Continuous extrusion device

A technology of extrusion device and extrusion wheel, applied in the direction of metal extrusion dies, etc., can solve the problems of long billet runner, huge equipment, high energy consumption, etc., to avoid dents and cracks, improve product quality, and shorten runners. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

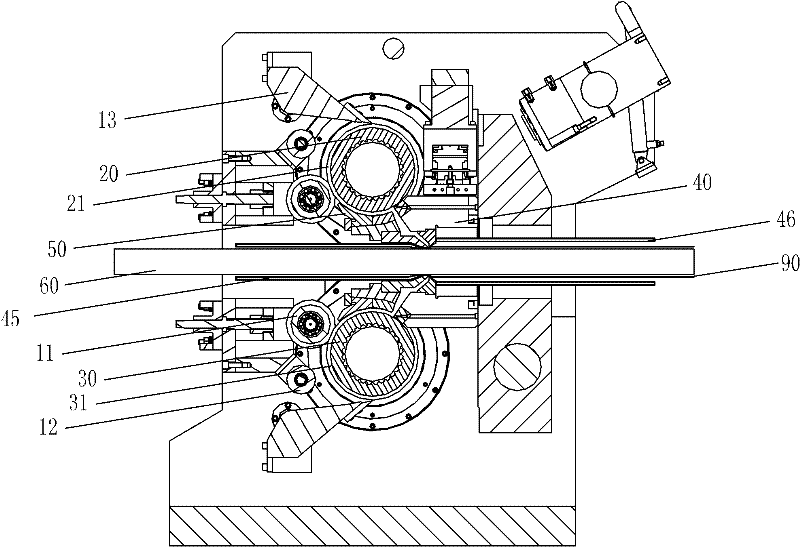

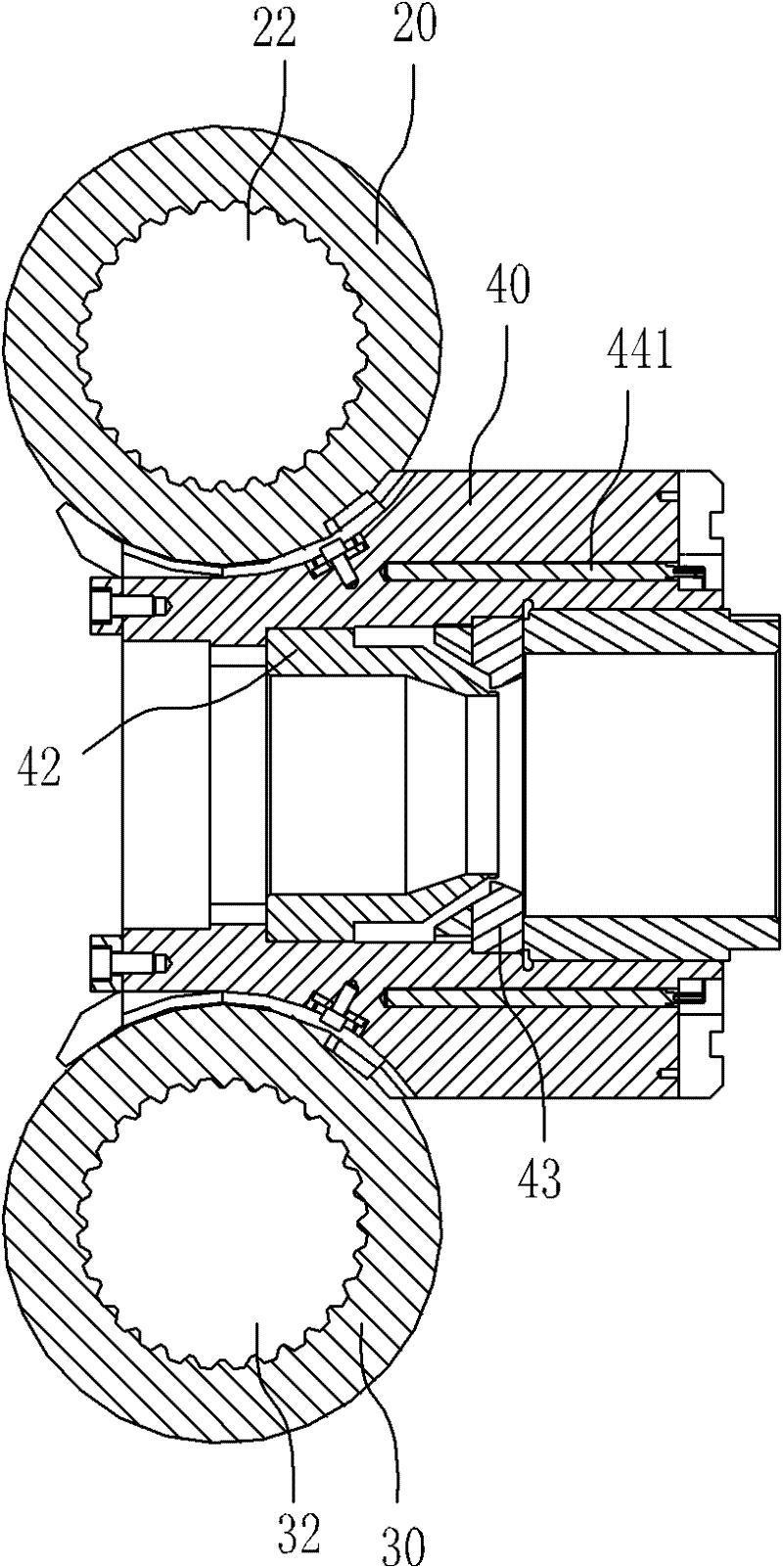

[0020] The continuous extrusion device comprises a frame 10, the frame 10 is in the shape of a torii, and two extrusion wheels 20, 30 whose rotating shafts are parallel to each other are arranged on the frame 10. As a preferred solution of the present invention, the extrusion wheels 20, 30 are selected to be arranged The upper and lower structures are arranged in parallel, and the following instructions are also described with the upper and lower parallel structures.

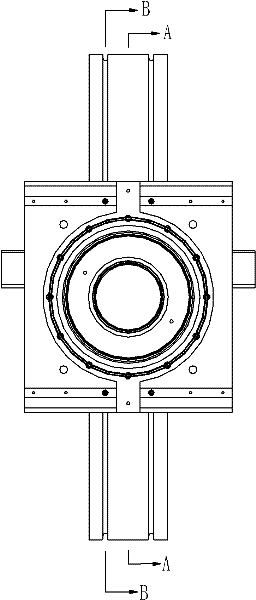

[0021] Such as figure 1 , Figure 5 As shown, the rotating shafts 22, 32 of the extrusion wheels 20, 30 are arranged in parallel up and down, the direction of rotation of the extrusion wheels 20, 30 is opposite, and the rims are respectively provided with at least one extrusion wheel groove 21, 31 in the circumferential direction, The extrusion wheel grooves 21, 31 are respectively provided with a guide sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com