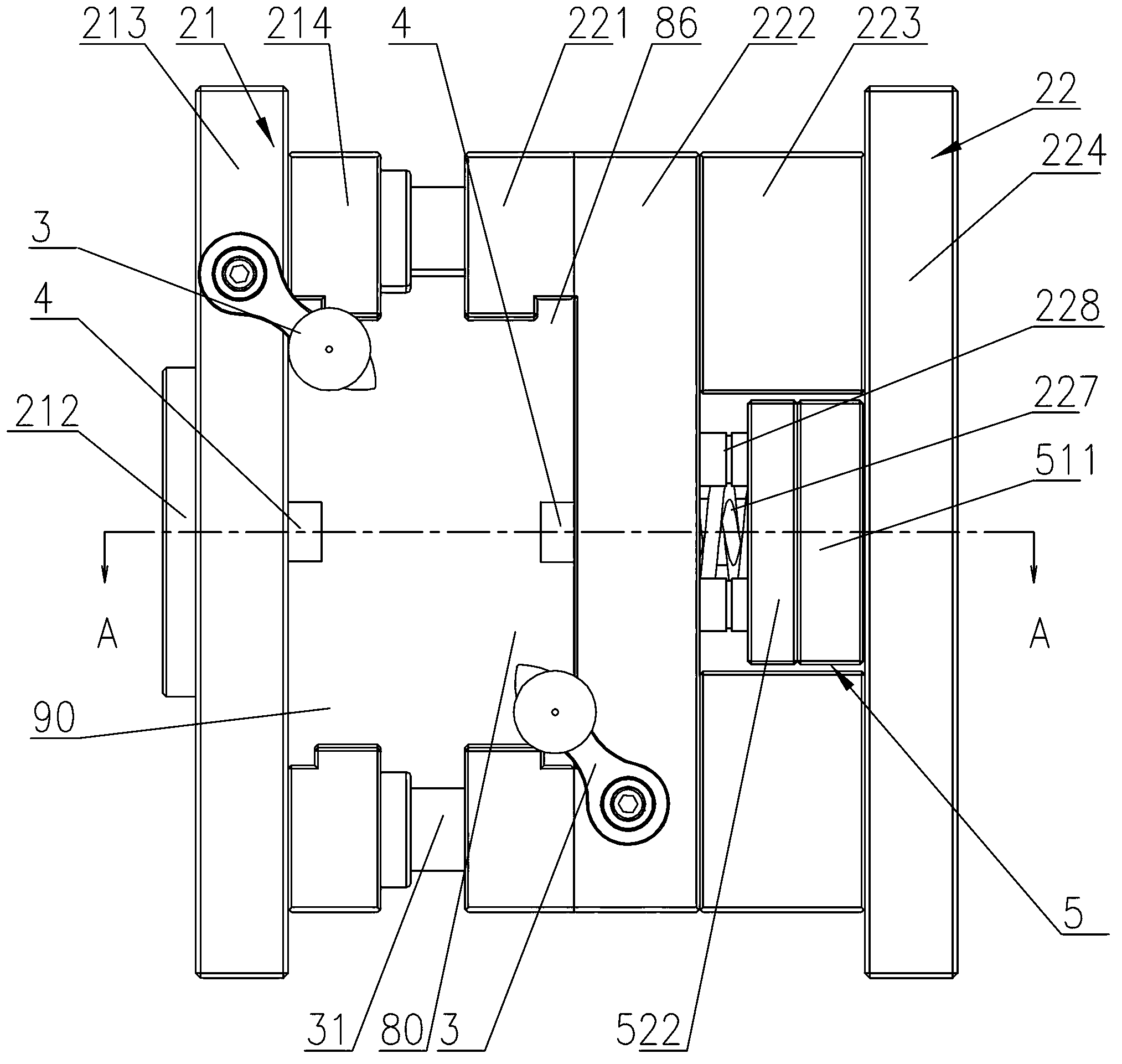

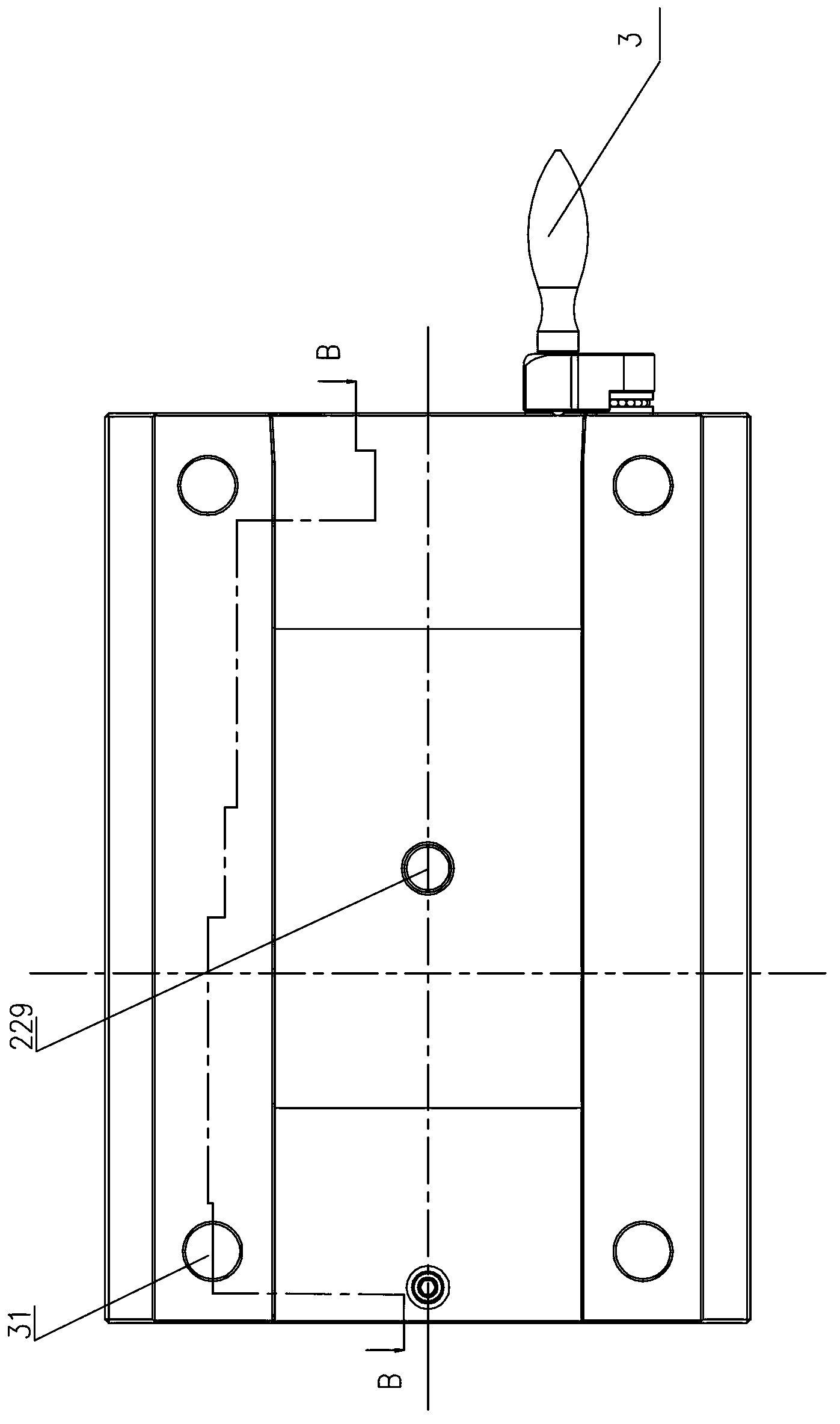

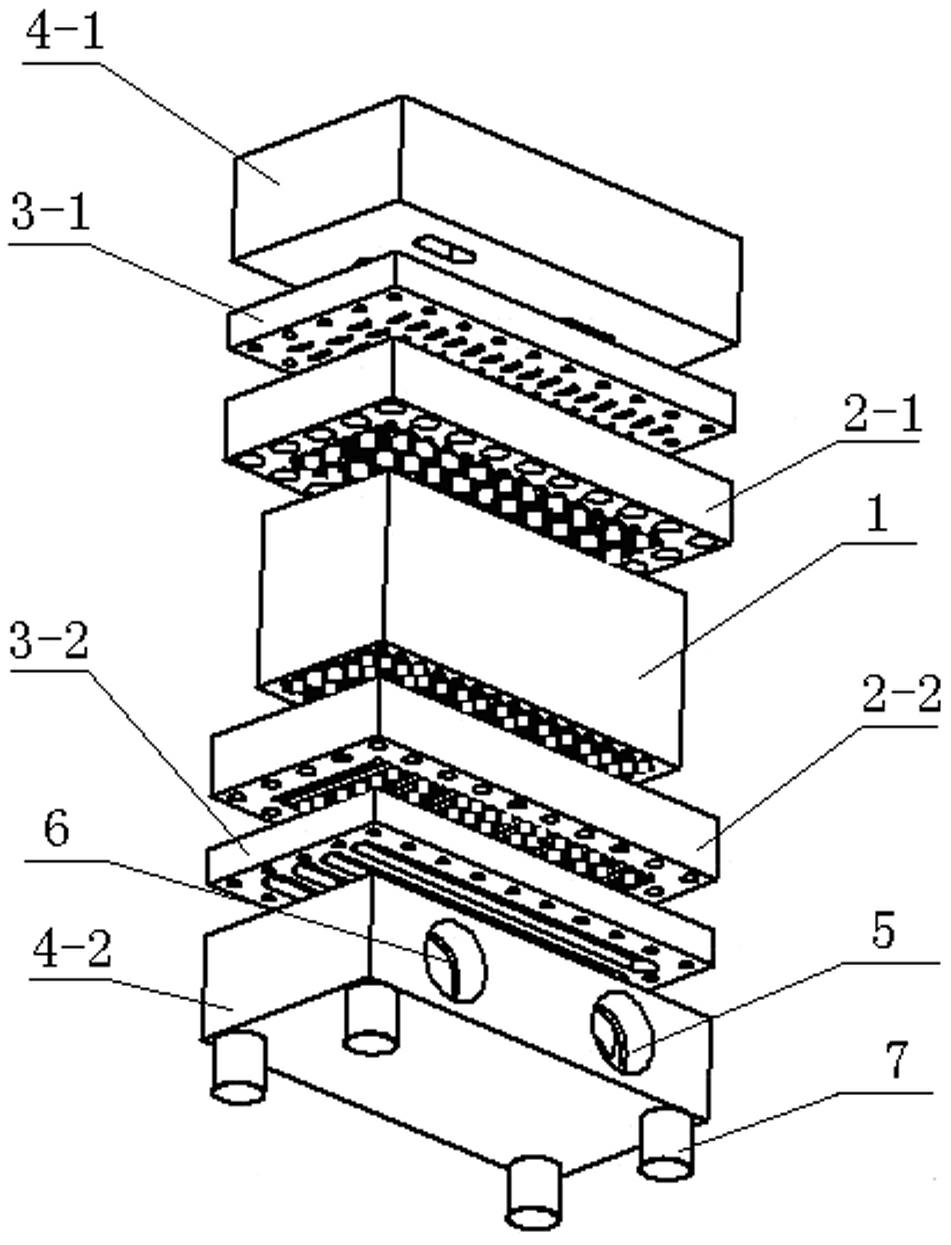

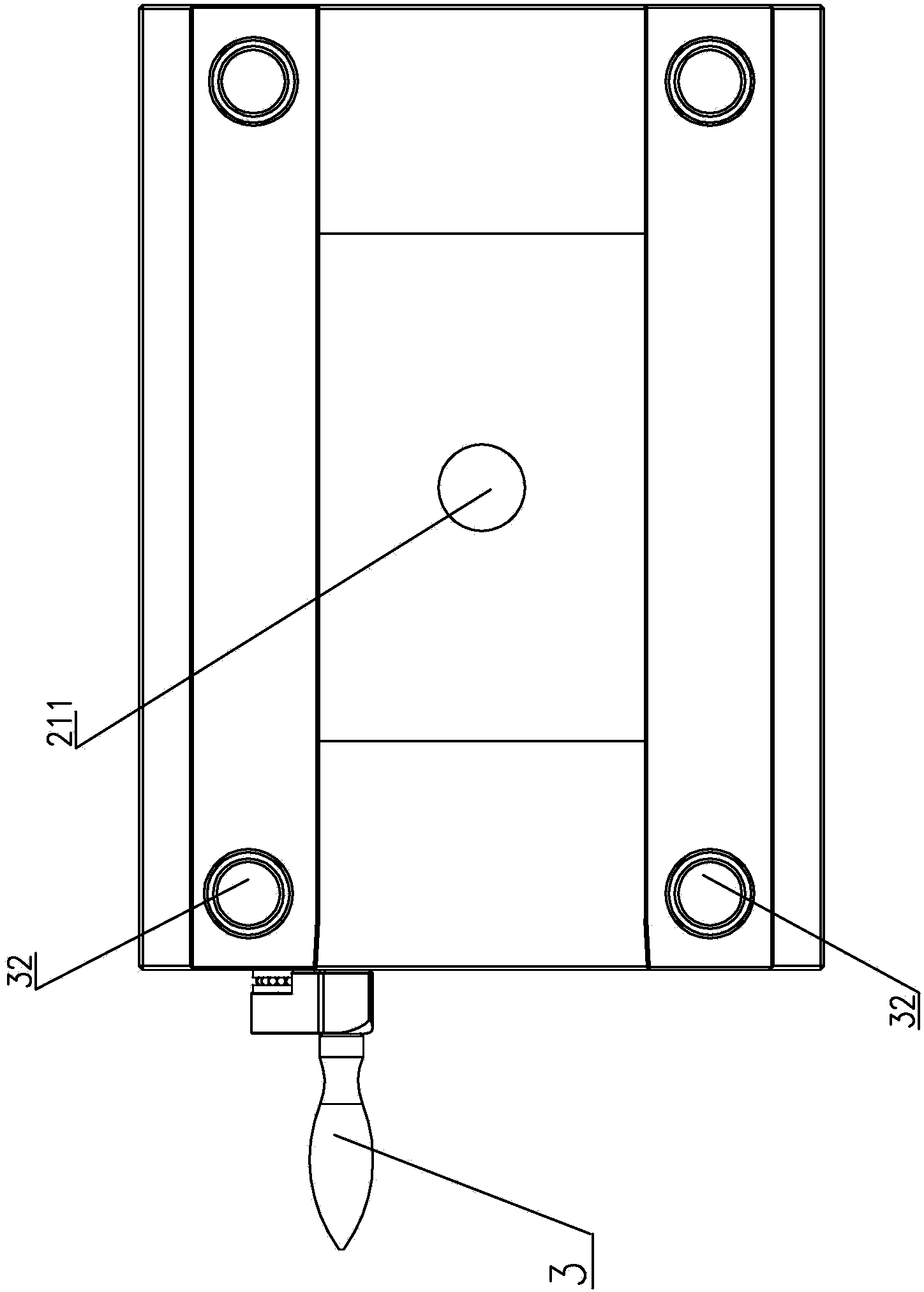

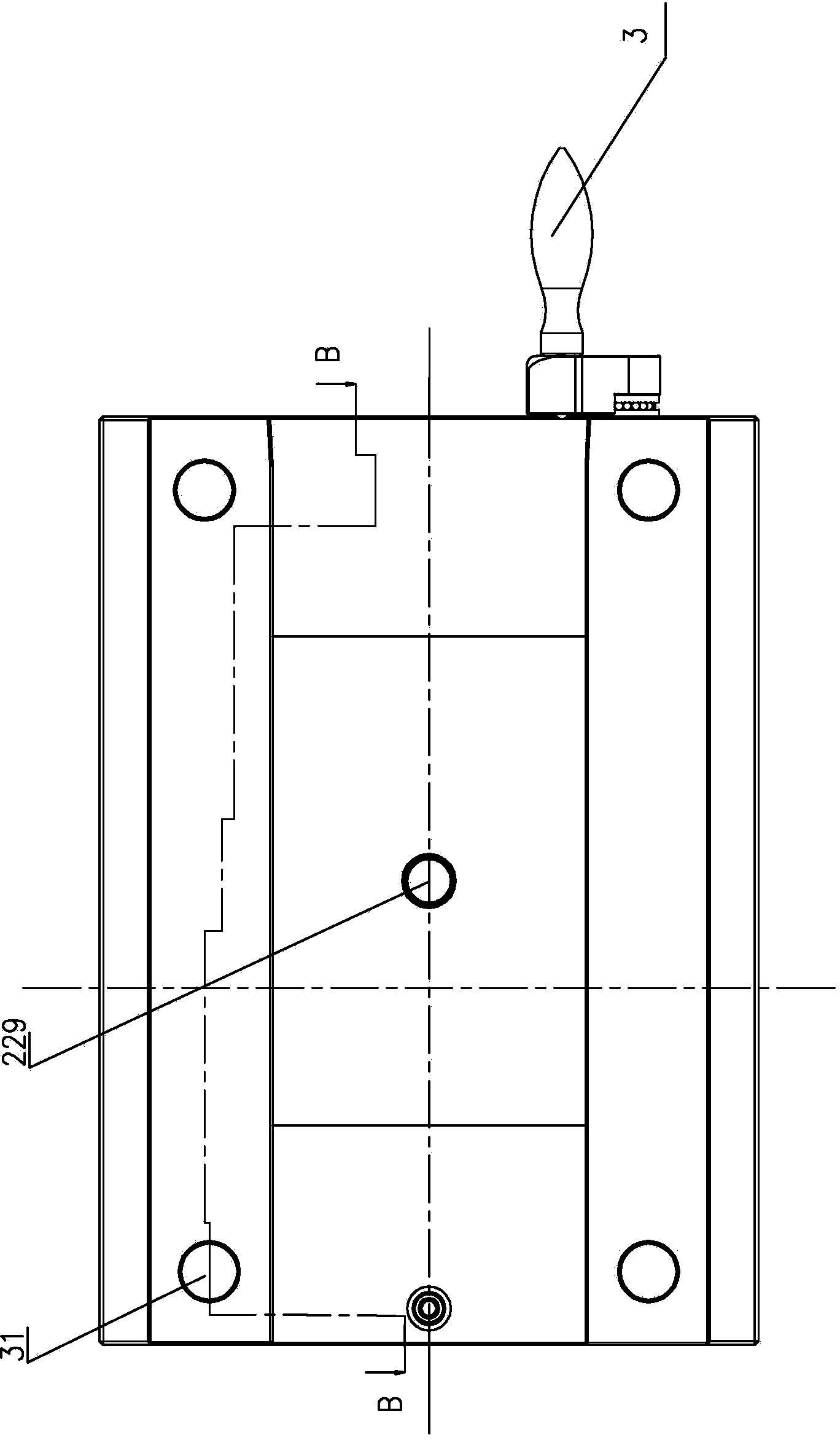

Injection mould with rapidly-replaced mould cores

The invention discloses an injection mould with rapidly-replaced mould cores. The injection mould is composed of a movable mould and a stationary mould, wherein a main body of the movable mould is composed of a movable mould base and a movable mould core movably arranged on the movable mould base; a main body of the stationary mould is composed of a stationary mould base and a stationary mould core movably arranged on the stationary mould base; the butt joint faces of the movable mould base and the stationary mould base are respectively provided with a mould core mounting sliding chute which horizontally extends from front to back; at least the front ends of the mould core mounting sliding chutes are provided with plug-in mounting holes for mounting or dismounting the mould cores; the mould cores are provided with tracks matched with the mould core mounting sliding chutes so as to move along the mould core mounting sliding chutes; and the mould cores are inserted to or dismounted from the mould core mounting sliding chutes on the mould bases through the plug-in mounting holes, thus the mould cores are replaced. According to the invention, only one set of mould base needs to be manufactured to be matched with the mould cores of different cavities which are manufactured according to spline standards tested based on different performance indexes; the mould replacing operation is easier and more convenient than that of the prior art, so that the mould replacing time is greatly shortened; and the manufacturing cost of various test spline moulds can also be greatly reduced.

Owner:广州现代塑料有限公司

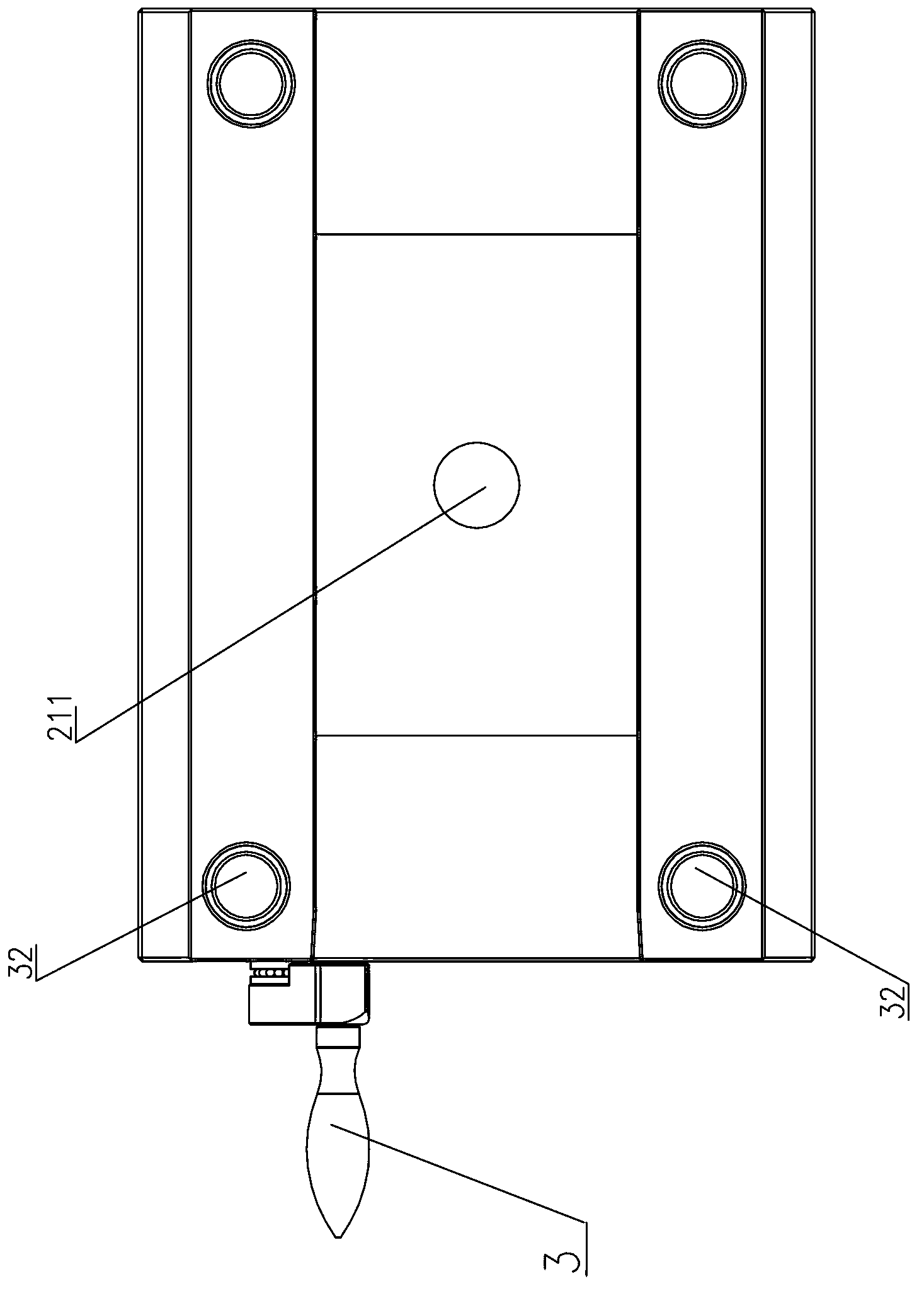

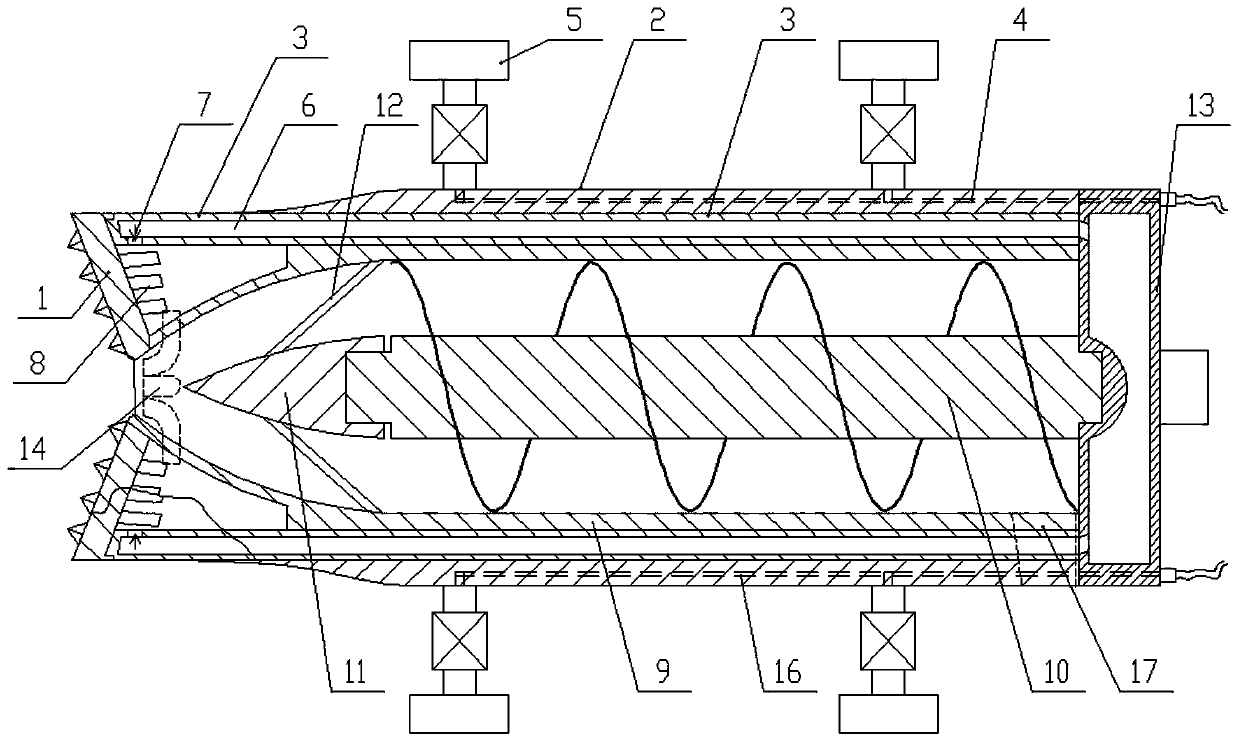

Pipeline dredging and guiding device for water conservancy construction

The invention discloses a pipeline dredging and guiding device for water conservancy construction. The pipeline dredging and guiding device comprises a rotating head, an outer cylinder, an inner cylinder, a core assembly and a rear end cover, wherein the rotating head comprises a conical shell-shaped main body, cutter teeth are arranged on the inner side wall of the main body, blades are arrangedon the outer side wall of the main body, and the blades are gradually shortened from the large end to the small end of the main body; an outlet of a water outlet pipeline is arranged by facing a cutting face of the rotating head; jet holes for ejecting water flow are formed nearby the bottoms of water injection cavities of the inner cylinder, and the water flow ejected from the jet holes just impacts the blades to drive the rotating head to perform rotary cutting; a mandrel is connected with a bullet structure through a connecting rod fixed on the inner wall of a core tube to be fixed in the core tube in a suspended manner, the rear end of a rotating shaft is mounted on the rear end cover, and a hollow cavity of the rear end cover is communicated with the water injection cavities of the inner cylinder; a discharge port penetrating through the inner cylinder and the outer cylinder is formed in the lower side wall, close to the rear end cover, of the core tube. The device is high in dredging capacity and quite high in dredging efficiency.

Owner:李建岗 +3

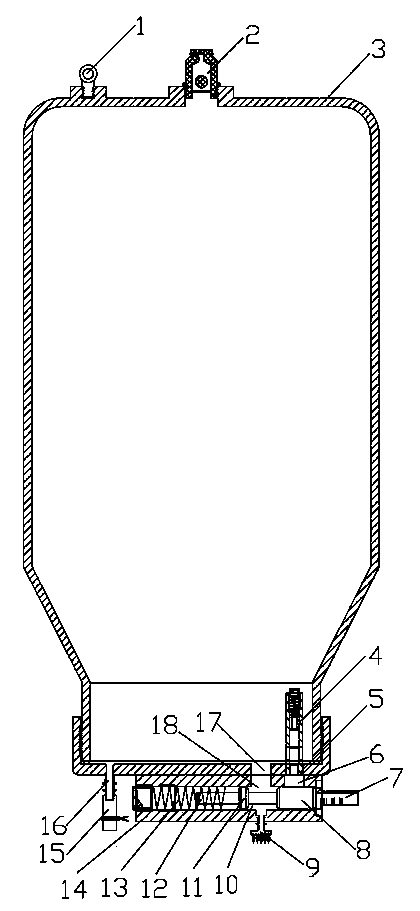

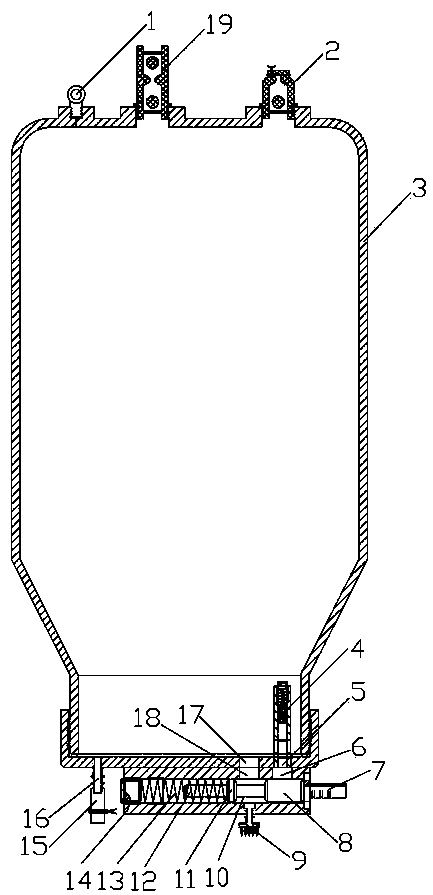

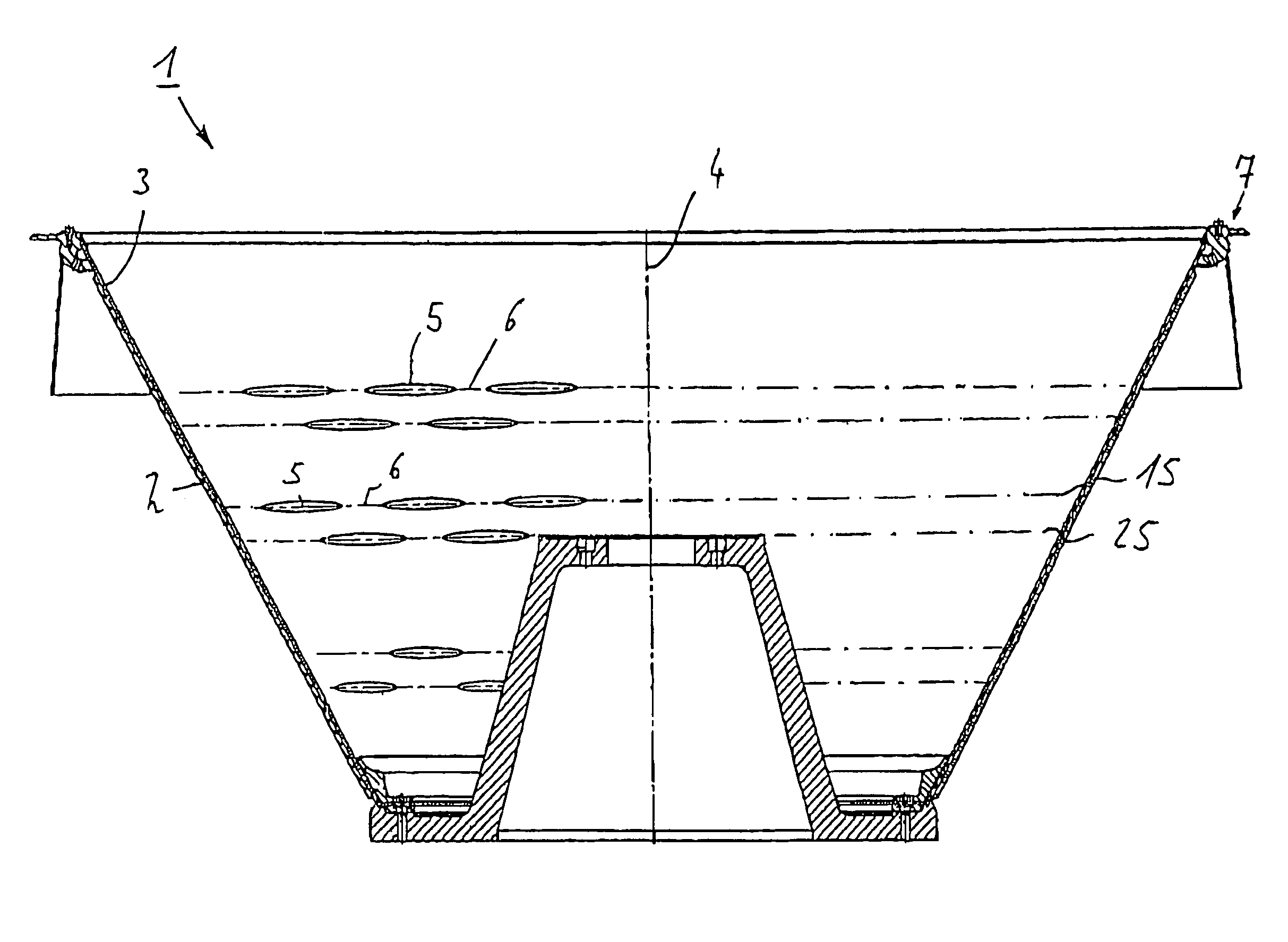

Water-saving-valve-controlled drip irrigation tank

InactiveCN104160922AReduce power consumptionLow investment costClimate change adaptationWatering devicesAgricultural irrigationDrip irrigation

The invention relates to agricultural irrigation devices, in particular to a water-saving-valve-controlled drip irrigation tank. The water-saving-valve-controlled drip irrigation tank is provided with a closed tank body, a ventilation overflow stop valve is arranged at the top of the tank body, and a water inlet and a water outlet are formed in the bottom of the tank body. The water-saving-valve-controlled drip irrigation tank is characterized in that a water inlet one-way valve is arranged on the inner side of the water inlet in a butt joint mode, an in-out linkage water valve is arranged at the bottom of the tank body and provided with a valve body, a piston cavity provided with a piston and a compression spring is arranged in the valve body, and a water inlet pipe is installed at the end, close to the piston, of the valve body to be communicated with the piston cavity. A water supply opening is formed in the valve body to be communicated with the water inlet in the bottom of the tank body, and a transition water opening is formed to be communicated with the water outlet in the bottom of the tank body. A water drip distribution device is further arranged on the valve body and communicated with the piston cavity. The water-saving-valve-controlled drip irrigation tank overcomes the defects that blocking occurs easily when drip irrigation is conducted through a water dropper, water yield cannot be adjusted, the water dropper is complex in structure, high in manufacturing cost and short in service life, and a system is large in power consumption. Meanwhile, the water-saving-valve-controlled drip irrigation tank is more stable and more reliable in work, low in failure rate and wide in agricultural crop irrigation application range.

Owner:HUBEI FOR LONG PIPE TECH CO LTD

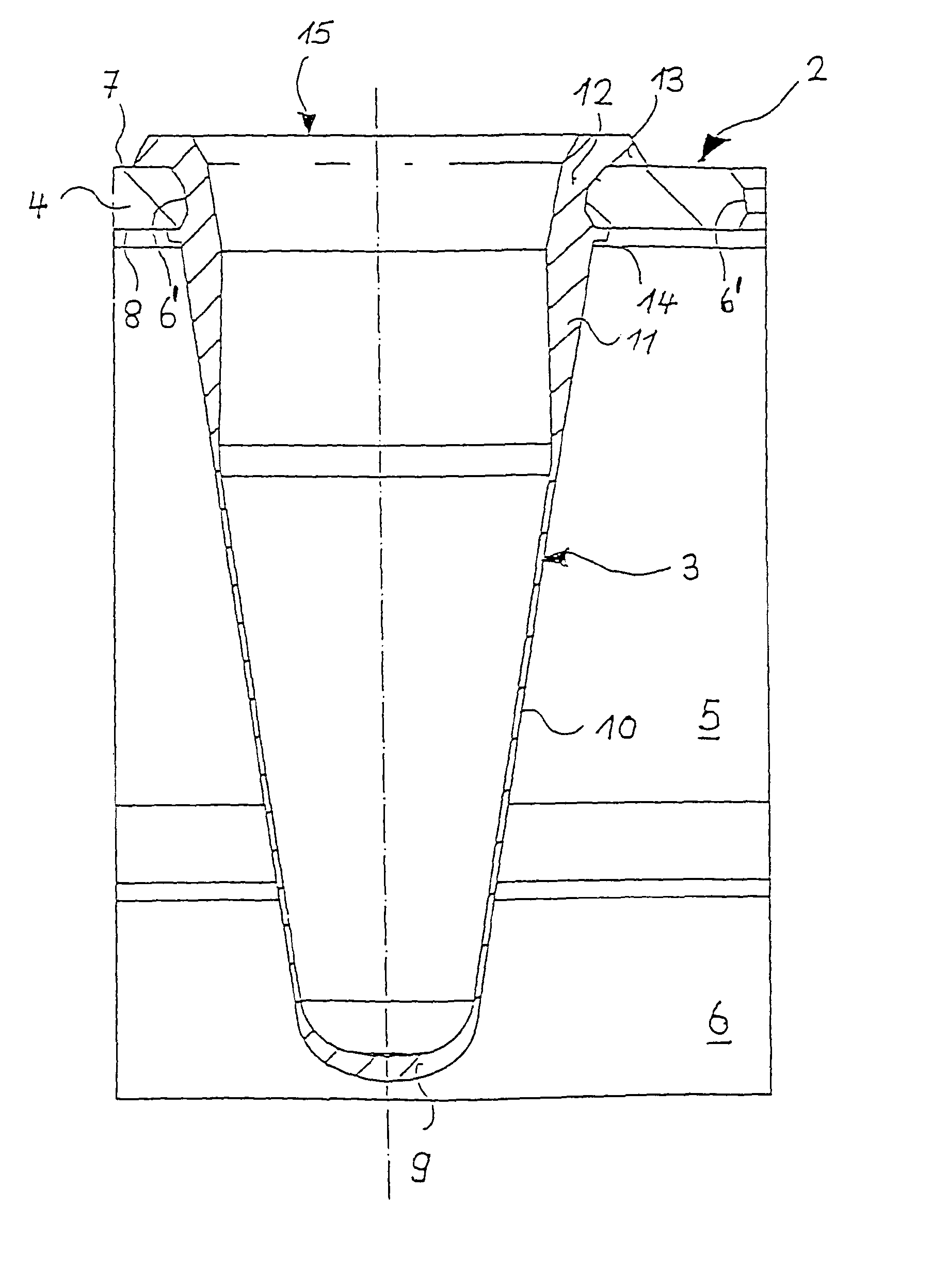

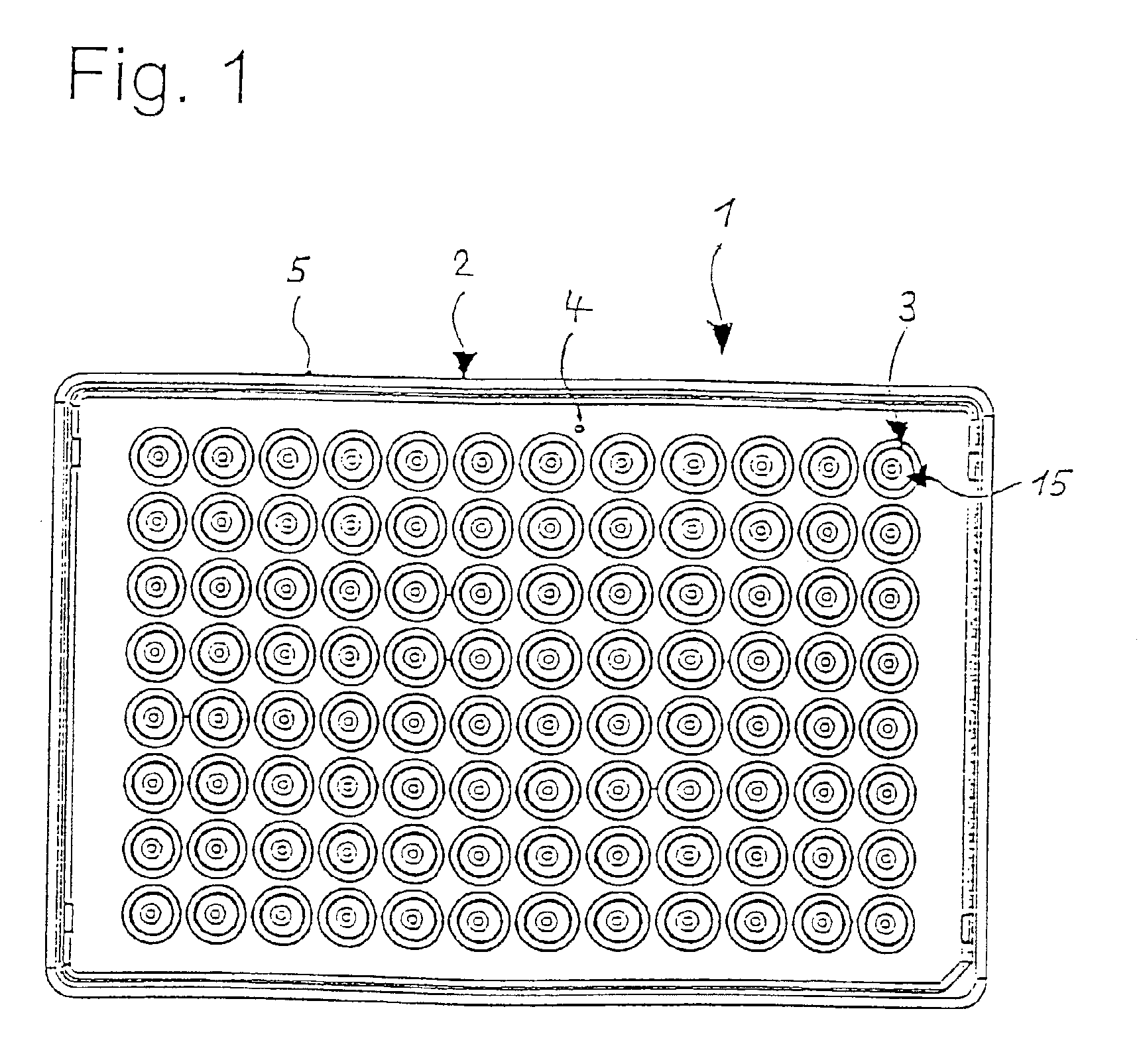

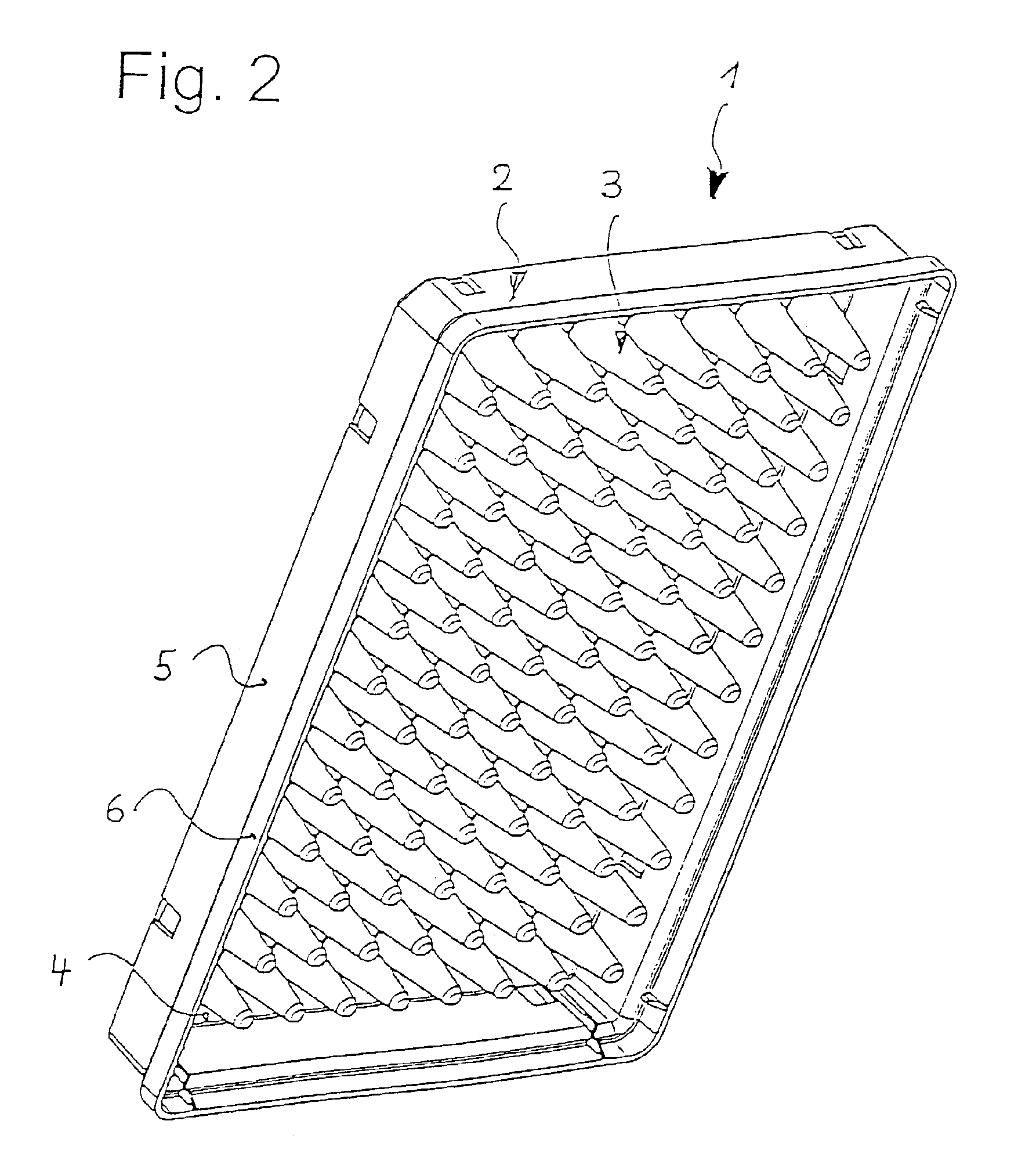

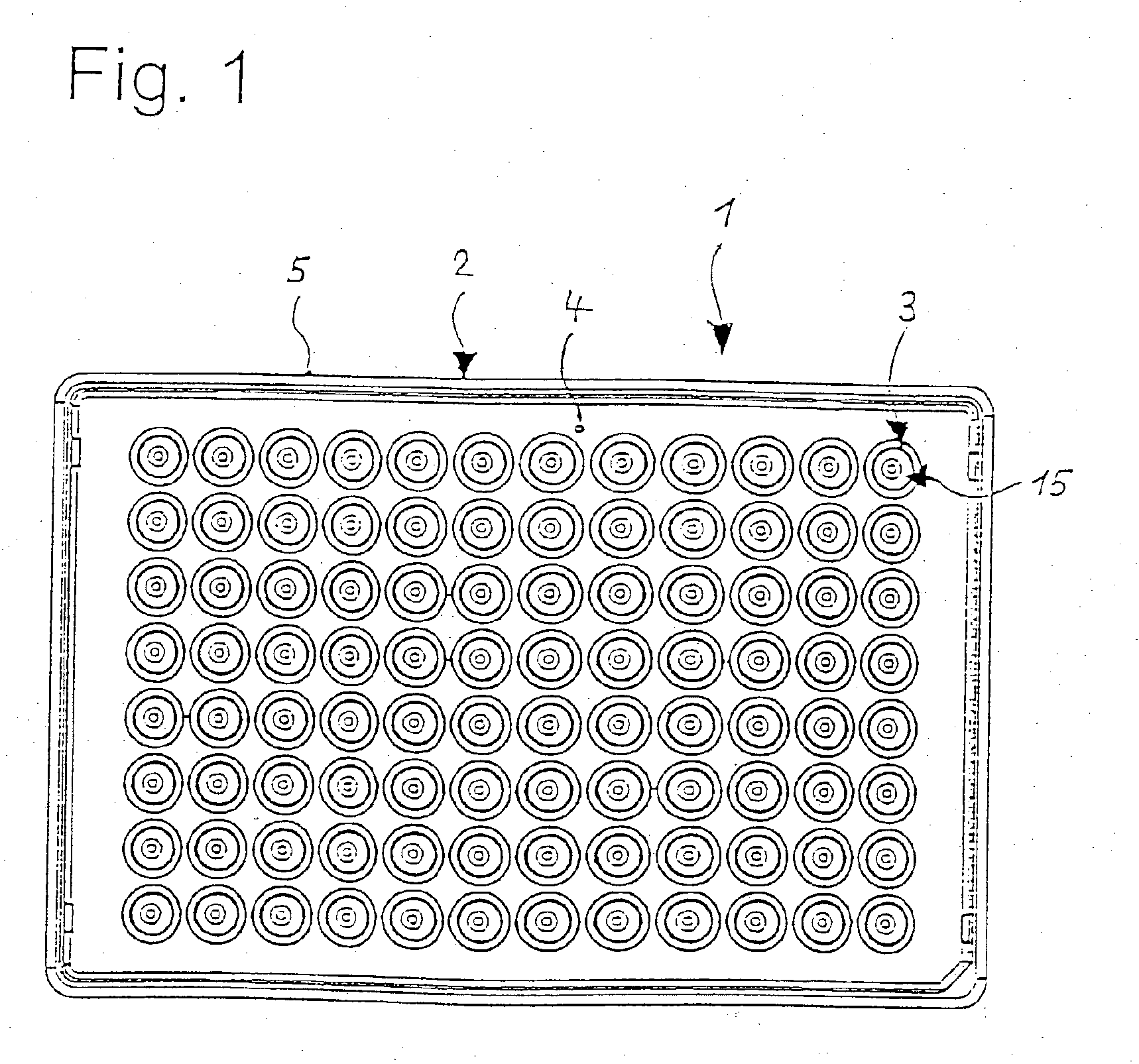

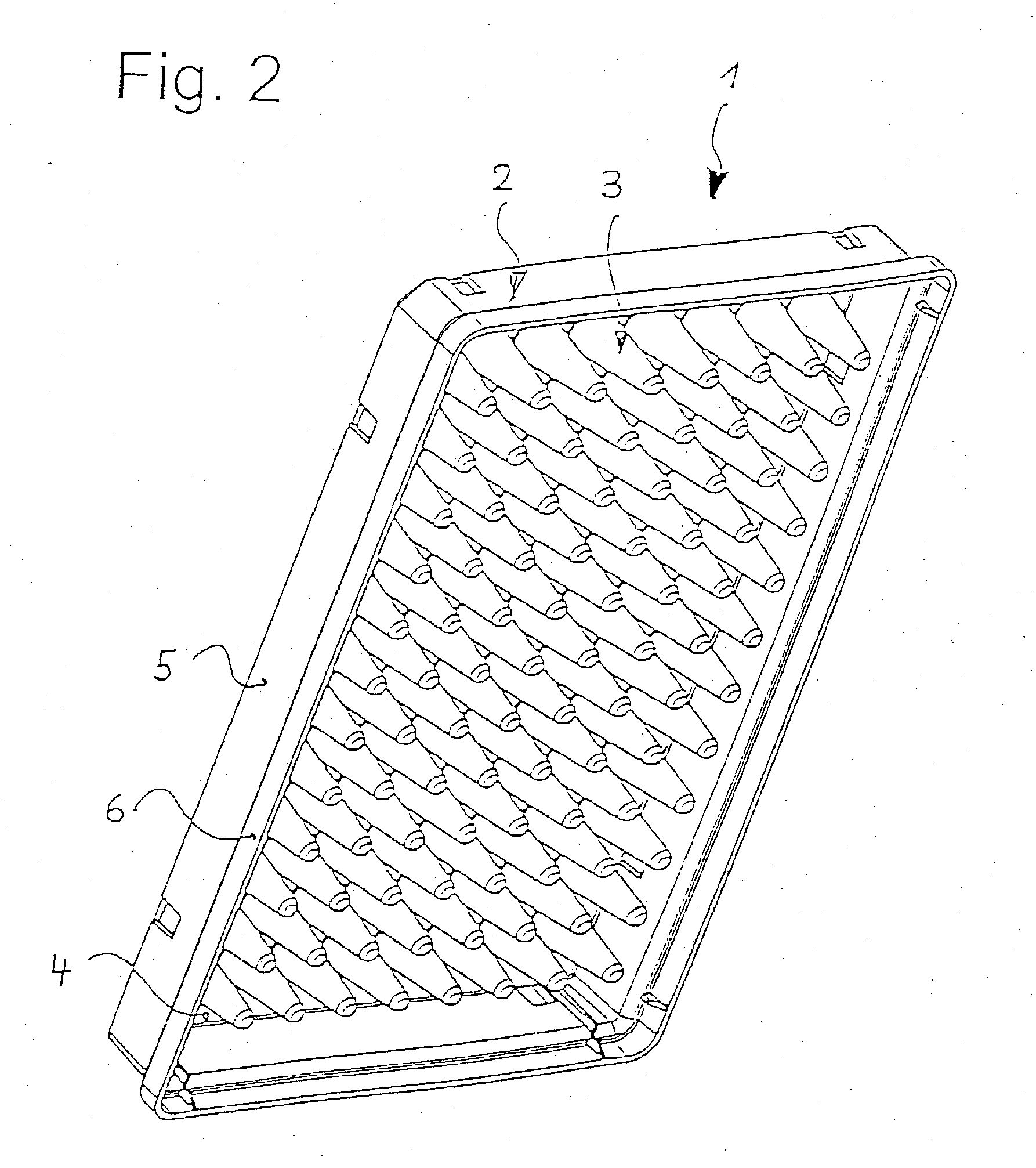

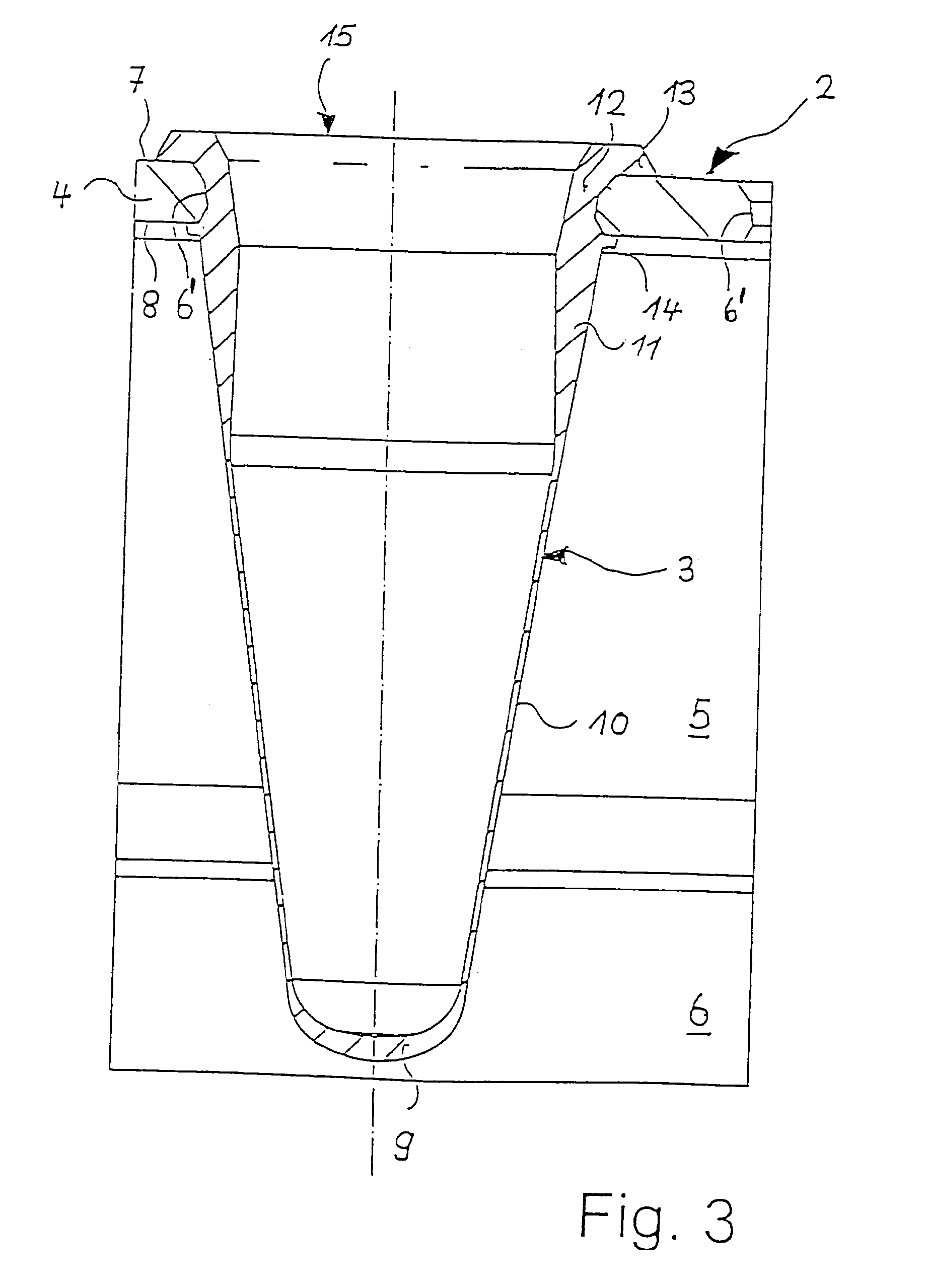

Microtitration plate

InactiveUS8728415B2Dimensionally stableIncrease injection pressureBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringPolypropylene

Owner:EPPENDORF SE

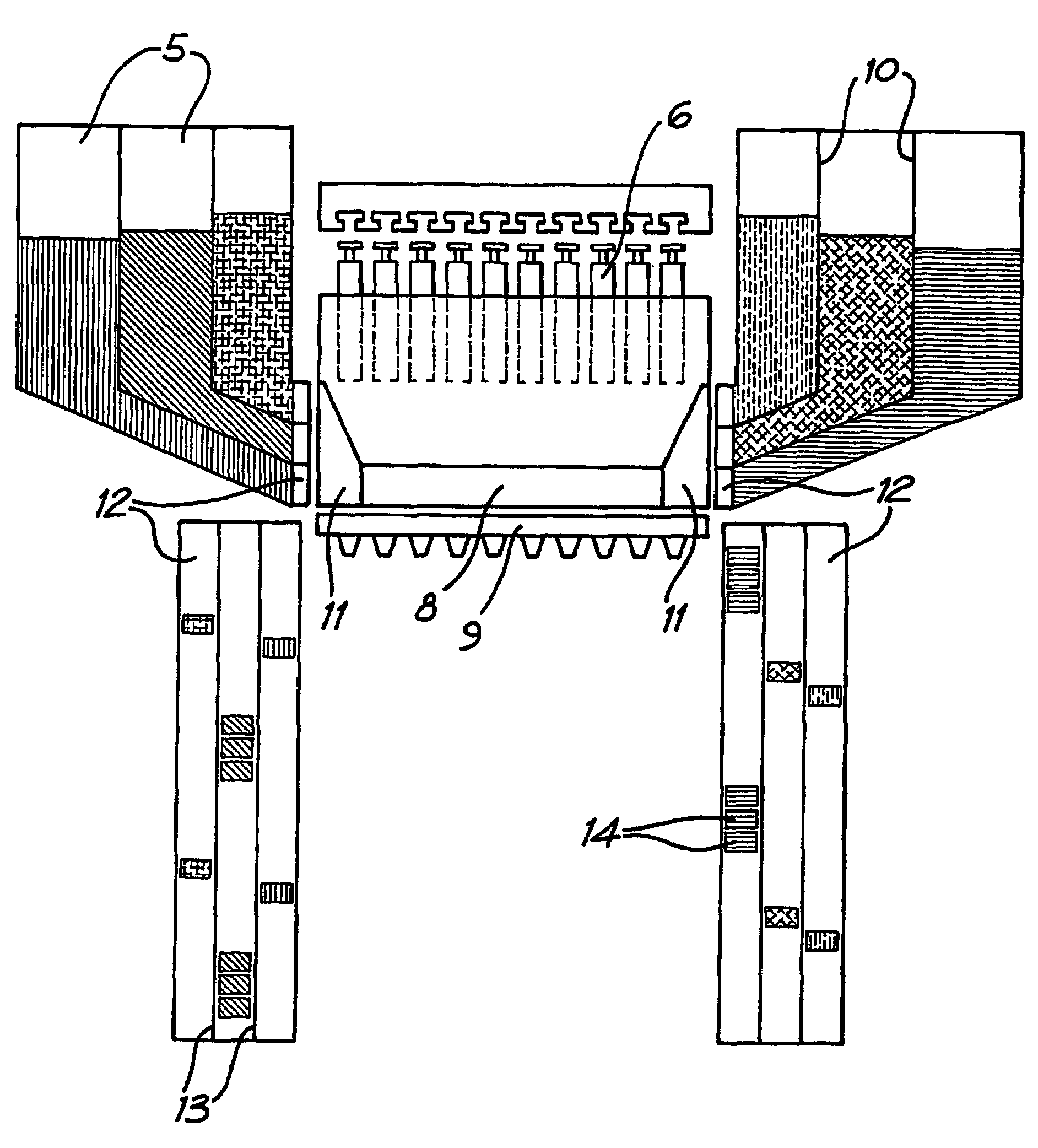

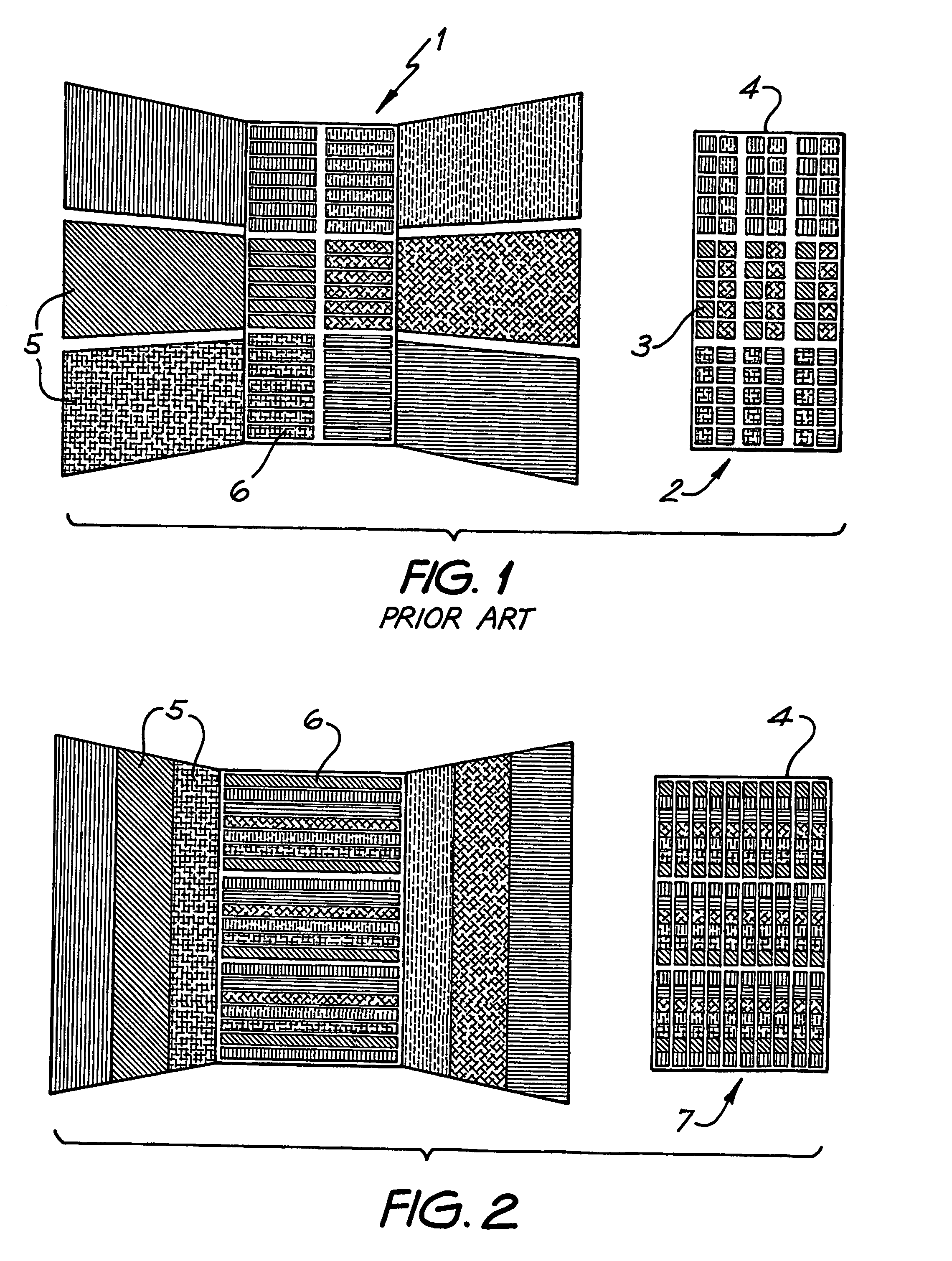

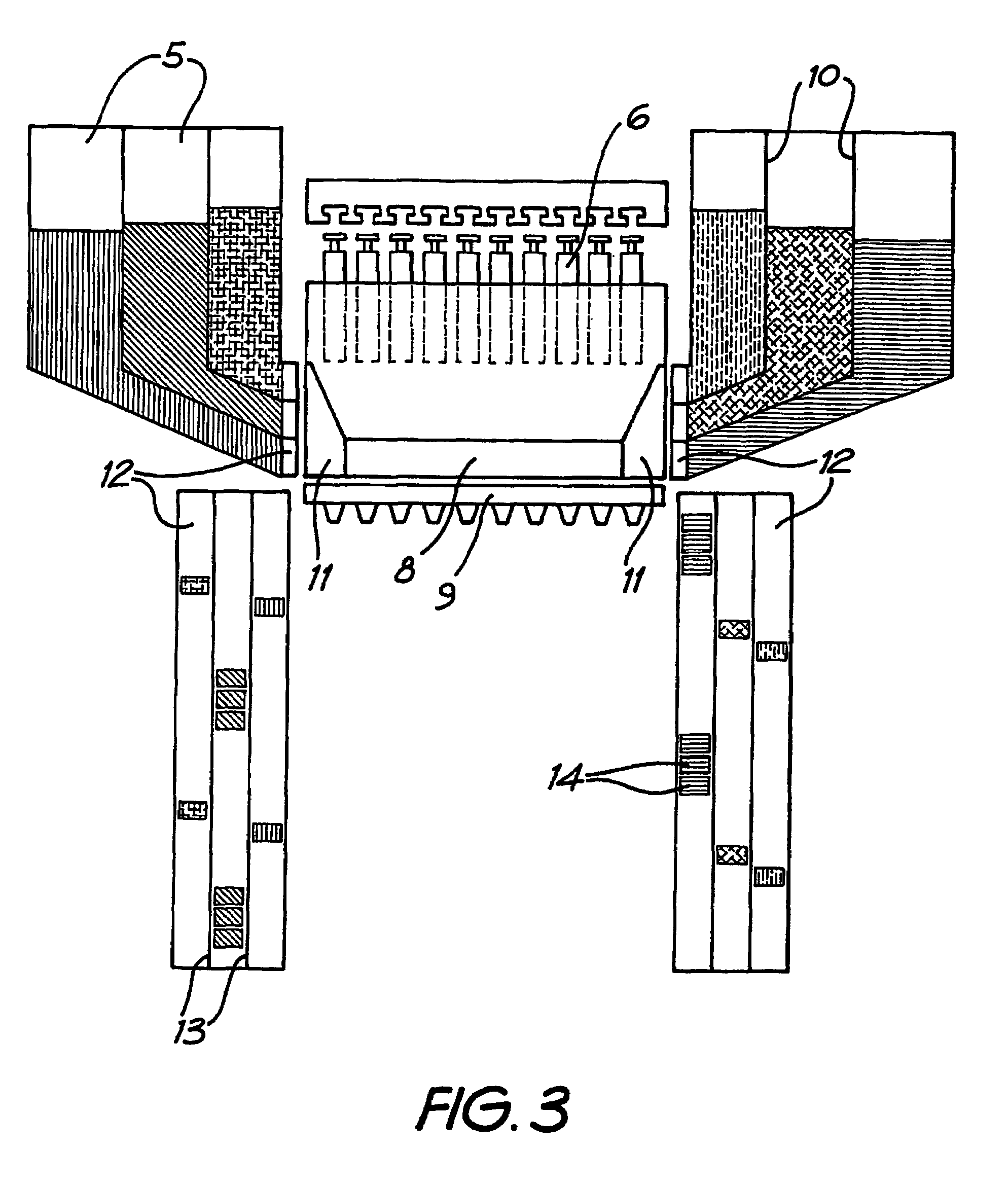

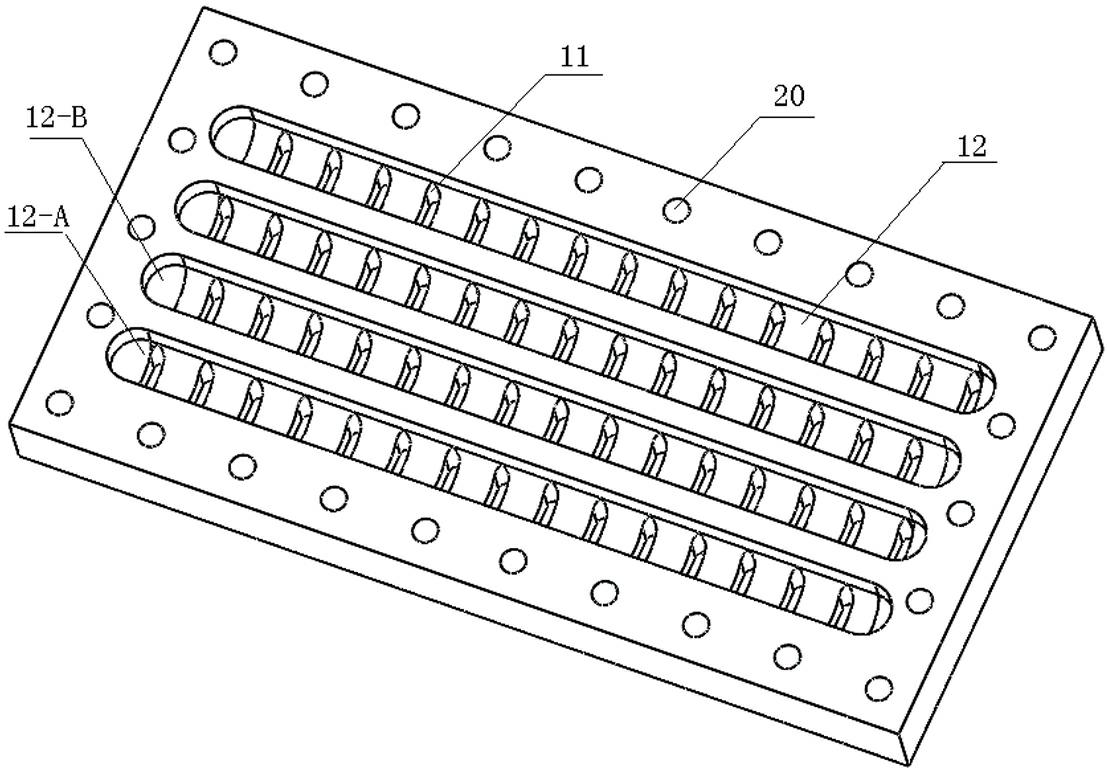

Food deposition apparatus and method of manufacturing a multi-component food product

Disclosed is apparatus for the storage and deposition of a plurality of liquid food components to a mold, said apparatus including: a deposition mechanism for intermittently depositing predetermined quantities of said plurality of liquid food components to said mold, said mechanism having a plurality of individual deposition points; a plurality of liquid food storage vessels, each having an outlet adapted to supply an individual liquid food component to said deposition mechanism; and a plurality of arrayed liquid food supply galleries extending from said liquid food storage vessels to said deposition mechanism, thereby to facilitate flow of said food components to said deposition points; where in said plurality of liquid food storage vessels are each equipped with an elongate outlet, said outlet being adapted to allow said liquid food to flow substantially directly into each supply gallery along that inlet region; and wherein there is provided a means for selectively allowing or preventing flow of the contents of each or any of said vessels to each or any of said galleries.

Owner:WM WRIGLEY JR CO

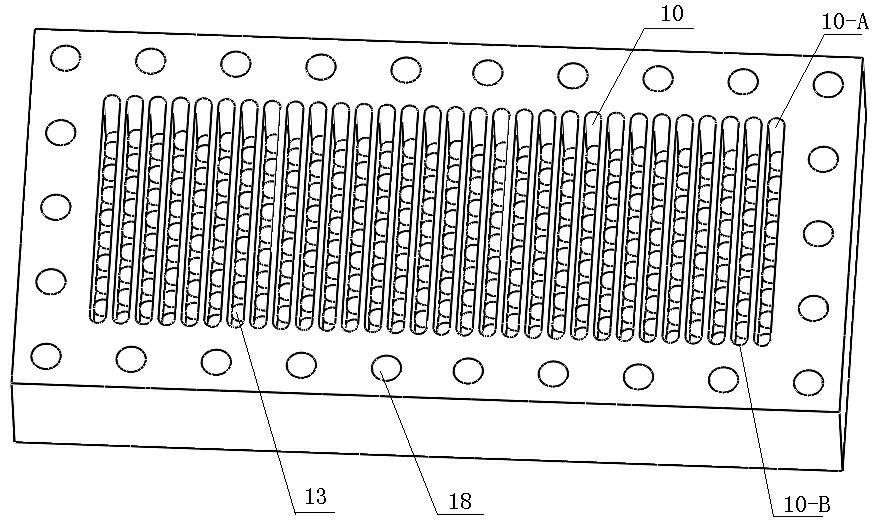

Honeycomb type heat exchanger adopting multiple times of diffluence and confluence

ActiveCN102322757AIncrease throughputUniform fluid flowLaminated elementsStationary plate conduit assembliesSuspended particlesHoneycomb

The invention discloses a honeycomb type heat exchanger adopting multiple times of diffluence and confluence. First-time diversion grooves used for performing confluence and diffluence on honeycomb holes in the first-time diversion grooves are alternately arranged on same end surfaces of honeycomb bodies in an upper heat exchange plate and a lower heat exchange plate, and confluence grooves and diffluence grooves in the first-time diversion grooves are arranged alternately; second-time to fourth-time diversion grooves and inter-communicated through holes which are communicated with the first-time diversion grooves are formed in an upper separation-combination device and a lower separation-combination device respectively, and the second-time to fourth-time diversion grooves realize 2 to 4 times of step-by-step diffluence and confluence; an upper connecting plate is arranged at the upper end of the upper separation-combination device, and a lower connecting plate is arranged at the lower end of the lower separation-combination device; a plurality of connecting through holes communicated with 2 to 4 diffluence or confluence grooves are formed in the upper connecting plate and the lower connecting plate; and cold fluid inlet and outlet and hot fluid inlet and outlet are formed at two ends of the upper connecting plate and the lower connecting plate respectively. The honeycomb typeheat exchanger is large in treatment flow capacity, high in heat exchange efficiency, strong in compressive strength, small in volume, light in weight and high in sealability, can treat liquid with high viscosity and suspended particles, can reduce the cost and is convenient to clean and mount, and the flow velocity of the fluid in each honeycomb hole is uniform and no laminar flow and dead corner exists.

Owner:JIANGSU TONGSHENG HEAT EXCHANGER

Microtitration plate

InactiveUS20120129250A1Dimensionally stableIncrease injection pressureBioreactor/fermenter combinationsBiological substance pretreatmentsMechanical engineeringEngineering

Owner:EPPENDORF SE

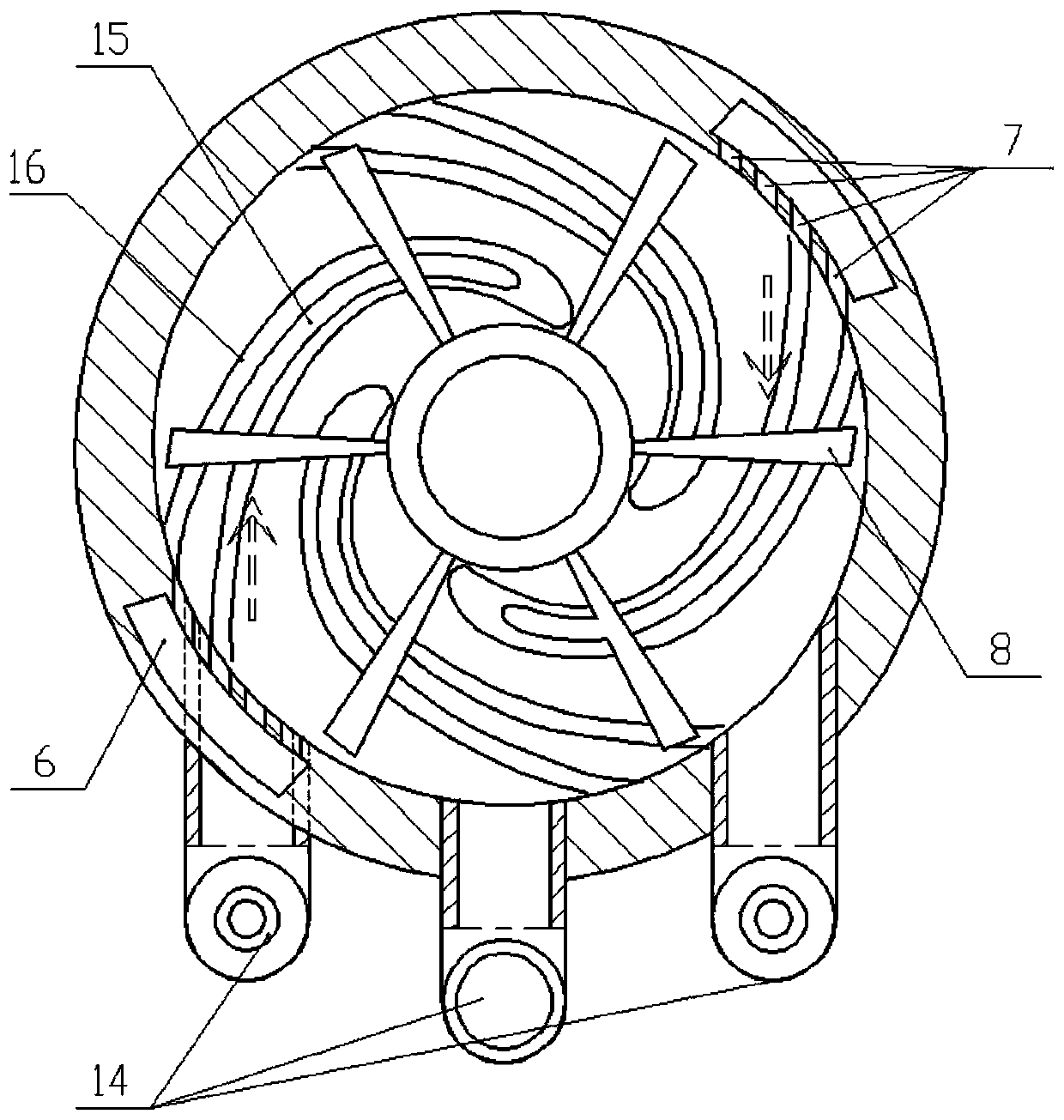

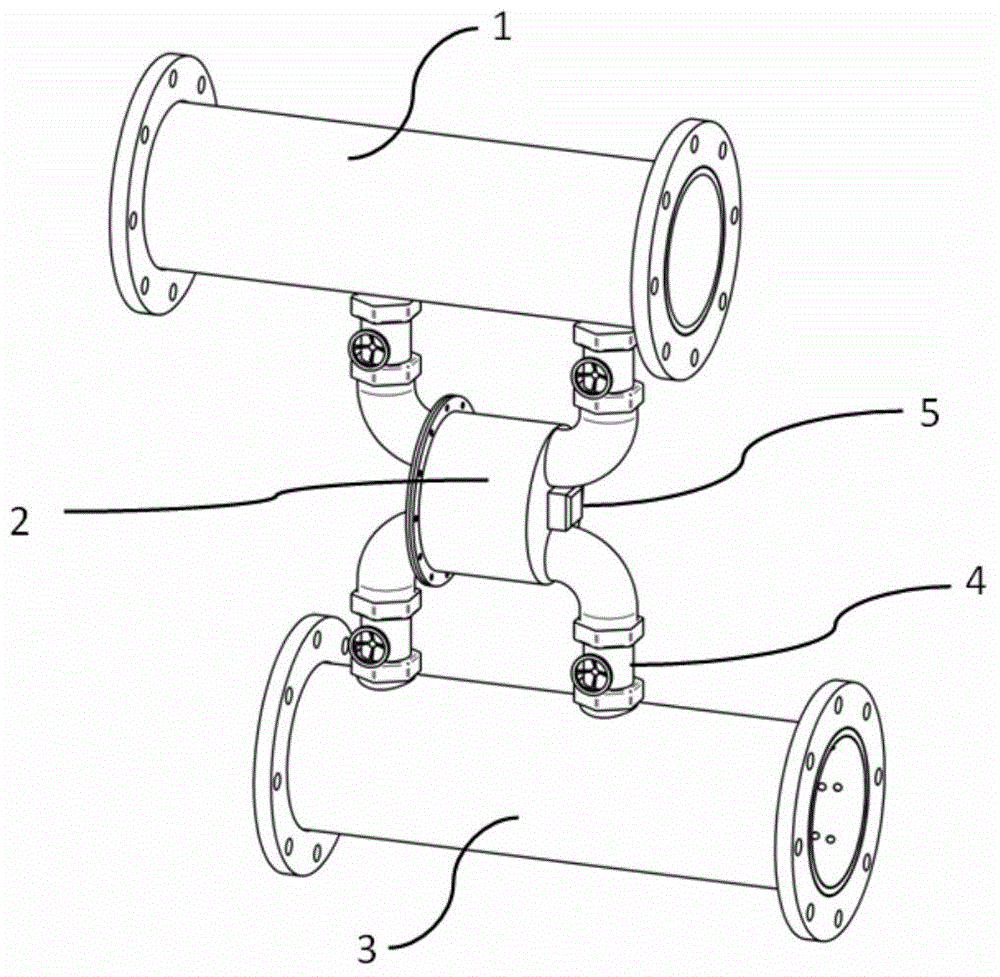

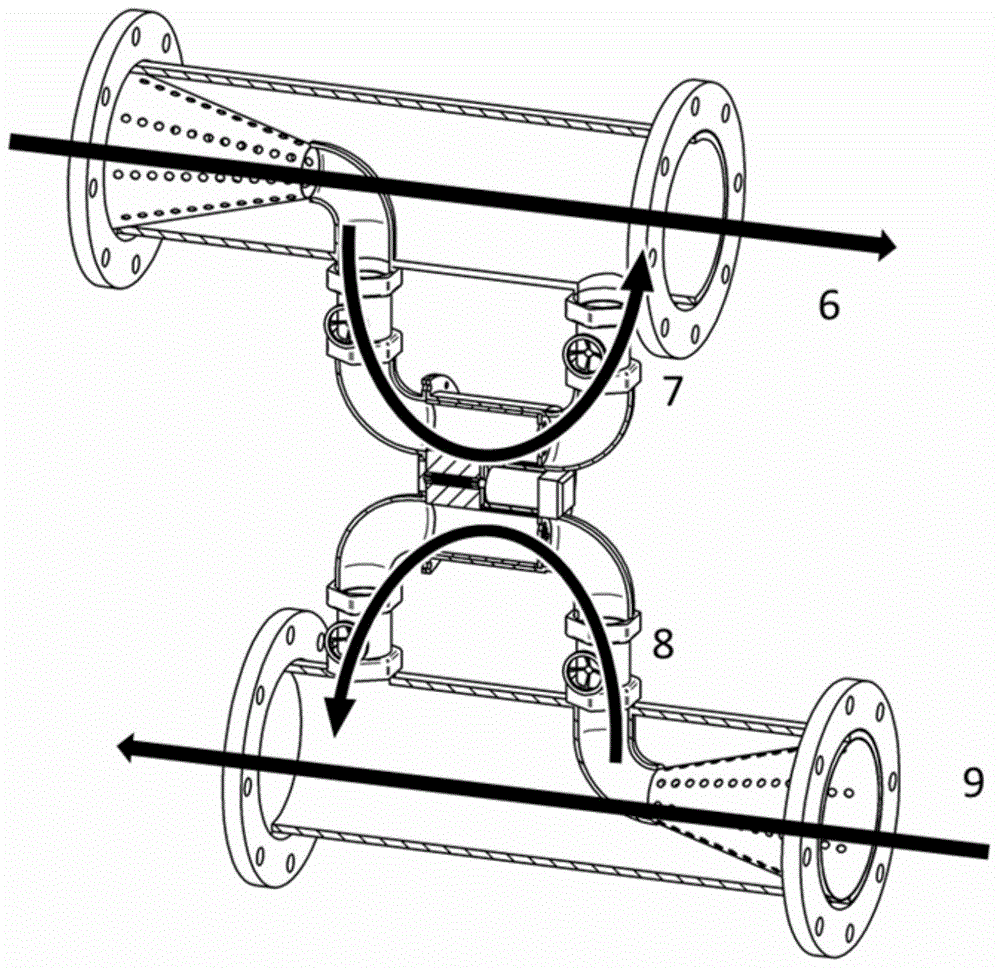

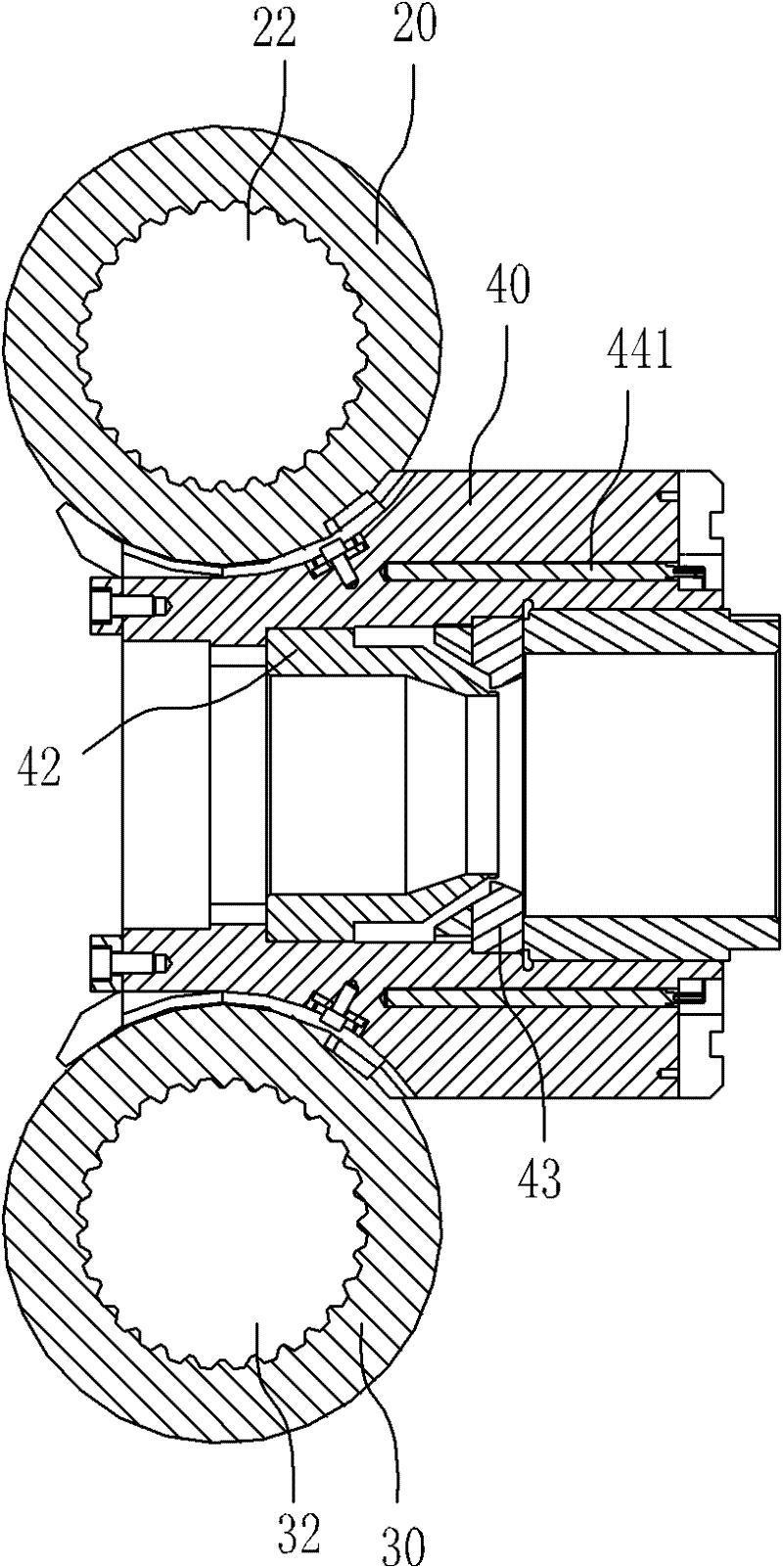

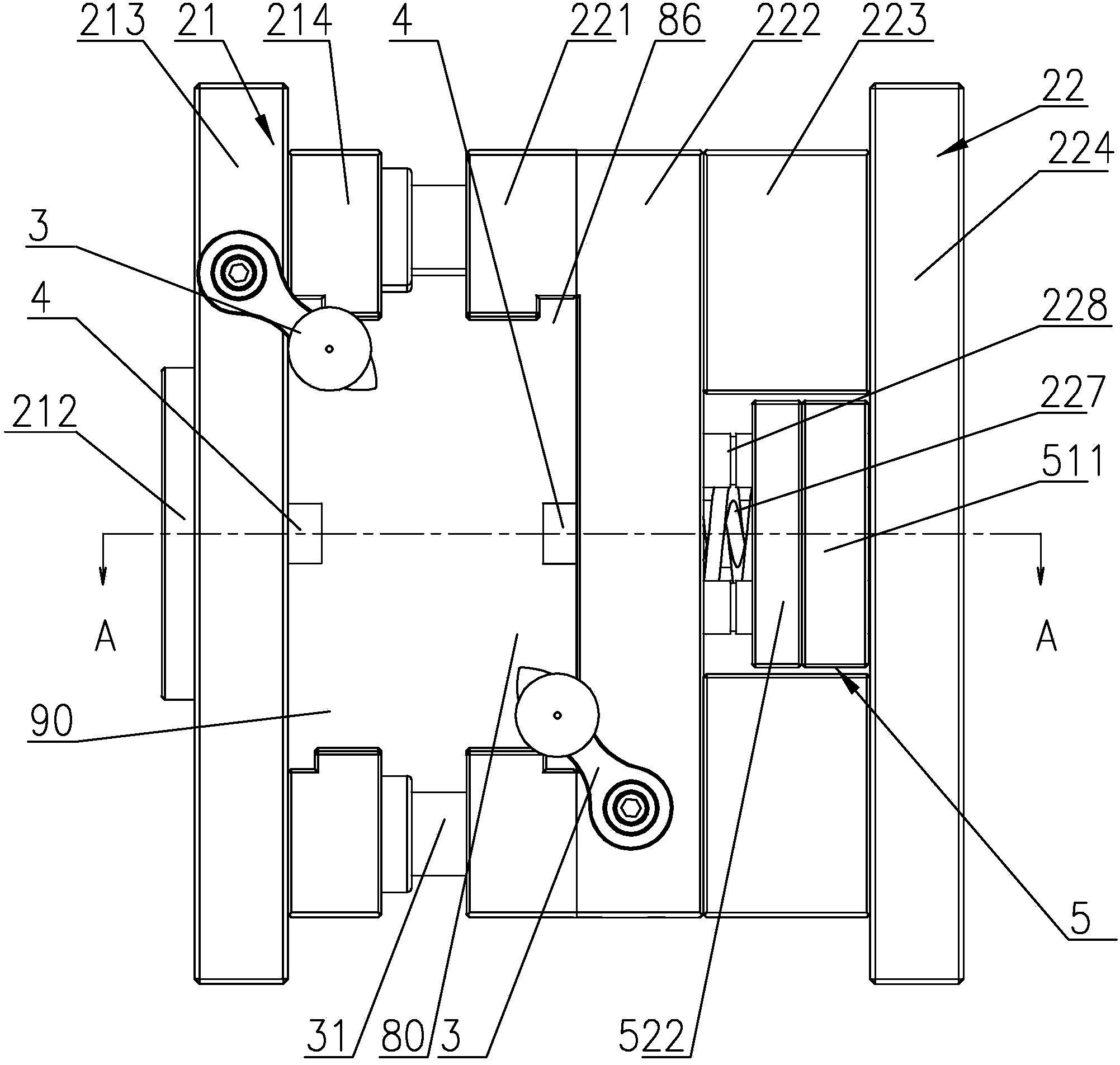

Rotary rubber ball automatic on-line continuous cleaning device and method

ActiveCN104896993ARunner shortLess curvesChemical industryNon-rotary device cleaningBall valveEngineering

The invention discloses a rotary rubber ball automatic on-line continuous cleaning device and a method. The cleaning device comprises a ball collecting drum, a ball storing drum, a ball charging drum, ball valves and a self-control motor and is characterized in that the ball storing drum comprises a cover plate, an inner drum, a filtering hole plate and an outer drum; the inner drum fixedly sleeve a rotating shaft of the self-control motor and is driven to rotate by the self-control motor; the outer drum sleeves the inner drum; the outer drum is connected with the cover plate; multiple through holes used for storing rubber balls are distributed in the inner drum along the circumference; the filtering hole plate is arranged between the inner drum and a bottom plate of the outer drum; a ball collecting opening and a ball outlet are arranged in the cover plate; the ball outlet is connected with an outlet end of the ball charging drum via a ball valve 3; a water inlet and a water outlet are arranged in the bottom plate; the water outlet is connected with the outlet end of the ball collecting valve via a ball valve 2; a ball collecting filtering screen is arranged in an inlet end of the ball collecting drum; the ball collecting filtering screen is connected with the ball collecting filtering screen via a ball valve 4; and the cleaning device is widely applicable in energy and chemical engineering field.

Owner:广州马顿节能工程设备有限公司

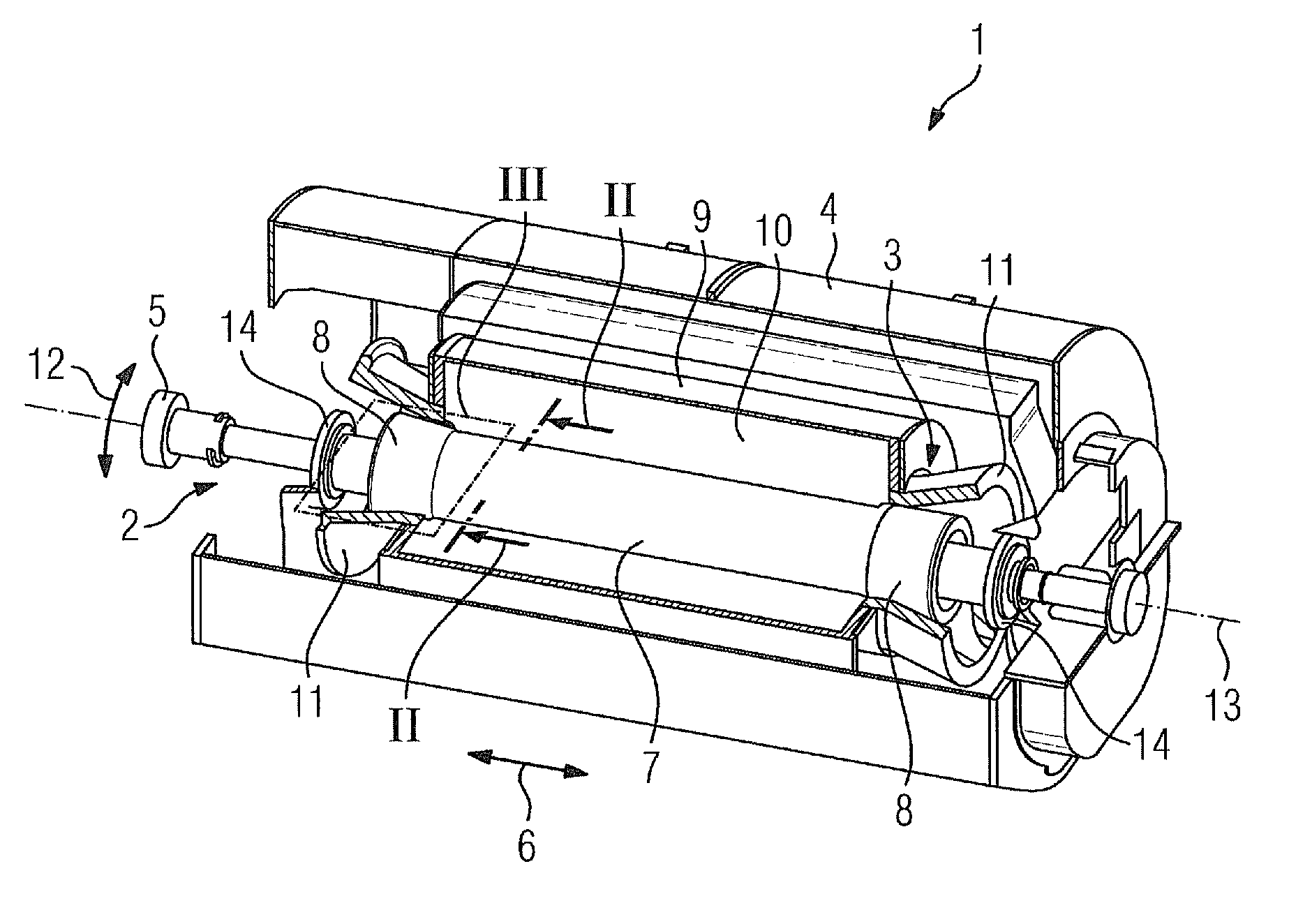

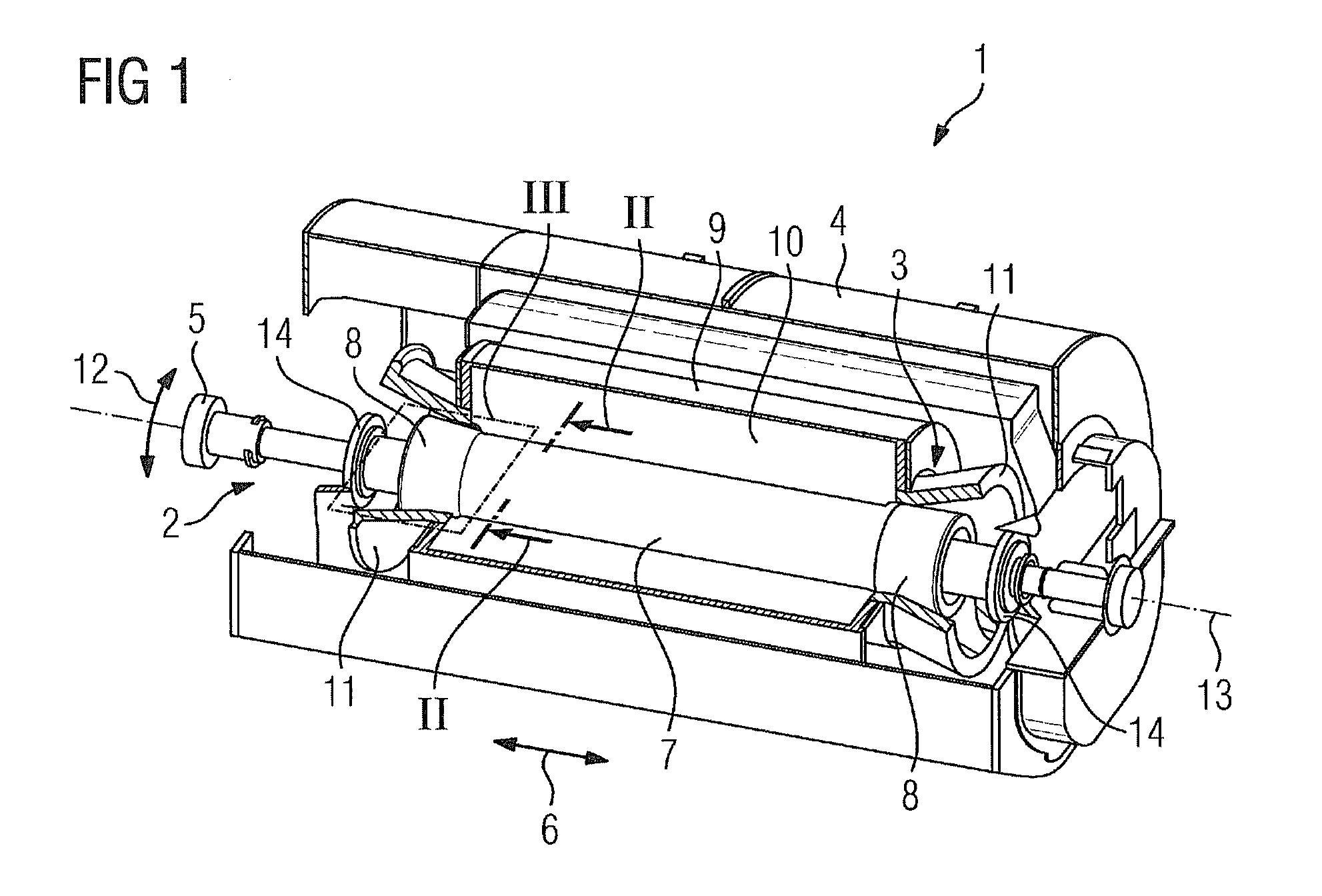

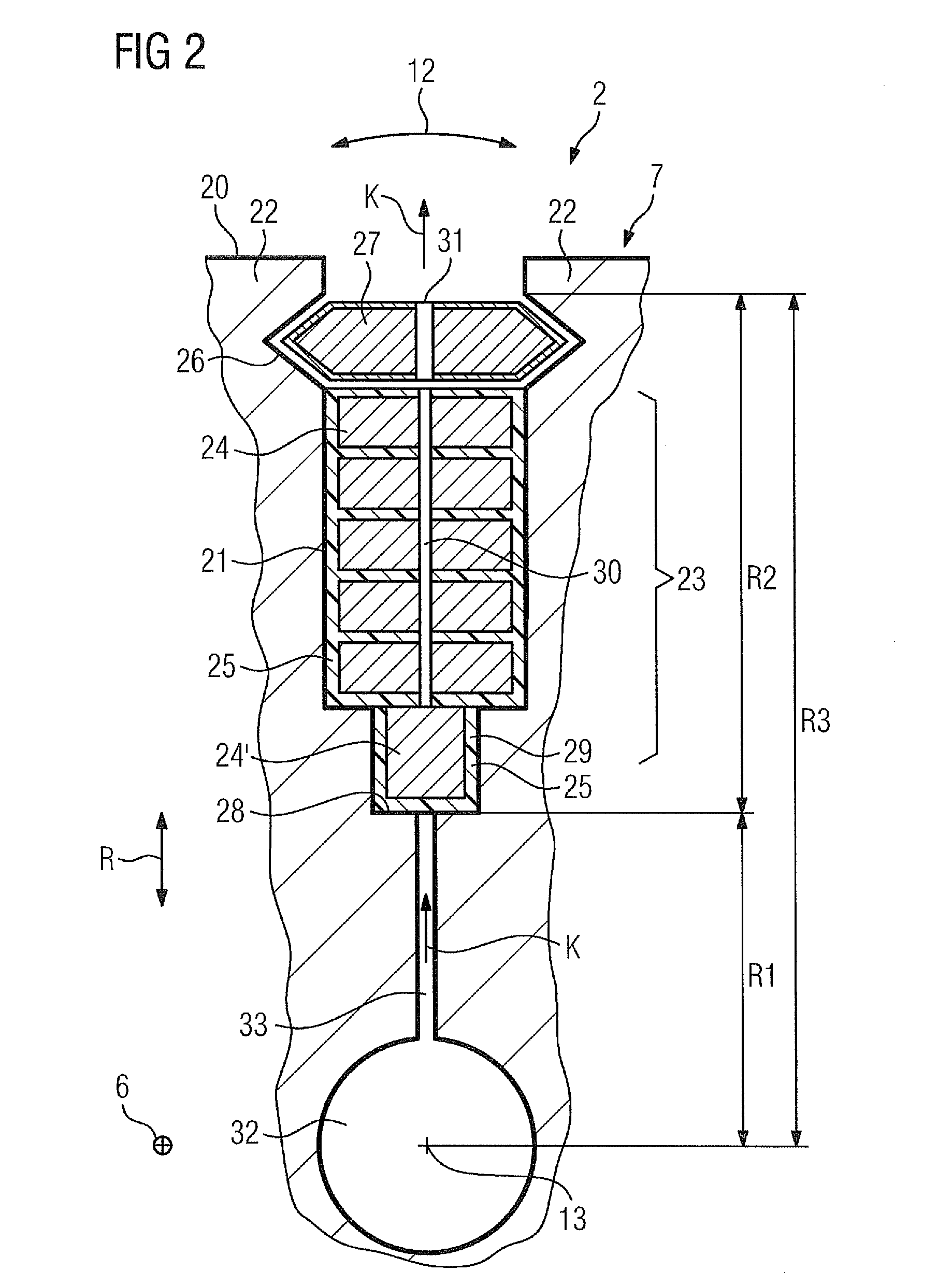

Rotor for a turbo generator, and turbo generator comprising a rotor

InactiveUS20120119603A1Maximize lengthImprove cooling effectMagnetic circuit rotating partsCooling/ventillation arrangementEngineeringMechanical engineering

A rotor for a turbo generator is provided. The rotor includes a cylindrical rotor shaft that expands in the center to form a rotor body, grooves introduced into the cylindrical surface of the rotor body, an excitation winding accommodated in the grooves, a feeding duct through which a cooling gas flows, and cooling ducts which penetrate the excitation winding substantially in the radial direction and connect the feeding duct to respective outlets in the cylindrical surface of the rotor body A distribution duct extending in the longitudinal direction of the shaft is arranged in the area of the central longitudinal axis. The feeding ducts are connected to the distribution duct via junction ducts. An admission duct for feeding the cooling gas is provided for each distribution duct.

Owner:SIEMENS AG

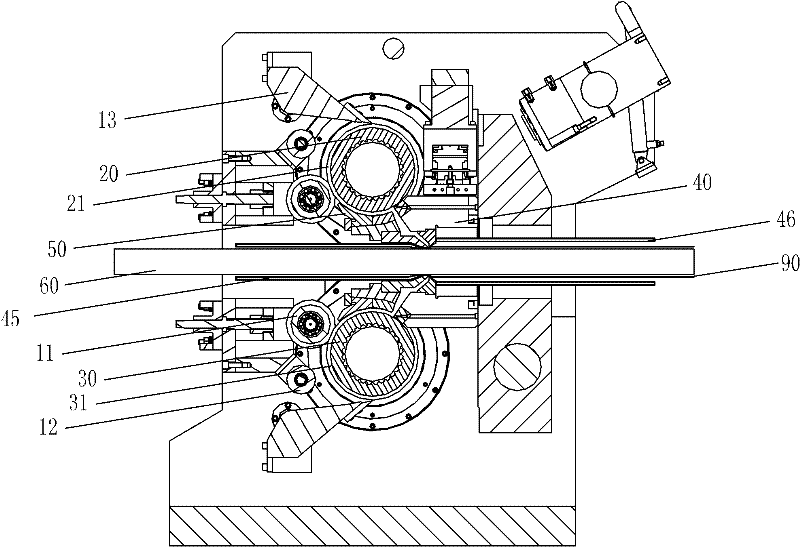

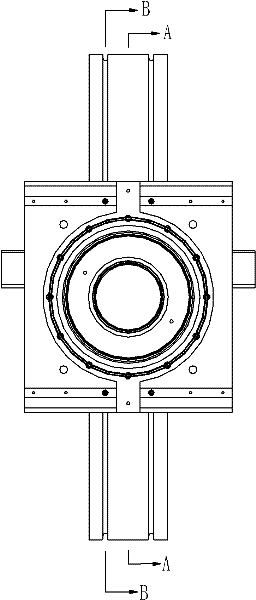

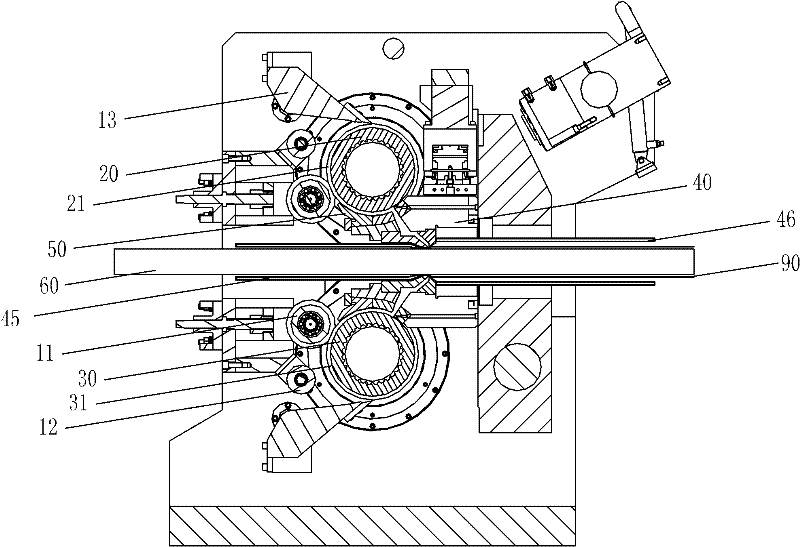

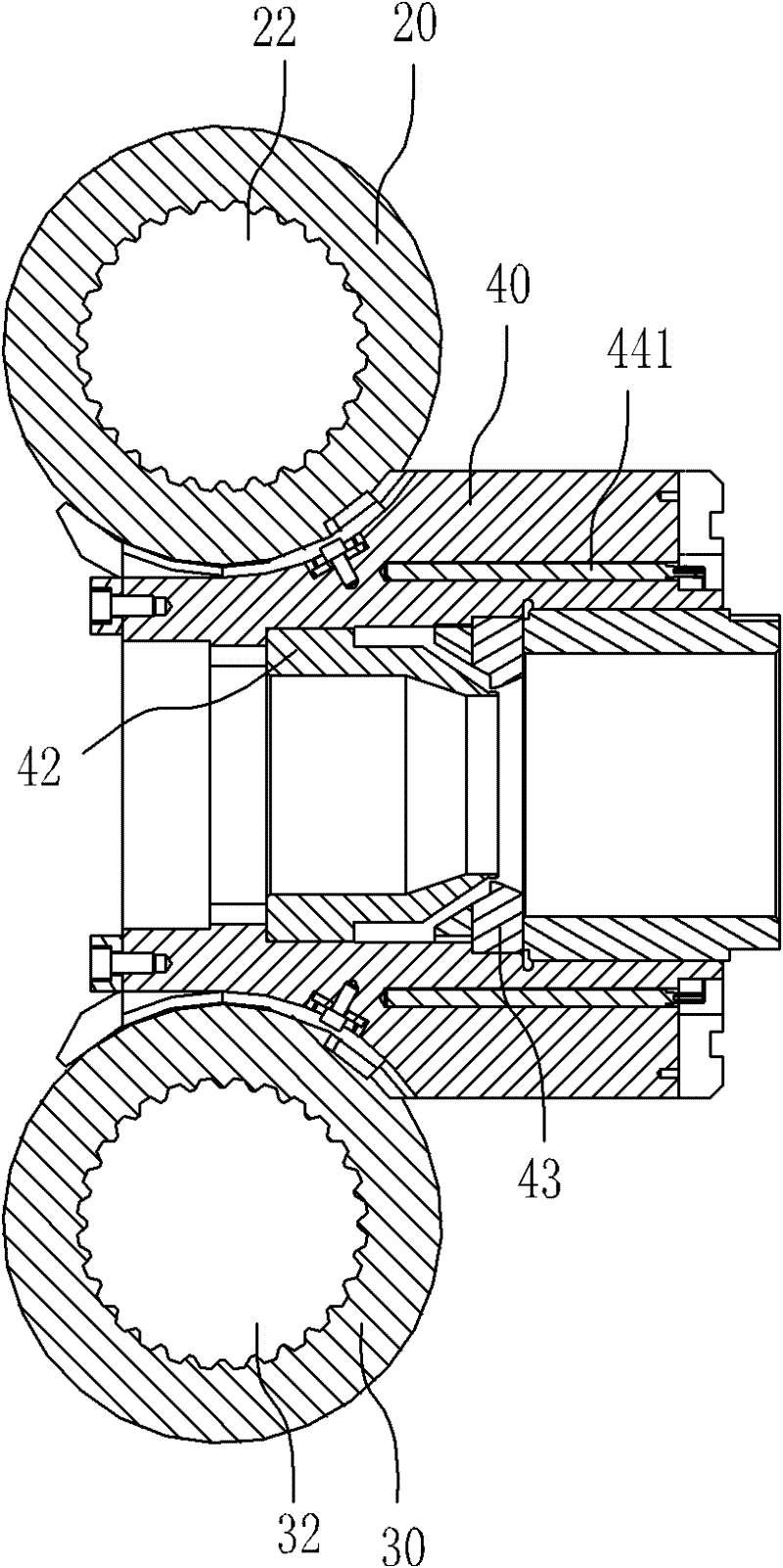

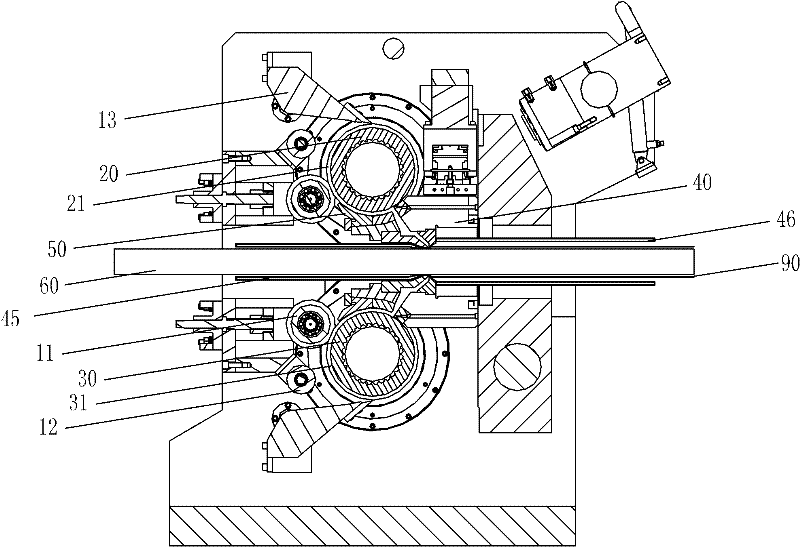

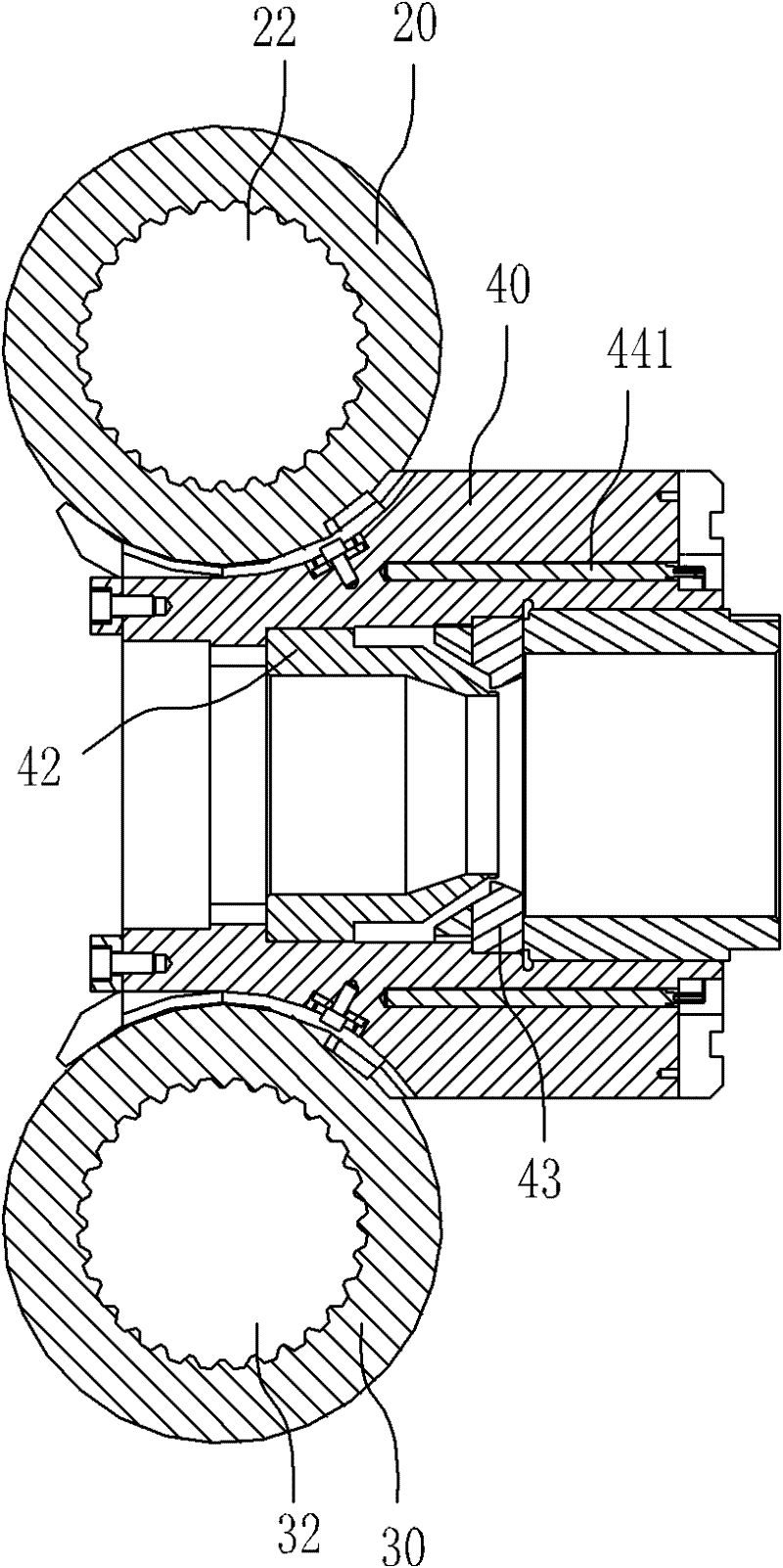

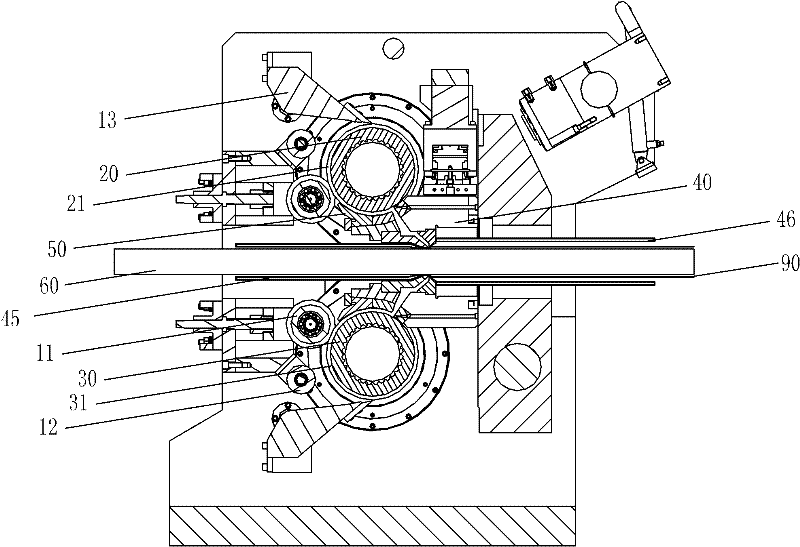

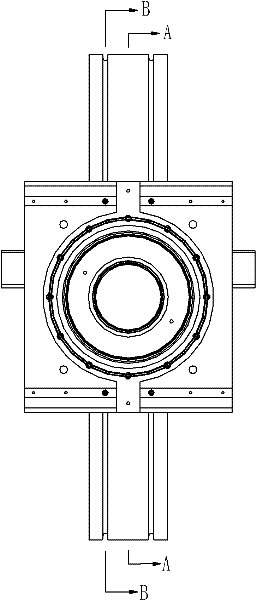

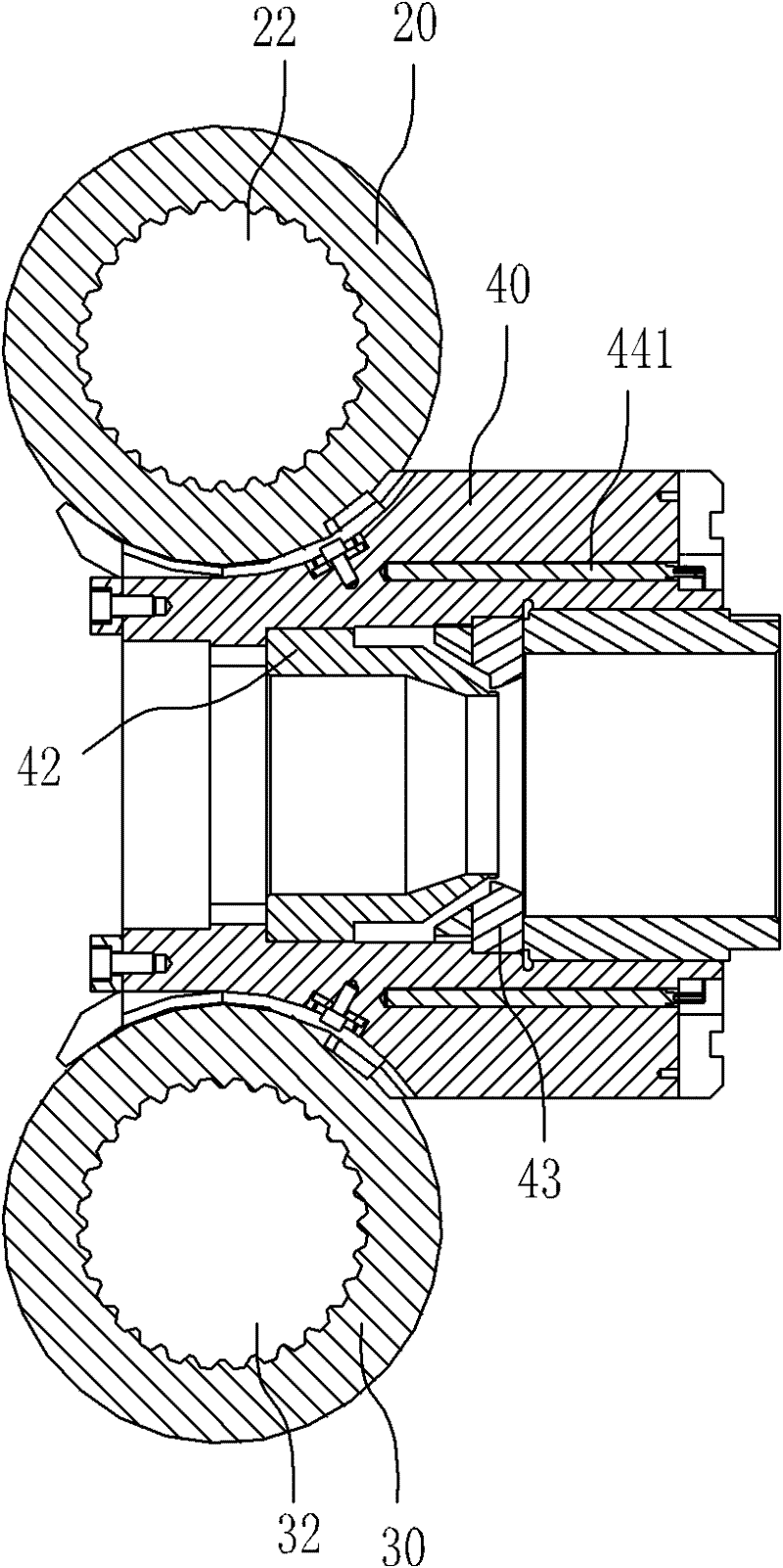

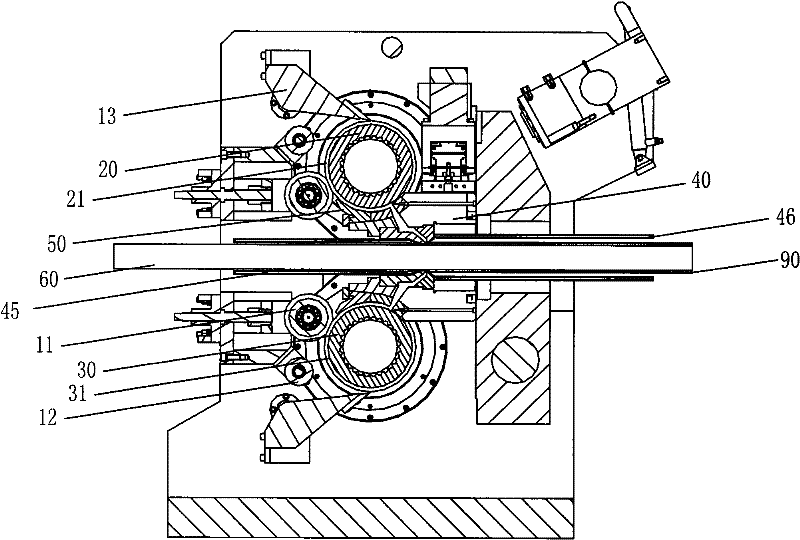

Continuous extrusion device

InactiveCN102205353ARunner shortSmall temperature differenceExtrusion diesTemperature differenceMechanical engineering

The invention relates to a continuous extrusion device, the frame of which is equipped with two extrusion wheels with mutually parallel rotating shafts. Opposite in rotating directions, each of the extrusion wheels has respectively at least one circumferential extrusion wheel groove on wheel rims. And the extrusion wheel grooves are respectively provided with a mating guide base. The guide bases and the extrusion wheel grooves together form extrusion cavities for passing blank materials. A die holder is installed between the extrusion wheels, and a channel is positioned inside the die holder for cables. Holes communicated with the extrusion cavities are symmetrically arranged on two sides of the axial core wire of the die holder along the radial direction. The holes are also communicated with a coated cavity of the die holder, and the outlet of the coating cavity is coated at the periphery of the cable outlet end in the channel. After entering the extrusion cavities, the blank materials for extrusion get into the coated cavity through the holes on the die holder. As the holes are arranged symmetrically along the radial direction of the die holder, so the blank materials for extrusion get into the coated cavity simultaneously from the upper and lower positions of the die holder. Thus, the channel for blank materials is shortened, and the temperature difference is small. With sufficient blank materials passing through the die holder, the device of the invention has increased output.

Owner:HEFEI SMARTER TECH GROUP CORP

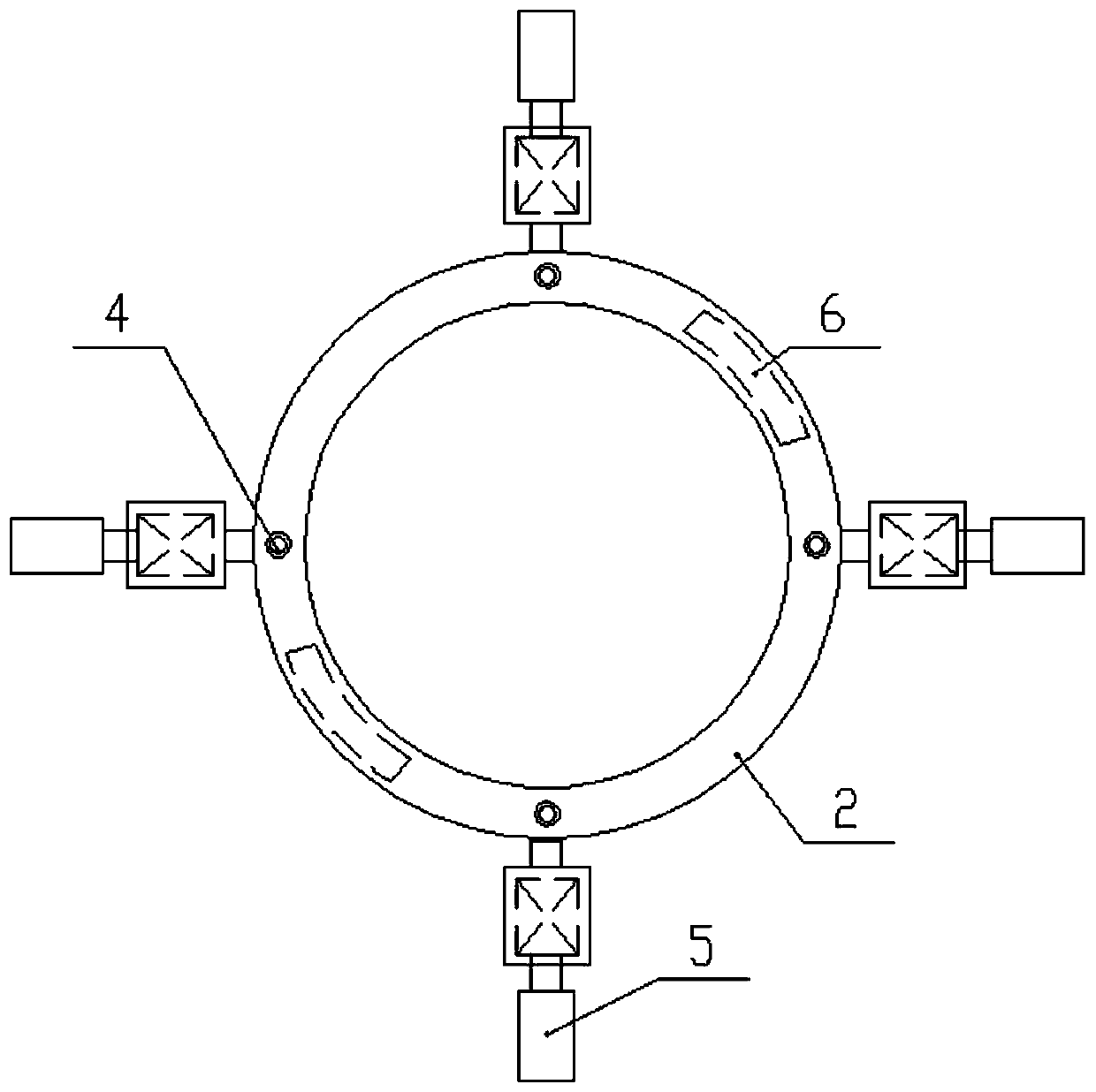

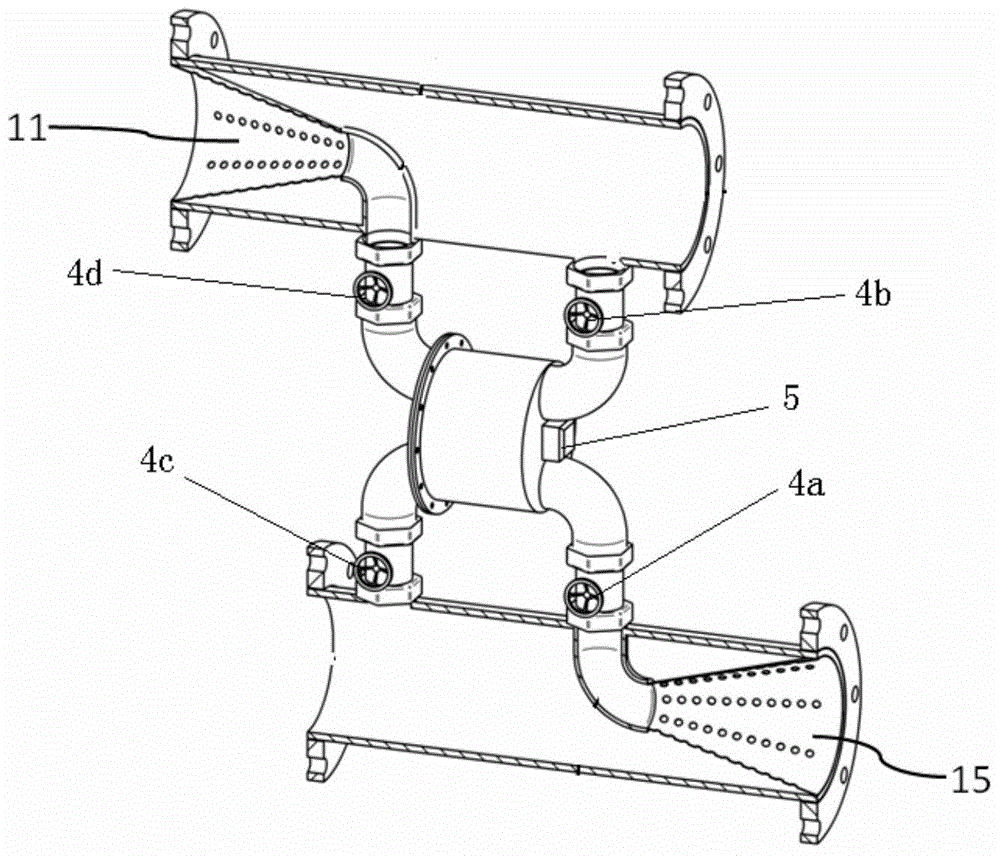

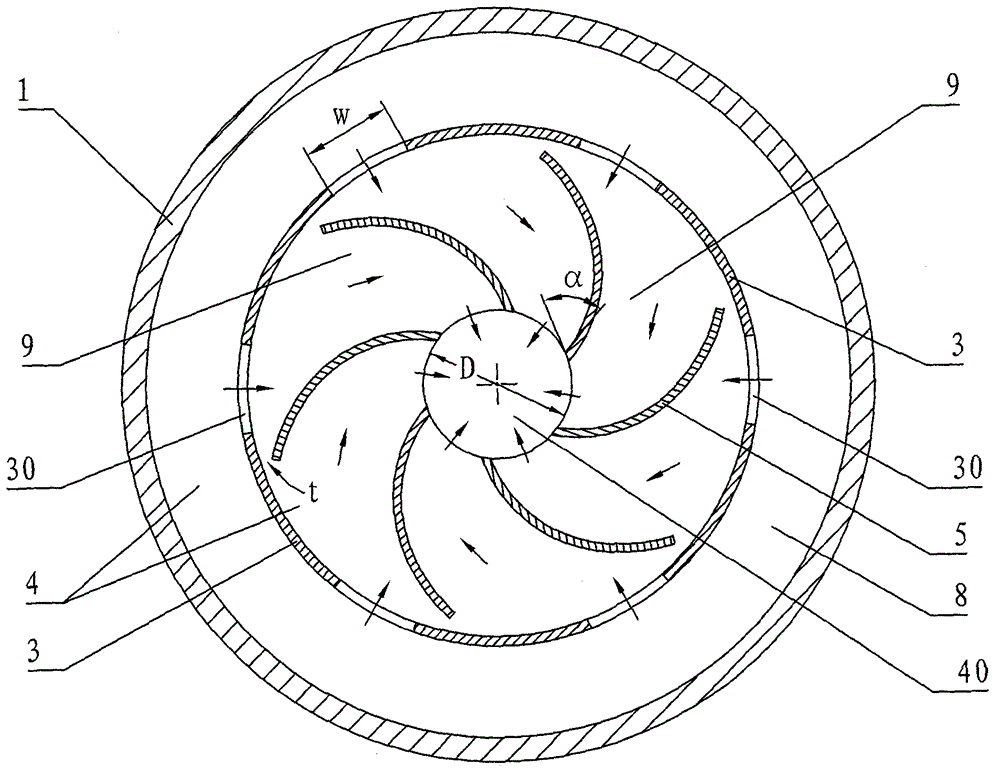

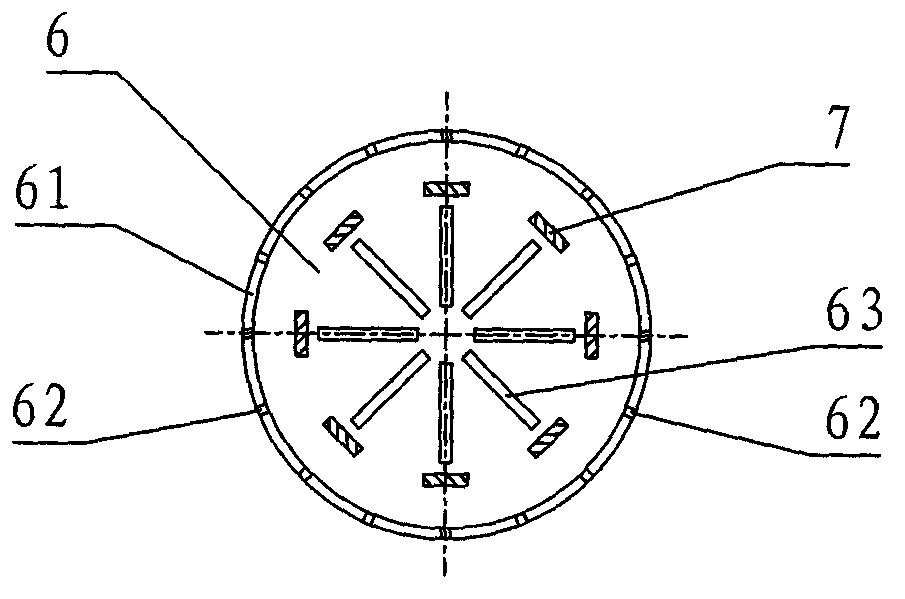

Quench mixer used for hydrogenation reactor

ActiveCN104096517AWell mixedMixed stronglyFlow mixersChemical/physical processesGas phaseEngineering

The invention discloses a quench mixer used for a hydrogenation reactor and aims to solve problems that a mixing effect is poor and a flow resistance of a mixed material flow is large when a quench mixer in the prior art is used for mixing and distributing a mixed material flow having a large amount of gas-phase reactants. The quench mixer is provided with a plurality of rotational-flow plates (5), wherein tops of the rotational-flow plates (5) are connected to a top baffle (2) and bottoms of the rotational-flow plates (5) are connected to a shutoff plate (4). A central hole (40) is formed in the center of the shutoff plate (4). A distribution plate (6) is arranged under the central hole. At least four arc-shaped plates (3) are disposed between the top baffle and the shutoff plate, around an edge of the top baffle and at external ends of the rotational-flow plates. A mixed material flow inlet (30) is arranged between each two adjacent arc-shaped plates. Each rotational-flow plate is arranged at a position corresponding to each mixed material flow inlet. A top baffle folded-edge (21) is disposed at the periphery of the top baffle. A distribution plate folded-edge (61) is disposed at the periphery of the distribution baffle. The quench mixer is mainly used in the hydrogenation reactor used for processing light-weight oil.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

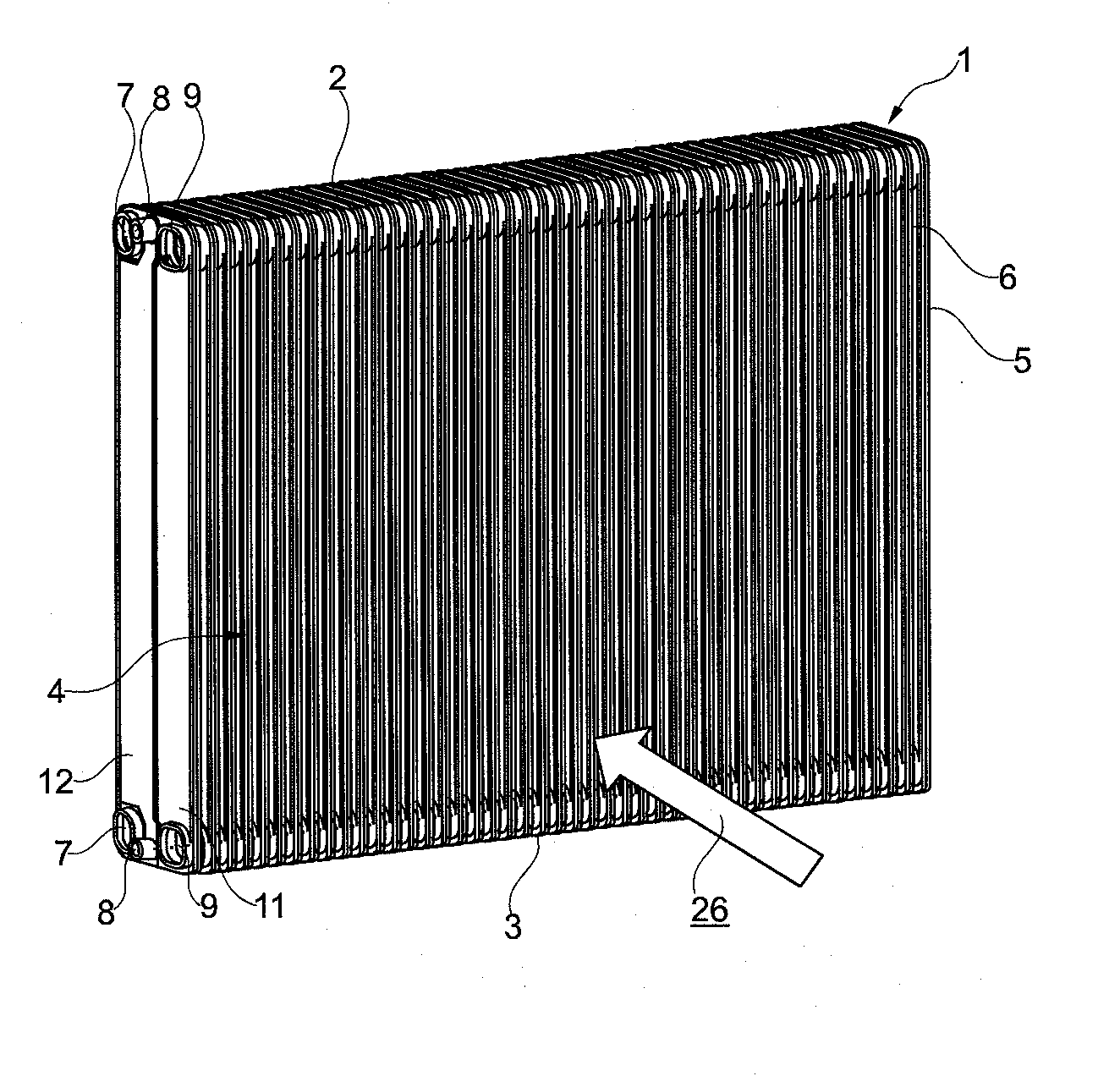

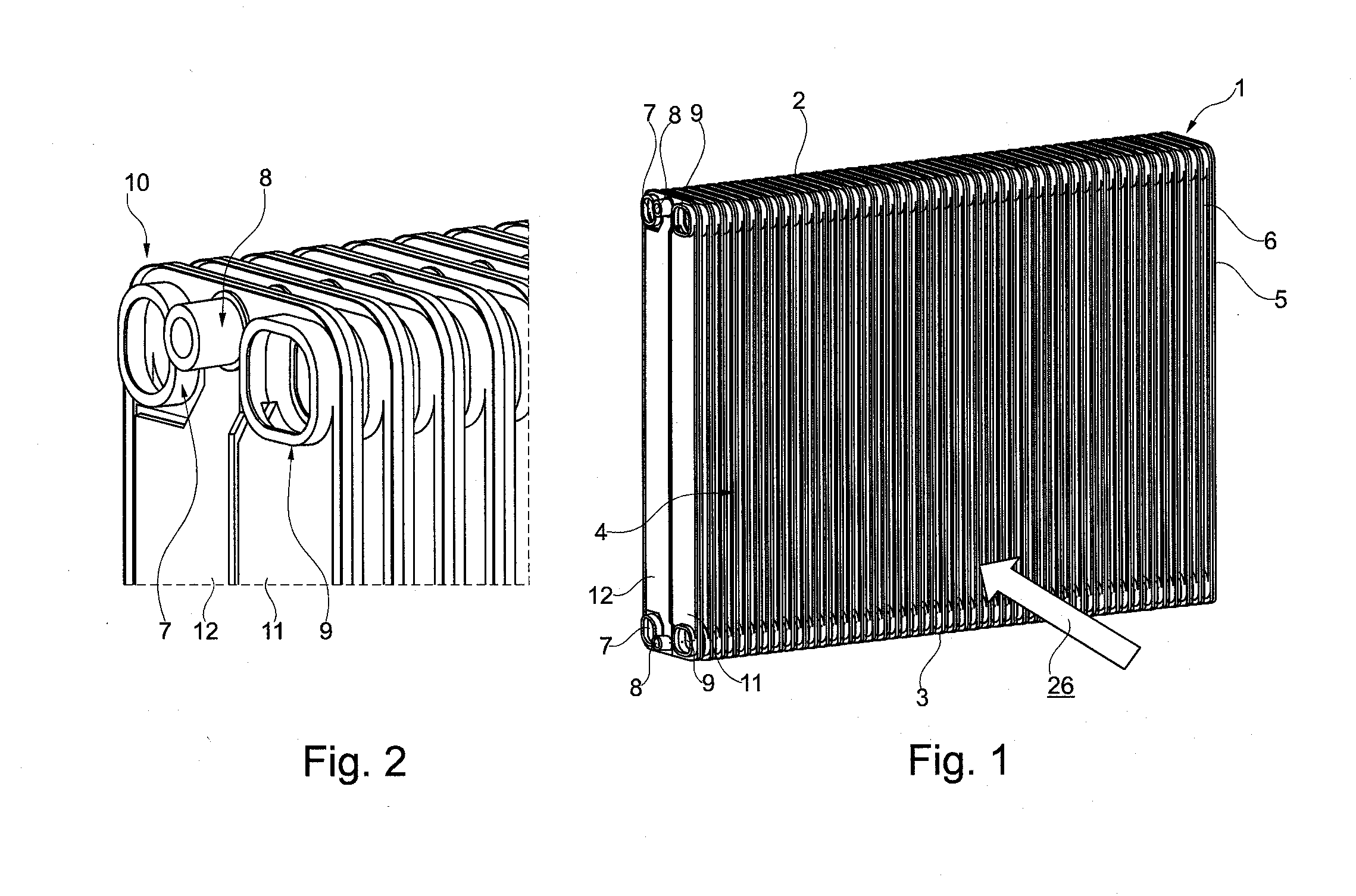

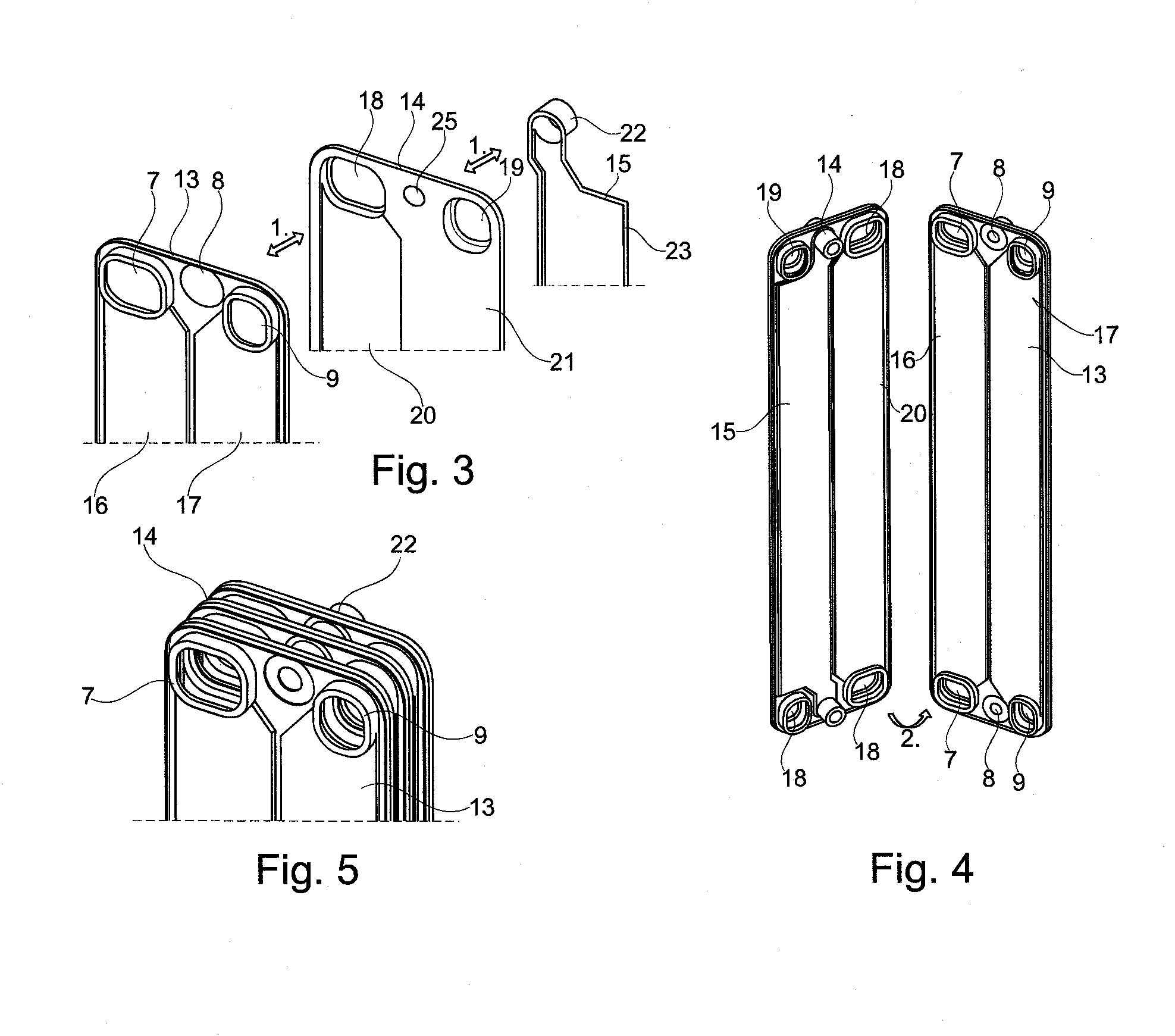

Heat exchanger

InactiveUS20140374076A1Easy to manufactureLow costHeat storage plantsStationary conduit assembliesMobile vehiclePlate heat exchanger

A plate-type heat exchanger, in particular for motor vehicles, is provided that includes a plurality of plate groups in order to form first and second and / or third flow paths, a spatial region for fourth flow paths being formed between adjacent plate groups, the plate groups having at least one plate pair having a first and second plate in order to form the first flow paths and the second flow paths, wherein a third plate can be arranged in interaction with one of the first or one of the second plates in order to form the third flow path.

Owner:MAHLE INT GMBH

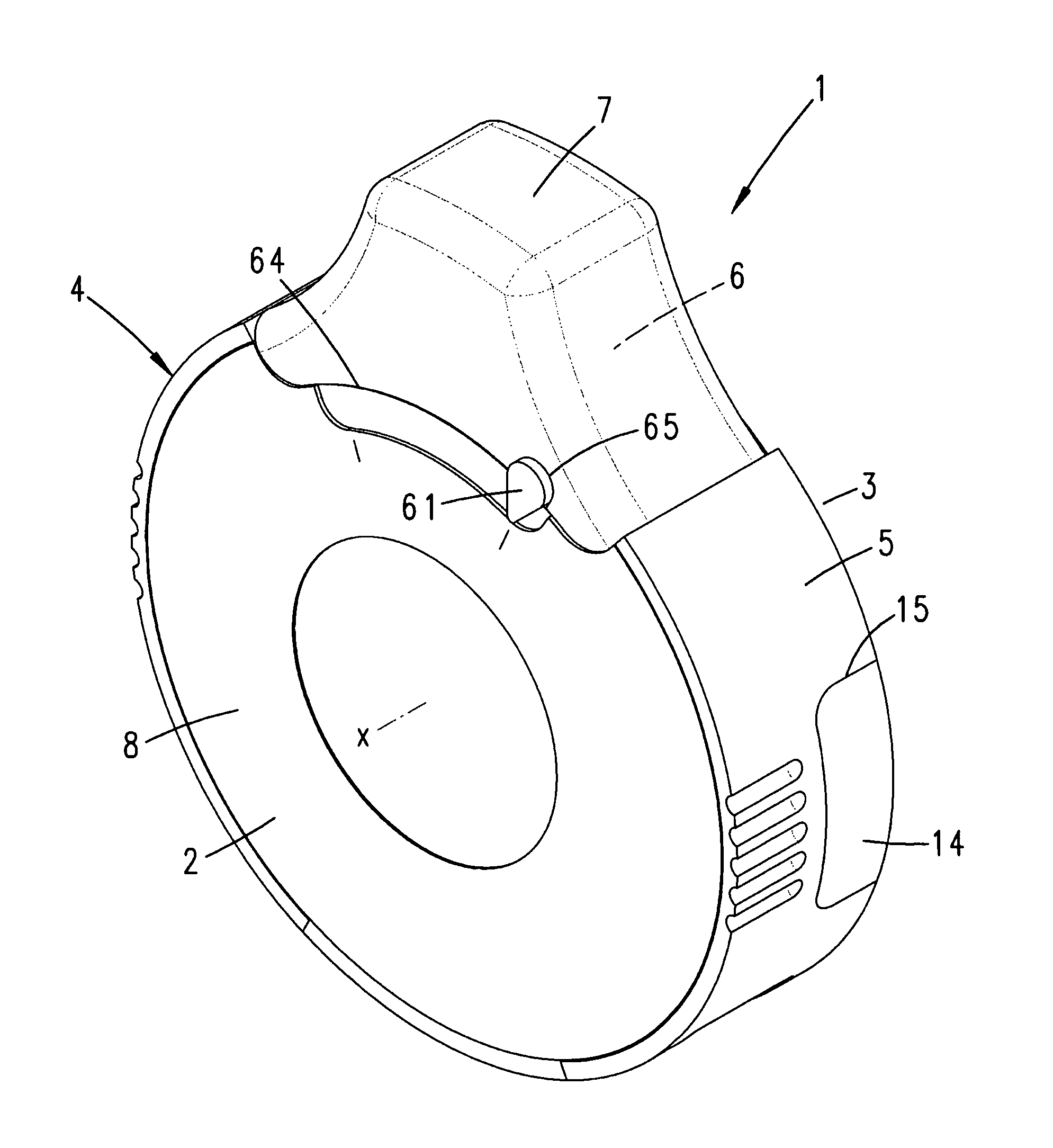

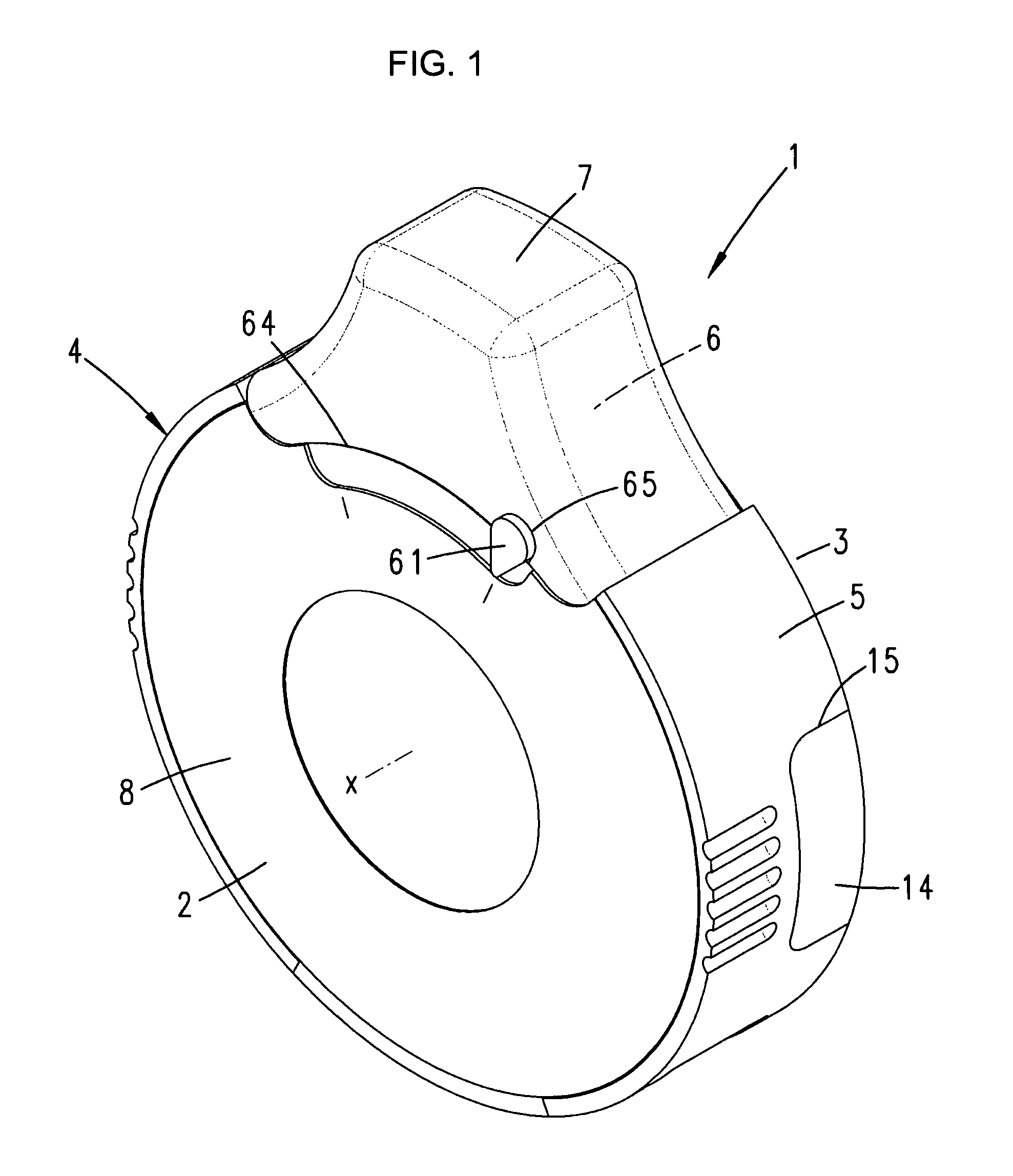

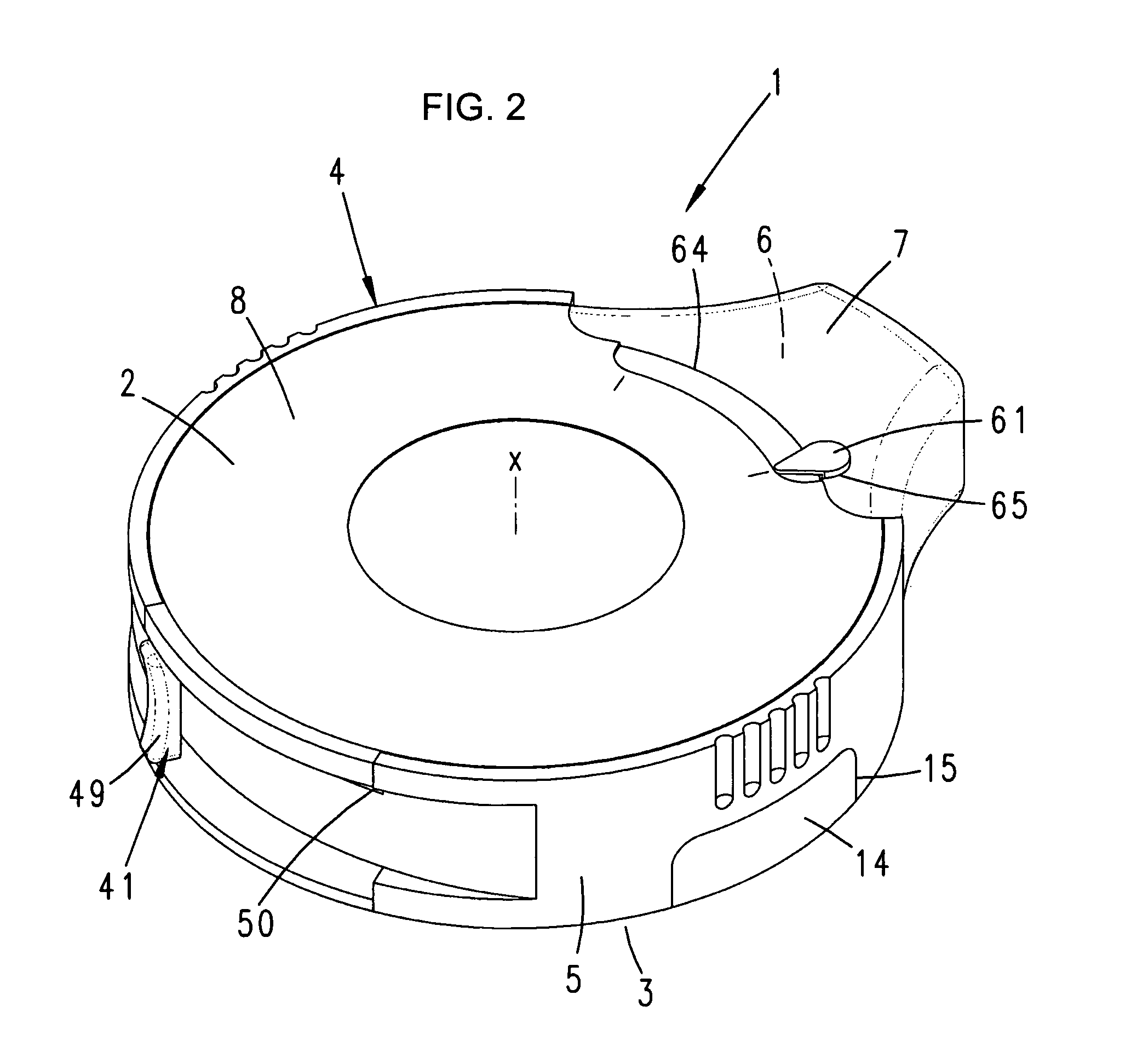

Dispenser for pulverulent substances

InactiveUS8434476B2Only be achieveAdversely affectedRespiratorsLiquid surface applicatorsEngineeringBlister pack

The invention relates to a dispenser (1) for pulverulent substances (30), in particular medicaments, from a blister pack (25), dome-shaped cavities (26) of which that are disposed on a base layer (28) can, by movement in a dispenser housing (4), be brought step by step into an emptying position, in which they can be opened by means of a needle (31) and can be emptied by a suction air stream (a) leading to a mouthpiece (6). To achieve optimum emptying of the cavities, it is proposed that the needle (31) passes crosswise through both lateral walls of the dome (29) of the cavities (preferably parallel to the base layer 28) in order to form a through path to the mouthpiece for suction air.

Owner:VON SCHUCKMANN ALFRED

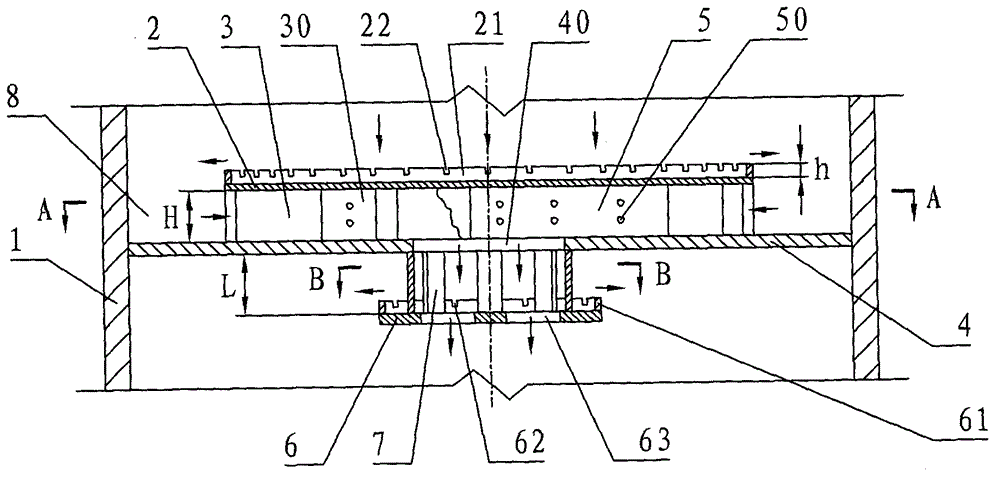

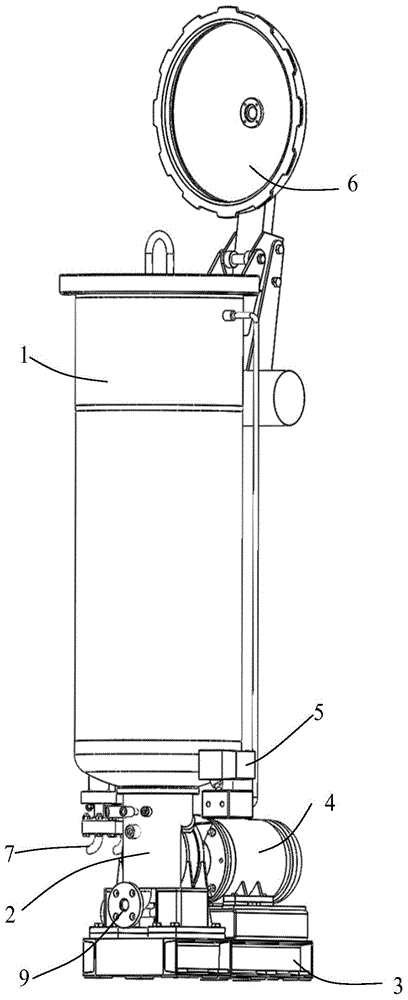

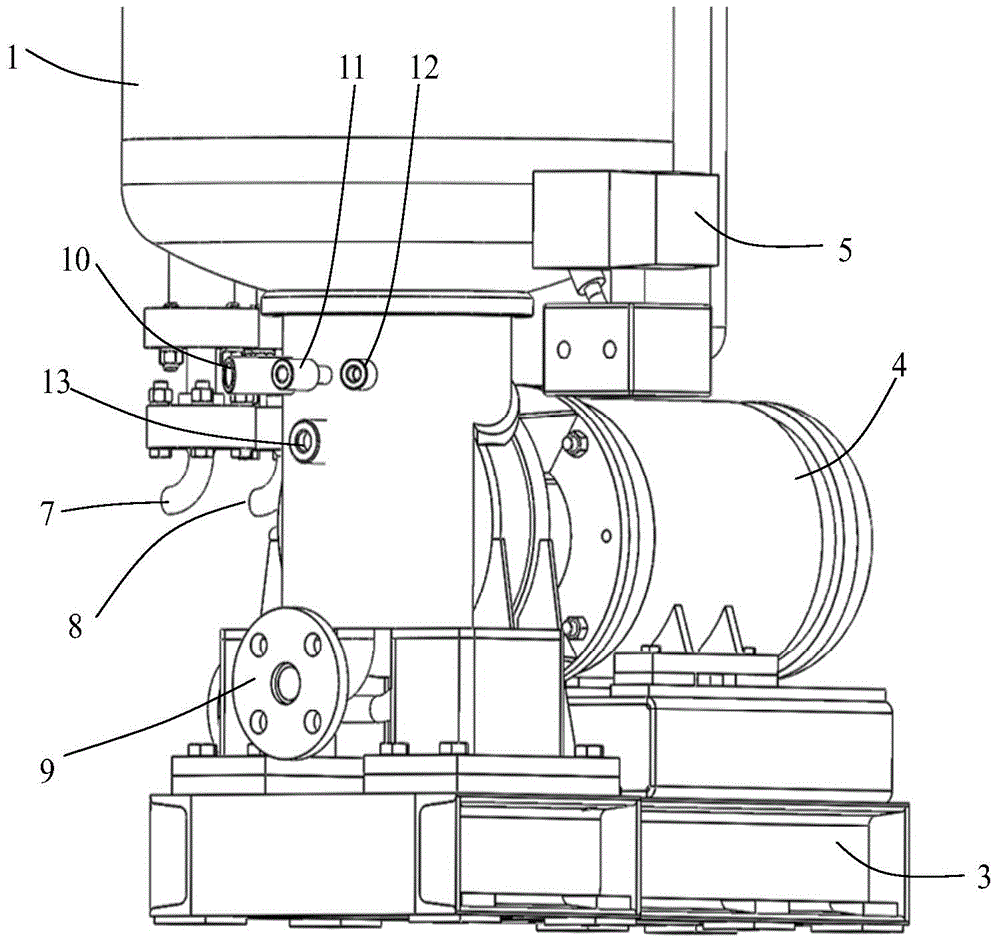

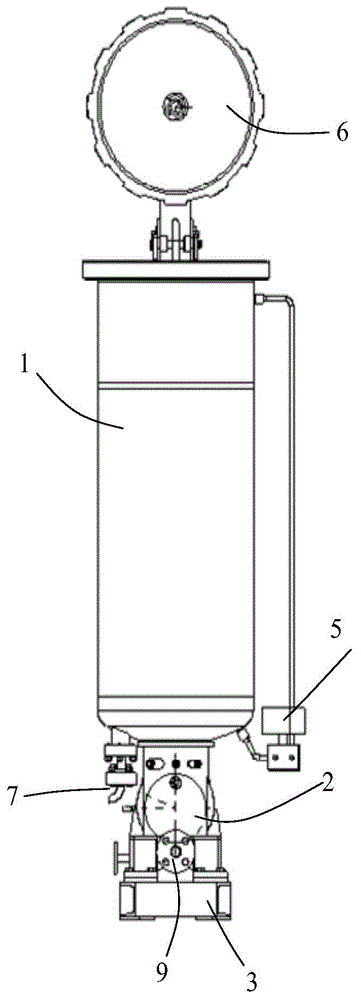

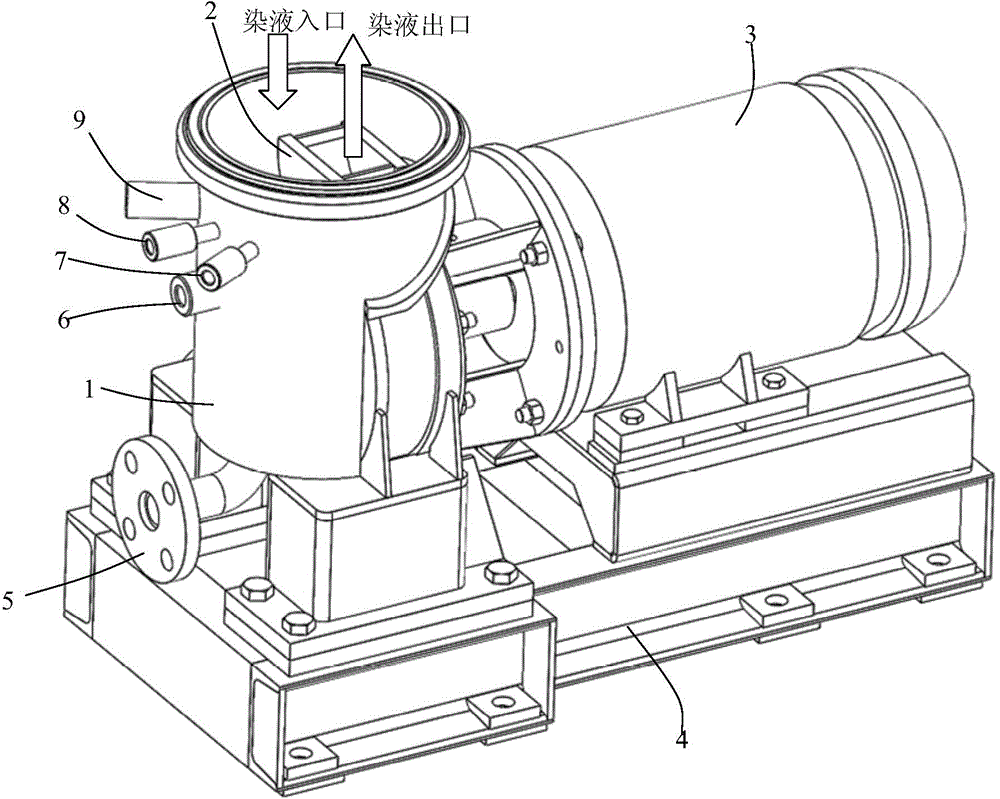

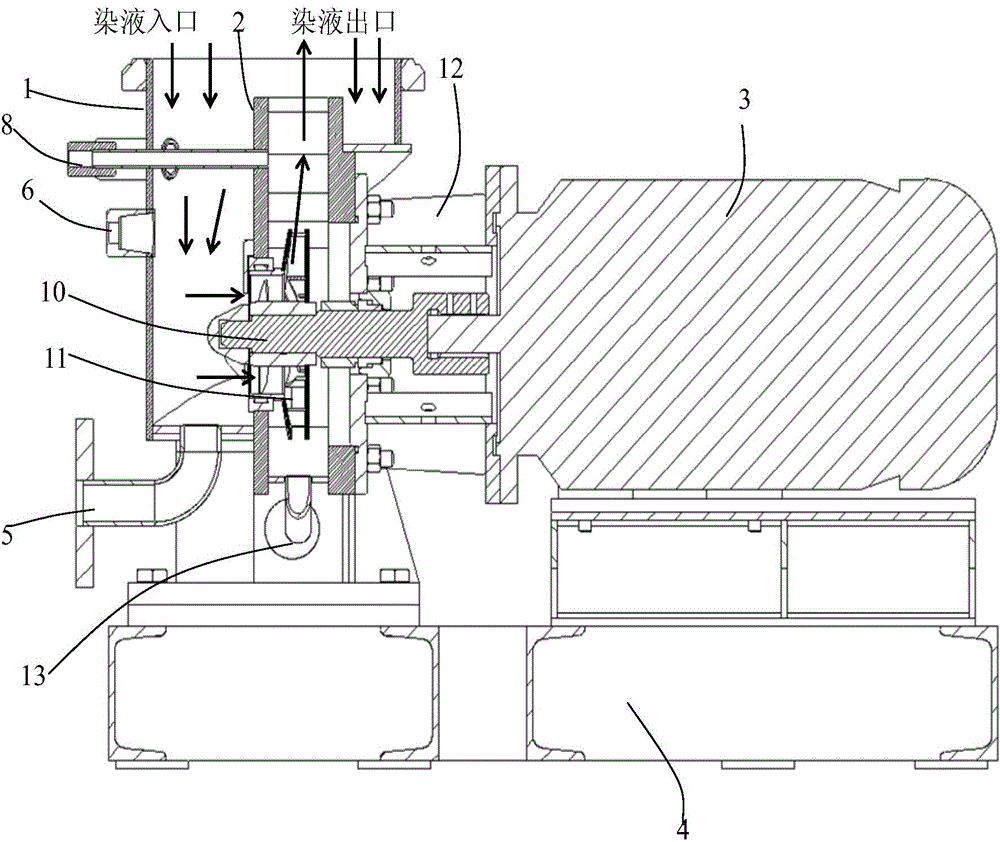

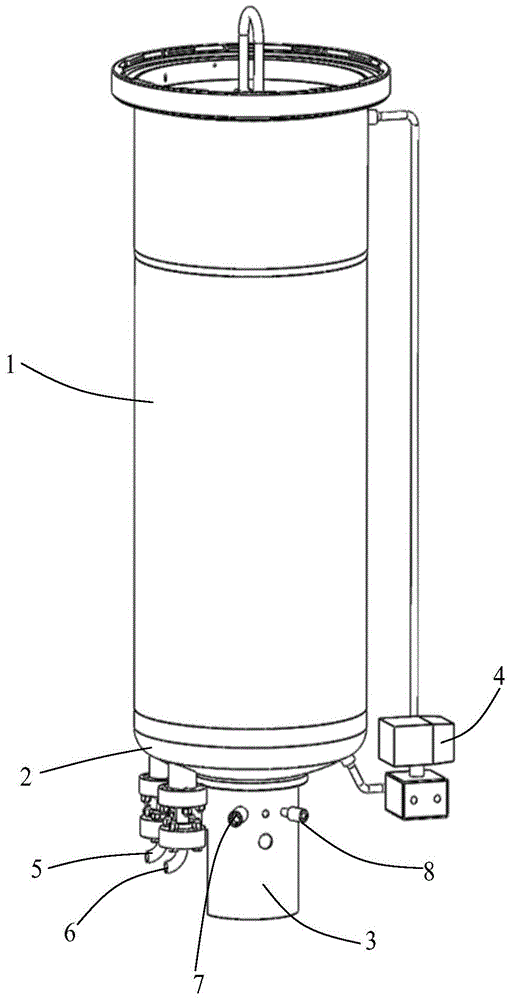

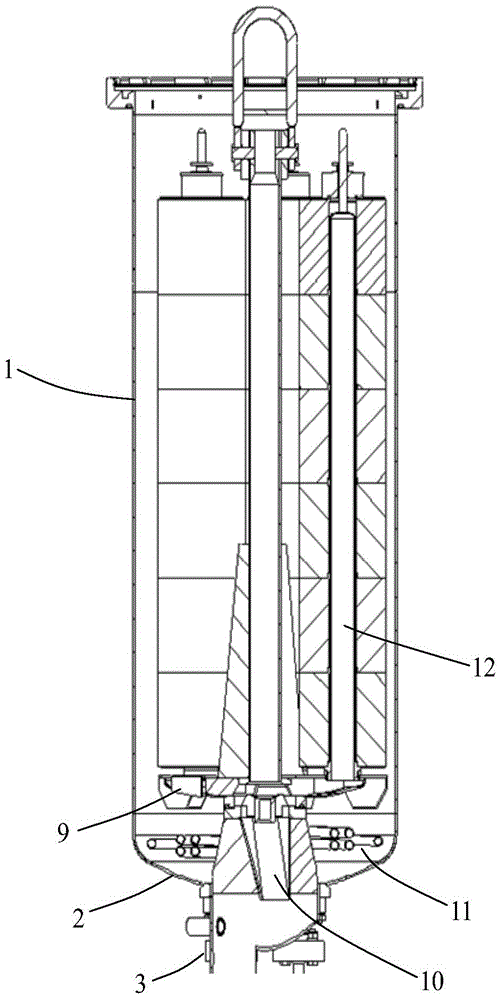

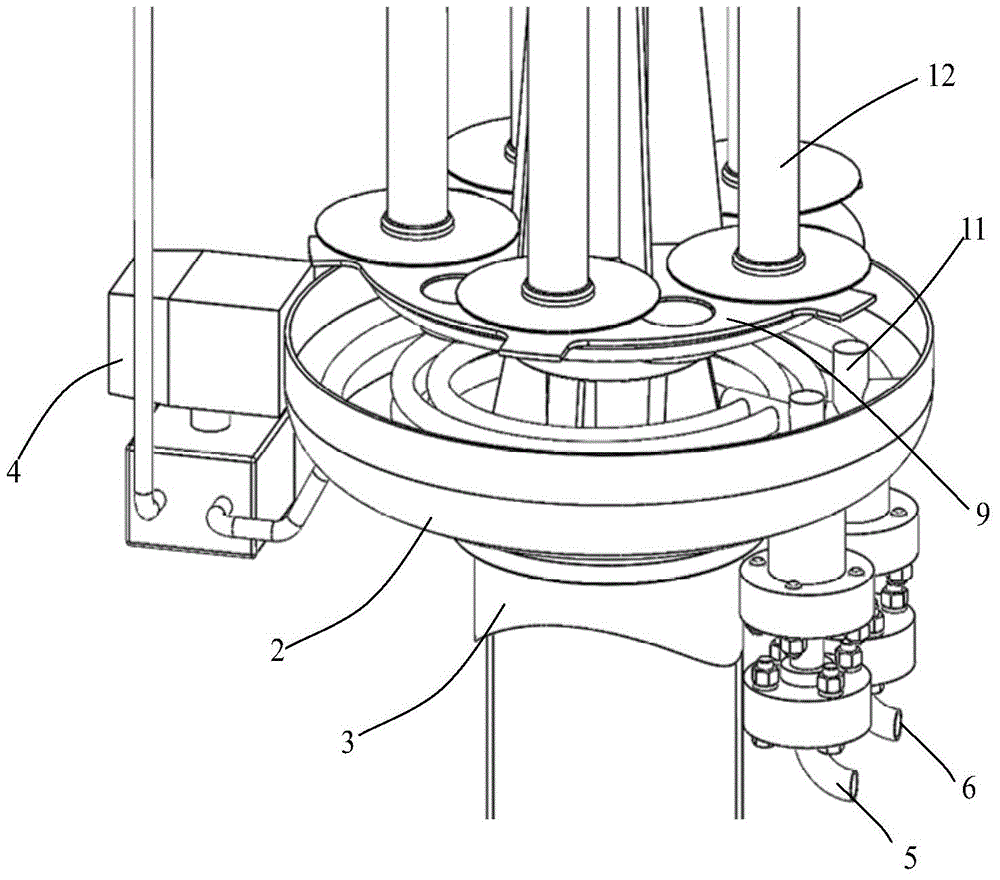

Yarn dyeing machine with 1:2 extremely-low bath ratio

ActiveCN104818591AEmission reductionIngenious structural designTextile treatment containersTextile treatment machine arrangementsYarnSocial benefits

The invention provides a yarn dyeing machine with a 1:2 extremely-low bath ratio. The yarn dyeing machine mainly comprises a yarn cylinder, a liquid collecting pipe, a base, a motor, a volumeter, a cylinder cover, a steam inlet, a steam outlet, liquid supply and discharging pipes, a liquid temperature meter, a high pressure meter, a low pressure meter, a hydro-acupuncture probing sleeve, a heat exchange pipe, a flow distribution disc, a round heaven and square earth pipe, a yarn bamboo pipe, a liquid collecting cavity, a mixed-flow pump, a flow guide pipe and a water baffle and the like. Due to the ingenious structural design, the 1:2 extremely-low bath ratio of the yarn dyeing machine close to the limit can be achieved, auxiliaries and dye are obviously saved, the waste liquid discharge is reduced, and the yarn dyeing machine is very obvious in economic and social benefits. The yarn dyeing machine is compact in structure, a flow channel is short, and the yarn dyeing machine has excellent energy efficiency.

Owner:高勋绿色智能装备(佛山)有限公司

Injection mould capable of being easily de-molded

The invention discloses an injection mould capable of being easily de-molded. The injection mould is formed by a movable mould and a fixed mould, which are used as the injection mould, wherein each one of the movable mould and the fixed mould comprises a molding part, a pushing-out mechanism, a mould guide part and a pouring system; a mould cavity is arranged in the mould; the mould cavity is arranged on the mould closing face of the single injection mould, namely, the mould cavity is arranged on the mould closing face of the movable mould or the mould closing face of the fixed mould; the mould closing face of the other injection mould has no mould cavity and is a plane; the movable mould and the fixed mould are closed to form the complete injection mould cavity. According to the injection mould disclosed by the invention, the structure of only arranging the mould cavity on the single injection mould is applicable to injection of a standard test sample strip or an injection piece with the similar shape. The injection mould has the beneficial effects of being beneficial to simplification of the structure of the mould, improving the manufacturability of the mould and reducing the cost of the mould.

Owner:广州现代塑料有限公司

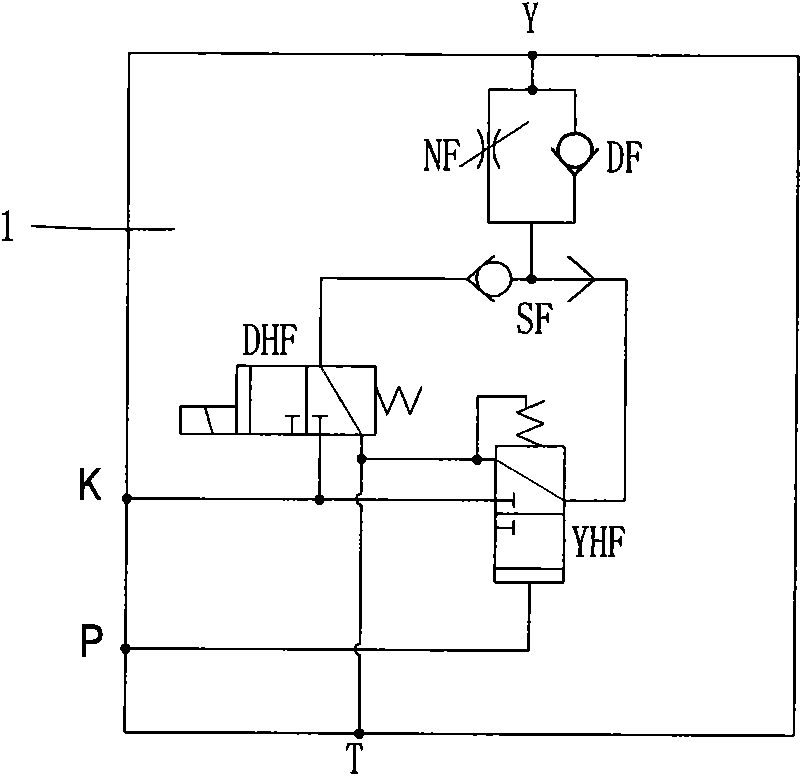

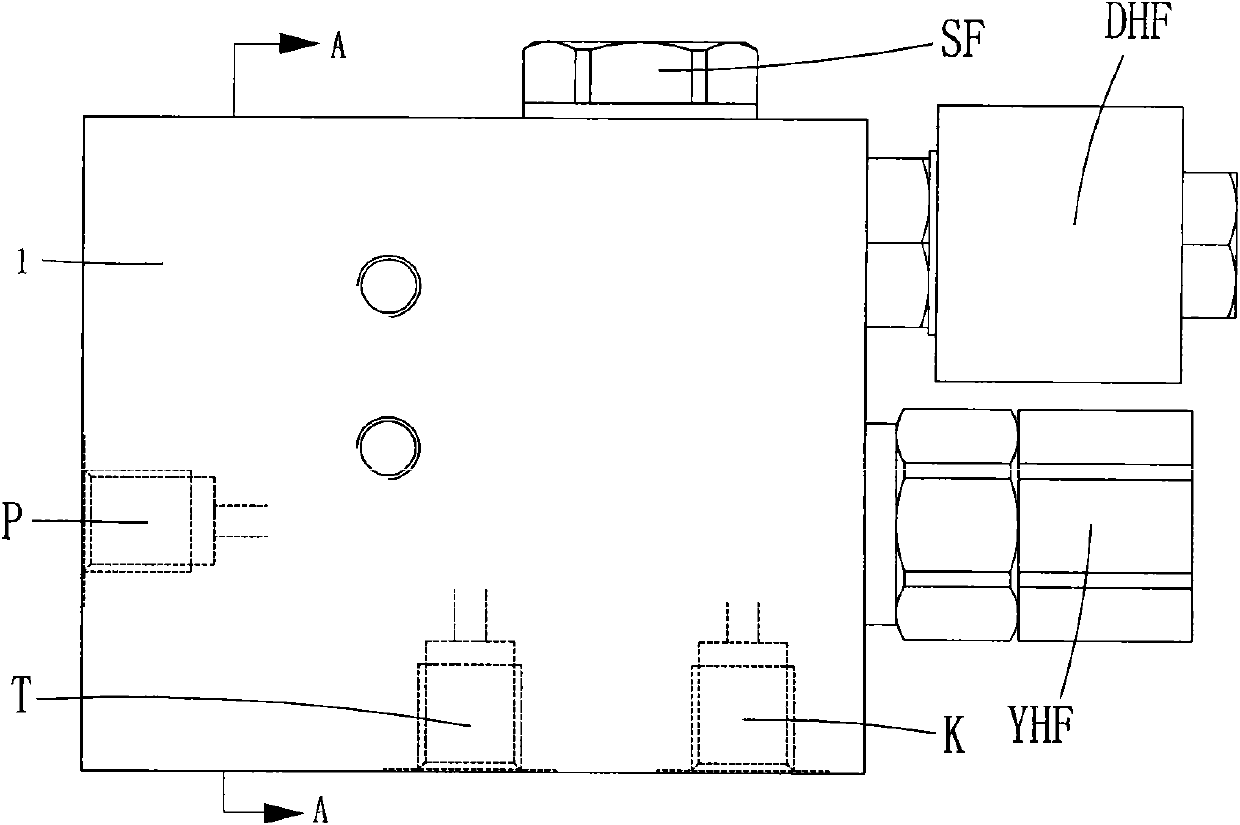

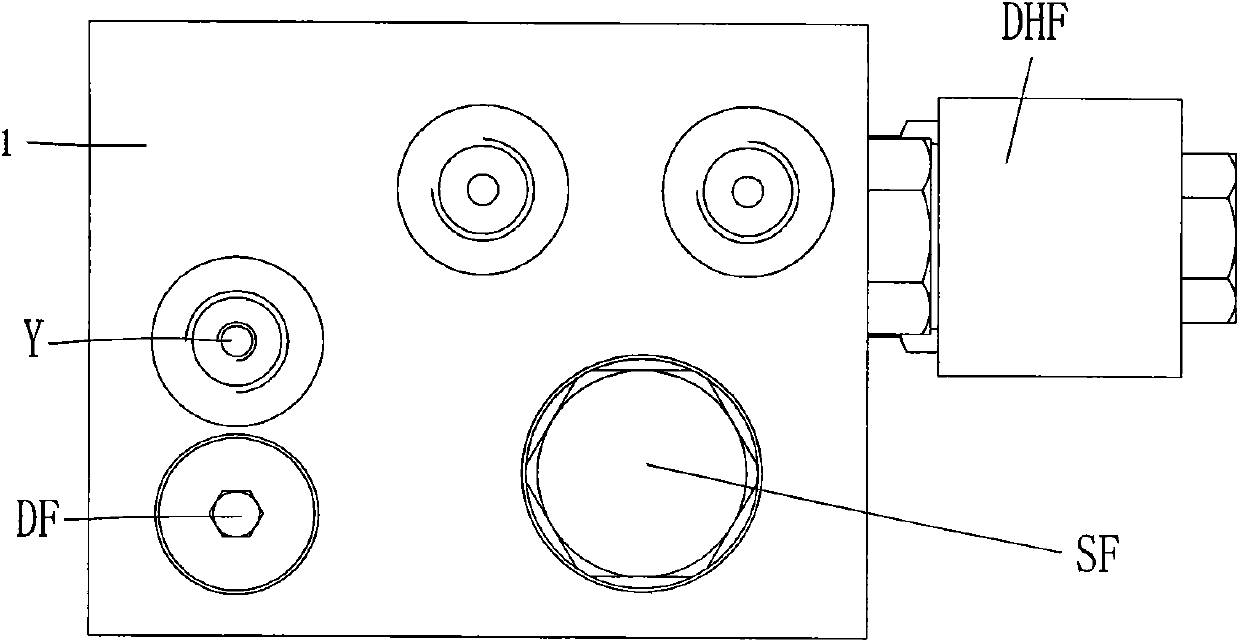

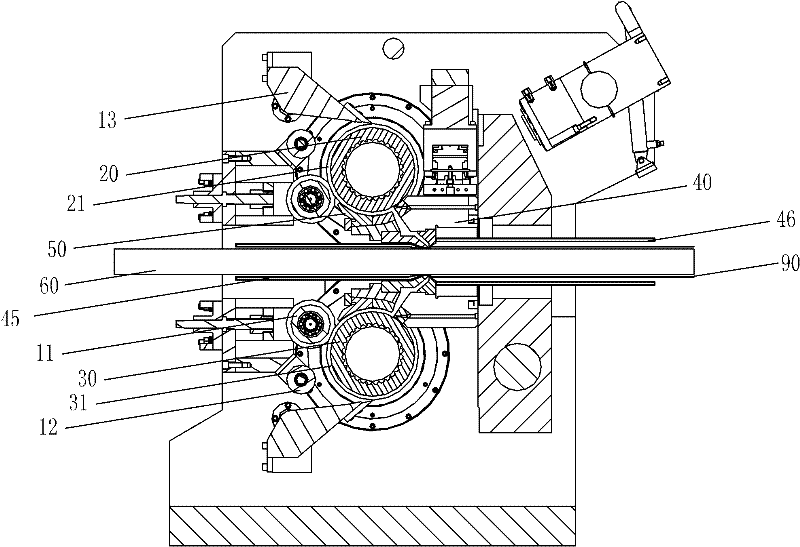

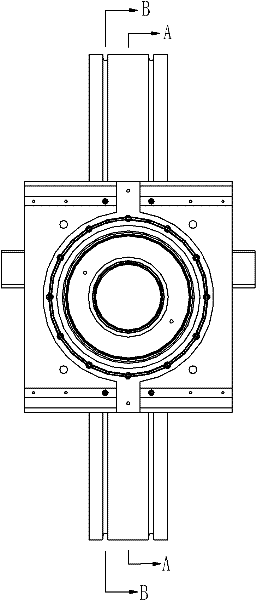

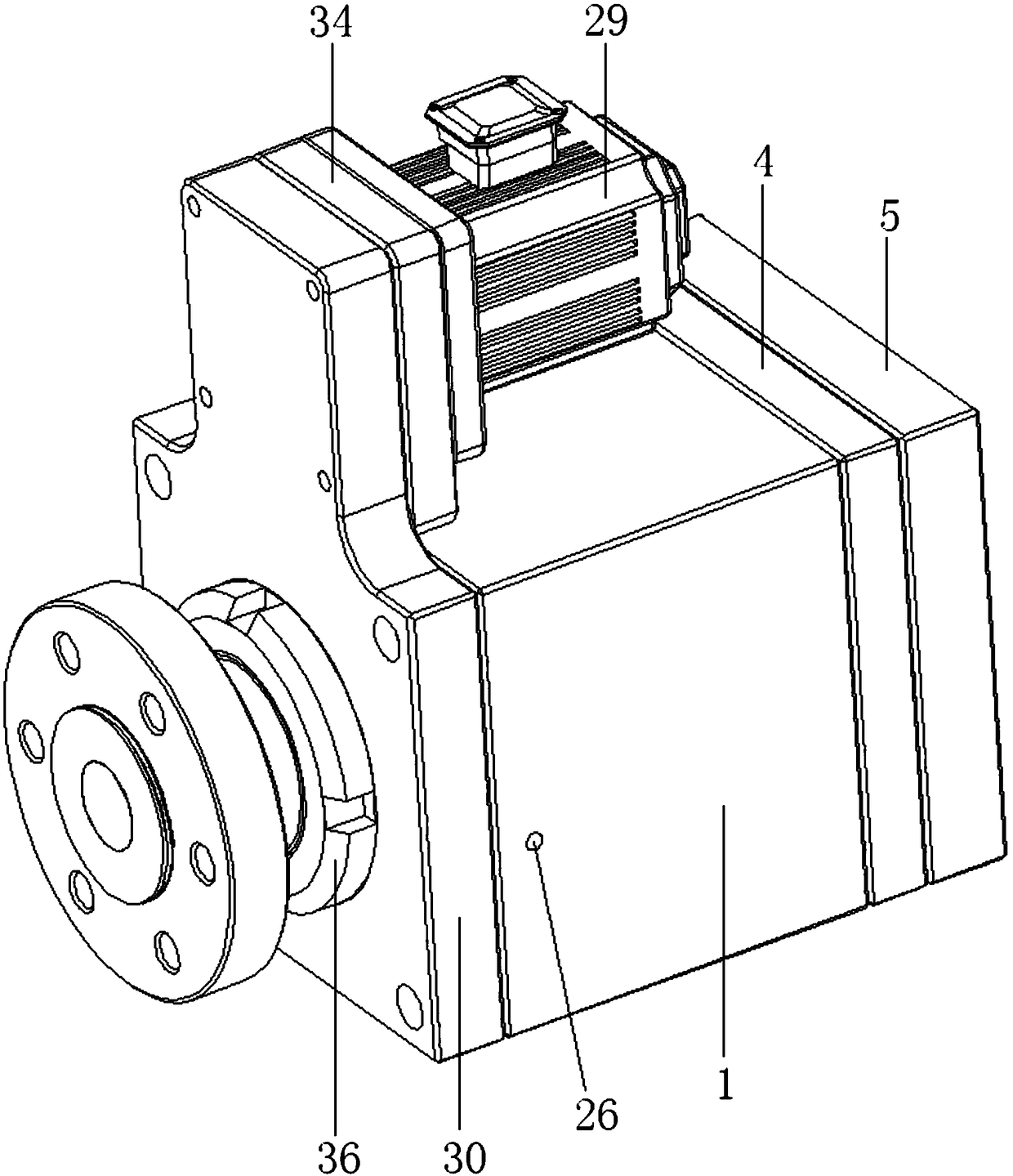

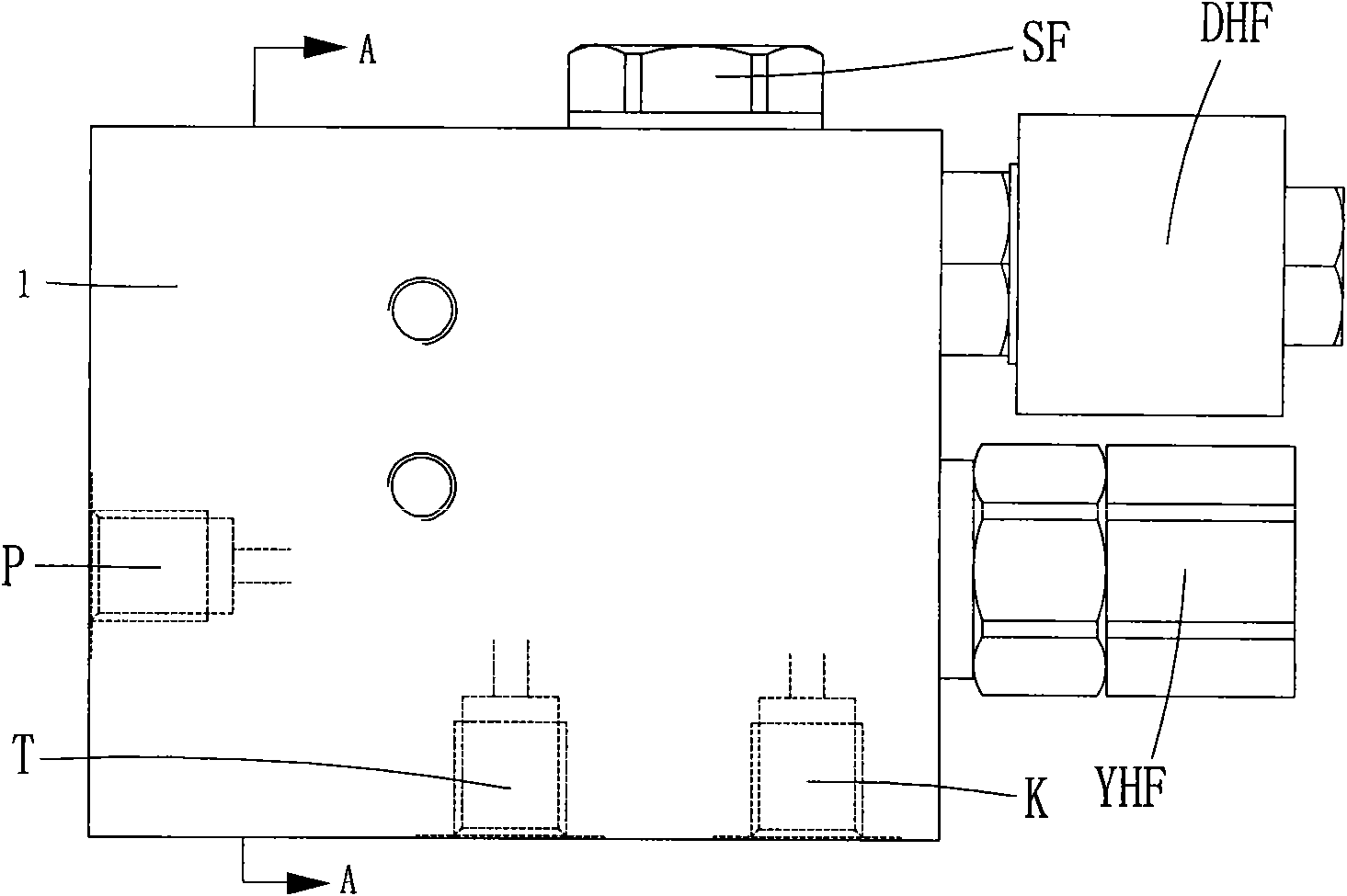

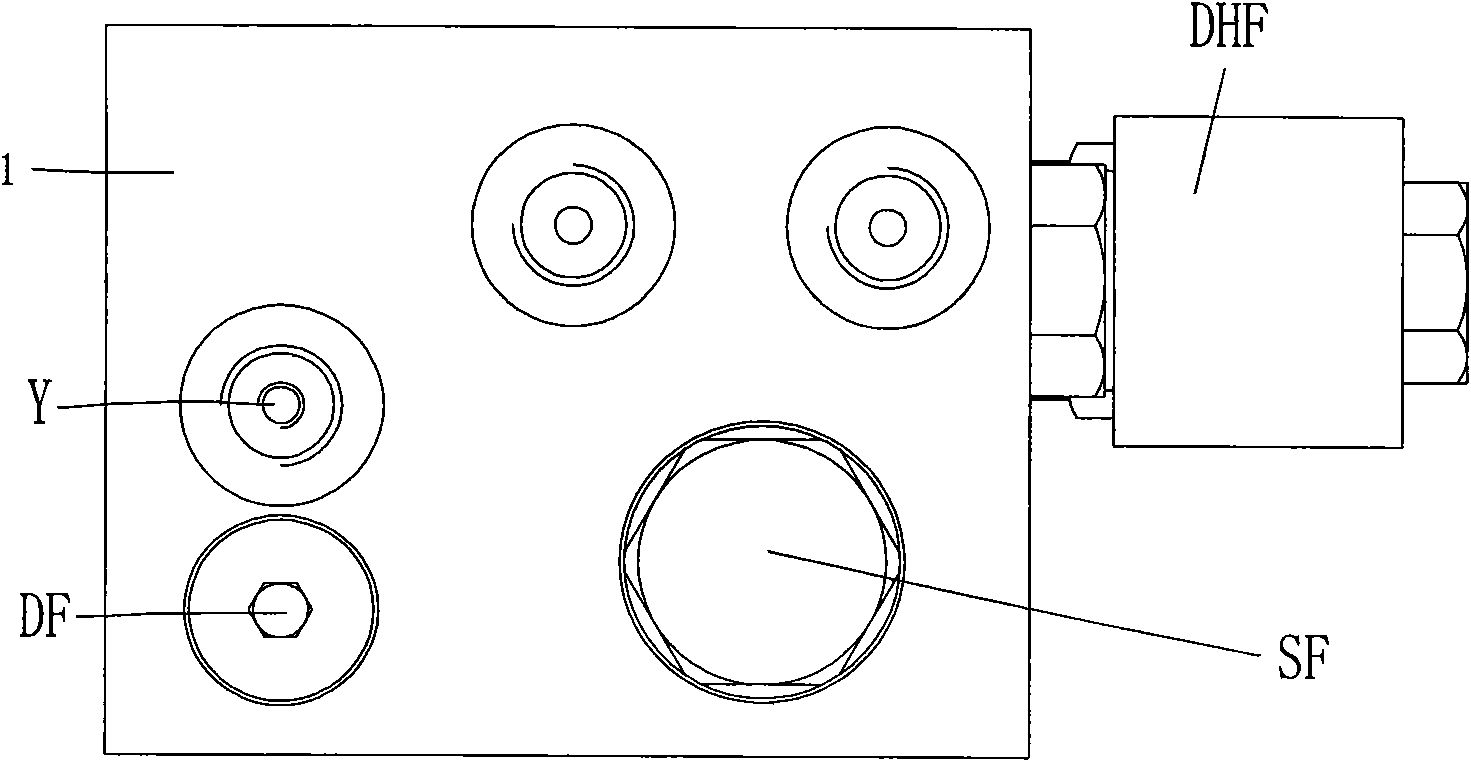

Upper structure electro-hydraulic rotary control valve of mechanical operation crane

ActiveCN101769275AReduce volumeHigh degree of automationServomotor componentsElectro hydraulicEngineering

The invention discloses an upper structure electro-hydraulic rotary control valve of a mechanical operation crane, which comprises a valve body, wherein the valve body is provided with a hydraulic reversing valve, a shuttle valve, an electromagnetic reversing valve, a one-way valve and an adjustable flow valve in a matching way, an oil inlet opening, an oil return opening and an oil output opening are arranged on the valve body, the oil inlet opening is communicated with pressure openings of the hydraulic reversing valve and the electromagnetic reversing valve, the oil return opening is communicated with oil return openings of the hydraulic reversing valve and the electromagnetic reversing valve, oil outlet openings of the hydraulic reversing valve and the electromagnetic reversing valve are respectively communicated with two oil inlet openings of the shuttle valve, an oil outlet opening of the shuttle valve is communicated with the oil output opening through the one-way valve and the adjustable flow valve which are in parallel connection, and all of the hydraulic reversing valve, the shuttle valve, an adjustable damping and the one-way valve adopt insertion type structures, are respectively inserted and arranged in the valve body, and are highly integrated. The invention has the advantages of simple structure, low manufacture cost, small size of the valve body, high atomization degree, shortened flow passage and convenient maintenance.

Owner:卢宇

Extrusion system

InactiveCN102228912ARunner shortSmall temperature differenceExtrusion diesTemperature differenceEngineering

The invention relates to an extrusion system. The rack of the extrusion system is provided with two extrusion wheels of which two spindles are parallel with each other; the rotation directions of the extrusion wheels are opposite, and the wheel ring of each extrusion wheel is provided with at least one extrusion race in the circumference direction; the extrusion races are respectively provided with guide bases which are matched with the extrusion races; the guide bases and the extrusion races form extrusion cavities through which blanks pass; a die seat is arranged between the extrusion wheels; the inside of the die seat is provided with a channel through which a cable passes through; holes communicated with the extrusion cavities are symmetrically arranged on two sides of the axial core wire of the die seat in the radial direction; the holes are communicated with the cladding cavity of the die seat; and the outlet of the cladding cavity is arranged at the periphery of a cable outlet end in the channel. After entering into the extrusion cavity, extrusion blanks enter into the cladding cavity through the holes on the die seat; because the holes are symmetrically arranged in the radial direction of the die seat, the extrusion blanks simultaneously enter into the cladding cavity from the upper and lower parts of the die seat, blank runners are shortened, temperature difference is small, the blank flowing through the die seat is abundant, and the yield is increased.

Owner:HEFEI SMARTER TECH GROUP CORP

Continuous extruder

InactiveCN102205355ARunner shortSmall temperature differenceExtrusion diesMechanical engineeringExtrusion

The invention relates to a continuous extruder. The invention relates to a continuous extruder. A frame of the continuous extruder is provided with two extrusion wheels, wherein the extrusion wheels have two rotating shafts parallel to each other. The two extrusion wheels have opposite rotation directions. Wheel rims of the extrusion wheels are respectively provided with at least an extrusion wheel groove in a circumferential direction. The extrusion wheel grooves are respectively provided with a guide seat matched with the same. The guide seat forms an extrusion chamber for passing through blank materials with the extrusion wheel groove. A die holder is arranged between the extrusion wheels. A channel for passing through a cable is arranged in the die holder. Two sides of axial core line of the die holder are symmetrically provided with holes communicated with the extrusion chamber along a radial direction, wherein the holes are communicated with a cover chamber. An outlet of the cover chamber is covered a periphery of an outlet end of the cable in the channel. With the present invention, extrusion blank materials enter the extrusion chamber and then enter the cover chamber. Because the holes are arranged symmetrically in the radial direction of the die holder, the extrusion blank materials can simultaneously enter the cover chamber in an upper position of the die holder and a lower position of the die holder so as to reduce a channel of the blank materials and provide small temperature difference of the blank materials, such that the blank materials flowing through the die holder is sufficient so as to improve output.

Owner:HEFEI SMARTER TECH GROUP CORP

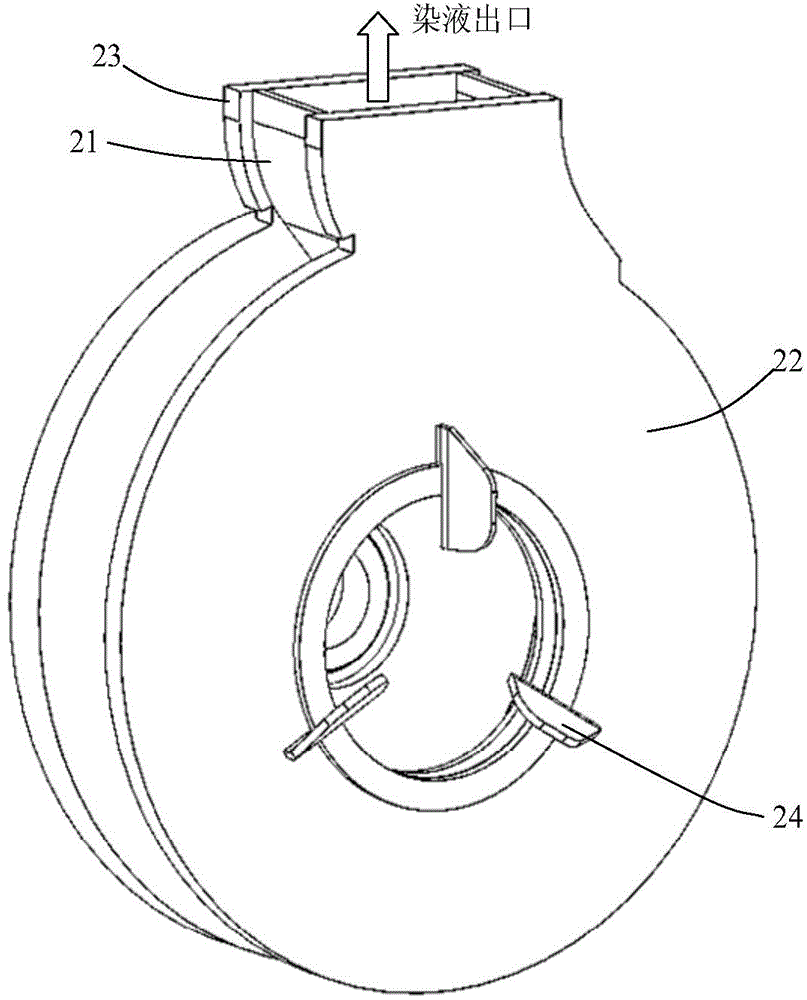

Power system of yarn dyeing machine with 1:2 extremely-low bath ratio and control method thereof

ActiveCN104818594AEmission reductionImprove energy efficiencyTextile treatment machine arrangementsYarnEngineering

The invention provides a power system of a yarn dyeing machine with a 1:2 extremely-low bath ratio and a control method thereof. The power system mainly comprises a drum, a liquid outlet flow guide module, a motor, a base a power shaft and a pump module, wherein the drum sleeves the outer portion of the liquid outlet flow guide module; and a drum inner cavity and the liquid outlet flow guide module are sealed through a sealing plate to form an independent liquid inlet flow channel. The liquid outlet flow guide module comprises a front disc, a flow guide plate and a rear disc. The two ends of the flow guide plate are connected with the front disc and the rear disc respectively to form a liquid outlet cavity which is a liquid outlet flow channel. The pump module is installed in the liquid outlet cavity of the liquid outlet flow guide module, and the flow guide plate is annular and is provided with a dye liquid outlet. A power source is provided for the pump module through the motor; and the drum, the liquid outlet flow guide module and the motor are installed on the base. The 1:2 extremely-low bath ratio of the yarn dyeing machine close to the limit can be achieved, auxiliaries and dye are obviously saved, and the waste liquid discharge is reduced. The power system is compact in structure, the flow channels are short, and the energy efficiency of the power system can be effectively improved.

Owner:高勋绿色智能装备(广州)有限公司

Dyeing liquor exchange and distribution system of ultralow-bath-ratio yarn dyeing machine and control method thereof

ActiveCN104878539ALittle savingsEmission reductionTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsYarnDistribution system

The invention provides a dyeing liquor exchange and distribution system of an ultralow-bath-ratio yarn dyeing machine and a control method thereof. The dyeing liquor exchange and distribution system mainly comprises a yarn vat, a seal head, a liquor collection tube, a volumeter, a liquor thermometer, a pressure gauge, a distribution plate, a circular-top square-bottom tube, a heat exchange tube, a yarn bamboo tube and the like. The dyeing liquor exchange and distribution system of the ultralow-bath-ratio yarn dyeing machine is integrated with functions such as dyeing liquor distribution, backflow collection, heating and monitoring of the yarn dyeing machine, has the advantages of compact structure, short flow passage and high efficiency. Dye liquor which needs to be accumulated in the dyeing liquor exchange and distribution system provided by the invention is less, a foundation is laid for realizing, the ultralow bath ratio of 1:2 which is close to the limit of the yarn dyeing machine, assistants and dyes can be obviously reduced and waste liquor emission is reduced.

Owner:高勋绿色智能装备(广州)有限公司

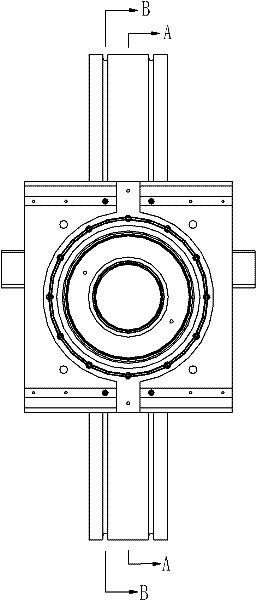

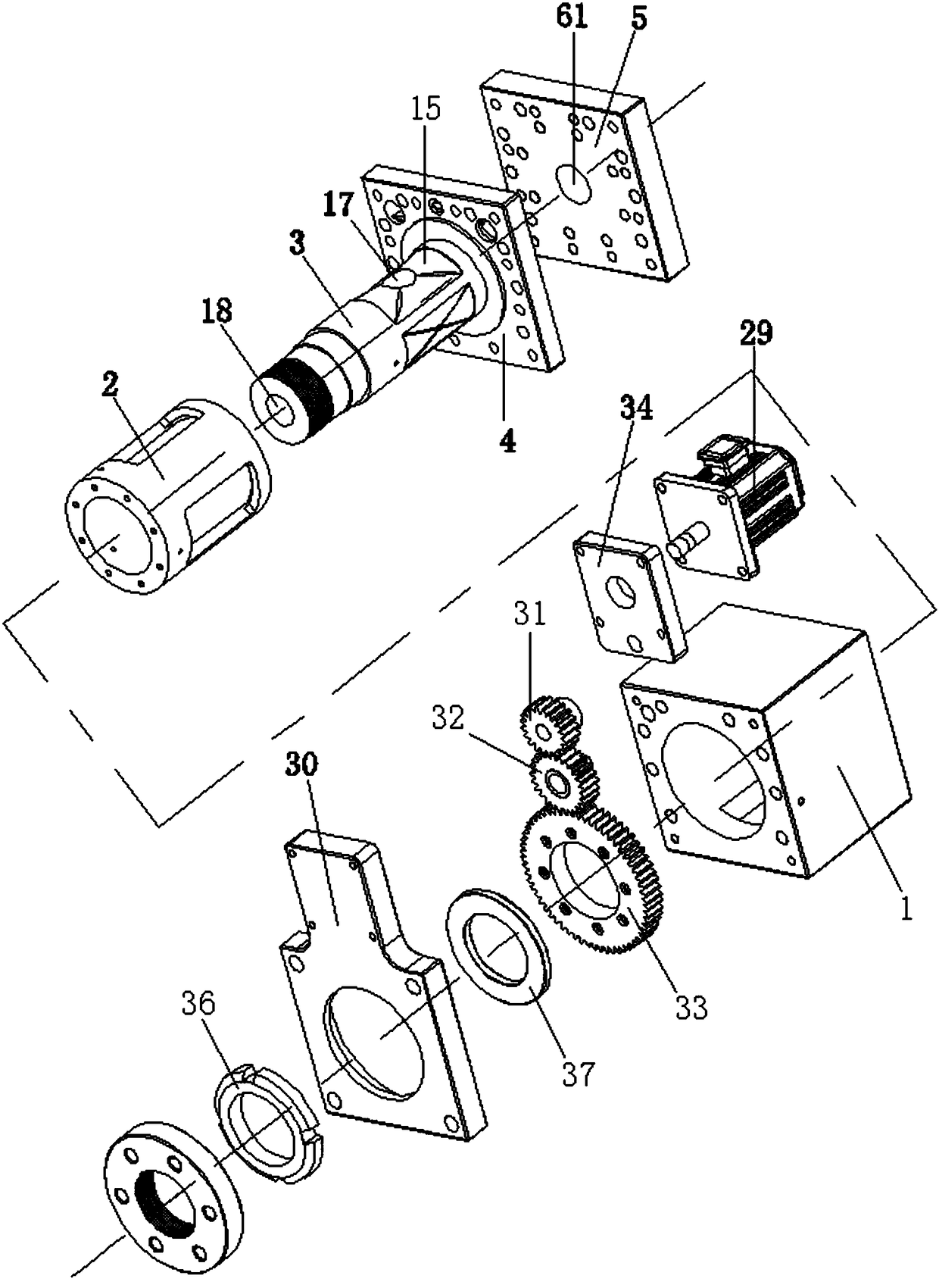

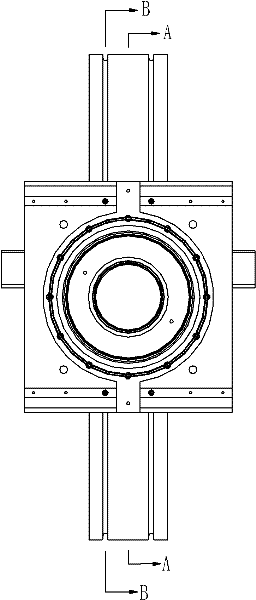

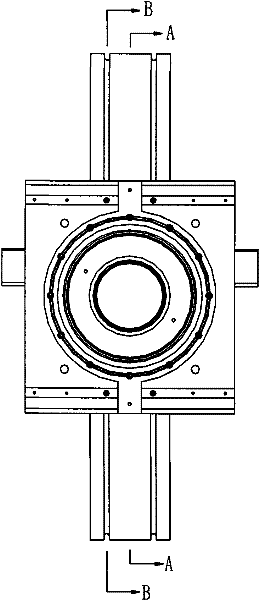

A rotary waveless screen changer

The invention belongs to the field of screen changers, and in particular refers to a rotary wave-free screen changer, which includes a screen changer shell, a filter cartridge, a filter screen, and a central shaft. Outside the shaft, the outer wall of the screen changer shell is provided with a feed port c, the inner wall of the screen changer shell is formed with a discharge trough, and the groove surface of the discharge chute is formed with a discharge port c, and the screen changer shell is connected with the discharge port The opposite end surface of the groove is formed with a net taking groove; the filter cartridge is formed with more than three filter grooves, the outer surface of the filter groove is installed with a filter net, and several filter holes are formed on the filter groove; the outer surface of the central shaft is formed with Feed trough, the position of the feed trough corresponds to the position of the discharge trough, the feed port d of the central axis flow channel is set in the middle of the feed trough, and the discharge port d of the central axis is set in the middle of the outer end of the central shaft; There is a driving mechanism on the shell of the net device; the invention has the advantages of simple structure, non-stop net changing, pre-filling and exhausting, no fluctuation, and high production efficiency.

Owner:ZHEJIANG LEENY TECH

Continuous extrusion device

ActiveCN102205354ARunner shortSmall temperature differenceExtrusion diesEngineeringTemperature difference

The invention relates to a continuous extrusion device. A stand of the continuous extrusion device is provided with two extruding wheels with mutually-parallel rotating shafts, rotation directions of the extruding wheels are opposite and rims are respectively provided with at least one extruding wheel groove in the circumference direction, guide seats matched with the extruding wheel grooves are respectively arranged on the extruding wheel grooves, the guide seats and the extruding wheel grooves form an extruding cavity through which blanks pass, a die holder is arranged between the extrudingwheels, a channel through which a cable passes is arranged inside the die holder, two sides of a die holder shaft core line are symmetrically provided with holes communicated with the extruding cavity along the radial direction, the holes are communicated with a wrapping cavity of the die holder, and an outlet of the wrapping cavity is wrapped on the periphery of the outlet end of the cable in the channel. The extruding blanks enter the extruding cavity and then enter the wrapping cavity through the holes on the die holder. Because the holes are symmetrically arranged in the radial direction of the die holder, the extruding blanks simultaneously enter the wrapping cavity at the upper position and the lower position of the die holder, and a runner of the blanks is shortened; and temperature difference is little and the blanks flowing through the die holder are sufficient, and thus the yield is increased.

Owner:HEFEI SMARTER TECH GROUP CORP

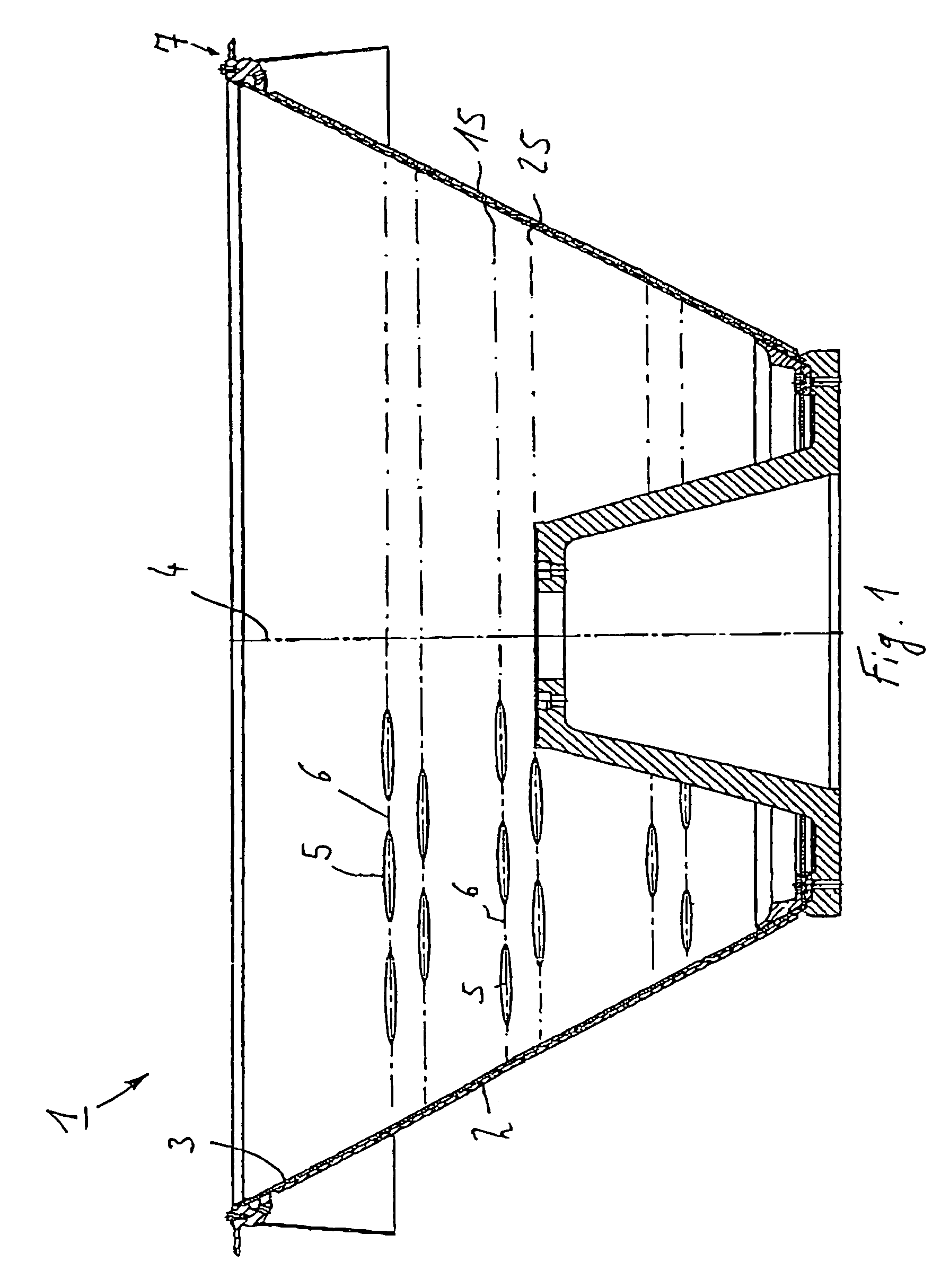

Centrifuge basket and centrifuge

ActiveUS7335302B2Easy to separateSimple processWater/sewage treatment by centrifugal separationRotary centrifugesMechanical engineeringCentrifuge

A centrifuge basket having a basket casing, on the inside of which is formed a working screen for separating off suspension liquid. The basket casing has openings of elliptical design. The openings are offset in relation to one another in the axial direction and in the circumferential direction of the basket casing. The contours of the openings overlap in the axial direction such that the basket circumference is covered by openings.

Owner:BRAUNSCHWEIGISCHE MASCHBAU AG

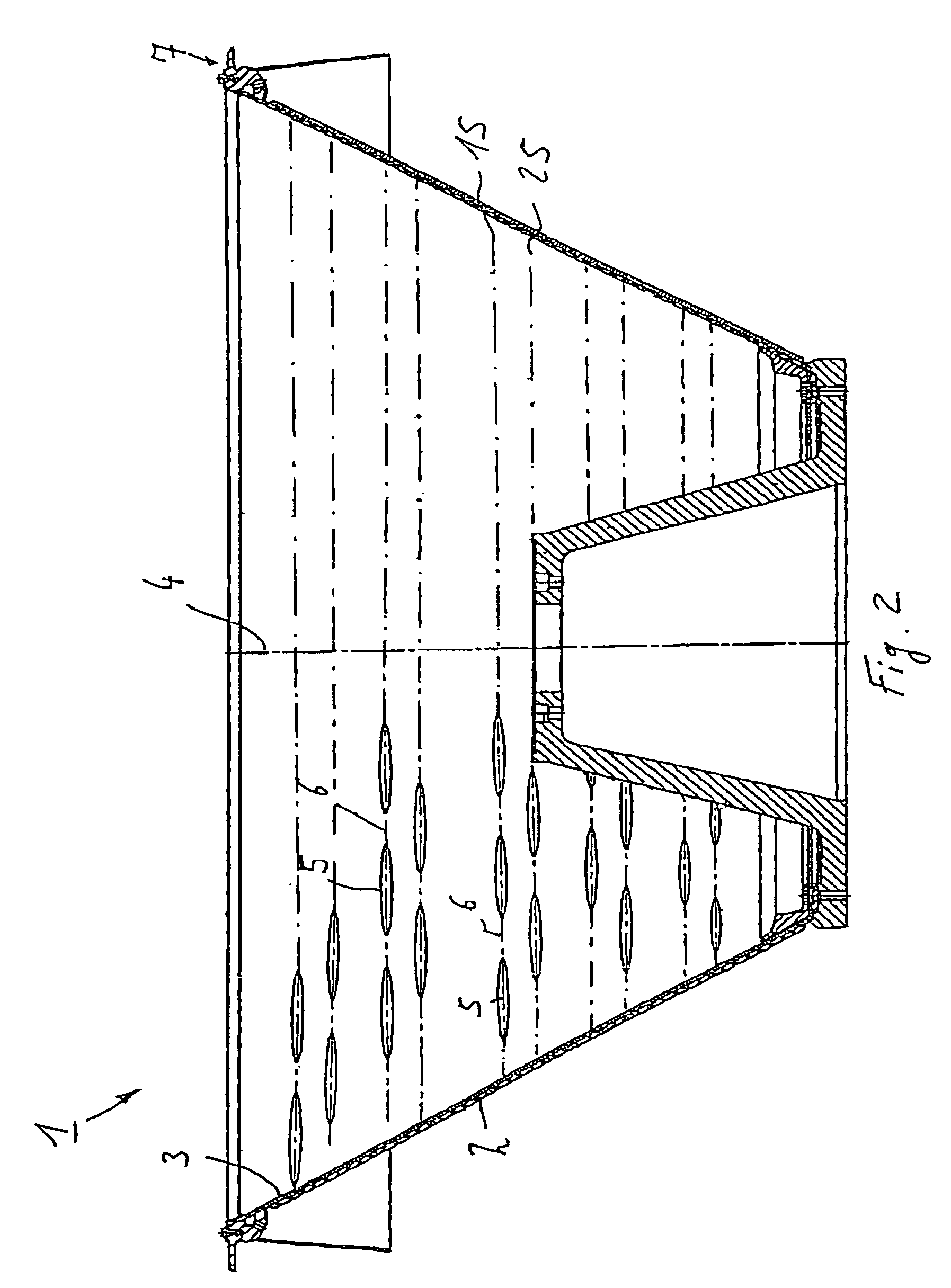

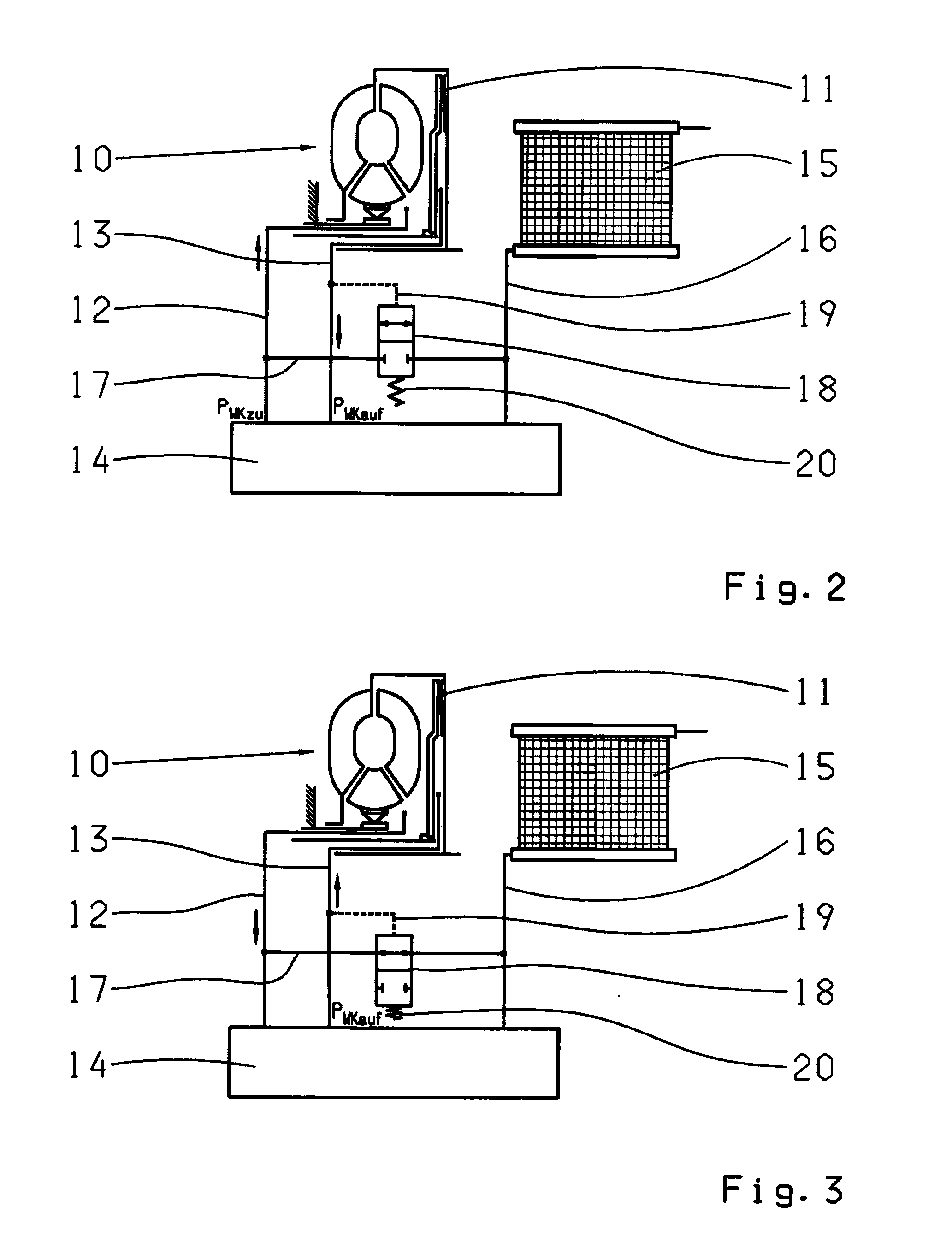

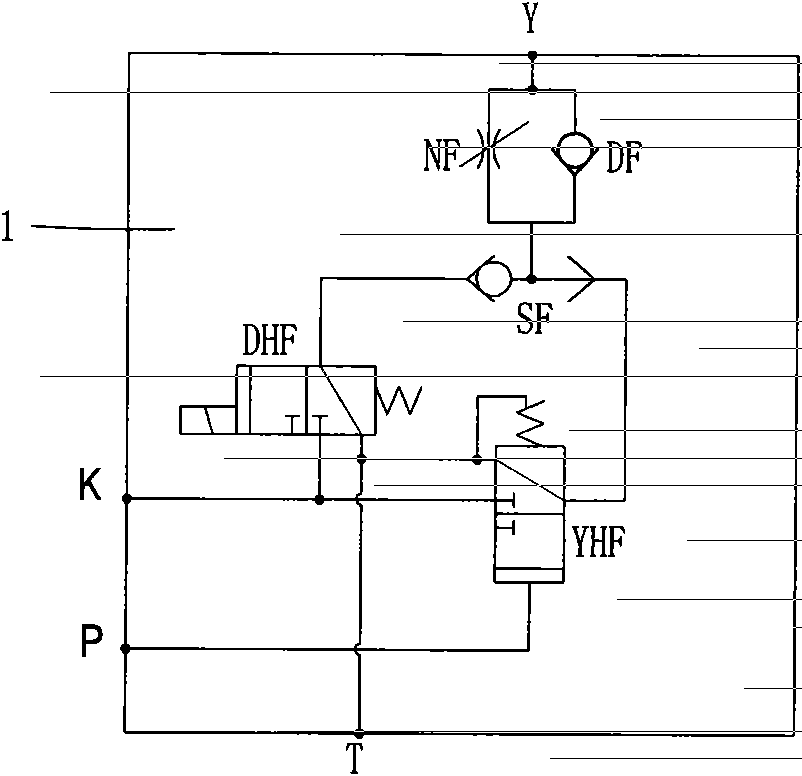

Hydraulic circuit arrangement for operating a hydrodynamic torque converter

ActiveUS20090298647A1Low pressure lossReduce lossesRotary clutchesFluid actuated clutchesHydraulic circuitEngineering

A hydraulic circuit arrangement for operating a hydrodynamic torque converter (1, 10) with a converter bridging clutch (11). The circuit arrangement comprises a hydraulic switching unit (3, 14) having at least one valve for controlling an inflow flow and a return flow of oil to the converter (1, 10) and the converter bridging clutch (11), an oil cooler (4, 15), a first line (5, 12) for acting upon the converter bridging clutch (11) with an engagement pressure (PWKzu) and a second line (6, 13) for acting upon the converter bridging clutch (11) with a disengagement pressure (PWKauf). The circuit arrangement comprises a bypass line (8, 17) which is connected directly with the oil cooler (4, 15) so as to bypass the hydraulic switching unit (3, 14).

Owner:ZF FRIEDRICHSHAFEN AG

Extruding equipment

InactiveCN102205351ARunner shortSmall temperature differenceExtrusion diesTemperature differenceEngineering

The invention relates to extruding equipment. Two extruding wheels with parallel rotating shafts are arranged on a frame of the extruding equipment, wherein the extruding wheels rotate in opposite directions. At least one strip of circumference-direction extruding wheel groove is arranged on each wheel rim. A corresponding guiding seat is arranged on each extruding wheel groove, wherein each guiding seat and the corresponding extruding wheel groove form an extruding chamber for delivering blank materials. A die holder is arranged between the extruding wheels. A channel is provided inside the die holder for delivering cables. Symmetry holes which communicate with the extruding chamber are arranged on the two sides of the core axis of the die holder in a radial direction. A cladding chamber of the die holder communicates with the holes, wherein the outlet of the cladding chamber is covered on the peripheral of the cable outlet of the channel. Blank materials enter the extruding chamber, and then enter the cladding chamber through the holes on the die holder. Because the holes are arranged symmetrically in a radial direction of the die holder, blank materials enter the cladding chamber simultaneously from both the upper part and the lower part of the die holder, such that the blank material paths are shortened, the temperature difference is reduced, the blank materials passing the die holder are sufficient, and the yield is improved.

Owner:HEFEI SMARTER TECH GROUP CORP

Extruder

ActiveCN101607277BRunner shortSmall temperature differenceExtrusion diesTemperature differenceMechanical engineering

The invention relates to an extruder. Extruding wheels with rotary shafts which are parallel to each other are arranged on a rack of the extruder, the rotation directions of the extruding wheels are reverse, at least one extruding wheel slot at the circumferential direction is respectively arranged on wheel rings, a guide seat which is matched with the extruding wheel slot is respectively arranged on the extruding wheel slot, the guide seat and the extruding wheel slot form an extruding cavity which is passed by a billet, a mold base is arranged between the extruding wheels, a channel passed by a cable is arranged in the mold base, holes which are communicated with the extruding cavity are symmetrically arranged on two sides of a shaft core line of the mold base along radial direction, the holes are communicated with a coating cavity of the mold base, and an outlet of the coating cavity is coated on the periphery at the outlet end of the cable in the channel. The extruding billet enters the extruding cavity and then enters the coating cavity through the holes on the mold base, as the holes are symmetrically arranged along the radial direction of the mold base, the extruding billetsimultaneously enters the coating cavity at the upper and the lower positions of the mold base, a flow passage of the billet is shortened, the temperature difference is small, the billet which passesthe mold base is enough, and the yield is improved.

Owner:HEFEI SMARTER TECH GROUP CORP

Upper structure electro-hydraulic rotary control valve of mechanical operation crane

ActiveCN101769275BReduce volumeHigh degree of automationServomotor componentsElectro hydraulicControl valves

The invention discloses an upper structure electro-hydraulic rotary control valve of a mechanical operation crane, which comprises a valve body, wherein the valve body is provided with a hydraulic reversing valve, a shuttle valve, an electromagnetic reversing valve, a one-way valve and an adjustable flow valve in a matching way, an oil inlet opening, an oil return opening and an oil output opening are arranged on the valve body, the oil inlet opening is communicated with pressure openings of the hydraulic reversing valve and the electromagnetic reversing valve, the oil return opening is communicated with oil return openings of the hydraulic reversing valve and the electromagnetic reversing valve, oil outlet openings of the hydraulic reversing valve and the electromagnetic reversing valve are respectively communicated with two oil inlet openings of the shuttle valve, an oil outlet opening of the shuttle valve is communicated with the oil output opening through the one-way valve and the adjustable flow valve which are in parallel connection, and all of the hydraulic reversing valve, the shuttle valve, an adjustable damping and the one-way valve adopt insertion type structures, are respectively inserted and arranged in the valve body, and are highly integrated. The invention has the advantages of simple structure, low manufacture cost, small size of the valve body, high atomization degree, shortened flow passage and convenient maintenance.

Owner:卢宇

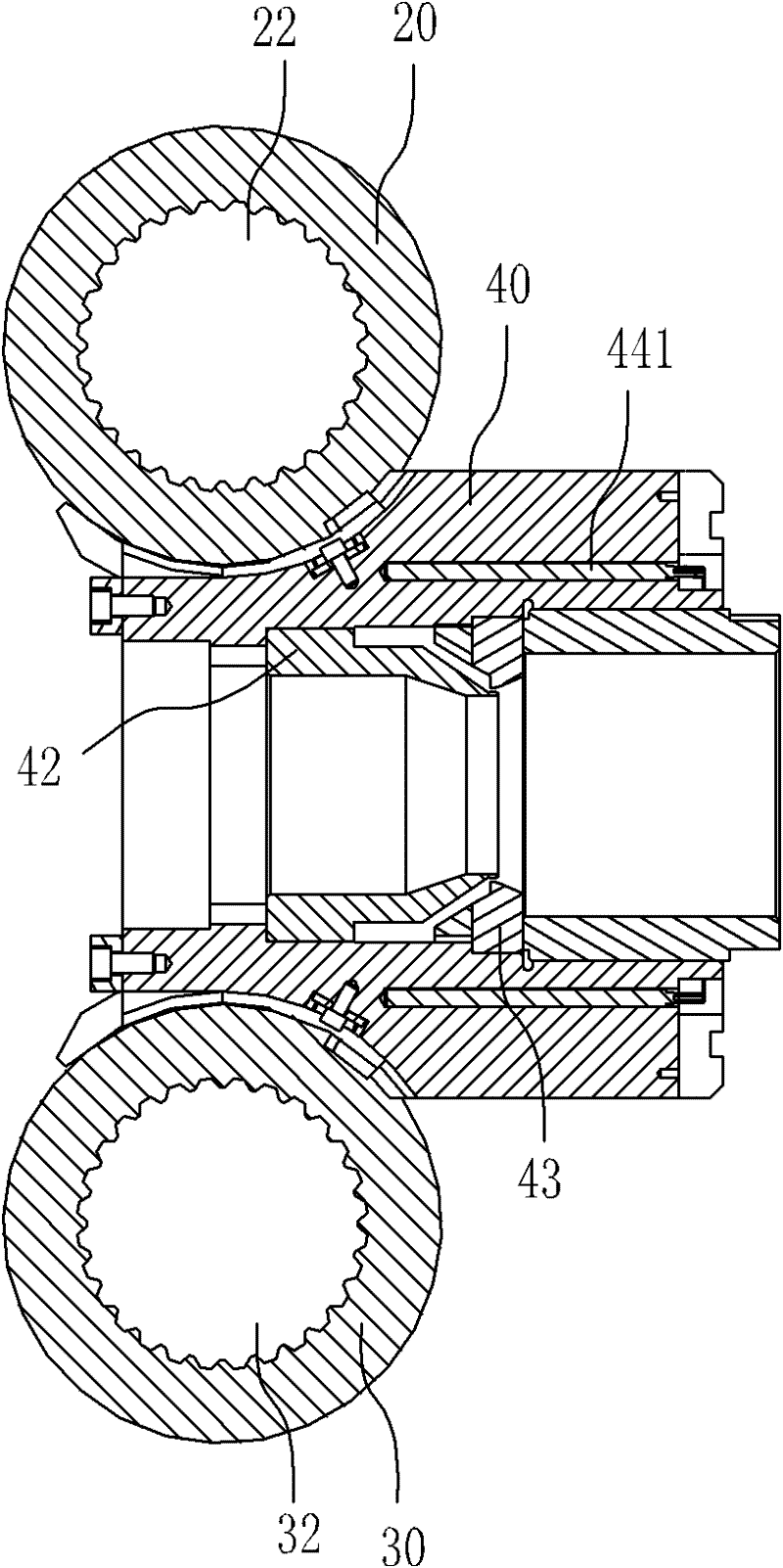

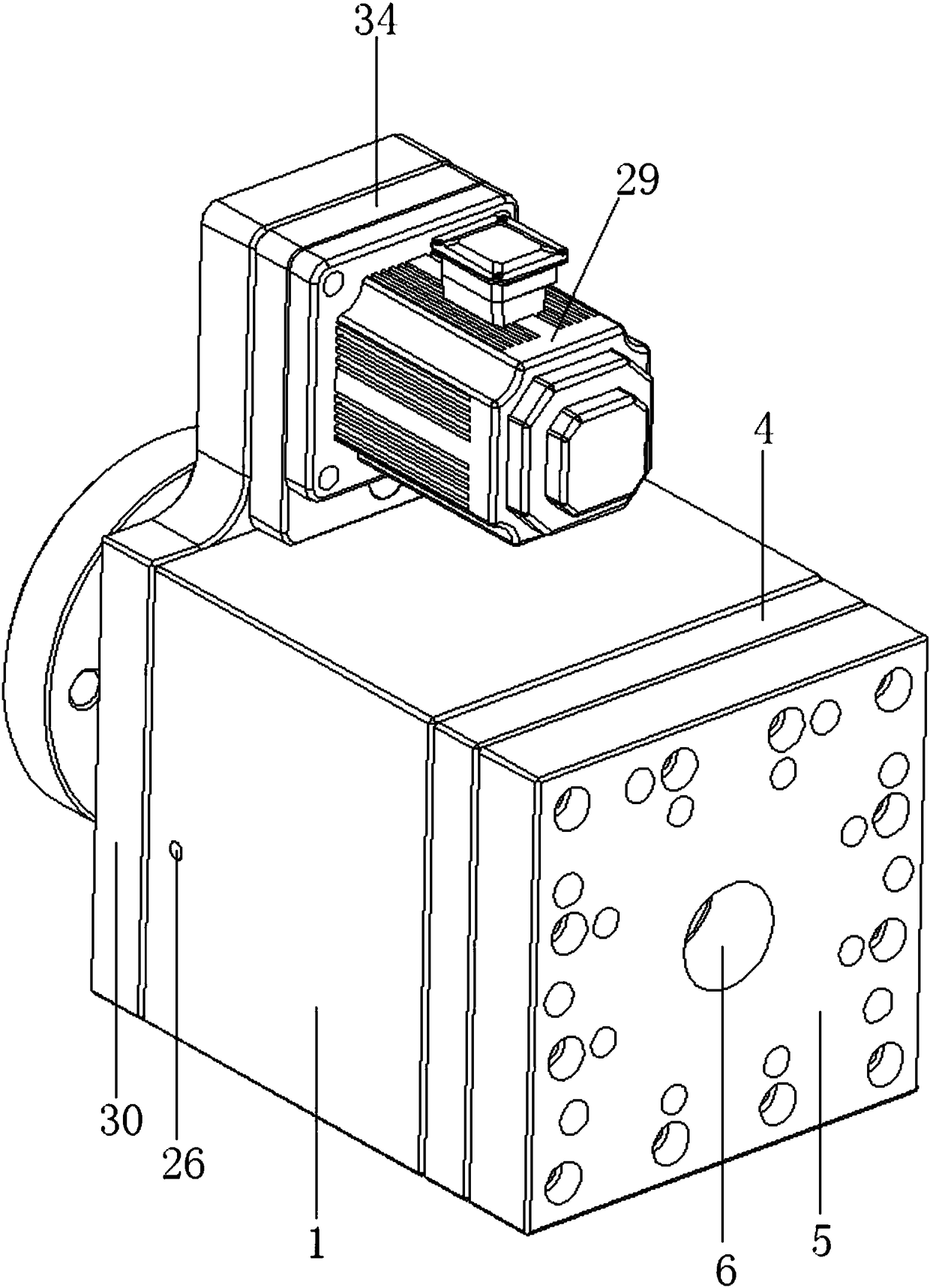

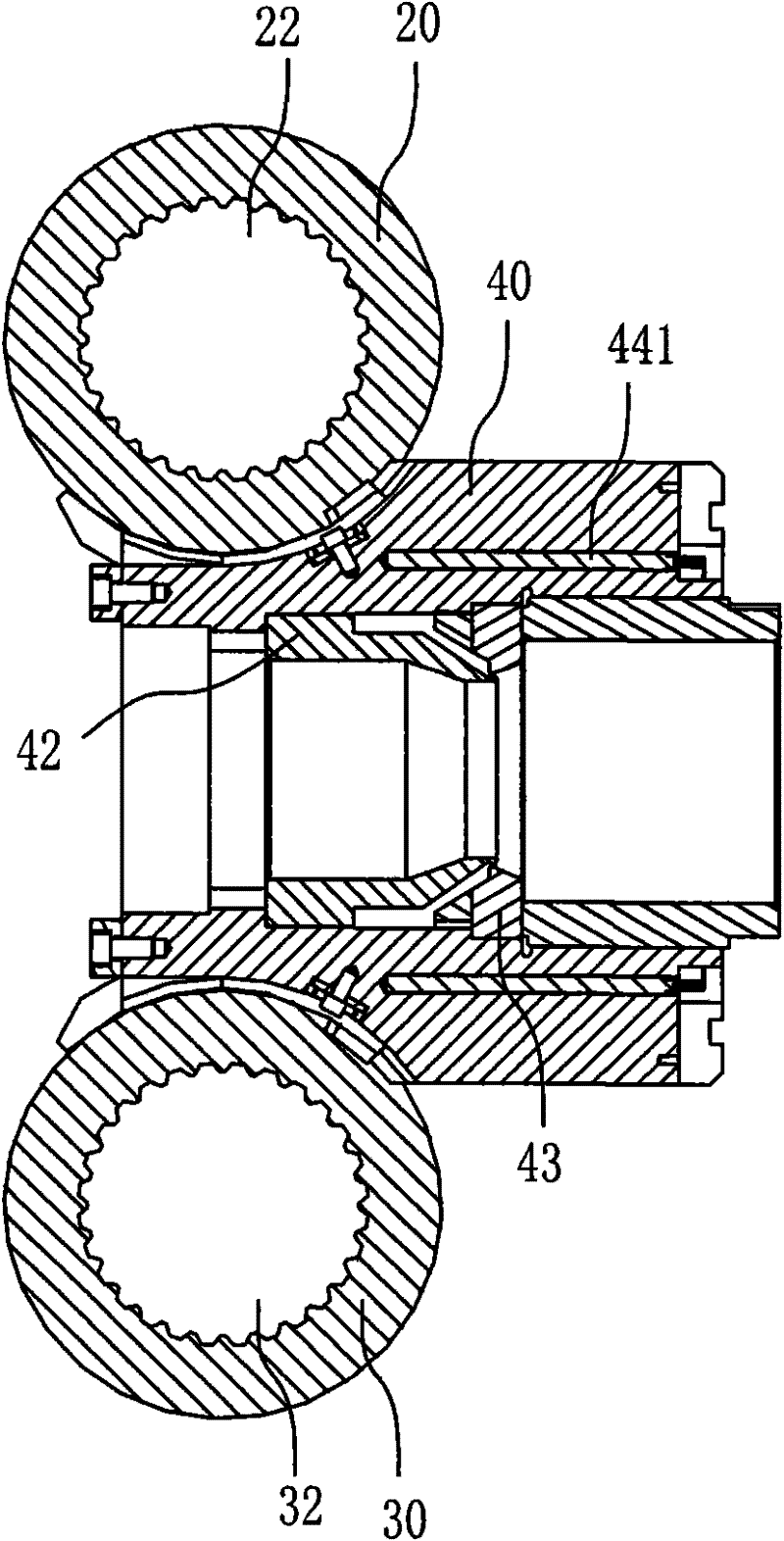

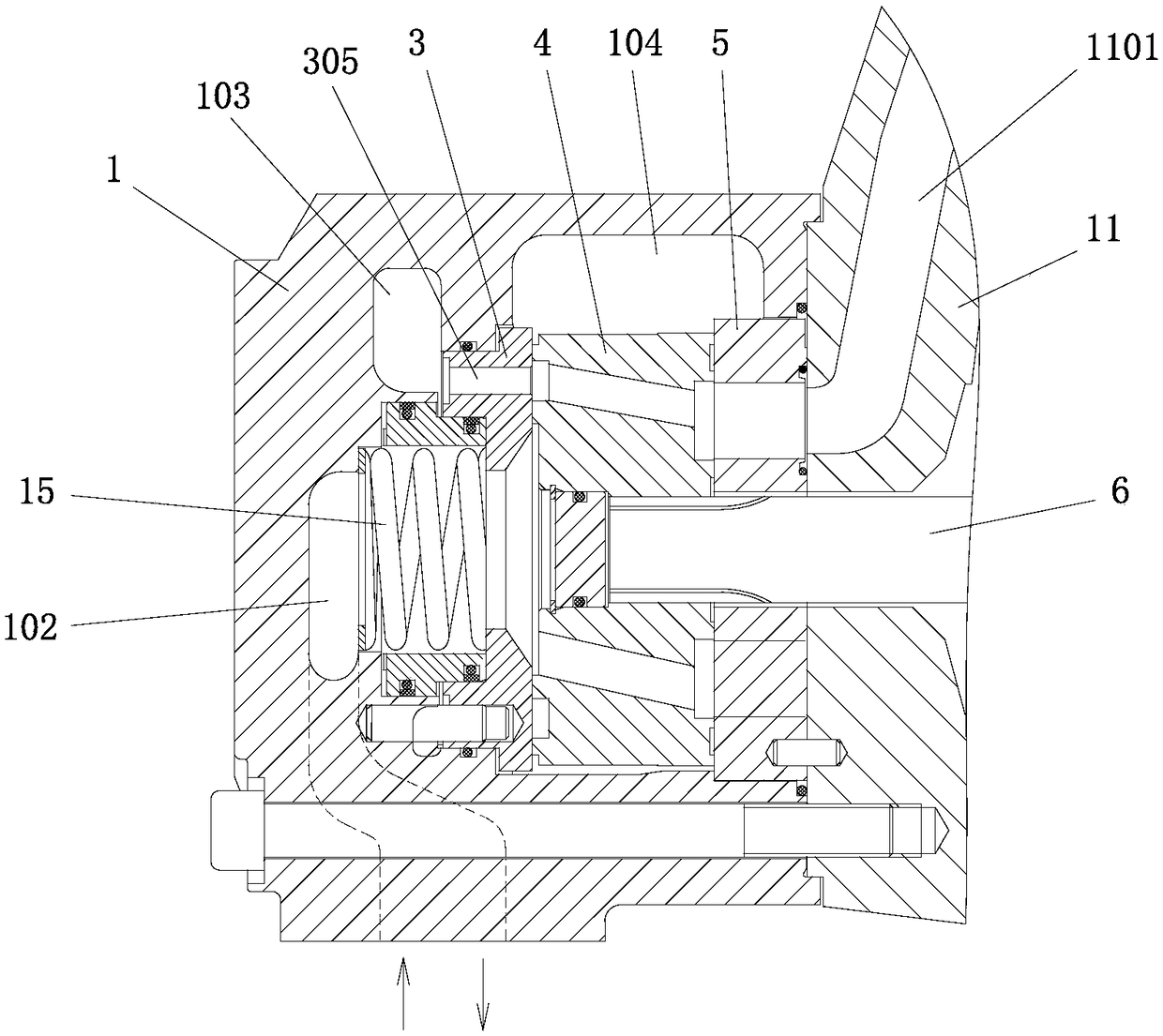

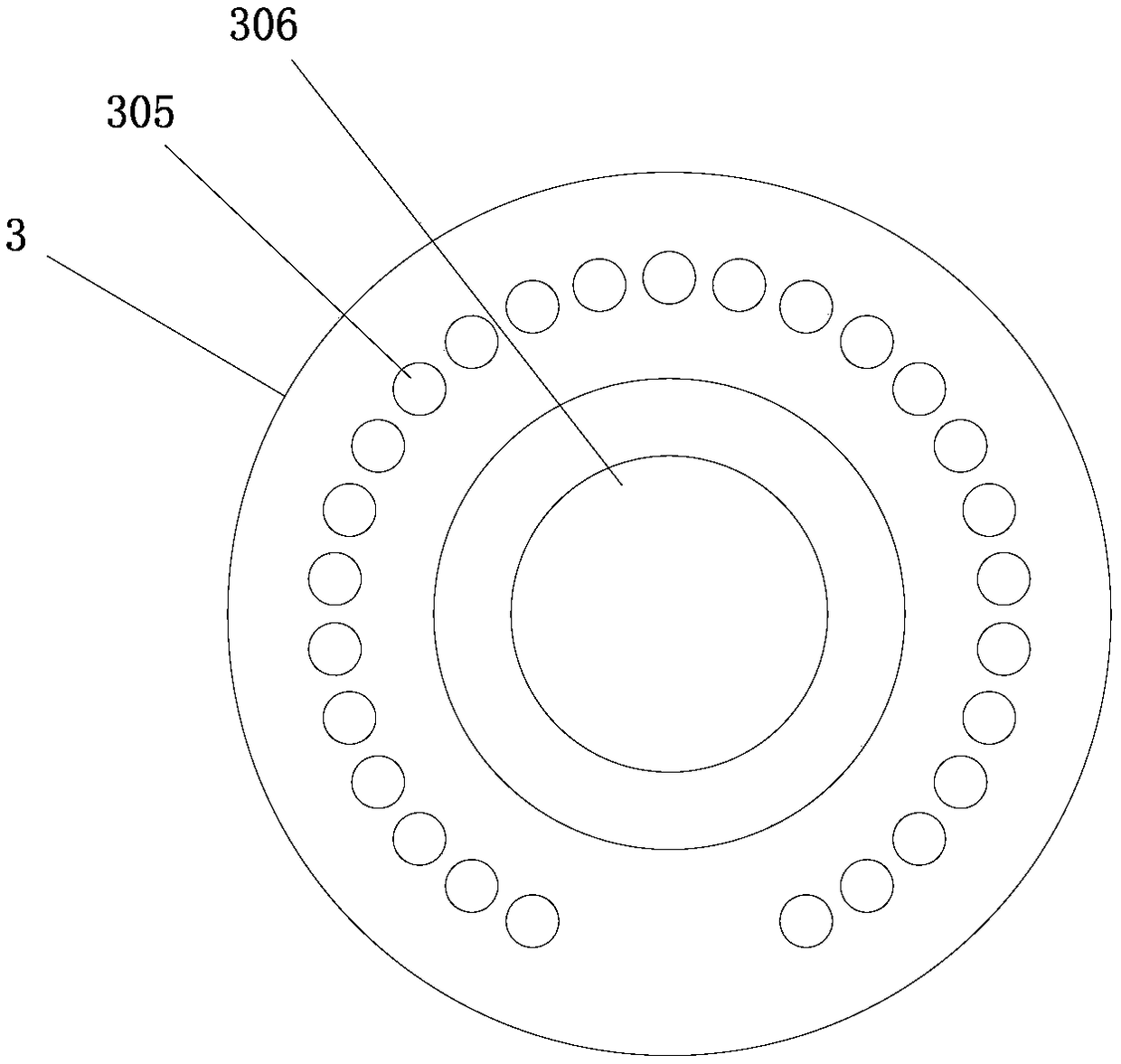

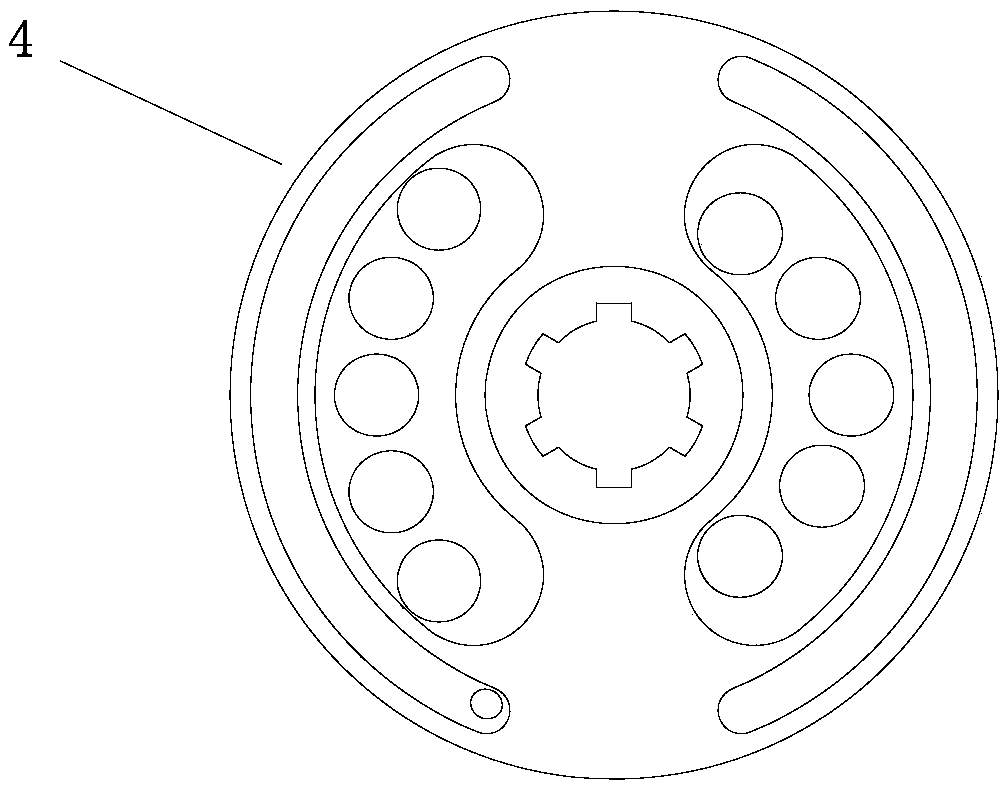

Compact efficient oil distribution mechanism for radial plunger hydraulic motor

ActiveCN108612620AReduce volumeCompact structureReciprocating piston enginesHydraulic motorDrive shaft

The invention provides a compact efficient oil distribution mechanism for a radial plunger hydraulic motor. The mechanism comprises a rear cover, a butterfly spring, a floating separation part, an oildistribution disc, an oil distribution plate, a transmission shaft and the like; under the action of the elastic force of the butterfly spring, initial pressing force always exists on three contact surfaces between the floating separation part and the oil distribution disc, the oil distribution disc and the oil distribution plate, and the oil distribution plate and the shell, and reliable sealingand abrasion compensation are guaranteed; a horn-shaped oil through hole is formed in the center of the floating separation part, and the floating separation part is of an integrated structure; the oil distribution disc is of a conical structure; and the floating separation part and the oil distribution disc divide the inner cavity of the rear cover into an oil passing containing cavity A and anoil passing containing cavity B. According to the compact efficient oil distribution mechanism for the radial plunger hydraulic motor, compared with the prior art, the size is small, the weight is light, the oil passing capacity is large, and the efficiency is high.

Owner:INTRA ITAL HYDRAULICS FOSHAN SHUNDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com