A rotary waveless screen changer

A screen changer, no fluctuation technology, applied in the field of screen changer, can solve the problems of raw material loss, uneven discharge, energy waste, etc., to achieve the effect of improving production quality and production efficiency, improving production efficiency, and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

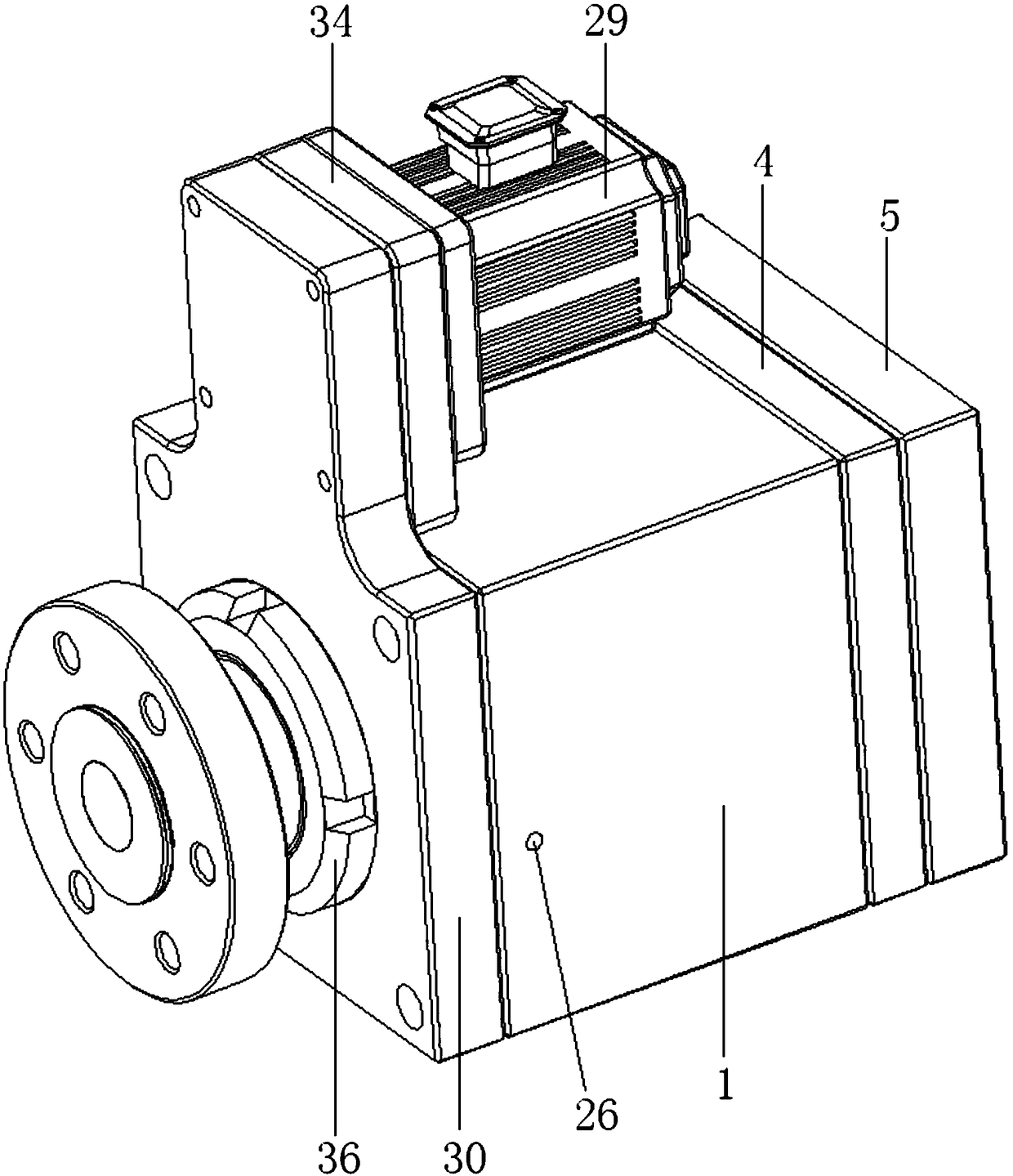

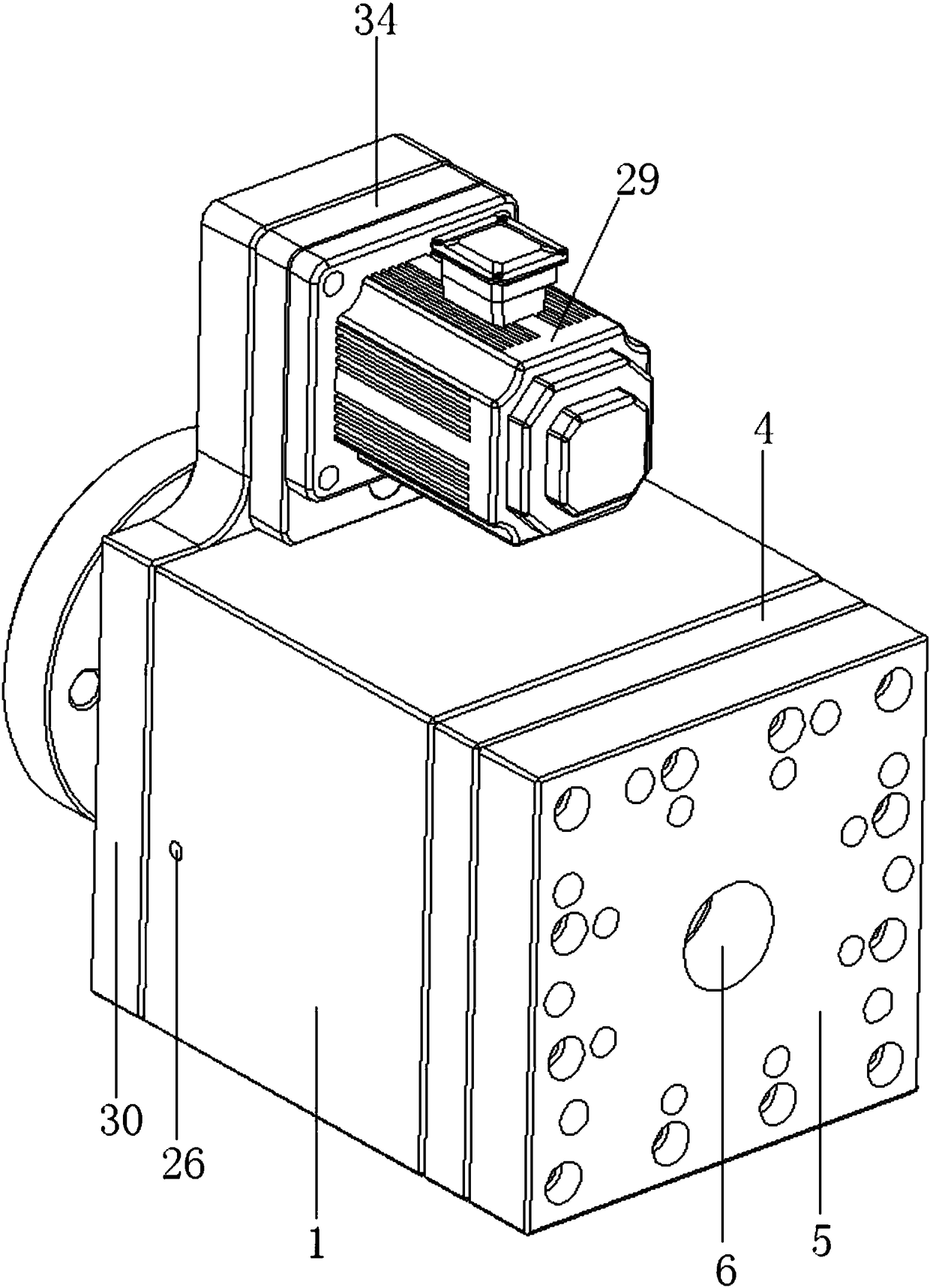

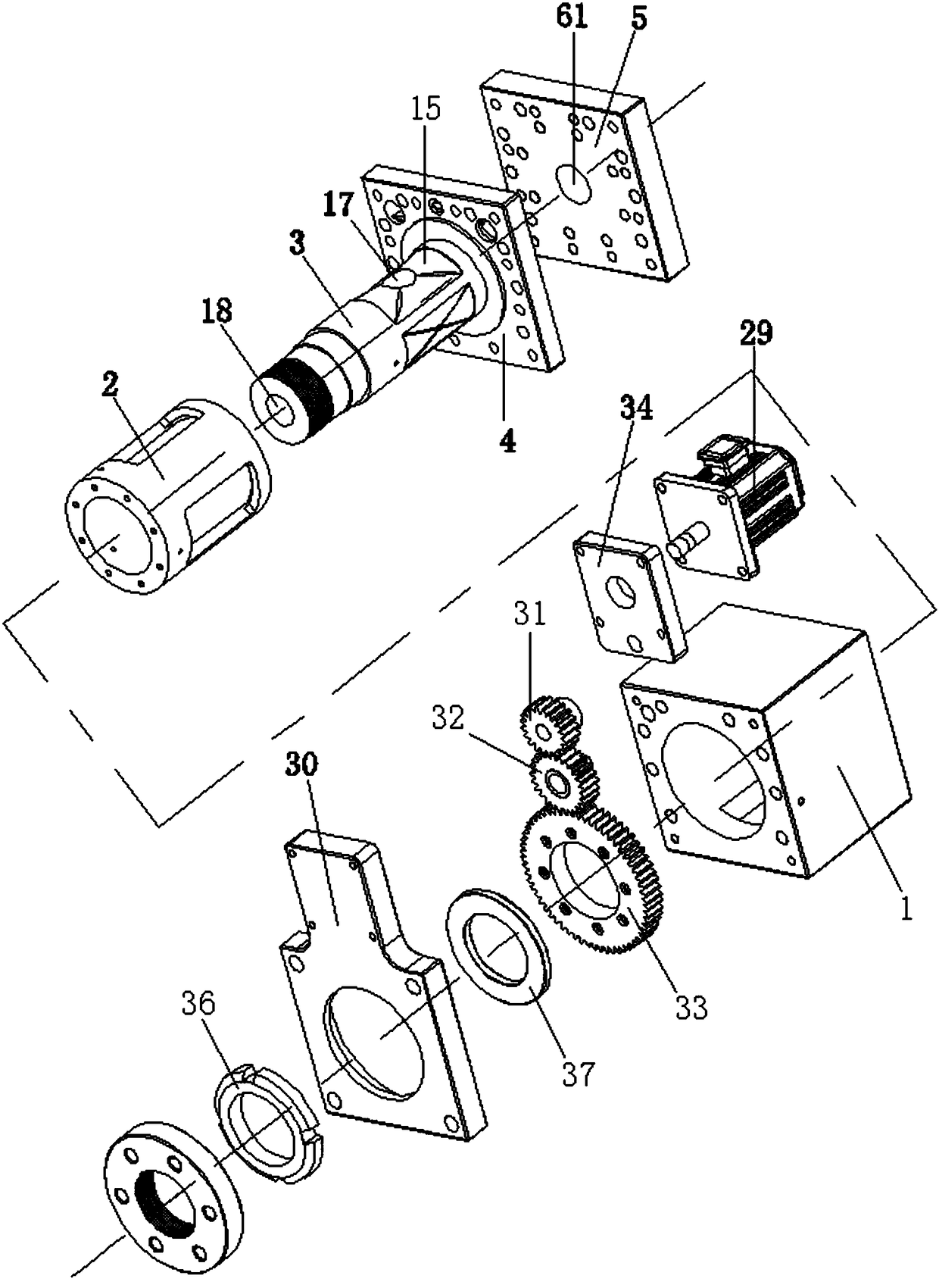

[0045] Embodiment 1: A rotary wave-free screen changer, including a screen changer housing 1, a filter cartridge 2, a filter screen, and a central shaft 3, the screen changer housing 1 is set outside the filter cartridge 2, and the filter cartridge 2 are set outside the central axis 3, the outer wall of the screen changer shell 1 is provided with a feed port c9, the inner wall of the screen changer shell is formed with a discharge trough 10, and the surface of the discharge chute 10 is formed with a discharge port c11; preferably, the discharge trough 10 of the present invention is arranged on the upper inner wall of the screen changer shell, and the screen changer shell 1 is formed with a net take-up groove 12 on an end surface opposite to the discharge trough 10; the preferred changer The lower end surface of the net shell is formed with a net slot 12;

[0046] More than three filter tanks 13 are formed on the filter cartridge 2, a filter screen is installed on the outer sur...

Embodiment 2

[0064] Embodiment 2: The design of Embodiment 2 is basically the same as that of Embodiment 1. The difference is that Embodiment 2 does not have the design of the diverter plate and the inlet flange, but directly sets the feed interface on the upper end of the screen changer shell. And the drive mechanism is arranged on the axis of the filter cartridge, the drive mechanism includes a servo motor, the output shaft of the servo motor is coaxially arranged with the filter cartridge, the output shaft of the servo motor is connected to a coupling sleeve 39, and the coupling sleeve 39 is fixed to the filter cylinder by screws Connection, one end of the central shaft with a discharge port is provided with a lock nut 36, the rotation of the central shaft is restricted by the lock nut, the other end of the central shaft is formed with a flange 42, and the flange 41 is against the end of the filter cartridge. Such a design makes the rotation more stable and the structure simpler.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com